Industrial hoses are the unsung heroes of countless operations, facilitating the transfer of everything from water and air to abrasive slurries and corrosive chemicals. Selecting the right hose, particularly its material, is paramount for ensuring efficiency, safety, and longevity within your specific application. This guide will delve into the diverse types of industrial hoses available, focusing on how material choice dictates performance.

Understanding the unique demands of your industrial process is the first step in making an informed decision. Whether you require resistance to extreme temperatures, high pressure, chemical compatibility, or abrasion resistance, the material of your industrial hose is the foundational element that will determine its suitability and ultimate success.

What are Industrial Hoses

Industrial hoses are flexible conduits designed to transfer various substances, including liquids, gases, slurries, and dry bulk materials, within industrial and commercial settings.

Unlike standard garden hoses, they are engineered for specific, often demanding, applications, incorporating specialized materials and robust construction to withstand high pressures, extreme temperatures, corrosive chemicals, abrasion, and other challenging environmental conditions encountered in manufacturing, agriculture, mining, construction, and many other sectors. Their selection is critical to operational safety and efficiency.

Types of Industrial Hoses

Industrial hoses are diverse, each type engineered with specific materials and constructions to excel in particular applications. Choosing the correct hose is vital for safety and efficiency, as different media, pressures, and environments demand tailored solutions. Understanding these distinctions ensures optimal performance and longevity for your operations.

Rubber Industrial Hoses

Rubber Industrial Hoses are highly versatile, known for their excellent flexibility, shock absorption, and resistance to abrasion. They can be formulated with various rubber compounds like EPDM, Neoprene, or Nitrile to provide specific chemical resistance or temperature ranges, making them suitable for a broad spectrum of industrial tasks.

Benefits: These hoses offer superior flexibility and durability, making them ideal for dynamic applications where movement or bending is common. They also provide good insulation and noise reduction properties.

What It’s Used for: Commonly used for air, water, general chemicals, petroleum products, and abrasive materials in construction, agriculture, and manufacturing.

PVC Industrial Hoses

PVC Industrial Hoses are lightweight, transparent, and offer good resistance to various chemicals, oils, and greases. Their transparency allows for visual monitoring of fluid flow, which can be advantageous in certain processes. PVC hoses are also generally more cost-effective than other industrial hose types.

Benefits: Their affordability and transparency are key benefits. They are also relatively easy to handle and offer good resistance to many common industrial fluids.

What It’s Used for: Widely used for water transfer, light chemical solutions, air lines, and food-grade applications where visual inspection of the media is desired.

Polyurethane Industrial Hoses

Polyurethane Industrial Hoses are prized for their exceptional abrasion resistance, high tensile strength, and good flexibility, even in cold temperatures. They are often reinforced with wire or fabric to enhance their structural integrity and pressure capabilities, making them extremely durable for demanding tasks.

Benefits: Their superior abrasion resistance makes them ideal for abrasive material transfer. They also offer excellent tear resistance and a longer lifespan in harsh environments.

What It’s Used for: Predominantly used for abrasive materials like grains, wood chips, powders, and slurries, as well as for pneumatic conveying and vacuum applications.

Silicone Industrial Hoses

Silicone Industrial Hoses are known for their remarkable temperature resistance, capable of handling both very high and very low temperatures without degradation. They are also highly flexible, odorless, and tasteless, making them suitable for sensitive applications where purity is paramount.

Benefits: Excellent performance in extreme temperatures, high flexibility, and resistance to UV and ozone. They are often specified for sterile or hygienic applications due to their non-reactive nature.

What It’s Used for: Commonly found in high-temperature fluid transfer, food and beverage processing, pharmaceutical manufacturing, and automotive coolant systems.

