Your life may depend on the hose you use underground. MSHA Certification is very important for stopping deadly fires in mines. If you do not follow these rules, people can get hurt or die. You could also get in trouble with the law. Your mining work could be at risk too. You should pick hoses that have strong safety features. Kingdaflex hydraulic hoses are known for being safe and flame-resistant in mining.

Why MSHA Certification and Flame Resistance Matter

Safety in Underground Mining

Your safety underground depends on using the right tools. Fires and explosions can happen in mines. MSHA certification helps hoses stop flames and not make fires worse. Certified hoses help prevent deadly accidents. Training is part of MSHA certification too. You and your team learn to spot dangers and act quickly. This training helps lower injuries and accidents. The table below shows how MSHA certification makes mining safer.

| Evidence Type | Description |

|---|---|

| Training Requirement | MSHA certification is needed for everyone on-site. It helps everyone know about hazards. |

| Improved Hazard Recognition | Workers with MSHA training see dangers faster. They take steps to stay safe. |

| Reduction in Accidents | Sites with good training have fewer injuries and accidents. Safety gets better. |

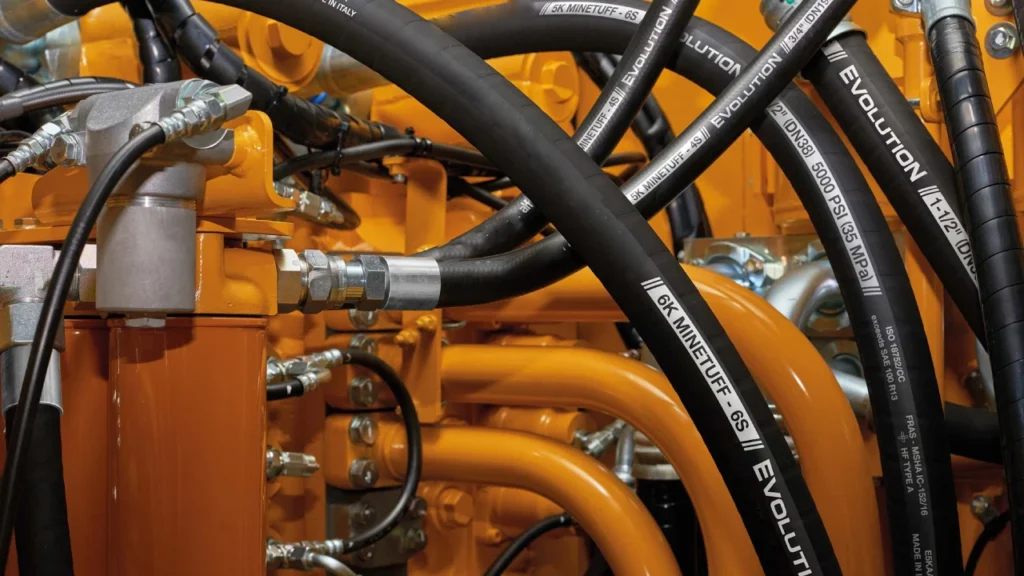

Kingdaflex hydraulic hoses meet these tough rules. They have covers that stop flames and features that fight static. You can trust them to keep you safe in hard mining jobs.

Legal and Regulatory Requirements

You must follow the law when working underground. The United States Department of Labor makes rules for mining. MSHA certification is not just advice. It is the law. If you use hoses that do not meet these rules, you could get fined or shut down. The table below lists some main MSHA rules for hoses in mining.

| Specification | Details |

|---|---|

| Hose Diameter | 5” Industrial Fire Hose |

| Standard Hose Length | 100 ft or 50 ft |

| Custom Lengths | You can ask for special sizes |

| MSHA Approved Hose | 1-1/2” MSHA Single Jacket Fire Hose (600LB Test) |

| Compliance | United States Department of Labor, Code of Federal Regulations, acceptance number 18-FHA080002 |

| Engineered Features | Stops harmful smoke when there is a fire |

Kingdaflex hoses are made to meet or beat these rules. You can count on them to follow the law and keep you safe.

Operational Reliability

You need tools that work every time. Hoses without certification can break under pressure. These breaks can cause leaks, bursts, and fires. Many mining accidents happen from high-pressure surges in hydraulic systems. Fast valve closures or pump stops can cause water hammer. This puts extra stress on hoses. Wrong installation, worn-out materials, and rubbing also cause hose problems.

MSHA-certified hoses work better and last longer. The table below shows how these hoses help your equipment work well and stay strong.

| Benefit | Description |

|---|---|

| Durability | MSHA-certified hoses can handle tough jobs and last longer. |

| Compliance with Regulations | These hoses meet safety rules and are safe for mining. |

| Effective Fluid Handling | They move fluids well and lower the chance of leaks or breaks. |

Kingdaflex hydraulic hoses are a good choice. They last longer, fight wear, and handle strong pressure. You fix things less and work safely more.

Understanding MSHA and Industry Standards

What Is MSHA?

It is important to know about the Mine Safety and Health Administration. MSHA helps keep miners safe at work. They make rules for mining and check if people follow them. Their main job is to protect workers underground. MSHA inspectors visit mines many times each year. They look for dangers and check if hoses and tools are safe. The table below shows what MSHA does:

Aspect Description Inspection Frequency Underground coal mines are inspected at least four times a year by MSHA inspectors. Reporting Violations Miners can report safety violations without fear of losing their jobs. Core Mission MSHA aims to reduce injuries, illnesses, and fatalities in the mining industry through oversight. Safety Standards Focus Emphasis on ventilation, roof support, and escape procedures in underground mining. Inspection Types MSHA conducts both scheduled and surprise inspections to ensure compliance with safety regulations. MSHA Certification Explained

You have to use hoses that have MSHA certifications. These certifications mean hoses pass hard tests. The tests check if hoses are strong and flame-resistant. Here are the main steps for MSHA certification:

- Construction Standards: Hoses must handle at least four times the system’s highest working pressure.

