We provide premium 4SH hydraulic hoses designed for high-pressure systems and demanding industrial applications. Built with four reinforced steel wire layers, they ensure maximum durability, flexibility, and resistance to abrasion, crushing, and extreme temperatures. Ideal for construction, agriculture, and automotive hydraulics, our hoses guarantee safe and reliable fluid transfer.

Exceptional Pressure Resistance – Our 4SH hoses withstand extremely high pressures, maintaining consistent performance and preventing leaks or bursts, ensuring safety and reliability in critical hydraulic systems.

Reinforced Steel Wire Construction – Built with four layers of steel wire reinforcement, these hoses provide superior strength, durability, and longevity in heavy-duty applications.

Flexibility and Maneuverability – Despite their high-pressure capability, 4SH hoses remain flexible, allowing easy routing and installation in tight spaces without compromising structural integrity.

Versatile Applications – Perfect for industrial, agricultural, and automotive machinery, delivering dependable performance under harsh conditions and reducing downtime and maintenance costs.

Our OEM 4SH hydraulic hose is manufactured using high-quality materials and advanced production techniques, ensuring superior performance and durability.

Our 4SH hydraulic hoses undergo rigorous quality control inspections to guarantee that they meet or exceed industry standards.

We offer tailored solutions to meet your specific requirements, including various sizes, lengths, and pressure ratings.

We provide competitive pricing on our OEM 4SH hydraulic hoses without compromising on quality or performance.

Pressure Rating

4SH hydraulic hoses are designed for high-pressure applications, capable of handling pressures up to 5000 PSI or more, making them ideal for heavy-duty industrial and construction equipment that requires maximum hydraulic performance.

4SP hoses operate at lower pressure ratings, typically up to 4000 PSI. While still durable, they are better suited for medium-duty hydraulic systems where extreme pressure resistance is not critical, offering a balance between strength and flexibility.

Construction Layers

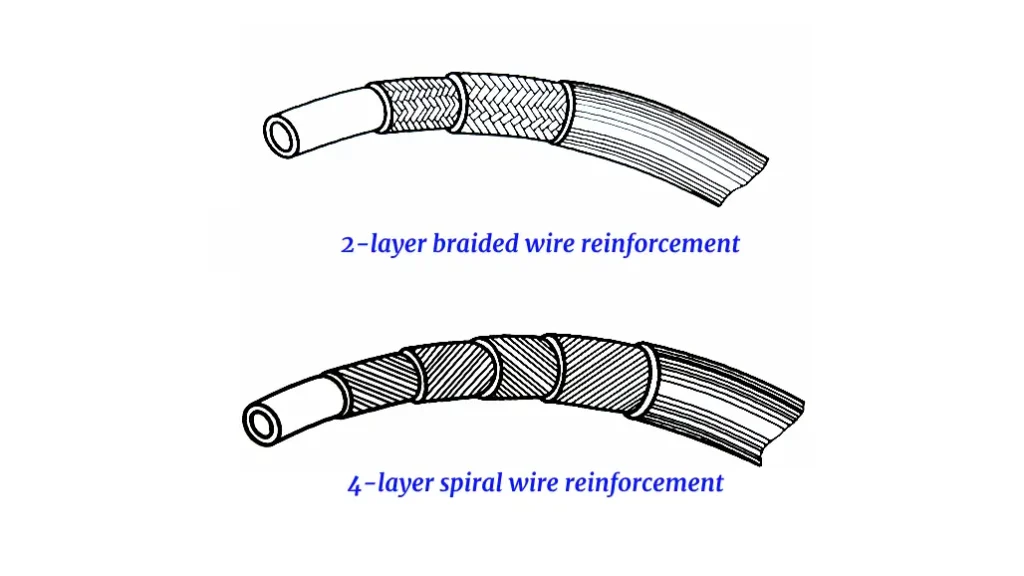

4SH hoses feature four layers of spiral steel wire reinforcement, providing superior strength, pressure resistance, and durability under demanding conditions. This design enhances flexibility while maintaining structural integrity for heavy-duty applications.

4SP hoses have four layers of braided steel wire, which provides moderate strength and good flexibility. While durable, the braid construction limits maximum pressure capacity compared to 4SH hoses, making them suitable for less extreme applications.

