Navigating the world of hydraulic hose fittings can seem daunting, with countless types, sizes, and standards to consider. From preventing leaks and ensuring optimal system performance to avoiding costly downtime and safety hazards, accurate identification is absolutely critical. This guide is your essential resource to demystify the process.

Whether you’re a beginner just starting out or an experienced professional looking to refine your skills, we’ll walk you through the key aspects of hydraulic fitting identification. You’ll learn to recognize different thread types, sealing methods, and body styles, transforming from uncertainty to confident expertise in no time.

What Are Hydraulic Hose Fittings?

Hydraulic hose fittings are connectors designed to secure hydraulic hoses to various hydraulic components. They provide a leak-free and reliable connection, allowing the transfer of hydraulic fluid and power within the system. Hose fittings come in different shapes, sizes, and types to accommodate specific hydraulic applications.

Importance of proper identification

Identifying hydraulic hose fittings accurately is vital for several reasons. It helps in selecting the correct replacement fittings, ensuring compatibility and preventing leaks. Proper identification also facilitates the troubleshooting process, as knowing the specific fittings aids in diagnosing and resolving system issues efficiently.

What is Hydraulic Fitting Identification

Hydraulic fitting identification is the process of accurately determining the specific type, size, and sealing method of hydraulic hose fittings and their corresponding ports. This critical skill is essential for proper assembly, maintenance, and repair of hydraulic systems. Given the vast array of international standards (e.g., JIC, BSP, NPT, Metric), thread types (tapered vs. parallel), and sealing mechanisms (O-rings, metal-to-metal flares, compression), precise identification prevents leaks, system failures, and costly downtime.

The identification process typically involves a combination of visual inspection, measurement, and reference to specialized charts or tools. Key elements to identify include whether the threads are male or female, tapered or parallel, the thread’s diameter and pitch, and the angle or type of sealing surface (e.g., 37° flare, O-ring face seal).

Tools like calipers, thread gauges, and seat angle gauges are indispensable for accurate measurements, helping technicians match existing fittings or select suitable replacements for new installations.

Why Are There So Many Different Types of Hydraulic Fittings?

The wide variety of hydraulic fittings stems from a complex interplay of factors, each contributing to the need for specialized solutions across diverse applications and industries. There isn’t a single “universal” fitting because hydraulic systems operate under a range of conditions and in numerous environments, each with unique demands.

Here are the primary reasons for the multitude of hydraulic fitting types:

Pressure Ratings: Hydraulic systems can operate from low pressures to extremely high pressures (e.g., several thousand PSI). Different fitting designs and materials are required to safely contain these varying pressure levels without leaking or failing.

Sealing Methods: Achieving a leak-proof seal is paramount in hydraulic systems. Various sealing mechanisms exist, including metal-to-metal (like flared or cone seats), elastomeric O-rings (face seals or boss seals), and tapered threads, each offering distinct advantages in specific applications.

Thread Standards: Historically, different regions and industries developed their own thread standards. This resulted in a global assortment of threads like NPT (National Pipe Tapered) in North America, BSP (British Standard Pipe) in Europe and other regions, and various metric threads (e.g., DIN standards) used internationally. Compatibility between these standards is critical.

Application-Specific Needs:

- Vibration and Shock: Some applications, like heavy machinery or mobile equipment, experience high vibration and shock, requiring fittings designed to maintain integrity under dynamic stress (e.g., ORFS fittings are known for this).

- Temperature Range: Fittings must withstand extreme temperatures, both hot and cold, without compromising their material properties or seal integrity.

- Fluid Compatibility: The type of hydraulic fluid (e.g., mineral oil, synthetic, water-based) can influence material selection for fittings to prevent corrosion or degradation.

- Space Constraints: Compact designs or angled fittings (e.g., elbows, tees) are necessary to route hoses in confined spaces.

- Ease of Assembly/Disassembly: Some applications benefit from quick-connect fittings for rapid component changes, while others prioritize permanent, highly robust connections.

Material Selection: Fittings are made from various materials (steel, stainless steel, brass, aluminum) chosen for their strength, corrosion resistance, weight, and cost-effectiveness in specific environments.

Industry-Specific Regulations and Standards: Industries like aerospace, marine, automotive, and agriculture often have their own stringent standards and preferred fitting types to ensure safety, performance, and interoperability.

Hydraulic Fitting Features

Here are the primary aspects to consider when identifying a hydraulic hose fitting:

Thread Type: This is the most crucial identifier. Hydraulic hose fittings have threads that screw onto hoses or components. Common thread types include:

- Metric Threads: Measured in millimeters (mm), these offer a standardized global approach.

- National Pipe Thread (NPT): A common thread type in North America, recognizable by its tapered design.

- British Standard Pipe Thread (BSPT): Another tapered thread type used internationally.

- Other Thread Types: Less common options like SAE (Society of Automotive Engineers) threads might exist in specific applications.

Fitting Body Size and Shape: Fittings come in various shapes and sizes to accommodate different connection needs within a system. Common types include:

- Straight Fittings: These provide a direct connection between the hose and another component.

- Elbow Fittings: They offer a 90-degree bend for changing flow direction.