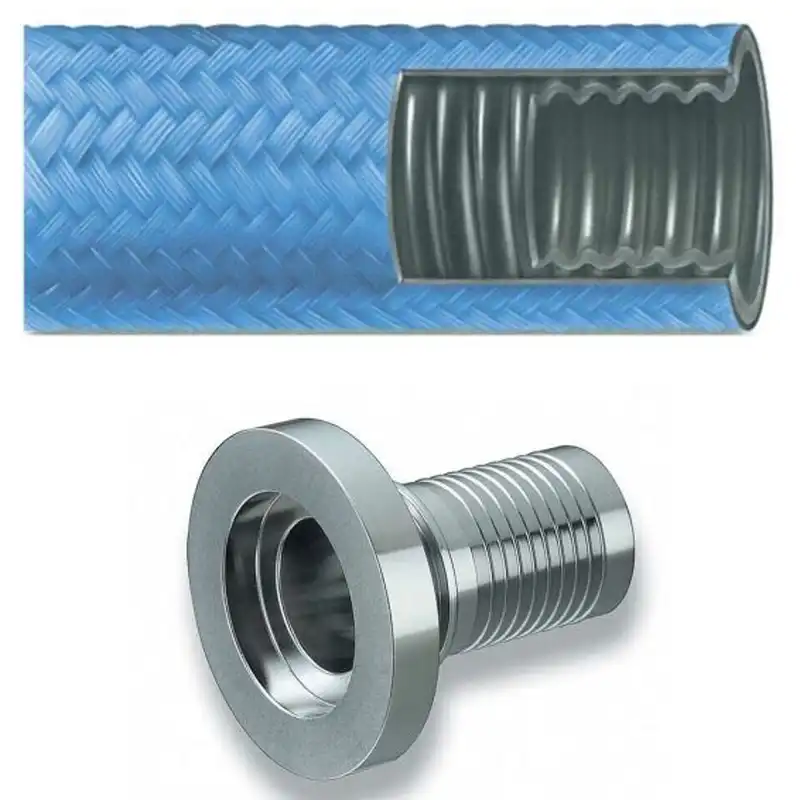

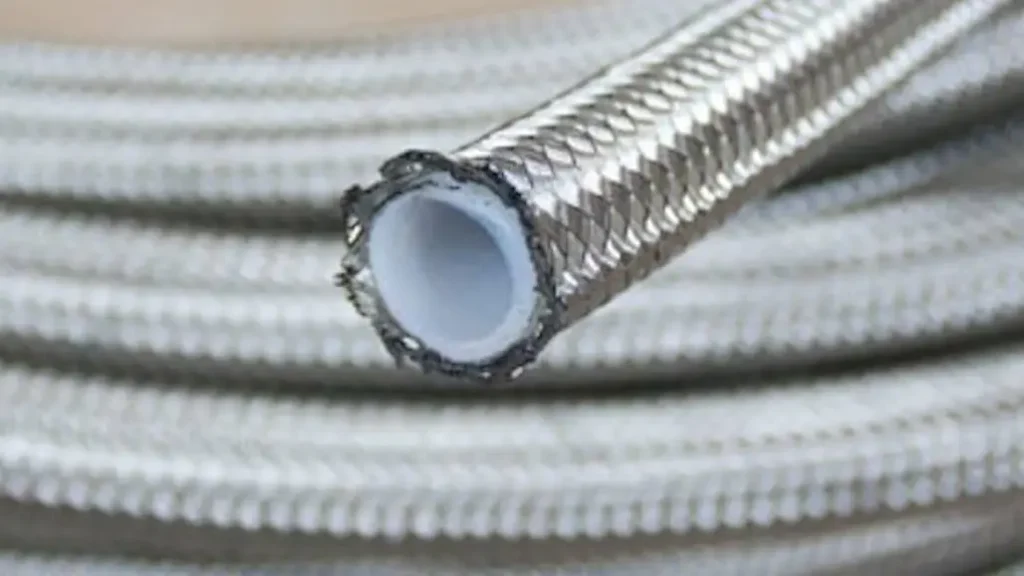

PTFE Industrial Hoses

PTFE (Polytetrafluoroethylene) Industrial Hoses offer unparalleled chemical resistance, making them the material of choice for highly corrosive or aggressive fluids. They also boast excellent temperature range, low friction, and are non-stick, preventing material buildup inside the hose.

Benefits: Extreme chemical inertness, high-temperature tolerance, and non-contaminating properties. Their smooth bore reduces pressure drop and prevents material adhesion.

What It’s Used for: Essential for transferring concentrated acids, strong alkalis, solvents, and other highly aggressive chemicals in chemical processing, pharmaceutical, and aerospace industries.

Metal Industrial Hoses

Metal Industrial Hoses, often made from stainless steel, are constructed with corrugated flexible tubes that allow for movement and vibration absorption while maintaining high strength. They are designed for applications involving extreme temperatures, high pressures, and highly corrosive or hazardous media where other materials would fail.

Benefits: Unmatched resistance to extreme temperatures, high pressures, and virtually all chemicals. They are highly durable, fire-resistant, and provide excellent barrier properties against permeation.

What It’s Used for: Critical in applications such as steam transfer, cryogenic liquids, high-temperature exhaust, corrosive chemical processing, and in environments requiring maximum safety and leak prevention.

