Hydraulic hoses are the lifelines of countless machines, from construction equipment to agricultural machinery. But what gives these hoses the remarkable strength to handle immense pressure? The answer lies in a crucial component: braiding. This blog will delve into what braiding is, how it works, and why it’s a non-negotiable feature for dependable hydraulic systems.

The process of braiding involves weaving layers of high-tensile steel wire or synthetic fibers around a hose’s inner tube. This creates a powerful reinforcement that prevents the hose from expanding and bursting under pressure. Understanding this fundamental element is key to appreciating the engineering behind every piece of heavy machinery you see.

What Is Braid for A Hydraulic Hose?

Braiding for a hydraulic hose is a critical reinforcement layer, typically made of high-tensile steel wire or synthetic fibers. Woven in a crisscross pattern around the inner tube, this layer provides the essential strength needed to contain the high pressures of hydraulic fluid, preventing the hose from expanding and bursting.

Types of Hydraulic Hose Braids

A hydraulic hose’s pressure rating is primarily determined by its reinforcement layer, known as braiding. Different types of braiding are used to meet specific pressure and flexibility requirements for various applications.

Wire Braid

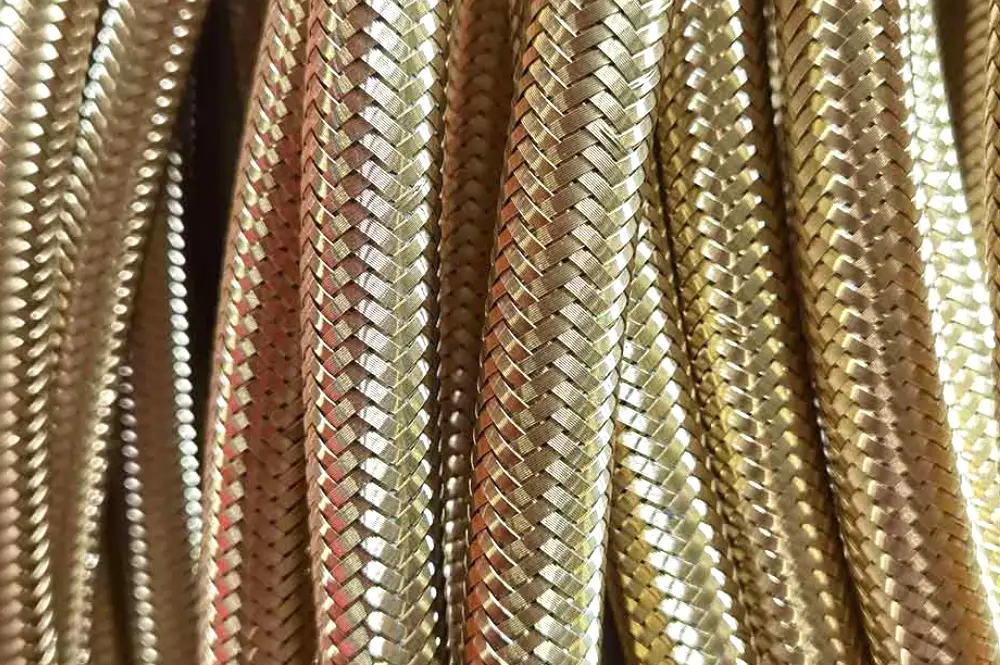

The wire braid is bundled parcelled and braided to cover the hydraulic hose pipe, and our hydraulic hose manufacturer can use the advanced hydraulic hose braiding machine to twine the stainless steel wire to create the wire braids. And we can call the obtained braid with the name “wire braid”. And the wire braid is flexible and suitable to absorb the frequent displacement.

We can add more layers of the wire braids to make the hydraulic hose much stronger while working under higher pressure, here we have different layers of the braids as the hydraulic hose reinforcement for your to choose from.

Single-Wire Braid

Single-wire braid hoses, often designated as 1SN or R1, feature a single layer of high-tensile steel wire braided around the inner tube. This design is common for low to medium-pressure applications and provides a good balance of strength and flexibility. The single layer allows for a tighter bend radius, which is beneficial in confined spaces.

