Hydraulic systems play a vital role in various industries, powering machinery and equipment with precision and efficiency. Within these systems, hydraulic hoses are crucial components that facilitate the transfer of hydraulic fluid and enable the smooth operation of machinery.

One type of hydraulic hose that has gained popularity in recent years is the textile braided hydraulic hose. In this article, we will explore the benefits of textile braided hydraulic hoses, their applications, factors to consider when choosing them, and proper maintenance practices.

What Are Textile Braided Hydraulic Hoses?

Textile braided hydraulic hoses are flexible hoses reinforced with woven textile fibers, usually made of high-strength synthetic materials such as polyester or nylon. These fibers provide additional strength and durability while maintaining flexibility, making the hoses suitable for low to medium-pressure hydraulic systems. The hose typically consists of an inner tube that carries the hydraulic fluid, the braided textile layer for reinforcement, and an outer protective cover to resist abrasion, weathering, and chemical exposure.

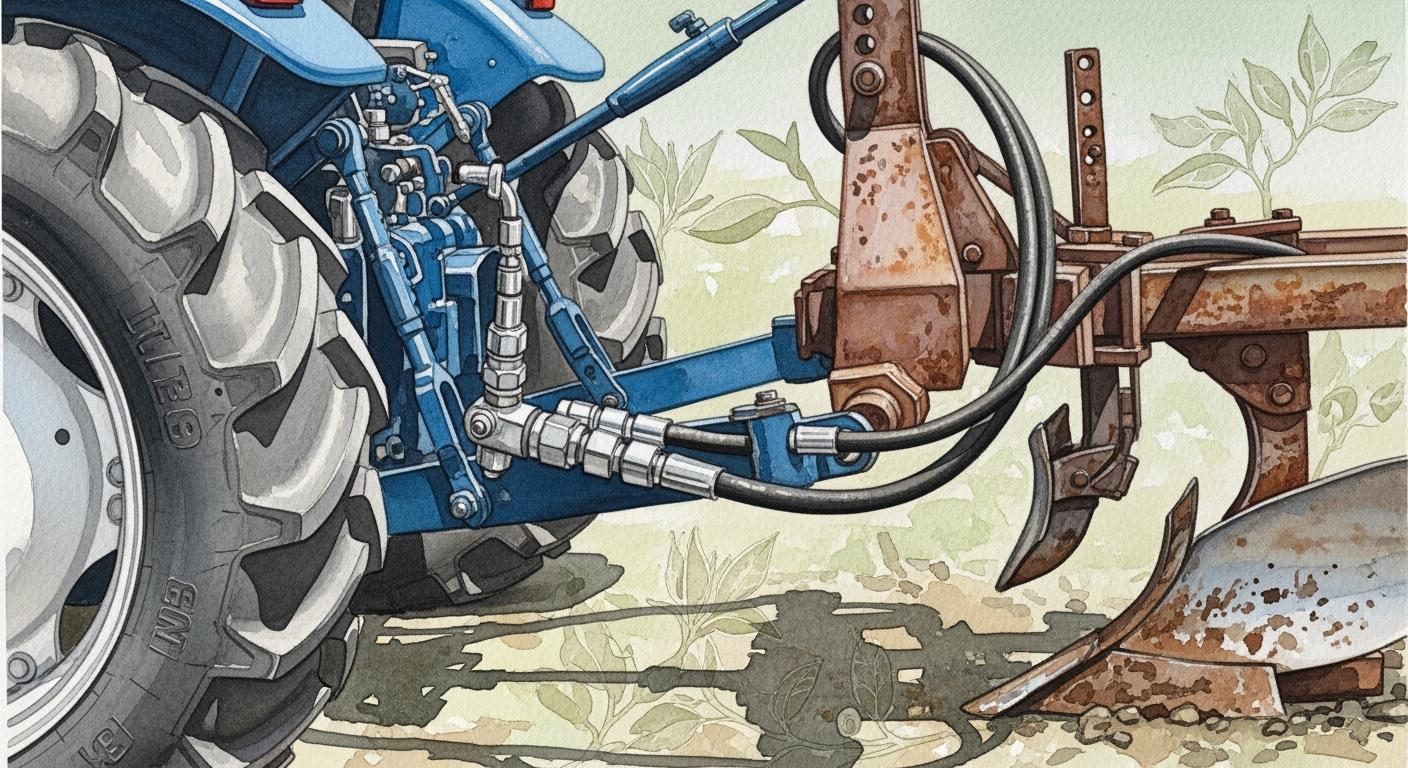

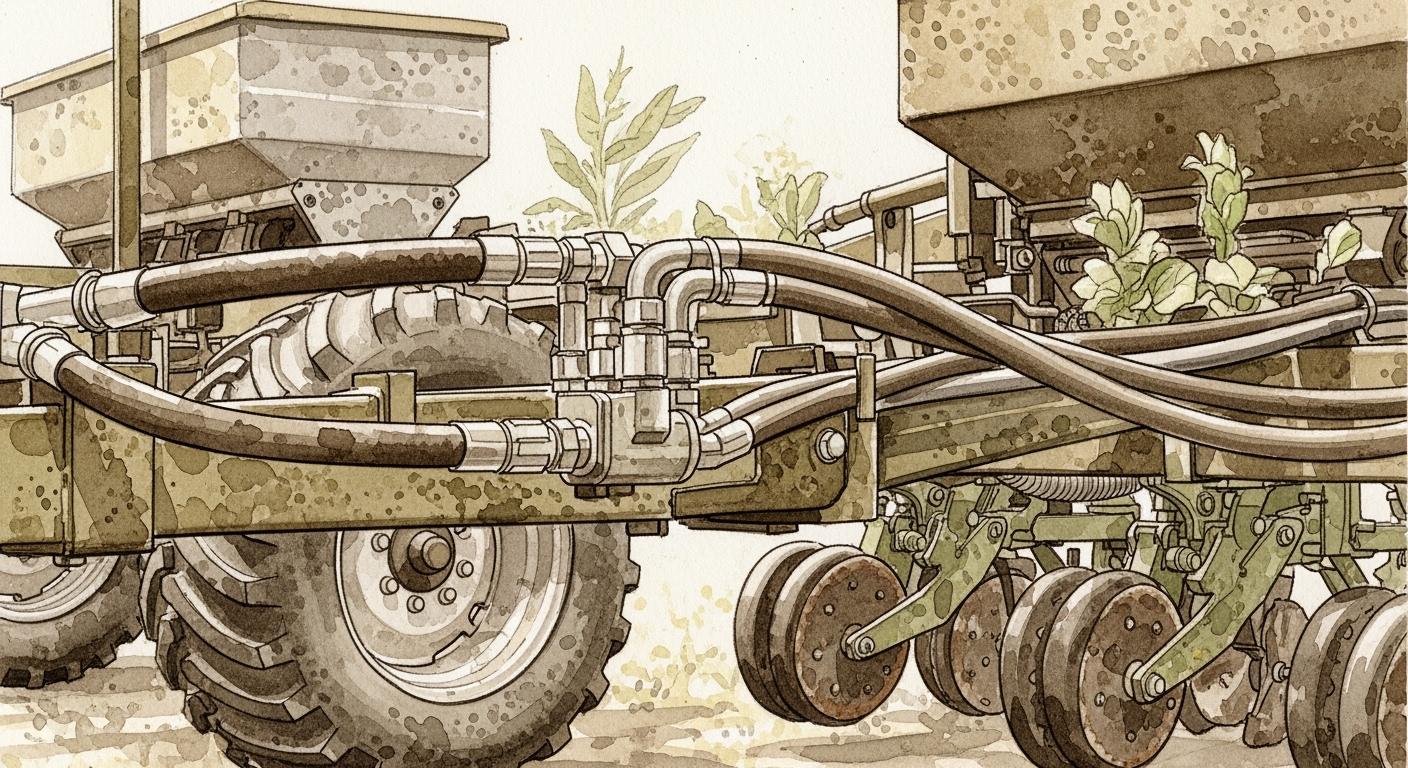

These hoses are widely used in applications where high flexibility and lightweight design are crucial, such as agricultural machinery, construction equipment, and industrial machinery. Textile braided hoses are ideal for situations requiring frequent movement or bending, as their woven reinforcement prevents kinking and ensures consistent fluid flow. Additionally, they are easier to handle and install compared to steel wire reinforced hoses, offering a cost-effective and reliable solution for many hydraulic systems.

How Do Textile Braided Hydraulic Hoses Work?

