Rubber hoses are an indispensable part of our daily lives, found everywhere from your car engine to your garden. While often overlooked, they are critical for the safe and efficient transfer of fluids and gases. This guide will uncover the fascinating world behind these essential components.

This comprehensive resource will explore rubber hoses from the inside out. We’ll delve into the specialized materials they are made of, their advanced manufacturing processes, and the diverse applications they serve across various industries, providing you with a complete understanding.

What is a Rubber Hose?

A rubber hose is a flexible tube, typically with a circular cross-section, that’s engineered to transport fluids, gases, or even abrasive materials from one point to another.

Unlike rigid piping, its primary advantage is its flexibility, which allows it to connect moving parts or navigate around obstacles. Made from a variety of synthetic or natural rubber compounds, its multi-layered construction usually includes an inner tube for material compatibility, a reinforcement layer for strength and pressure resistance, and an outer cover for protection against environmental factors like abrasion and weathering.

What is Rubber Hose Made of?

A rubber hose is a complex composite structure, with its exact composition varying based on its intended application. However, a typical hose consists of three main layers: an inner tube for material compatibility, a reinforcement layer for structural integrity, and a protective outer cover. The specific materials for each layer are carefully selected to withstand the pressures, temperatures, and fluids of a particular job.

- Inner Tube: Composed of a specialized synthetic rubber like EPDM or NBR, designed to be compatible with the conveyed fluid and resist chemical degradation.

- Reinforcement Layer: Features a braided or spiraled textile cord, such as polyester or rayon, providing the necessary strength to withstand high-pressure applications.

- Outer Cover: A durable synthetic rubber compound, like SBR or neoprene, protects the hose from abrasion, ozone, UV rays, and external environmental damage.

- Fittings: Typically made of metal (brass, steel) or plastic, the fittings are securely attached to the hose ends to ensure a reliable, leak-proof connection.

What is a Rubber Hose Used for?

A rubber hose is a highly versatile product, primarily used to safely and efficiently transport a wide range of fluids, gases, and even abrasive materials from one point to another. Its flexibility and resistance to various environmental and operational conditions make it an ideal choice for connecting moving parts in complex systems. It serves critical roles across numerous industries, from simple home applications to complex industrial processes.

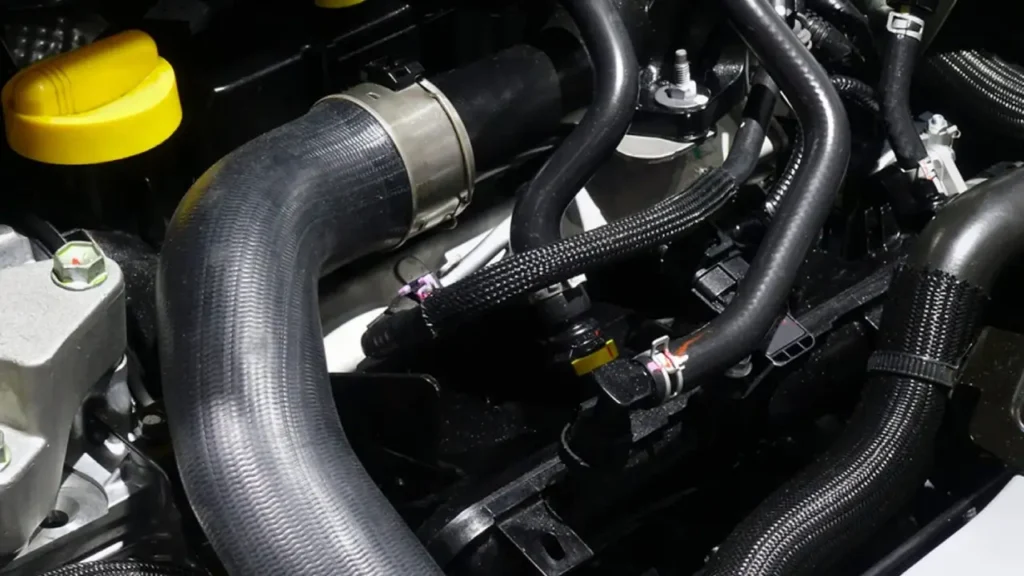

- Automotive: Used extensively for cooling systems (radiator hoses), fuel lines, and air intake systems, handling high temperatures, pressure, and exposure to various fluids.