The construction of a single-wire braid hose is ideal for return lines, some agricultural machinery, and light-duty industrial equipment where excessive pressure is not a concern. While not as strong as multi-layered options, its lightweight and flexible nature make it a versatile and cost-effective solution for many hydraulic systems.

More layers of wire braid can be applied for higher pressure, and we have the 1-wire braid hydraulic hose and 2-wire braid hydraulic hose.

- 1-wire braided hydraulic hose: DIN EN857 1SC, SAE 100R17, SAE 100R1A/DIN EN853 1ST, SAE 100R1AT/ DIN EN853 1SN, SAE 100R2A / DIN EN853 2ST, SAE 100R5

- 2-wire braided hydraulic hose: DIN EN857 2SC, SAE 100R16, SAE 100R2AT / DIN EN853 2SN

Double-Wire Braid

Double-wire braid hoses, commonly labeled as 2SN or R2, contain two distinct layers of braided steel wire separated by a rubber layer. This construction significantly increases the hose’s pressure capacity compared to its single-braid counterpart. The two layers of reinforcement provide a much stronger “cage” to contain the high pressure of the hydraulic fluid.

Used widely in high-pressure applications, such as construction equipment and heavy-duty machinery, double-wire braid hoses are the industry standard for demanding tasks. While they are less flexible and have a larger bend radius than single-braid hoses, their superior pressure resistance makes them essential for systems where safety and performance under high stress are critical.

Multi-Wire Braid

Multi-wire braid hoses, sometimes known as 3SN or even 4SN, feature three or more layers of braided wire. This design is engineered for extremely high-pressure applications, such as large-scale industrial presses, mining equipment, and very heavy machinery. The additional layers of reinforcement provide exceptional strength and durability, preventing failure under the most intense conditions.

While these hoses offer the highest pressure ratings among braided types, they are also the least flexible and have the largest outside diameter. They are a specialized solution for systems where no other type of hose can safely handle the required pressure. Their robust construction ensures maximum safety and longevity in the most punishing of environments.

Quote Braided Hydraulic Hose

Fabric Braided

Fabric braided hydraulic hoses are a unique category where the reinforcement is made from textile fibers, such as polyester, rayon, or aramid, instead of steel wire. This type of braiding is designed for low-pressure applications, including return lines and air or water systems. The use of fabric makes these hoses exceptionally lightweight and flexible, allowing for easy routing and installation in tight or complex spaces.

Despite their lower pressure rating, fabric braided hoses offer excellent abrasion resistance and a high degree of kink resistance. Their flexibility makes them ideal for applications where hoses are frequently moved or where a tight bend radius is required. They are a cost-effective alternative to wire-braided hoses in applications that do not require the immense strength of steel.

What is a Braided Hydraulic Hose Made Of?

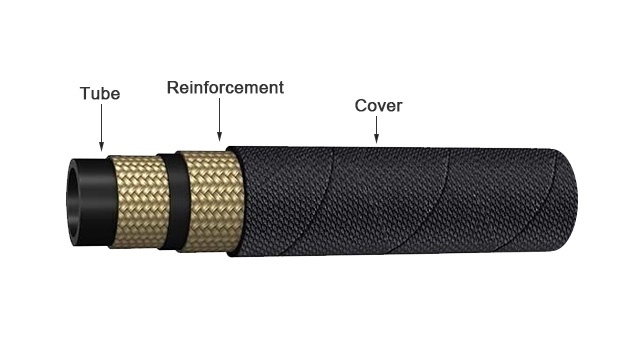

A braided hydraulic hose is made of several distinct layers, each serving a specific purpose to handle high-pressure fluids and withstand external elements. The key components of the braided hydraulic hoses are:

- Inner Tube: The innermost layer is made of a synthetic rubber or thermoplastic that’s compatible with the fluid it’s carrying. This ensures a leak-proof path for hydraulic fluid.

- Braided Reinforcement: This critical layer consists of one or more woven layers of high-tensile steel wire or synthetic fibers. The crisscross pattern provides the immense strength to contain internal pressure.