Textile braided hydraulic hoses operate by transmitting hydraulic fluid under pressure from a pump to various components of a hydraulic system. The textile braid reinforces the hose, allowing it to withstand internal pressure while remaining flexible for smooth operation and safe fluid transfer.

- Fluid Transmission: The inner tube carries hydraulic fluid efficiently, ensuring consistent pressure and flow. The textile braid prevents expansion and maintains hose shape, allowing stable performance even in dynamic conditions where flexibility and bending are frequent.

- Pressure Resistance: The woven textile fibers reinforce the hose, distributing internal pressure evenly and preventing ruptures. This reinforcement enables the hose to operate safely in low to medium-pressure systems while minimizing the risk of leaks or bursts.

- Flexibility and Durability: The braid allows the hose to bend and move without kinking, making it suitable for machinery with moving parts. The outer cover protects against abrasion, weather, and chemicals, extending hose lifespan and reducing maintenance costs.

- System Efficiency: By maintaining structural integrity under pressure, textile braided hoses ensure hydraulic systems work efficiently. Smooth fluid flow, minimal leakage, and reliable pressure transmission contribute to better machine performance and operational safety.

Advantages of Textile Braided Hydraulic Hoses

Textile braided hydraulic hoses offer a combination of flexibility, strength, and reliability, making them ideal for low to medium-pressure hydraulic applications. Their woven reinforcement enhances durability while remaining lightweight, providing a cost-effective and easy-to-install solution for machinery and equipment that require frequent movement and bending.