- Agriculture: Serves in irrigation systems, fertilizer sprayers, and for transferring agricultural chemicals, where durability and resistance to weathering are essential for long-term use.

- Construction: Employed for concrete pumping, air compressors, and water drainage, where hoses must endure extreme pressure, physical abrasion, and harsh environmental conditions on job sites.

- Marine: Crucial for marine engines, fuel lines, sanitation systems, and bilge pump discharge, designed to be resistant to saltwater, fuel, oil, and engine heat.

- Industrial: Found in factories for pneumatic tools, chemical transfer, and material handling, where hoses are customized to safely convey specific substances under controlled pressure and temperature.

How Long Do Rubber Hoses Last?

The lifespan of a rubber hose is not fixed and depends on a combination of operational, environmental, and material factors. While a well-maintained hose can last for many years, its life expectancy is significantly affected by the conditions it is exposed to. Key elements such as the type of fluid it carries, the pressure and temperature it operates under, and external factors like abrasion and UV exposure all contribute to its eventual degradation.

- Operational Conditions: The hose’s life is directly impacted by its operating pressure, fluid temperature, and the frequency of pressure cycles, as these can cause premature fatigue and weakening of the hose.

- Fluid Compatibility: The chemical composition of the fluid inside the hose must be compatible with its inner tube material; otherwise, it can lead to swelling, softening, or cracking from the inside out.

- Environmental Exposure: Constant exposure to high heat, ozone, sunlight (UV), and moisture can cause the outer rubber cover to become brittle and crack, compromising the hose’s protective layer.

- Physical Stress: Repeated bending, twisting, or abrasion against other components can physically damage the hose’s reinforcement and cover, accelerating wear and increasing the risk of failure.

- Age of Hose: Even with minimal use, the rubber compound will naturally degrade over time due to aging and thermal oxidation, leading to a loss of its original flexibility and strength.

Types of Rubber Hoses

Rubber hoses are not a one-size-fits-all product; they are highly specialized based on their intended use. Different types are engineered with specific materials and constructions to handle varying pressures, temperatures, and fluids. Understanding these distinctions is crucial for selecting the right hose.

Rubber Washer Hose

A rubber washer hose is designed for residential and commercial washing machines. Its robust, reinforced construction allows it to withstand the high water pressure and temperature fluctuations of laundry cycles. The hose is also engineered to be flexible, resisting kinks and making it easy to install behind an appliance.

Rubber Fuel Hose

Rubber fuel hoses are used to transfer flammable liquids like gasoline and diesel. They are engineered with a specialized inner tube that is chemically resistant to petroleum products, preventing degradation and leaks. Their durable construction ensures a safe and reliable connection within a vehicle’s fuel system.

Rubber Brake Hose

A rubber brake hose is a critical safety component used in a vehicle’s hydraulic braking system. Its reinforced, multi-layered design is built to withstand extreme internal pressures without expanding. This ensures a consistent and responsive brake pedal feel, providing reliable stopping power for safe operation.

Molded Rubber Hose

Molded rubber hoses are custom-shaped to fit specific engine or equipment compartments. Unlike straight hoses, they are manufactured with precise curves and bends to navigate around obstacles and connect components with a perfect fit. They are commonly used as OEM parts in automotive and industrial machinery.

Rubber Propane Hose

A rubber propane hose is specifically designed for the safe transfer of liquefied petroleum gas (LPG) to appliances. Its material is resistant to oil and weathering, providing a durable and flexible connection. This hose ensures a secure, leak-free seal for grills, heaters, and other gas-powered devices.

How to Bend a Rubber Hose?

