In this article, we will guide you through the process of how to loosen hydraulic hose, ensuring optimal functionality and preventing costly repairs. So, let’s dive in and learn how to effectively loosen hydraulic hoses.

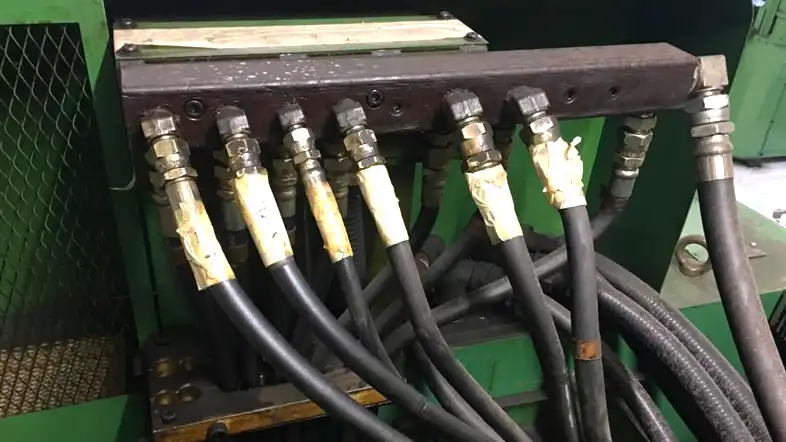

Hydraulic hoses play a crucial role in various industries, powering the movement of heavy machinery and equipment. However, over time, these hoses can become tight or stuck, leading to potential problems and decreased performance.

Why Hydraulic Hose Loose

Hydraulic hoses are essential components in hydraulic systems, responsible for transmitting fluid pressure and enabling the operation of machinery.

Over time, due to factors such as heat, pressure, and general wear and tear, these hydraulic hoses can become tight or stuck, hindering their performance and potentially causing damage to the system.

Loosening hydraulic hoses is a necessary maintenance task to ensure smooth operations and prevent failures.

Importance of Properly Functioning Hydraulic Hoses

Properly functioning hydraulic hoses are crucial for the performance and safety of hydraulic systems. When hydraulic hoses become tight or stuck, it can lead to increased friction, restricted fluid flow, and potential leaks.

These issues can result in decreased system efficiency, reduced equipment lifespan, and even hazardous situations for operators. Regular hydraulic hose maintenance and addressing tight hydraulic hoses promptly are essential to prevent costly repairs and ensure optimal system performance.

Common Issues with Hydraulic Hoses

Before we delve into the process of loosening hydraulic hoses, it’s important to understand the common issues that may arise when these hoses become tight or stuck.

Tight or Stuck Hydraulic Hoses

Tight or stuck hydraulic hoses can occur due to various reasons, including:

- Improper installation: Incorrect routing or clamping of the hoses can lead to tension and tightening.

- Age and wear: Over time, hydraulic hoses can experience internal or external swelling, hardening, or deformation, causing them to become tight.

- High temperatures: Exposure to high temperatures can cause the hose materials to expand, resulting in tightness.

- Contamination: Foreign particles, such as dirt or debris, can accumulate in the hose assembly, causing blockages and restricting movement.

Related: How to Tighten Hydraulic Hose Fittings?

Signs of a Loosening Hydraulic Hose

Identifying the signs of a loosening hydraulic hose is crucial for timely maintenance. Some common indicators include:

- Reduced system performance: If you notice a decrease in the efficiency or power output of your hydraulic system, it could be due to a tight or partially blocked hose.

- Fluid leaks: Leaks around the hose fittings or along the hose itself can indicate excessive pressure or tightness.

- Increased noise or vibration: Unusual noises or excessive vibrations during system operation may suggest a problem with the hydraulic hoses.

- Restricted movement: If the machinery or equipment powered by hydraulic systems experiences limited or jerky movement, it could be due to a hose that needs loosening.

Tools and Equipment Needed

Before starting the process of loosening hydraulic hoses, gather the following tools and equipment:

Wrenches

Depending on the size and type of fittings used, you will need appropriate wrenches, such as adjustable wrenches or socket wrenches, to loosen the hose connections.