- High Flexibility: The textile braid allows the hose to bend and move easily without kinking. This flexibility ensures smooth operation in tight spaces and dynamic machinery environments, reducing stress on connectors and extending the overall service life of the hydraulic system.

- Lightweight Design: Compared to steel-reinforced hoses, textile braided hoses are lighter, making them easier to handle, install, and route in complex hydraulic systems. Reduced weight also minimizes strain on equipment, contributing to improved efficiency and safer operation.

- Durability and Strength: Woven textile fibers provide excellent resistance to internal pressure, abrasion, and wear. This reinforcement maintains hose integrity under continuous use, preventing leaks, ruptures, or deformation, and ensuring reliable hydraulic performance over time.

- Cost-Effective Solution: Textile braided hoses are generally more affordable than metal-reinforced alternatives. They offer a practical balance of strength, flexibility, and longevity, allowing businesses to reduce maintenance costs and downtime while maintaining consistent hydraulic system performance.

Applications of Textile Braided Hydraulic Hoses

Textile braided hydraulic hoses are widely used in industries where flexibility, durability, and reliable fluid transmission are essential. Their lightweight design and resistance to wear make them suitable for a variety of machinery and equipment in low to medium-pressure hydraulic systems across multiple applications.

- Agricultural Machinery: These hoses are ideal for tractors, harvesters, and irrigation systems. Their flexibility allows them to withstand constant movement, bending, and vibration, ensuring smooth hydraulic operation while resisting abrasion and extending the lifespan of equipment used in demanding farm environments.