- Outer Cover: The outermost layer is a synthetic rubber or durable thermoplastic that protects the inner layers from abrasion, weather, oil, and other environmental damage.

High Pressure Steel Braided Hydraulic Hose

High-pressure steel-braided hydraulic hoses are engineered to handle extremely demanding applications by incorporating one or more layers of high-tensile steel wire braiding as reinforcement. This woven or crisscross pattern provides exceptional burst resistance, enabling the hose to contain fluids under immense pressure without expanding or rupturing.

They are the industry standard for most heavy-duty machinery and are essential for safety and reliability in high-stress environments.

- Durable Construction: These hoses have an inner tube for fluid conveyance, a steel wire braid for high-pressure containment, and a tough outer cover for protection. This multi-layered design ensures longevity and performance.

- High-Pressure Resistance: The steel braiding is the key to their strength, allowing them to withstand thousands of pounds per square inch of pressure, far exceeding the capabilities of unreinforced or fabric hoses. This makes them ideal for systems in heavy machinery.

- Broad Applications: They are used in countless industries, including construction, agriculture, mining, and manufacturing, powering everything from excavators and cranes to industrial presses and hydraulic lifts.

How to Manufacture the Braided Hydraulic Hose?

Manufacturing braided hydraulic hoses is a multi-step process that ensures a high-quality, durable final product capable of withstanding extreme pressure. It combines material preparation, precise extrusion, and a crucial braiding phase.

This process is a careful sequence of engineering to build the hose’s strength from the inside out.

Step 1: Extruding the Inner Tube

The first step involves extruding a seamless inner tube from a synthetic rubber compound or thermoplastic material. This inner layer is the fluid-carrying component and must be chemically compatible with the specific hydraulic fluid to prevent degradation and leaks.

The inner tube is then cooled and cured to give it the necessary shape and chemical properties. This process ensures the tube maintains its integrity and provides a smooth, non-porous pathway for the fluid.

Step 2: Braiding the Reinforcement Layer

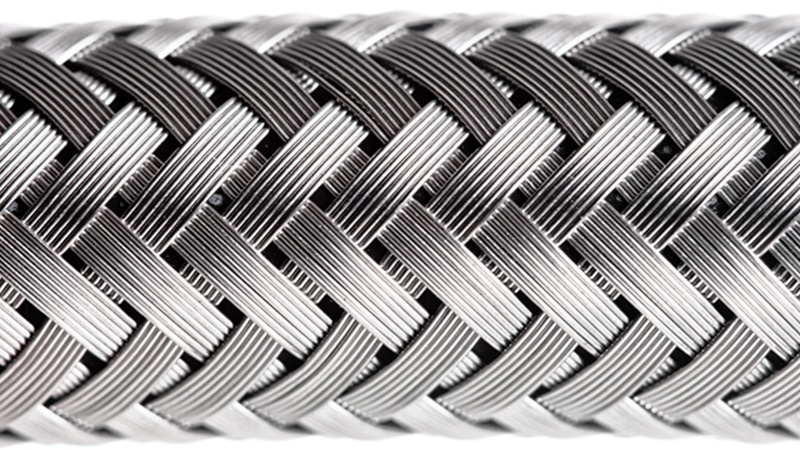

After the inner tube is prepared, it’s fed into a braiding machine. This machine precisely weaves high-tensile steel wire or synthetic fibers around the inner tube in a specific crisscross pattern. The number of braided layers depends on the required pressure rating.

This braiding process is critical as it provides the tensile strength to resist the high internal pressure of the hydraulic fluid. The angle and tension of the braid are carefully controlled to ensure optimal performance and flexibility.

Step 3: Applying the Outer Cover

Once the braiding is complete, a final layer of synthetic rubber or thermoplastic is extruded over the braided reinforcement. This outer cover serves as a protective shield for the hose’s inner components.

This outer cover protects the hose from external factors like abrasion, weather, oil, and ozone. A proper cover extends the hose’s service life, ensuring its durability and reliability in harsh operating environments.

Step 4: Final Vulcanization and Finishing

In the final step, the entire hose is placed in an oven or steam chamber to undergo vulcanization. This curing process permanently bonds all the layers together into a single, cohesive unit, giving the hose its final shape and strength.