Composite Industrial Hoses

Composite Industrial Hoses are built from multiple layers of thermoplastic films and fabrics, spirally wound and often reinforced with internal and external wire helices. This multi-layer construction allows for exceptional flexibility, lightweight design, and broad chemical compatibility by selecting different material layers.

Benefits: Highly flexible and lightweight, making them easy to handle. They offer excellent chemical resistance due to their customizable multi-layer design and are less prone to kinking than other types.

What It’s Used for: Ideal for the transfer of a wide range of petroleum products, chemicals, and solvents, particularly in loading and unloading operations for road tankers, rail cars, and marine vessels.

Here are different types of industrial hoses below:

| Hose Type | Key Material Characteristics | Primary Benefits | Common Uses |

| Rubber | Flexible, abrasion-resistant, various compounds (EPDM, Nitrile) | Flexible, durable, good insulation, shock absorption | Air, water, general chemicals, petroleum, abrasive materials |

| PVC | Lightweight, transparent, good chemical/oil resistance | Affordable, transparent, easy to handle, general chemical resistance | Water transfer, light chemicals, air lines, food-grade applications |

| Polyurethane | Exceptional abrasion resistance, high tensile strength, flexible | Superior abrasion resistance, long lifespan, tear-resistant | Abrasive materials (grains, powders), pneumatic conveying, vacuum systems |

| Silicone | High/low temperature resistance, flexible, odorless, tasteless | Extreme temperature performance, high flexibility, purity | High-temp fluids, food/pharma processing, automotive coolant |

| PTFE | Unparalleled chemical resistance, high temp, low friction | Extreme chemical inertness, high temp tolerance, non-contaminating | Concentrated acids, solvents, aggressive chemicals |

| Metal | Stainless steel, corrugated, high strength | Unmatched temp/pressure/chemical resistance, durable, fire-resistant | Steam, cryogenics, high-temp exhaust, corrosive chemicals |

| Composite | Multi-layered thermoplastic films/fabrics, wire reinforced | Flexible, lightweight, broad chemical compatibility, less kinking | Petroleum products, diverse chemicals, solvents (tanker loading/unloading) |

How to Choose Suitable Industrial Hoses?

Choosing the suitable industrial hose is a critical decision that directly impacts operational safety, efficiency, and cost-effectiveness. It involves a systematic evaluation of several key factors to ensure the hose performs reliably under specific application conditions and is compatible with the media being transferred.

- Chemical Compatibility: The most crucial factor is ensuring the hose’s inner tube, cover, and fittings are chemically compatible with the media being conveyed. Refer to chemical resistance charts to prevent degradation, permeation, or contamination.

- Temperature Range: Consider the maximum and minimum temperatures of both the conveyed material and the ambient environment. The hose must be rated to safely operate within these extremes without material degradation or loss of integrity.

- Pressure Rating: Determine the maximum working pressure and any potential surge pressures of the system. The hose’s working pressure rating must exceed these values, and a safety factor (typically 3:1 or 4:1) should always be applied.

- Size and Length: Select the correct inside diameter (ID) to achieve the desired flow rate and minimize pressure drop. The length should be adequate to prevent kinking or excessive tension, but not so long as to create unnecessary slack or trip hazards.

- Application Environment: Evaluate external factors such as abrasion, crushing, ozone exposure, UV radiation, and potential for kinking. The hose’s cover material and construction should be robust enough to withstand these environmental stresses.

- End Fittings: Choose fittings that are compatible with the hose material, the conveyed media, and the connection points of your equipment. Ensure proper installation techniques are used to prevent leaks and ensure secure connections.

- Flexibility and Bend Radius: Consider the required flexibility and minimum bend radius for the application, especially if the hose needs to navigate tight spaces or is subject to frequent movement.

Conclusion

In conclusion, the careful selection of industrial hose materials is not merely a technicality but a critical investment in operational safety and efficiency. Each material offers distinct advantages, making a thorough understanding of your specific needs paramount for optimal performance and longevity.

By aligning the hose material with the demands of your fluid, temperature, pressure, and environment, you can mitigate risks, reduce downtime, and ensure a more reliable process. This informed decision-making extends the life of your equipment and safeguards your personnel.

For a wide range of high-quality industrial hoses, including durable and reliable wholesale chemical hoses, consider Kingdaflex. We offer solutions tailored to your specific requirements, ensuring you get the right material for your needs.