Navigating the world of industrial hoses can be complex, especially when choosing between CPE and PTFE. Both offer unique benefits, but understanding their differences is crucial for optimal performance. This blog post aims to demystify the distinctions between CPE and PTFE hoses, providing clarity on their respective strengths.

We’ll delve into the material properties, temperature ranges, chemical resistance, and typical applications of each hose type. By exploring these key factors, you’ll gain the knowledge needed to make informed decisions and select the ideal hose for your specific needs.

What Is CPE Hose

A CPE hose is a type of synthetic rubber hose constructed from chlorinated polyethylene (CPE). This material is created by chlorinating polyethylene resin, which imparts enhanced properties like resistance to chemicals, oils, fuels, and extreme temperatures. This makes CPE hoses highly versatile and suitable for a wide range of applications where durability and resistance to harsh environments are crucial.

Essentially, CPE hoses bridge the gap between standard rubber hoses and more specialized, high-performance options like PTFE. Their ability to handle a broad spectrum of fluids and temperatures, coupled with their flexibility and durability, makes them a popular choice in various industries, including automotive, industrial, and marine. They are designed to provide reliable fluid and gas transfer in demanding conditions.

What Is PTFE Hose

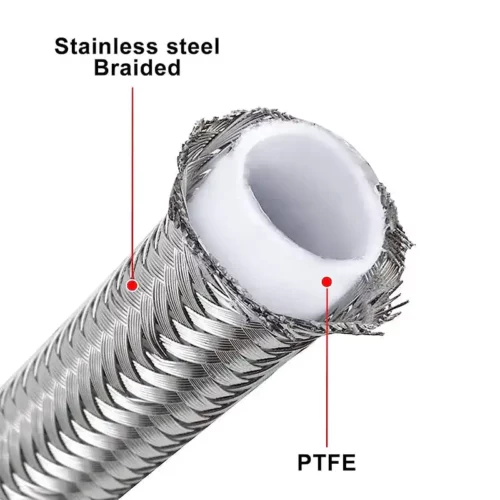

PTFE hose is a type of hose made from polytetrafluoroethylene, a synthetic fluoropolymer. This material is renowned for its exceptional chemical resistance, handling virtually any known chemical, and its wide temperature range, performing reliably in both extreme heat and cold. PTFE’s unique molecular structure also gives it a very low coefficient of friction, making it non-stick and ideal for high-purity applications.

Due to its superior properties, PTFE hose is often used in demanding environments where other materials would fail. It finds applications in aerospace, chemical processing, pharmaceuticals, and high-performance automotive systems. Its ability to withstand harsh conditions and maintain its integrity makes it a premium choice for critical fluid transfer applications.

CPE vs PTFE Hose

When choosing between CPE (chlorinated polyethylene) and PTFE (polytetrafluoroethylene) hoses, understanding their key differences is crucial. Both offer distinct advantages depending on the specific application and its requirements.

CPE hoses provide a balance of performance and affordability. They are known for:

- Good chemical resistance against oils, fuels, and many chemicals.

- Flexibility, making them easier to install in various configurations.

- Cost-effectiveness compared to PTFE hoses.

- Suitability for general-purpose applications in automotive, industrial, and marine settings.

PTFE hoses, on the other hand, excel in extreme conditions and offer:

- Exceptional chemical resistance, compatible with virtually any fluid.

- Wider temperature range, withstanding both very high and low temperatures.

- Non-stick properties, ideal for high-purity applications.

- Superior performance in demanding environments like aerospace, chemical processing, and high-performance automotive.

Ultimately, the choice depends on factors like the specific fluids being handled, temperature requirements, budget constraints, and the overall demands of the application.

Here’s a table showing the key differences between CPE hoses and PTFE hoses:

| Feature | CPE Hose | PTFE Hose |

| Chemical Resistance | Good | Excellent |

| Temperature Range | Moderate | Wide |

| Flexibility | High | Moderate |

| Cost | Lower | Higher |

| Applications | General Purpose | Demanding Environments |

Which is Better PTFE or Rubber Fuel Hose?

Determining whether PTFE or rubber fuel hose is “better” depends heavily on the specific application and priorities. Both materials have distinct advantages and disadvantages.

PTFE fuel hoses excel in demanding environments. Their key benefits include:

- Superior Chemical Resistance: PTFE is virtually impervious to all types of fuels, including modern ethanol-blended fuels, which can degrade rubber hoses.

- High Temperature Tolerance: PTFE can withstand a much wider range of temperatures than rubber, making it ideal for high-performance engines.

- Low Permeability: PTFE hoses prevent fuel vapors from escaping, reducing odors and potential safety hazards.

- Durability: PTFE hoses generally have a longer lifespan than rubber hoses.

However, rubber fuel hoses still have their place. They offer:

- Flexibility: Rubber hoses are significantly more flexible than PTFE, making them easier to install in tight spaces.

- Cost-Effectiveness: Rubber hoses are typically much less expensive than PTFE hoses.

- Adequate Performance: For many standard automotive applications, rubber hoses provide sufficient performance.

In essence, if you prioritize maximum durability, chemical resistance, and safety, PTFE is the superior choice. If cost and flexibility are primary concerns, rubber hoses may be adequate for less demanding applications.

How to Choose CPE Hose and PTFE Hose

Choosing between CPE and PTFE hoses involves a careful assessment of your application’s specific requirements. Begin by analyzing the fluids that will be conveyed. If you’re dealing with highly corrosive chemicals or fuels, PTFE’s exceptional chemical resistance makes it the clear choice. For less aggressive fluids like standard oils or coolants, CPE may be sufficient, offering a more cost-effective solution.

Next, consider the operating temperature range. PTFE excels in extreme temperatures, while CPE is suitable for moderate temperature applications. If your application involves high pressures or high temperatures, PTFE will provide superior performance and longevity. Evaluate the flexibility needed for installation; CPE offers greater flexibility, which can be crucial in tight spaces.

Finally, factor in your budget and the expected lifespan of the hose. While PTFE hoses are more expensive, their durability and resistance to degradation can result in long-term cost savings. If the application is less demanding and budget constraints are a primary concern, CPE hoses provide a reliable and economical option. Carefully weighing these factors will lead you to the most suitable hose for your specific needs.

Conclusion

CPE hoses offer a cost-effective solution for general fluid transfer, balancing flexibility and chemical resistance. PTFE hoses excel in extreme conditions, providing superior chemical and temperature resistance for demanding applications. Choosing between them depends on your application’s specific requirements, considering factors like temperature, chemical exposure, and budget.

Understanding these differences is crucial for selecting the optimal hose. Whether your needs lean toward CPE’s versatility or PTFE’s extreme resilience, we can assist.

For wholesale CPE and PTFE hoses tailored to your needs, contact Kingdaflex today. We offer a wide range of high-quality hoses at competitive prices.