When it comes to selecting the right hose for your system, choosing between rubber and silicone hoses can be challenging. Both materials offer unique benefits and are used in a variety of applications, from automotive to industrial systems. Understanding their key differences can help you make an informed decision for your needs.

Rubber hoses are known for their durability, flexibility, and resistance to various environmental factors. On the other hand, silicone hoses are prized for their superior temperature resistance and flexibility in extreme conditions. In this blog, we will explore the key differences between rubber and silicone hoses, helping you determine which material is best suited for your specific application.

What are Rubber Hoses?

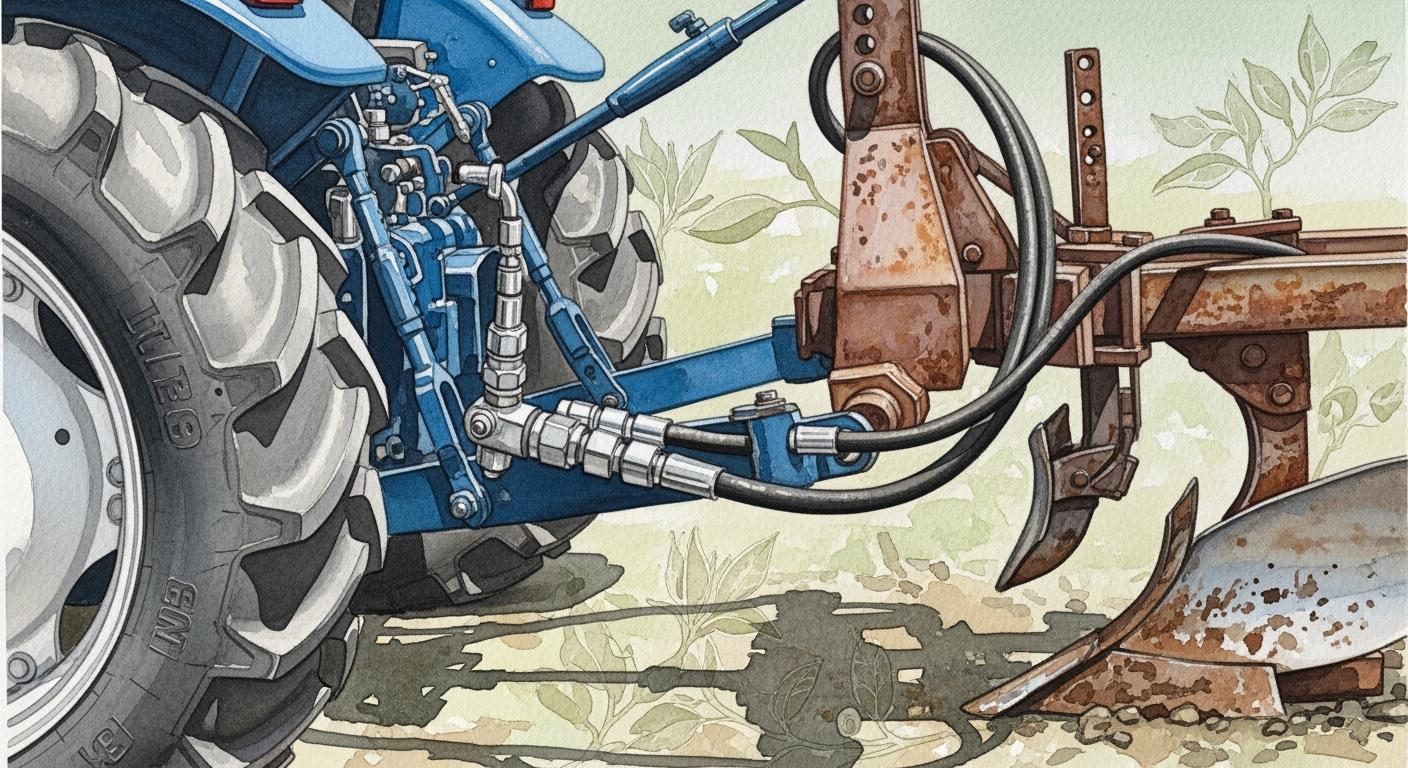

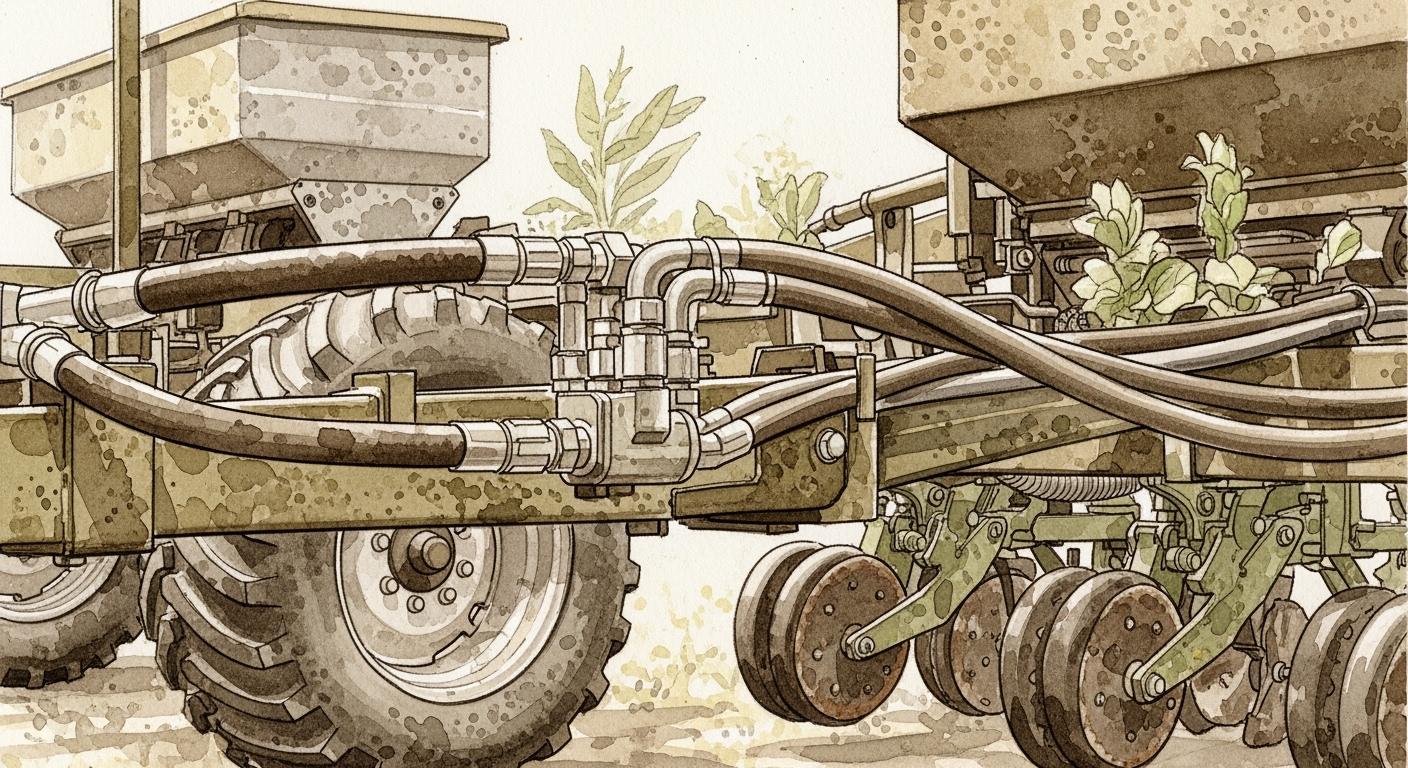

Rubber hoses are flexible tubes made from various types of rubber compounds, designed to transport fluids, gases, or other materials in a variety of applications. Known for their durability, flexibility, and resistance to wear, heat, and chemicals, rubber hoses are commonly used in automotive, industrial, hydraulic, and plumbing systems.

They offer reliable performance in both high-pressure and high-temperature environments, making them ideal for applications that require flexibility, resilience, and long-lasting functionality.

What are Silicone Hoses?