- Construction Equipment: Textile braided hoses are used in excavators, loaders, and cranes. Their ability to handle repetitive motion and low to medium pressure helps maintain consistent hydraulic performance, reduces maintenance needs, and enhances operational efficiency on construction sites.

- Industrial Machinery: Textile braided hoses support manufacturing and production equipment, including presses, conveyor systems, and automated machines. Their durable yet flexible design ensures reliable fluid transfer, preventing downtime while maintaining safe and efficient operation in industrial settings.

- Material Handling: Forklifts, pallet movers, and other handling equipment benefit from textile braided hoses. They provide dependable hydraulic performance in dynamic applications, allowing smooth lifting and maneuvering while resisting wear, kinking, and pressure fluctuations during repetitive tasks.

- Automotive Systems: Used in low-pressure hydraulic lines for braking, steering, and cooling systems, these hoses ensure safe fluid transfer and flexibility within compact spaces, supporting the efficiency and reliability of various vehicle hydraulic components.

Factors to Consider when Choosing Textile Braided Hydraulic Hoses

Selecting the right textile braided hydraulic hose is crucial for ensuring safety, efficiency, and durability in hydraulic systems. Considering factors such as pressure rating, temperature tolerance, compatibility with fluids, and flexibility helps match the hose to specific applications and operational requirements.

- Pressure Rating: Ensure the hose can handle the system’s maximum operating pressure. Choosing a hose with appropriate pressure tolerance prevents bursts, leaks, and system failure, ensuring reliable hydraulic performance and protecting both equipment and operators.

- Temperature Range: Consider the hose’s resistance to high and low temperatures. A suitable temperature range maintains fluid viscosity and hose integrity, preventing cracking, softening, or deformation under varying environmental and operational conditions.

- Fluid Compatibility: Verify that the hose material is compatible with the hydraulic fluids used. Proper compatibility prevents chemical degradation, swelling, or leaks, ensuring consistent performance and extending the hose’s service life in the hydraulic system.

- Flexibility and Bend Radius: Evaluate the hose’s flexibility and minimum bend radius for the application. Adequate flexibility allows installation in tight spaces, smooth movement during operation, and reduced stress on fittings and connectors.

- Durability and Abrasion Resistance: Consider the hose’s outer cover material for protection against wear, abrasion, and environmental factors. A durable cover enhances lifespan, reduces maintenance costs, and ensures continuous, safe operation in demanding conditions.

- Length and Fittings: Ensure the hose length suits the system layout and that compatible fittings are available. Correct length and proper connections minimize stress, leaks, and operational inefficiencies while optimizing system performance.

Proper Maintenance and Care for Textile Braided Hydraulic Hoses

To maximize the lifespan and performance of textile braided hydraulic hoses, proper maintenance and care are essential. Consider the following practices:

Regular inspections and checks

Periodically inspect the hoses for any signs of wear, damage, or leaks. Look for abrasions, bulges, cracks, or any visible deterioration. Replace damaged hoses promptly to prevent failures and minimize downtime.

Proper storage and handling

Store hydraulic hoses in a clean and dry environment away from direct sunlight and extreme temperatures. Avoid bending or crushing the hoses during storage and handling, as this can cause internal damage.

Prompt replacement of damaged hoses

If you identify any issues during inspections or while in use, replace the damaged hoses immediately. Operating with damaged hoses can lead to leaks, reduced performance, and potential safety hazards.

Avoiding excessive bending and twisting

Minimize excessive bending or twisting of the hoses during installation and operation. Excessive stress can weaken the hose structure and lead to premature failure. Follow the recommended bending radius to maintain hose integrity.

Conclusion

Textile braided hydraulic hoses offer numerous benefits that make them an excellent choice for various applications. Their high flexibility, resistance to abrasion cost-effectiveness, and compatibility with different fluids make them a versatile solution in industries such as automotive, agriculture, construction, and more.

By considering factors like pressure rating, temperature range, size, and maintenance practices, you can ensure the optimal performance and longevity of these hoses in your hydraulic systems.