Lubricants

Applying lubricant to the hose fittings and connections can help reduce friction and ease the loosening process. Use a suitable lubricant recommended for hydraulic systems.

Hose Clamps

Hose clamps are useful for temporarily securing the hose ends and preventing fluid leakage during the loosening process. Ensure you have clamps that match the hose diameter.

Steps to Loosen a Hydraulic Hose

Now that you have the necessary tools and equipment, follow these step-by-step instructions to effectively loosen a hydraulic hose:

Step 1: Safety Precautions

Before working on hydraulic hoses, ensure the system is depressurized and the equipment is shut down. Relieve any remaining pressure by operating the system controls. Additionally, wear appropriate safety gear, such as gloves and protective eyewear, to protect yourself from any potential hazards.

Step 2: Identifying the Loosening Point

Inspect the hydraulic hose assembly and identify the specific point where the hose needs to be loosened. This is usually at the connection points, such as fittings, adapters, or couplings.

Step 3: Applying Lubricant

Using the appropriate lubricant, apply a generous amount to the fittings and connections. Allow the lubricant to penetrate and reduce friction for a few minutes.

Step 4: Using Wrenches to Loosen

With the aid of wrenches, carefully loosen the fittings by turning them counterclockwise. Avoid applying excessive force, as it may damage the fittings or the hose itself. If the fitting is stuck, try using gentle back-and-forth movements to free it up.

Step 5: Testing and Adjusting

Once the fittings are loosened, check for any signs of damage or wear on the hose itself. Inspect the connections for leaks and make any necessary adjustments. Ensure that the fittings are not overtightened or under tightened, as both can lead to problems. Perform a thorough visual inspection and start the hydraulic system to verify proper hose functionality.

How to Loosen Hydraulic Hose Fittings?

Hydraulic systems are integral to many industrial and mobile applications, relying on high-pressure fluid transfer through hoses and fittings. Over time, these fittings can become incredibly tight due to pressure, corrosion, or thread locker, making disassembly challenging. Knowing the correct and safe procedures for loosening them is crucial for maintenance and repair, preventing damage to components and ensuring worker safety.

Step 1: Prioritize Safety

Before attempting to loosen any hydraulic hose fitting, always ensure the system is depressurized. Residual pressure can cause fittings to eject violently, leading to severe injury. Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and sturdy footwear. Have spill containment readily available, as hydraulic fluid can be under pressure and may spray when connections are broken.

Step 2: Gather the Right Tools

The success of loosening hydraulic fittings heavily depends on using the correct tools. You’ll typically need a set of open-end wrenches, adjustable wrenches, or specialized hydraulic fitting wrenches designed to grip multiple sides of the fitting to prevent rounding. A wire brush can be useful for cleaning the fitting, and penetrating oil or heat may be necessary for stubborn connections.

Step 3: Clean the Fitting

Dirt, rust, and debris can obscure the fitting’s shape and make it difficult to get a good grip with a wrench. Use a wire brush or a rag to thoroughly clean the area around the fitting. This also allows for better penetration of any loosening agents you might apply later.

Step 4: Apply Penetrating Oil

For fittings that appear seized or corroded, a high-quality penetrating oil can work wonders. Apply the oil generously to the threads and the joint where the fitting connects. Allow it to soak in for several minutes, or even longer for extremely stubborn fittings, to allow the oil to wick into the threads and break down rust or corrosion.