Silicone hoses are high-performance flexible tubes made from silicone rubber, known for their exceptional resistance to extreme temperatures, ranging from -100°F to 500°F. These hoses are commonly used in applications where flexibility, durability, and temperature resistance are critical, such as automotive, industrial, and food-grade systems.

Silicone hoses are chemically inert, making them ideal for use in systems that handle harsh chemicals, fluids, and gases. Their ability to maintain flexibility in both high and low temperatures, along with their excellent electrical insulating properties, makes them a top choice for high-performance and specialized applications.

Rubber vs Silicone Hoses

When choosing between rubber and silicone hoses, it’s essential to consider the unique properties of each material. Both have distinct advantages depending on the application, with differences in temperature tolerance, chemical resistance, durability, flexibility, and cost. Here’s a detailed comparison:

Temperature Resistance

Rubber hoses are versatile but have a limited temperature range compared to silicone hoses. Rubber typically performs well within a temperature range of -40°F to 250°F, making them suitable for many automotive and industrial applications. However, in extreme heat or cold, their performance can degrade over time.

Silicone hoses, on the other hand, excel in both high and low temperatures, with a range of -100°F to 500°F. This exceptional temperature tolerance makes silicone hoses ideal for high-performance engines, food-grade systems, and environments with fluctuating temperature conditions. The material maintains its flexibility even at extreme temperatures.