Flexibility

4SH hoses, with spiral construction, are slightly stiffer due to the layered steel spirals, which may affect routing in tight spaces but ensures maximum pressure endurance. They excel in applications requiring heavy fluid transfer under extreme pressure.

4SP hoses are more flexible because of their braided steel design. This flexibility allows easier installation and bending in confined spaces, making them ideal for mobile equipment or systems requiring frequent hose movement.

Temperature & Abrasion Resistance

4SH hoses offer excellent temperature resistance and withstand extreme environmental conditions. Their reinforced layers protect against abrasion, crushing, and kinking, making them highly reliable for continuous heavy-duty operations.

4SP hoses also offer good temperature and abrasion resistance but slightly less than 4SH. They perform well in standard industrial or agricultural applications but are less suited for continuous high-pressure environments.

Applications

4SH hoses are widely used in heavy machinery, construction equipment, and high-pressure hydraulic systems requiring maximum reliability, durability, and pressure handling capabilities in extreme conditions.

4SP hoses are typically used in medium-duty industrial machinery, agricultural equipment, and mobile hydraulic systems where moderate pressure and flexibility are more important than extreme pressure endurance.

The pressure rating for a 4SH hydraulic hose can vary depending on several factors, including:

Generally, 4SH hydraulic hoses are designed to withstand high pressures, often ranging from several thousand to tens of thousands of pounds per square inch (psi). However, it’s crucial to consult the manufacturer‘s specifications for the exact pressure rating of a particular 4SH hose.

When selecting a 4SH hydraulic hose, it’s essential to ensure that its pressure rating is sufficient for your application. Factors such as the maximum operating pressure of your hydraulic system and the specific demands of your machinery should be taken into consideration.

If you have a specific 4SH hydraulic hose in mind, please provide its manufacturer, size, and any other relevant information so I can give you a more accurate estimate of its pressure rating.

We are a leading provider of premium OEM 4SH hydraulic hoses. Our commitment to quality, reliability, and customer satisfaction sets us apart in the industry.

4SH hydraulic hose is a type of hydraulic hose that is commonly used in industrial applications. It is known for its durability, flexibility, and high-pressure resistance.

The “4SH” designation typically refers to the hose’s construction, which often includes a synthetic rubber inner tube, a braided steel wire reinforcement, and a synthetic rubber or neoprene outer cover.

Key features and benefits of 4SH hydraulic hose include:

4SH hydraulic hoses are commonly used in various industries, including construction, mining, agriculture, and manufacturing.

The primary difference between 4SP and 4SH hydraulic hoses lies in their reinforcement structure:

Sum up:

It’s important to consult the specific specifications of each hose type to determine the most suitable option for your particular application.

The working pressure of a 4SH hydraulic hose varies depending on the specific manufacturer, size, and construction. Factors such as the thickness of the steel wire reinforcement, the quality of the rubber components, and the overall design of the hose contribute to its pressure rating.

Generally, 4SH hoses are designed to withstand high pressures, often ranging from several thousand to tens of thousands of pounds per square inch (psi). However, it’s crucial to consult the manufacturer‘s specifications for the exact working pressure of a particular 4SH hose.

When selecting a 4SH hose, it’s essential to ensure that its pressure rating is sufficient for your application. Factors such as the maximum operating pressure of your hydraulic system and the specific demands of your machinery should be taken into consideration.

If you have a specific 4SH hydraulic hose in mind, please provide its manufacturer, size, and any other relevant information so I can give you a more accurate estimate of its working pressure.

The pressure rating for a 4-wire hydraulic hose can vary depending on several factors, including:

Generally, 4-wire hydraulic hoses are designed to withstand high pressures, often ranging from several thousand to tens of thousands of pounds per square inch (psi). However, it’s crucial to consult the manufacturer‘s specifications for the exact pressure rating of a particular 4-wire hose.

When selecting a 4-wire hydraulic hose, it’s essential to ensure that its pressure rating is sufficient for your application. Factors such as the maximum operating pressure of your hydraulic system and the specific demands of your machinery should be taken into consideration.

If you have a specific 4-wire hydraulic hose in mind, please provide its manufacturer, size, and any other relevant information so I can give you a more accurate estimate of its pressure rating.