- Tee Fittings: These fittings have three ports, allowing for branching or merging fluid flow paths.

- Reducer Fittings: They connect hoses with different diameters, enabling seamless transitions within the system.

- Bulkhead Fittings: These fittings mount directly onto equipment or panels, providing a secure connection point for hoses.

Material: The material of the fitting should be compatible with the operating pressure, fluid type, and environmental conditions of the hydraulic system. Common materials include:

- Steel: Provides high strength for high-pressure applications.

- Stainless Steel: Offers superior corrosion resistance in harsh environments.

- Brass: A cost-effective option for moderate pressure applications.

Sealing Mechanism: This component creates a tight seal between the hose and the fitting body to prevent leaks. Common sealing mechanisms include:

- O-Rings: A versatile and widely used sealing solution.

- Flat Face Seals: Offer a metal-to-metal contact for high-pressure applications.

- Crimped Connections: The hose is permanently attached to the fitting using a crimping tool.

Here’s how you can leverage your newfound knowledge of hydraulic hose fitting characteristics:

- Identify System Requirements: Determine the hose size (diameter), thread type (compatibility), pressure rating, and desired flow direction needed for your hydraulic system.

- Consult Resources: Utilize reference materials like manufacturer catalogs, online resources, or consult a hydraulics professional. Look for fittings that match your hose size, thread type, pressure rating, and offer the desired body style and sealing mechanism.

- Inspect Existing Fittings: If you’re replacing a fitting, examine the existing component. Look for markings or measure the thread diameter to identify the type. You can also use thread gauges for precise identification.

Remember: When in doubt, it’s always best to consult a qualified hydraulics professional for guidance on selecting the most appropriate fitting for your specific application.

How to Identify Hydraulic Fittings

Accurately identifying hydraulic fittings is a fundamental skill for anyone working with hydraulic systems. This guide will walk you through the essential steps, transforming you from a novice to a confident expert in recognizing the myriad of fitting types. Understanding these identification techniques is crucial for ensuring proper assembly, preventing leaks, and maintaining system integrity.

Visual Inspection and General Characteristics

The first step in identifying a hydraulic fitting involves a careful visual inspection of its overall appearance and general characteristics. Look for distinguishing features such as the presence of a flare, the shape of the sealing surface, and any visible markings or codes. Note whether the fitting is male or female, and observe the general size and proportion of the component.

Beyond the basic form, pay attention to the material from which the fitting is made, as this can offer clues about its intended application or pressure rating. Steel, stainless steel, and brass are common materials, each with different properties. Also, observe if there are any unique design elements, such as a swiveling nut or a specific body shape, which can narrow down the possibilities.

Thread Type Identification

Once the general characteristics are noted, focusing on the thread type is paramount. This is often the most critical aspect of identification. Begin by determining if the threads are tapered (like NPT) or parallel (like BSPP or SAE Straight Thread O-Ring Boss). Tapered threads will gradually decrease in diameter towards the end, creating a seal when tightened, whereas parallel threads maintain a consistent diameter.

After determining if the thread is tapered or parallel, you’ll need to measure the thread’s diameter and pitch. For tapered threads, you’ll typically measure the outside diameter at the largest point and use a thread gauge to determine the pitch (threads per inch or threads per millimeter). For parallel threads, measure the outside diameter of the male thread or the inside diameter of the female thread, and again use a thread gauge to find the pitch. This information, combined with the sealing method, will help pinpoint the exact thread standard.

Sealing Method Identification

The sealing method is another crucial element for accurate identification, as it dictates how the fitting achieves a leak-free connection. Observe the end of the fitting or the port it connects to for specific sealing features. Common sealing methods include a 37° flare (common in JIC fittings), a 45° flare (found in SAE 45° fittings), an O-ring face seal (ORFS), an O-ring boss (SAE O-Ring Boss), or a metal-to-metal cone seal (often seen in metric fittings like DIN L and S series).

The presence and location of an O-ring are key indicators. If an O-ring is present, note its position – whether it’s on a flat face (ORFS), in a groove on a boss (SAE O-Ring Boss), or perhaps internal to the fitting. For flare fittings, the angle of the cone is critical and can be measured with a flare gauge. Understanding the sealing mechanism is vital because even if the threads appear similar, an incorrect sealing method will lead to leaks and system failure.

Measurement and Sizing

Accurate measurement is the final step in confirming the identity of a hydraulic fitting. This involves using precision tools such as calipers, thread gauges, and sometimes angle gauges. For male threads, measure the outside diameter (OD), and for female threads, measure the inside diameter (ID) of the thread. Use a thread pitch gauge to determine the number of threads per inch (TPI) for imperial threads or the pitch in millimeters for metric threads.

Once you have these measurements, compare them to standardized charts and tables. These resources correlate specific OD/ID and pitch combinations with established fitting standards like JIC, SAE, NPT, BSP, and metric types (e.g., DIN). Double-check the sealing surface angle (37° or 45° for flares) if applicable, and ensure all measurements align with a known standard to definitively identify the hydraulic fitting.