Durability

Rubber hoses are known for their toughness and can handle rough conditions like abrasion, wear, and high pressure. However, over time, exposure to sunlight, ozone, and chemicals can cause rubber hoses to degrade. Regular maintenance and replacement might be necessary to ensure long-term performance.

Silicone hoses, while less resistant to wear and abrasion compared to rubber, have superior chemical resistance and UV stability. This makes them an excellent choice for environments with harsh chemicals or exposure to UV light. However, silicone hoses may not be as durable in high-abrasion situations.

Flexibility

Rubber hoses are highly flexible and can bend easily, even in tight spaces, which makes them ideal for a wide range of industrial and automotive applications. Their flexibility ensures that they can withstand vibrations and movements without breaking or cracking under pressure.

Silicone hoses offer excellent flexibility as well, especially in high-temperature conditions, where rubber hoses may stiffen or lose their flexibility. Silicone’s ability to maintain its elasticity at extreme temperatures is one of its standout features, making it suitable for automotive engines, HVAC systems, and industrial applications.

Chemical Resistance

Rubber hoses are generally resistant to a range of chemicals, oils, and gases, but their resistance varies depending on the specific rubber compound used. Nitrile rubber hoses, for instance, are resistant to oils and fuels, while EPDM rubber hoses handle heat and ozone better.

Silicone hoses, however, excel in chemical resistance, particularly when exposed to oils, fuels, and most acids. Their non-reactive nature makes them an ideal choice for sensitive applications such as food processing, pharmaceutical, and chemical industries. This chemical stability ensures that silicone hoses can perform in environments where rubber hoses might degrade.

Cost

Rubber hoses are often more affordable than silicone hoses, making them an economical choice for general-purpose applications. They offer good performance for standard conditions without the premium cost associated with silicone. Rubber hoses are more commonly used in automotive and industrial systems due to their cost-effectiveness.

Silicone hoses tend to be more expensive due to the high-performance materials and manufacturing processes involved. While they offer superior performance, especially in extreme environments, the added cost may not be necessary for applications with standard operating conditions. Silicone hoses are typically used in high-performance or specialized applications.

Here are some differences between rubber and silicone hoses:

| Aspect | Rubber Hoses | Silicone Hoses |

|---|---|---|

| Temperature Resistance | -40°F to 250°F | -100°F to 500°F |

| Durability | Resistant to abrasion, wear; degrades over time | Superior chemical resistance, UV stability |

| Flexibility | Highly flexible, great for tight spaces | Maintains flexibility in extreme temperatures |

| Chemical Resistance | Varies by type, generally good | Excellent, non-reactive to oils, fuels, and acids |

| Cost | More affordable, cost-effective | More expensive due to high-performance materials |

How to Choose Rubber and Silicone Hoses?

Choosing between rubber and silicone hoses depends on the specific needs of your application. Both materials offer unique benefits, and understanding their properties will help you make the right decision. Key factors to consider include:

- Temperature Range: Rubber hoses are suitable for moderate temperature conditions, while silicone hoses excel in both extreme heat and cold, offering a broader temperature range for specialized applications.

- Chemical Resistance: Silicone hoses provide superior chemical resistance, making them ideal for environments exposed to oils, fuels, and acids. Rubber hoses, however, may offer better abrasion resistance but can degrade with certain chemicals.

- Flexibility and Durability: Rubber hoses are highly flexible and can handle a range of movements without cracking, making them suitable for dynamic applications. Silicone hoses maintain their flexibility under extreme conditions, though they may not be as durable in high-abrasion settings.

- Cost Efficiency: Rubber hoses tend to be more cost-effective for standard applications. Silicone hoses, while more expensive, are ideal for high-performance applications where temperature tolerance and chemical stability are critical.

- Application Requirements: For general-purpose uses such as automotive or industrial systems, rubber hoses are typically sufficient. For specialized environments such as food processing, high-performance engines, or systems requiring extreme heat resistance, silicone hoses offer the best performance.

Conclusion

Choosing the right hose material is essential for ensuring efficient fluid transfer and long-lasting performance in your systems. Rubber hoses are cost-effective, versatile, and ideal for moderate temperature and pressure applications. They provide the necessary strength and flexibility for most industrial and automotive uses.

Silicone hoses, on the other hand, excel in extreme temperature conditions and are perfect for high-performance applications. Their ability to withstand both very high and low temperatures, along with their chemical resistance, makes them ideal for specialized systems like high-performance engines or food-grade environments.

At Kingdaflex, we offer a wide range of wholesale rubber hoses tailored to meet your unique application needs. With our high-quality, durable hoses and exceptional customer service, we ensure reliable performance and value for every project. Contact us today to find the right hose for your system.