It is a scenario familiar to anyone operating hydraulic equipment in northern climates, high-altitude mining sites, or industrial cold storage facilities.

It is -10°C (14°F) on a crisp winter morning. You replace a hydraulic line on a forklift. You grab a coil of SAE 100R7 thermoplastic hose, expecting it to uncoil smoothly. And it fights back like a rigid plastic stick. You try to bend it into position, but it resists with a force that makes you worry it might snap.

You check the datasheet. It clearly states the Temperature Range: -40°C to +100°C. So, why does it feel frozen solid when it is only -10°C?

This is the “Frozen Stick” phenomenon, a top trending topic on industrial forums worldwide. Users frequently ask, “Is my hose defective?” or “Did I buy the wrong material?”

As a leading manufacturer of both rubber and thermoplastic hoses, Kingdaflex believes in transparency. The hose isn’t defective—it is behaving exactly as its chemistry dictates. While the specification sheet confirms it will function at -40°C, it doesn’t promise it will remain flexible.

In this guide, we will explore the science behind why R7/R8 hoses stiffen in the cold, how they compare to traditional rubber, and the five golden rules to keep them running safely through the winter.

The Science of Stiffness: Why Plastic Reacts to Cold

To understand the stiffness, we must look at the “anatomy” of the hose found in our Kingdaflex catalogue.

SAE 100R7 and SAE 100R8 hoses are constructed from three distinct layers:

- Tube: An oil-resistant synthetic thermoplastic core (Nylon).

- Reinforcement: One or two braids of high tensile synthetic fiber.

- Cover: An abrasion-resistant polyurethane.

This construction is fundamentally different from a standard rubber hose (like SAE 100R1 or R2), which uses synthetic rubber compounds like NBR or SBR.

The Glass Transition Temperature (Tg)

The culprit behind the stiffness is a concept called Glass Transition Temperature (Tg).

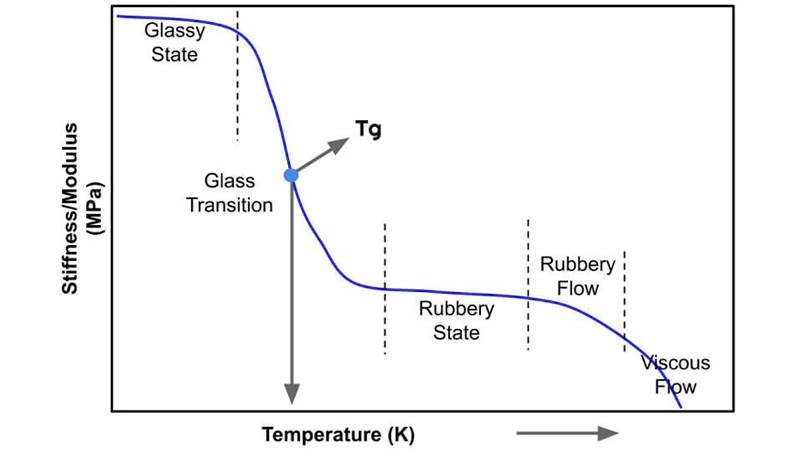

At a molecular level, polymers (plastics and rubbers) exist in two states: “rubbery” (flexible) and “glassy” (rigid).

- Rubber (Elastomers): Rubber has a very low Tg. Its molecules remain amorphous and “stretchy” even as temperatures drop significantly below freezing. It retains its flexibility curve much longer.

- Thermoplastics (Nylon & Polyurethane): The materials used in R7/R8 hoses—Nylon (tube) and Polyurethane (cover)—are semi-crystalline polymers. As the temperature drops, their molecular chains pack together tightly.

While the hose is rated to -40°C, this rating indicates the Service Temperature—the point at which the material will hold pressure without shattering. It does not indicate the Flexibility Temperature. Long before the hose reaches its failure point, it enters that “glassy” phase where the flexibility modulus skyrockets, making the hose feel stiff and unyielding.

R7/R8 vs. Rubber: The Cold Weather Showdown

If rubber stays flexible, why do we use thermoplastic hoses in winter at all? It comes down to a tradeoff between flexibility and functionality.

Flexibility: Rubber Wins

There is no debating this fact: A wire-braided rubber hose (like the SAE 100R1AT) will be easier to bend and route at -20°C than an R7 thermoplastic hose. If your application requires the hose to flex constantly in deep freeze (like a dynamic arm on an outdoor machine), rubber offers less resistance.

Weight and Handling: Thermoplastic Wins

However, stiffness isn’t the only factor. SAE 100R8 hoses are significantly lighter than their rubber counterparts.

For example, a 3/8″ SAE 100R7 weighs only 0.17 kg/m.

A comparable 3/8″ SAE 100R1AT rubber hose weighs 0.36 kg/m.