After vulcanization, the hose is cut to length, and any necessary end fittings or couplings are attached. Each finished hose then undergoes rigorous pressure testing to ensure it meets the required performance and safety standards before being shipped.

Are Steel Braided Hoses Better?

It depends on the application. For high-pressure, demanding environments, steel-braided hoses are generally better because the steel reinforcement provides superior strength, durability, and pressure resistance. They are the industry standard for heavy machinery and high-stress applications.

However, they are less flexible and heavier than fabric-braided alternatives. If an application requires a more lightweight, flexible, and cost-effective solution for lower pressures, such as air or water lines, a fabric-braided hose may be the better choice.

What is Braided Hose Used For?

Braided hoses are primarily used for applications that require a combination of high-pressure resistance, flexibility, and durability. The braid, whether steel wire or textile, prevents the hose from expanding and bursting under pressure.

- Hydraulic Systems: These hoses are essential in hydraulic systems for heavy machinery, construction equipment, and manufacturing, where they transfer fluid under high pressure to power various components.

- Automotive: They are widely used in vehicles for brake lines, power steering, and fuel systems, as their strength and resistance to heat and abrasion ensure safety and reliable performance.

- Industrial and General Use: Beyond hydraulics, they are also used for transporting air, water, and other fluids in low- to medium-pressure applications, like pneumatic tools or certain plumbing connections.

Does Braided Hydraulic Hose Kink?

Yes, braided hydraulic hoses can kink, though their braided reinforcement is designed to resist it. Kinking typically occurs when the hose’s minimum bend radius is exceeded during installation or operation. It’s a common issue that restricts fluid flow, reduces hose life, and can lead to a dangerous burst.

- Improper Installation: The most frequent cause of kinking is bending the hose too sharply, exceeding its specified minimum bend radius. Using a hose that is too long, too short, or improperly routed can also force it into positions where it kinks.

- Incorrect Hose Selection: Choosing a hose that doesn’t have the right pressure rating or flexibility for the application can lead to kinking under stress. More rigid, high-pressure hoses with multiple braid layers are more prone to kinking if not properly routed.

- External Damage and Wear: Repeated flexing or twisting, exposure to extreme temperatures, or physical damage can degrade the hose’s structure over time, making it more susceptible to kinking and internal failure.

How to Choose the Best Braided Hydraulic Hoses?

Choosing the best braided hydraulic hose for your application requires careful consideration of several key factors to ensure safety, efficiency, and longevity. Simply picking a hose based on its appearance or price can lead to costly and dangerous failures. The right selection depends on a thorough understanding of your system’s specific demands and operating conditions.

- Pressure Rating: Match the hose’s working pressure to your system’s maximum operating pressure, including any pressure spikes. Choosing a hose with a higher pressure rating provides a critical safety margin and extends its service life, preventing premature failure.

- Size and Length: The hose’s inner diameter (ID) and overall length are crucial. An undersized hose can cause excessive heat, pressure drops, and reduced efficiency, while an oversized one is unnecessarily heavy and expensive. Proper length allows for movement without kinking.

- Fluid Compatibility and Temperature: Ensure the hose’s inner tube and outer cover materials are compatible with the hydraulic fluid being used. Additionally, the hose must be rated to withstand the full range of both fluid and ambient temperatures it will encounter in its operating environment.

Conclusion

Braided hydraulic hoses are essential for ensuring the safety and performance of hydraulic systems. The woven reinforcement provides the crucial strength needed to withstand high pressures, making these hoses the industry standard. Their durability and reliability prevent equipment failure and keep operations running smoothly.

For all your industrial needs, choosing a trusted supplier is key. As a leading manufacturer and exporter, Kingdaflex specializes in providing high-quality braided hydraulic hoses. We offer a wide range of products designed to meet the rigorous demands of various applications, ensuring you get dependable, long-lasting performance.

With decades of experience and a commitment to quality, Kingdaflex is your ideal partner. We provide wholesale braided hydraulic hoses that are both affordable and durable, backed by a robust supply chain and a full production line. Contact us today to learn more about our products and how we can support your business.