Delivering cost-effective, high-performance hose solutions for mining, construction, and heavy industries worldwide. We combine advanced technology with strict international standards to tailor every hose to your exact specifications.

We specialize in a comprehensive range of custom hydraulic hoses to meet every application’s unique demands. From single-wire braided hoses (SAE 100R1AT) ideal for medium pressure to multi-spiral hoses (EN856 4SP/4SH) designed for extreme high-pressure systems, we ensure durability and performance.

We offer a wide range of customizable lengths, from short assemblies for tight spaces to extended hoses for large-scale operations. Additionally, we provide precise customization of both the inner diameter (ID) and outer diameter (OD), ensuring the correct fluid flow rate and pressure handling for your specific machinery and system design.

The inner tube and outer cover materials can be selected to resist specific temperature extremes, both hot and cold. We ensure compatibility with various fluids, including petroleum-based oils, synthetic lubricants, water-based fluids, and chemicals, preventing material degradation and leaks.

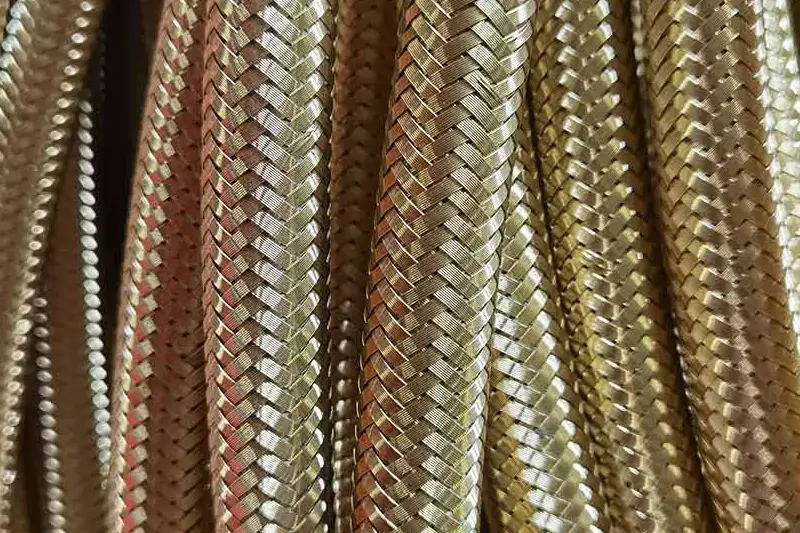

The reinforcement is critical for a hose’s strength. We offer single-wire braid (1SN/1SC), double-wire braid (2SN/2SC), or multiple-wire spiral (4SP/4SH) configurations. This allows us to tailor the hose’s pressure capacity, flexibility, and resistance to impulse cycles according to your application’s specific demands.

The hydraulic hose’s outer cover is its primary defense against environmental damage. We can customize the cover to be highly resistant to abrasion, ozone, UV rays, or extreme weather. Options include smooth or wrapped finishes and a variety of materials designed for industrial, mining, or marine applications.

We offer a vast selection of crimped and reusable fittings, including but not limited to JIC, BSP, NPT, ORFS, and metric types. The material and design of these fittings are customized to ensure a perfect, leak-proof connection to your equipment, preventing costly downtime and maintenance.

We provide a comprehensive private labeling service, allowing your brand name, logo, part number, and technical specifications to be permanently printed on the hose layline. This simplifies inventory management, ensures product traceability, and reinforces your brand identity in the market.

For assemblies with angled fittings, we can ensure the precise orientation of the fittings to one another. This is crucial for proper installation and prevents the hose from kinking or twisting, which can lead to premature failure and reduce the efficiency of the hydraulic system.

To enhance durability in harsh environments, we can add a protective sleeve or guard. Options include spring guards, nylon fabric sleeves, or polyurethane wraps. This customization protects the hose from external abrasion, impacts, and heat, significantly extending its service life.

Don't just take our word for it. Our hoses meet or exceed strict SAE 100R and DIN EN standards. Every batch undergoes rigorous impulse testing to ensure they can withstand high-pressure surges without failure.

We go beyond standard lengths. We offer private labeling to build your brand, varied hose orientation options , and protective sleeving for harsh environments. From flexible 1-wire braids to heavy-duty multi-spiral assemblies, we build exactly what your application demands.

Our facility utilizes precise braiding and spiral winding machinery combined with controlled vulcanization to ensure uniform rubber density and superior adhesion between the inner tube and reinforcement layers.

We combine the cost advantages of Chinese manufacturing with a professional logistics team to offer competitive pricing without compromising on the speed of delivery.

We use strictly controlled synthetic rubber. Our automatic monitoring system ensures precise wall thickness and concentricity, preventing weak points that could lead to early leaks.