In cold weather, dragging a heavy rubber hose through snow and ice is exhausting. Even if the R7/R8 is stiffer, its lightweight nature makes it easier to manhandle over long distances, such as in rescue tools or mobile agricultural spraying.

The “Memory” Effect

Thermoplastic materials have a strong “plastic memory.” If an R7 hose is stored in a tight coil in a freezing van overnight, it will “remember” that coiled shape. When you try to straighten it out the next morning, it fights to return to the coil. Rubber has less memory and relaxes faster.

The Risks: What Happens If You Force It?

The biggest mistake operators make is treating a cold thermoplastic hose like a warm one. The “Operating Temperature” of -40°C to +100°C is a safety rating, not a permission slip to abuse the hose.

1. Micro-Cracking

When the Polyurethane cover is in its “glassy” state, forcing it to bend tighter than its recommended radius can cause micro-cracks. While the synthetic fiber reinforcement is tough, a cracked cover allows moisture to enter (or in the case of steel wire hoses, causes rust).

2. Fitting Stress

A stiff hose acts like a lever. If the hose refuses to bend, vibration and movement from the machine are transmitted directly to the metal fittings. In extreme cold, this added stress can cause fittings to loosen or crack, leading to leaks.

3. Impact Shattering

The abrasion-resistant polyurethane cover is incredibly tough against rubbing. However, at extreme sub-zero temperatures, it becomes harder. A sharp impact—like dropping a heavy wrench on the hose or a rock strike—can cause the cover to chip or shatter rather than dent.

Golden Rules for Cold Weather Handling

You don’t need to abandon R7/R8 hoses in winter. You just need to adjust your maintenance habits. Here are Kingdaflex’s top 5 tips for surviving the cold.

1. Warm Before Install

Never take an R7/R8 hose directly from a cold storage shed to the machine for installation. The materials need time to relax. Store the hose assembly in a heated room (above 10°C) for at least 2 hours before installation. This returns the Nylon core and Polyurethane cover to their flexible state, ensuring a tight seal at the fittings.

2. Respect the Bend Radius

In the Kingdaflex catalogue, we list the Bend Radius for every size.

- For a 3/8″ SAE 100R7, the minimum bend radius is 70mm.

- For a 3/8″ SAE 100R8, it is also 70mm.

In freezing temperatures, treat these numbers as the absolute limit, not a suggestion. We recommend increasing the bend radius by 20-30% in winter to reduce stress on the stiffened materials.

3. The “Warm-Up” Lap

Just as you warm up your engine, warm up your hydraulics. Before operating the boom or attachment at full speed, circulate the hydraulic fluid. As the warm oil flows through the oil-resistant synthetic thermoplastic core, it warms the hose from the inside out, restoring flexibility within minutes.

4. Watch for Blisters

While cold weather generally slows down gas permeation, rapid depressurization in cold conditions can be risky. If you are using the hose for compressed gases (like nitrogen or air), ensure your hose cover is “pin-pricked” (perforated) to allow gas to escape, preventing the stiff cover from blistering.

5. Use Protection (Spiral Guards)

In winter, hoses often rub against sharp ice, frozen mud, or jagged metal. Since the hose is stiffer, it doesn’t “move away” from abrasion sources as easily. We highly recommend installing a Plastic Spiral Guard. Made of PP (Polypropylene), this guard protects the hose from external cuts and crushing. It handles temperatures down to -50°C, making it even more cold-resistant than the hose cover itself!

When R7/R8 is Still the Best Winter Choice

Despite the stiffness, there are specific winter scenarios where SAE 100R7/R8 remains the only correct choice.

- Utility Trucks (Cherry Pickers): For repairing power lines in winter storms, safety is paramount. You must use the non-conductive (orange cover) version of the R7/R8 hose. A rubber hose, while more flexible, often contains carbon black or steel wire that conducts electricity. The stiffness of R7 is a small price to pay for electrical insulation.

- Cold Storage Forklifts: In food warehouse freezers, standard rubber hoses can shed black particles or leave marks. The clean Polyurethane cover of an R7 hose is non-marking and cleaner, making it the standard for indoor heavy equipment, even at -20°C.

Conclusion

The complaint that “R7 hoses feel like hard plastic in winter” is valid, but it is not a defect. It is the nature of the high-performance materials—Nylon and Polyurethane—that give these hoses their incredible durability, light weight, and chemical resistance.

Our SAE 100R7 and SAE 100R8 hoses are fully rated to function safely at -40°C. By understanding the “Glass Transition” and following our simple warm-up and handling protocols, you can utilize the superior strength of thermoplastic hoses year-round without fear of failure.

Working in the Arctic or a specialized freezer environment? Don’t guess on safety. Contact us today. We can help you select the right hose and protective guards for your extreme temperature application.