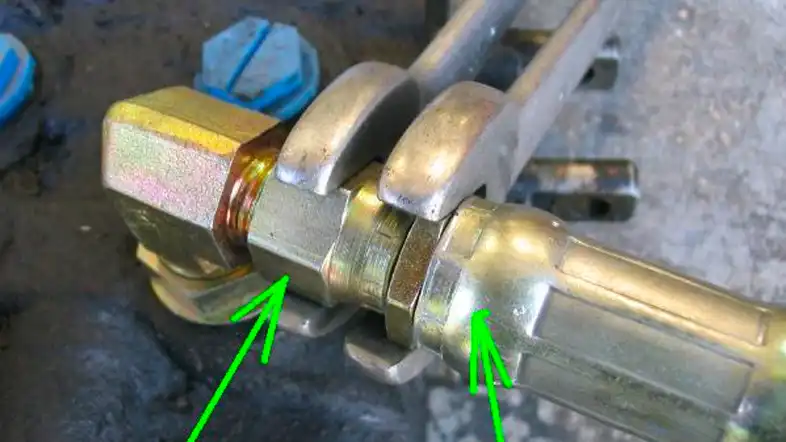

Step 5: Use Proper Wrench Technique

When ready to loosen the fitting, position your wrenches correctly. For two-piece fittings, use one wrench to hold the stationary part (e.g., the valve or pump port) and the other to turn the rotating part (the hose fitting nut). Apply steady, firm pressure in the counter-clockwise direction. Avoid sudden jerking motions, as this can round the fitting or cause you to slip. If the fitting doesn’t budge, apply more penetrating oil and allow it to soak longer.

Step 6: Consider Heat (with Caution)

As a last resort for extremely stubborn fittings, localized heat can be applied, but with extreme caution. A heat gun or small torch can expand the metal, potentially breaking the bond. However, never apply excessive heat, especially near rubber hoses, seals, or flammable hydraulic fluid, as this can cause damage or fire. Always have a fire extinguisher nearby and ensure proper ventilation.

Step 7: Tap the Fitting

Sometimes, a sharp tap with a hammer on the wrench or the fitting itself (never directly on the hose) can help break a stubborn bond. This shock can sometimes be enough to dislodge threads that are seized. However, be careful not to deform the fitting or surrounding components.

Step 8: Reassemble with Care

Once the fitting is loosened, clean the threads thoroughly and inspect them for damage. When reassembling, apply a thin layer of hydraulic thread sealant or thread locker (if specified by the manufacturer) to the threads to ensure a leak-free connection. Torque the fitting to the manufacturer’s specifications to prevent overtightening, which can lead to future seizing, or undertightening, which can cause leaks.

Preventive Measures

To maintain the optimal performance of your hydraulic hoses and minimize the likelihood of them becoming tight or stuck, consider the following preventive measures:

Regular Inspection and Maintenance

Implement a regular inspection schedule to identify any signs of wear, leaks, or tightening issues. Promptly address any concerns and perform necessary maintenance tasks, such as replacing worn-out hoses or tightening loose connections.

Using Correct Hydraulic Fluids

Ensure that the hydraulic system is filled with the recommended hydraulic fluids specified by the manufacturer. Using the wrong type of fluid can lead to hose swelling, deterioration, and other issues.

Conclusion

Loosening hydraulic hoses is a critical maintenance task that ensures the proper functioning and longevity of hydraulic systems. By following the step-by-step guide outlined in this article, you can effectively address tight or stuck hydraulic hoses, preventing potential failures and optimizing system performance. Remember to prioritize safety, use the appropriate tools and equipment, and perform regular hydraulic hose inspection to identify and address issues promptly.

FAQs

How often should I inspect my hydraulic hoses?

Regular inspection of hydraulic hoses is essential to detect any signs of wear, tightening, or leaks. It is recommended to inspect hoses at least once every three to six months or as advised by the equipment manufacturer.

Can I use any type of lubricant on hydraulic hoses?

No, it is crucial to use lubricants specifically designed for hydraulic systems. Consult the equipment manufacturer’s recommendations or a hydraulic specialist to determine the suitable lubricant for your specific hydraulic hoses.

What are the signs of a failing hydraulic hose?

Signs of a failing hydraulic hose include fluid leaks, reduced system performance, increased noise or vibration, and restricted movement of machinery or equipment.

How tight should the hose clamps be?

Hose clamps should be tightened sufficiently to prevent fluid leakage but not excessively, as overtightening can damage the hose or fittings. Follow the manufacturer’s guidelines for proper tightening torque.

What happens if a hydraulic hose is not properly tightened?

If a hydraulic hose is not properly tightened, it can result in fluid leaks, reduced system efficiency, and potential damage to the equipment or machinery. It is crucial to ensure all hose connections are appropriately tightened to avoid these issues.