Braided or spiraled layers of high-tensile steel wire. For our high-pressure series, we ensure even tensioning of the wires to handle extreme surges (up to 4000+ PSI), balancing flexibility with burst resistance.

The outer cover protects against abrasion and UV. We offer both Smooth (easy to clean) and Wrapped (heavy-duty protection) finishes to suit your specific installation environment.

The hose undergoes a precise curing process. We monitor temperature curves strictly to ensure optimal adhesion between the rubber and steel wire, preventing delamination (layer separation) during use.

Each batch undergoes proof pressure testing (at 2x working pressure) and random impulse testing cycles to verify fatigue resistance, meeting SAE/DIN standards before it leaves our factory.

The hydraulic hose manufacturing process involves a series of precise steps to create a durable, multi-layered product. It starts with forming the inner tube, followed by the careful application of reinforcement layers and the protective outer cover. Each stage is critical to ensuring the hose can withstand high pressure and harsh environmental conditions.

Downtime costs money. We supply abrasion-resistant hydraulic hoses with MSHA-approved covers specifically for excavators and bulldozers.

From boom cylinders to track tensioners, our hoses meet SAE 100R12/R13 standards, ensuring they handle the constant flexing and external abuse on rugged job sites.

For extreme drilling rigs and rock crushers, standard hoses fail. We engineer heavy-duty multi-spiral hoses (4-wire and 6-wire) designed to withstand pressure surges up to 6000 PSI. Our assemblies offer superior impulse resistance, guaranteeing safety in deep-pit and underground mining operations.

Safety is non-negotiable. Our hoses for onshore and offshore rigs are formulated with specialized compounds to resist heat, oil, and ozone.

We also provide additional fire-resistant sleeving and stainless steel fittings to prevent corrosion in saline environments.

From tractors to irrigation systems, our hoses resist generic agricultural chemicals and intense UV exposure.

We focus on high flexibility for tight routing in compact machinery, offering cost-effective braided hydraulic hoses that keep your harvest season running smoothly.

Reinforcement determines a hose’s working pressure and flexibility. At Kingdaflex, we engineer the reinforcement layer to balance burst pressure safety factors with the bend radius required for your installation.

Application: Medium-pressure hydraulic lines, return lines, and compact machinery.

Construction: Manufactured with 1 or 2 layers of high-tensile steel wire braid (1SN/2SN).

Why Choose This: Braided hoses offer superior flexibility and a tighter bend radius, making them easier to route through narrow spaces in agricultural and general industrial equipment.

Standards: Meets SAE 100R1AT, R2AT, and R17 standards.

Application: Heavy-duty excavators, mining drills, and hydrostatic drives.

Construction: Reinforced with 4 or 6 alternating layers of spirally-wound high-tensile steel wire (4SP/4SH/R13/R15).

Why Choose This: Engineered to withstand extreme pressure surges and high-impulse cycles (up to 1,000,000+ cycles). The spiral design eliminates the “scissoring” effect of braids, preventing fatigue failure under peak loads.

Performance: Rated for pressures up to 6000+ PSI.

At Kingdaflex, a custom hydraulic hose is more than just a rubber tube. It is a tailored assembly engineered to your specific length, pressure (up to 6000+ PSI), and fitting requirements. We manufacture everything from standard 1-wire braided hoses to heavy-duty 6-wire spiral hoses specifically to fit your machinery perfectly.

Standard hoses often fail due to improper length or incompatible pressure ratings. Customizing your hose with Kingdaflex ensures precise routing (preventing abrasion) and exact fluid compatibility. This directly reduces downtime and extends the lifespan of your heavy equipment in mining and construction environments.

We recommend the industry-standard S.T.A.M.P.E.D. method: Size, Temperature, Application, Media, Pressure, Ends, and Delivery. Simply send us these details (or your technical drawing), and our engineers will identify the perfect reinforcement layers and outer cover protection for your specific needs.

Absolutely. We specialize in high-pressure solutions. For extreme applications, we utilize multi-spiral steel wire reinforcement (4-wire or 6-wire) to handle intense pressure surges and impulses. Our hoses are rigorously tested to meet or exceed SAE and DIN standards, ensuring safety even under peak loads.

Each hydraulic hose is manufactured under controlled processes and tested according to applicable standards. Typical tests include dimensional inspection, pressure testing, leakage checks, and visual inspection to ensure consistent performance and safety before delivery.

Yes. We stand behind Kingdaflex quality. Every custom hose undergoes strict quality control, including dimension checks and impulse testing before shipping. If there is any defect in materials or workmanship, we provide a clear warranty policy to ensure your investment is protected.