- Inspection and Maintenance: You must check hoses often for cracks, leaks, or wear. Replace damaged hoses right away.

- Fire Prevention: Only use fire-resistant hoses and fluids in underground mines. Keep hoses away from ignition sources.

Kingdaflex hoses meet these rules or do even better. They pass tough flame tests and work under high pressure. You can trust them to help keep your mine safe.

Key Industry Standards for Mining Hoses

You need to follow more than just MSHA rules. Other standards also help keep mining safe. These rules cover flame resistance, pressure, and how hoses are made. The table below lists some products and the standards they meet:

Product Name Standards Met Features Plicord® Mine Conduit MSHA Fabric-reinforced, suitable for electrical cable cover, flame-resistant cover. Caplugs IC-319/2 MSHA Superior pinhole & burst protection, anti-static, self-extinguishing, UV & chemical resistance. Caplugs IC-264/0 MSHA Fire retardant, prevents electrical charge buildup, safe working temperature +280° F to -40° F. You should always check if your hoses meet all the rules. The federal mine safety and health act and the mine improvement and new emergency response act set these rules. Kingdaflex hoses are made to meet these standards and certifications. This helps you stay safe and follow the law.

Compliance and Safety Risks

Dangers of Non-Compliance

Ignoring the rules in mining is dangerous. Hoses without certification can break while being used. This can cause leaks, bursts, or even fires. Inspections are there to keep everyone safe. Skipping these checks makes accidents more likely. Not following the rules puts all workers in danger. Mistakes can happen fast if you do not pay attention. Every missed inspection adds to your list of problems. Each problem is a warning that something is wrong. If you ignore these warnings, you will get even more violations. The number of problems can grow quickly. More violations make your mine less safe.

Fire Hazards and Safety Failures

Fire is a big danger in underground mines. Hoses without certification can make fires worse. They might not last long enough to help stop a fire. You need hoses that can handle heat and pressure. Using the wrong hose means more danger and more rule-breaking.

Rubber-type hoses used in deluge-type water spray and water sprinkler systems could be unsafe and do not work as well as steel piping, says a new safety alert from the Mine Safety and Health Administration. These hoses might not last through the high heat needed to put out a fire. They can also move around when water flows, which means water might not reach the fire.

You should only use hoses that pass all required checks. If you do not, you face more danger and more violations. Every time you do not meet the rules, it is another violation. You need to count every violation and fix it right away.

Legal and Financial Consequences

Breaking the rules does not just hurt safety. It can also cause legal and money problems. You might have to pay fines for each violation. Too many violations can mean losing your license to work. You must keep up with all inspections to avoid more trouble. Real stories show what happens when rules are ignored:

- At a bauxite mine in Western Australia, hoses broke often and caused safety risks and work stoppages.

- Workers saw many spills and leaks because hoses were old or not put in right.

- One time, a 2,000-psi hose burst and sprayed oil near a worker, showing the real danger.

- The mine leaders saw they needed a better plan to take care of hoses and stop these problems.

Every violation matters. If you let them add up, you could lose your job or money. Using MSHA-compliant hoses like Kingdaflex helps you pass checks, lower risks, and avoid breaking rules. This keeps your team, your business, and your future safe.

Achieving and Maintaining Compliance

Selecting MSHA Certified Hoses

You must pick the right hoses for your mine. First, check if the hose has MSHA certification. This helps you follow the rules and stay safe. Here are some steps to help you choose:

- Make sure the hose works with the material you move. Think about if it is rough or can cause rust.

- Match the hose to your pump’s pressure and flow. This keeps your hydraulic system safe and stops problems.

- Choose hoses that fit your mine’s needs and follow safety rules.

Kingdaflex has hydraulic hoses that meet these rules. Using the right hoses keeps you safe and helps you follow the law.

Inspection and Maintenance Best Practices

Inspections help keep your mine safe and legal. You should check hose couplings before every shift. Look for leaks, cracks, or loose parts. Early checks lower fire risks and protect health. Make a plan for how to do inspections and repairs. Use a checklist for each inspection. Write down what you find every time. Good care and regular checks help hoses last longer. This also helps you follow the rules and stay healthy.

Inspection Step Frequency Documentation Needed Visual check of hoses Before each shift Inspection log Check hydraulic fluid Weekly Maintenance record Inspect fittings Before each shift Inspection log Review documentation Monthly Compliance documentation Staff Training and Documentation

Training is important for safety and following the rules. You need to teach your team how to check hoses and put them in right. Training should show how to spot problems and follow steps. Hold training often so everyone knows what to do. Write down all training in your records. Good records help you report problems and show you follow the rules. Keep track of all checks, repairs, and reports. This helps you pass audits and keeps everyone safe.

You must not skip MSHA certification or flame resistance for mining hoses. These things help keep you safe from fire and trouble with the law. They also stop your equipment from breaking down. Check your hoses often and pick ones that are certified and flame-resistant. The table below explains why these hoses are important for your safety and your mine’s future.

Feature Benefit Flame Retardancy Lowers the chance of a big fire in small spaces. Anti-Static Properties Helps you follow safety rules and lowers fire risks. Temperature Range Works well in hot or cold places and stays flexible. Pick brands you trust, like Kingdaflex, to protect your team and keep your mine working well.