Bending a rubber hose properly is crucial to prevent kinking, which can restrict flow and cause damage. The right technique ensures the hose maintains its integrity, flexibility, and performance, even in tight-fit applications.

Step 1: Assess the Hose and Bend

Before you begin, inspect the hose for any existing damage. Determine the required bend radius and choose a hose with a sufficient wall thickness and flexibility for the bend. This preparation ensures the hose can withstand the process without compromising its structure.

For best results, warm the hose slightly, but avoid high heat which can damage the rubber. A hose that is too cold will be stiff and more prone to cracking. A little warmth makes it more pliable and easier to work with.

Step 2: Use a Bending Tool

To prevent the hose from collapsing or kinking at the bend, use a flexible bending spring or a mandrel. Insert the tool into the hose before you start the bend. This provides internal support and helps the hose maintain its circular shape.

With the spring in place, slowly and carefully form the hose into the desired bend. Apply steady pressure and avoid sharp, forceful movements. Once bent, the spring can be removed by twisting it and pulling it out, leaving a clean bend.

Step 3: Apply Gentle Heat

For particularly stiff or thick-walled hoses, you may apply gentle, indirect heat using a heat gun. Move the heat gun continuously along the bending area. This softens the rubber and makes it pliable, facilitating the bend without cracking the material.

Never use an open flame or overheat the hose, as this will permanently damage the rubber compound, leading to future failure. The goal is to warm the hose, not to melt it. Overheating compromises the hose’s integrity and safety.

How to Clean a Rubber Hose?

A rubber hose should be cleaned regularly to remove dirt, grime, and any fluid residue that could lead to premature degradation or a loss of performance. The cleaning process is generally straightforward but requires a gentle approach to avoid damaging the rubber. Regular maintenance extends the hose’s lifespan and ensures it remains flexible and reliable for all its applications.

- Use Mild Soap: Start by cleaning the hose with warm water and a small amount of mild dish soap to remove surface dirt.

- Avoid Harsh Chemicals: Do not use strong detergents, solvents, or petroleum-based cleaners, as these can dry out or damage the rubber.

- Scrub Gently: Use a soft bristle brush or a clean cloth to gently scrub the hose’s surface, reaching into any grooves.

- Rinse Thoroughly: After washing, rinse the hose completely with clean water to remove all soap residue.

- Dry Completely: Allow the hose to air-dry fully before storing it to prevent mildew and degradation.

How to Choose Suitable Rubber Hoses?

Choosing a suitable rubber hose requires a careful assessment of several key factors to ensure safety and optimal performance. Selecting the right hose is a critical step, as using an improper hose can lead to premature failure, property damage, or injury. The primary considerations are matching the hose’s specifications to the demands of the application, particularly regarding the fluid, pressure, and environmental conditions.

- Fluid Compatibility: The hose material must be chemically compatible with the fluid or gas it will transfer to prevent degradation.

- Operating Pressure: The hose’s working and burst pressure ratings must exceed the system’s maximum operational pressure.

- Temperature Range: Ensure the hose can withstand both the maximum and minimum temperatures of the fluid and the environment.

- Hose Dimensions: The inner diameter must be correct for the required flow rate, and the length for a proper, non-stressed fit.

- Environmental Conditions: Consider external factors like abrasion, UV exposure, and ozone, which can affect the hose’s outer cover.

Conclusion

In conclusion, understanding the components, types, and applications of rubber hoses is crucial for making informed choices. As we have explored, these seemingly simple products are highly engineered solutions, critical for everything from vehicle safety to industrial operations, and their proper selection cannot be overstated.

With this ultimate guide, you are now empowered with the knowledge to identify the right hose for any job. Whether you need a hose resistant to high pressure, chemicals, or extreme temperatures, knowing the key factors ensures a long-lasting, reliable, and above all, safe solution for your specific needs.

For businesses seeking a dependable partner, we invite you to get wholesale rubber hoses from our Kingdaflex factory. With our decades of manufacturing expertise and stringent quality control, we provide durable, customized hoses to meet your exact specifications. Contact our team today to discuss your project requirements.