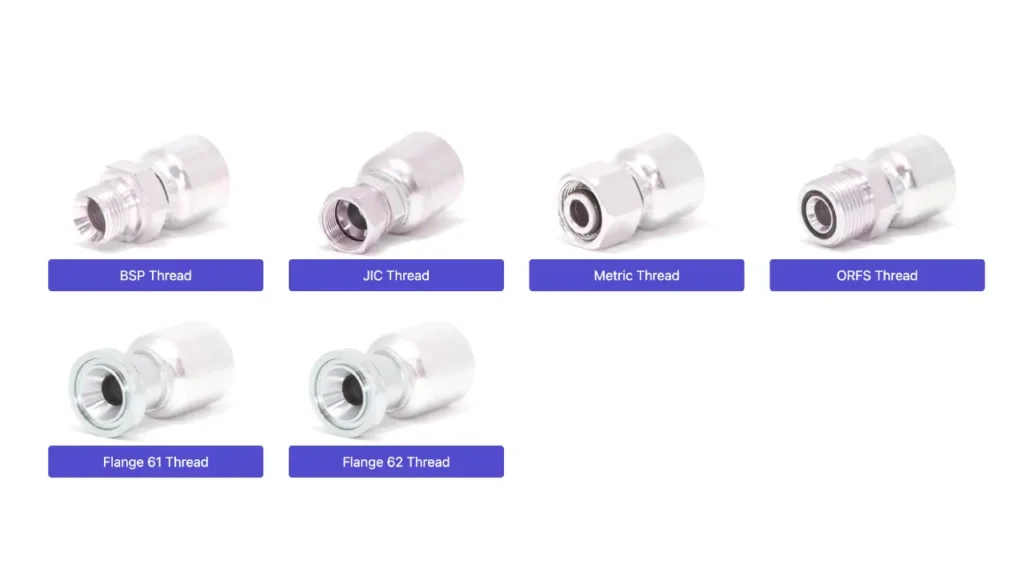

Common Types of Hydraulic Hose Fittings

JIC fittings:

JIC (Joint Industry Council) fittings feature a 37-degree flare and are widely used in

hydraulic systems. They provide excellent sealing capabilities and are known for their reliability and ease of installation.

NPT fittings:

NPT (National Pipe Thread) fittings have tapered threads and are commonly used in pipe connections. They create a tight seal and are ideal for applications where high pressure and vibration resistance are required.

BSP fittings:

BSP (British Standard Pipe) fittings have parallel threads and are popular in Europe and many other countries. They are known for their versatility and can be found in various hydraulic applications.

ORFS (O-Ring Face Seal) fittings utilize an O-ring to create a seal between the fitting and the mating surface. They are widely used in applications that require high pressure and leak-free connections.

SAE flange fittings:

SAE (Society of Automotive Engineers) flange fittings are designed for high-pressure applications. They feature a flange connection and are commonly used in hydraulic systems found in heavy machinery and industrial equipment.

This table briefly describes each hydraulic hose fitting type and their typical applications.

| Hydraulic Hose Fitting Types | Description |

|---|---|

| JIC Fittings | Joint Industry Council fittings with a 37-degree flare. They provide a reliable and leak-free connection. Commonly used in hydraulic systems. |

| NPT Fittings | National Pipe Thread fittings with tapered threads. Ideal for high-pressure and vibration-resistant applications. Commonly used in pipe connections. |

| BSP Fittings | British Standard Pipe fittings with parallel threads. Versatile fittings commonly found in European hydraulic applications. |

| ORFS Fittings | O-Ring Face Seal fittings that use an O-ring to create a tight seal. Suitable for high-pressure applications and provide leak-free connections. |

| SAE Flange Fittings | Society of Automotive Engineers flange fittings designed for heavy machinery and industrial equipment. Provide a secure and high-pressure connection. |

Hydraulic Hose Fitting Manufacturer Guidelines

Always follow the manufacturer’s guidelines and recommendations when working with hydraulic hose fittings. Adhering to these instructions ensures proper installation, operation, and maintenance, reducing the risk of accidents or equipment failure.

Proper installation techniques:

Correct installation techniques are essential for leak-free connections and optimal performance. Clean the fittings, apply appropriate thread sealants or tape, and tighten them to the recommended torque specifications. Improper installation can result in leaks, system damage, or safety hazards.

Regular inspection and maintenance:

Regular inspection and maintenance of hydraulic hose fittings are crucial for identifying potential issues early on. Periodically check for leaks, signs of wear, or damage. Replace fittings that show signs of deterioration to maintain system integrity and prevent costly failures.

Conclusion

Identifying hydraulic hose fittings doesn’t have to be daunting. By understanding the key characteristics like thread type, seal, and size, you can confidently distinguish between various fittings. This systematic approach transforms you from a beginner to an expert in no time, ensuring correct connections and preventing costly errors.

Mastering fitting identification is crucial for maintaining efficient and safe hydraulic systems. With practice, you’ll quickly recognize different types, saving time and ensuring compatibility for every application. This expertise streamlines your work and enhances system reliability.

For all your hydraulic fitting needs, look no further. We offer a comprehensive selection of wholesale hydraulic fittings, providing the quality and variety you require to confidently apply your newfound identification skills.