Fire rated sleeves are essential protective coverings designed to shield hoses, cables, and wiring from extreme heat, flames, and molten splashes. They are widely used across industrial, automotive, and aerospace applications, ensuring safety, preventing damage, and maintaining operational efficiency in environments where fire hazards are present.

Choosing the right fire rated sleeve involves understanding material types, temperature ratings, and installation methods. Different sleeves offer varying levels of heat resistance, flexibility, and durability. By selecting the correct sleeve, you can protect critical components, reduce maintenance costs, and ensure long-lasting performance in high-temperature and fire-prone environments.

What Are Fire Rated Sleeves?

Fire rated sleeves are fire-resistant enclosures that surround penetrations, such as cables, pipes, or ducts, passing through fire-rated walls or floors. These sleeves are constructed using fire-resistant materials and are designed to maintain the integrity of fire barriers, preventing the spread of flames, heat, and smoke.

Importance of Fire-Rated Sleeves

Fire-rated sleeves play a critical role in protecting hoses, cables, and wiring from extreme heat, flames, and molten splashes. They prevent component damage, reduce downtime, and enhance overall safety in industrial, automotive, and aerospace environments where fire hazards are a concern.

- Protects Critical Components: Fire rated sleeves shield hoses, fuel lines, and electrical cables from high temperatures, preventing melting, charring, or failure. This protection ensures uninterrupted operation, reduces costly repairs, and extends the lifespan of components exposed to heat or fire.

- Enhances Workplace Safety: By preventing fires from spreading along unprotected hoses and cables, these sleeves help safeguard personnel and equipment. They reduce the risk of accidents, injuries, and equipment damage, making workplaces safer and compliant with fire safety regulations.

- Improves Reliability and Efficiency: Heat-resistant sleeves minimize unexpected system failures caused by thermal exposure. Reliable protection ensures that machines and electrical systems continue running smoothly, maintaining operational efficiency and reducing downtime in critical industrial and automotive applications.

- Versatile Applications: Fire rated sleeves are suitable for diverse environments, including manufacturing plants, automotive engines, aerospace systems, and welding or metalworking areas. Their flexibility and high-temperature resistance make them essential for protecting sensitive hoses, wires, and cables in multiple settings.

- Cost-Effective Solution: Investing in fire rated sleeves reduces maintenance costs, prevents equipment replacement, and avoids financial losses due to fire-related damage. Their durability and protective properties make them a long-term, economical choice for high-risk environments.

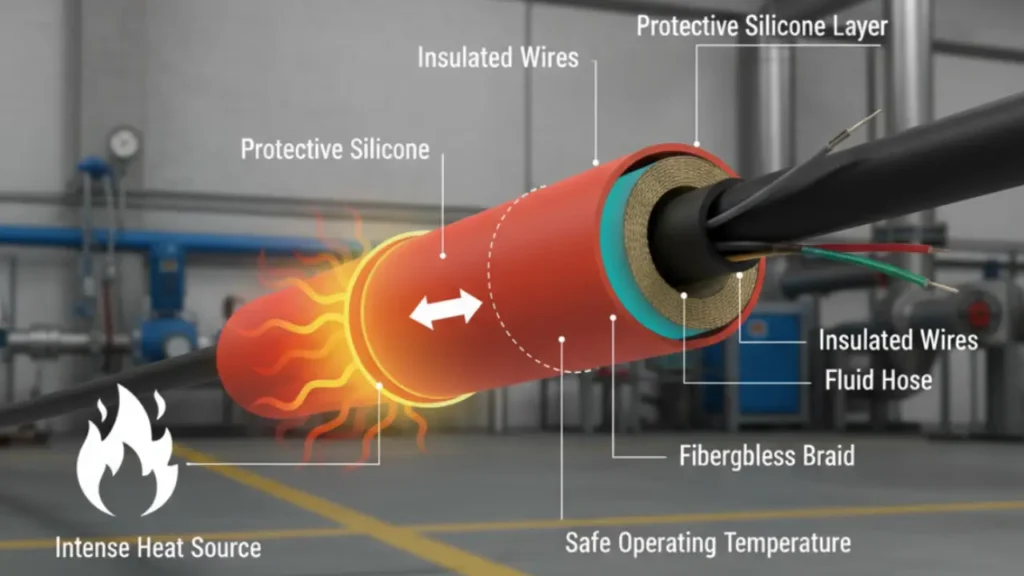

How Fire Rated Sleeves Work

Fire rated sleeves protect hoses, cables, and wiring by providing a thermal barrier against extreme heat, flames, and molten splashes. They are made from heat-resistant materials such as fiberglass or silicone-coated fabrics, which prevent fire damage and maintain the integrity of critical components.

- Heat Insulation: The sleeve’s material resists high temperatures, preventing the underlying hose or cable from melting or warping. This insulation maintains operational functionality even in prolonged exposure to heat, ensuring safety and uninterrupted performance in industrial, automotive, and aerospace applications.

- Flame Resistance: Fire rated sleeves are engineered to withstand direct contact with flames. They prevent fire from spreading along hoses or wiring, protecting adjacent components and reducing the risk of catastrophic damage in high-temperature or hazardous environments.

- Molten Splash Protection: In applications like welding or metalworking, molten metal can damage hoses and cables. Fire rated sleeves act as a shield, absorbing and deflecting molten splashes to prevent burns, shorts, or component failure.

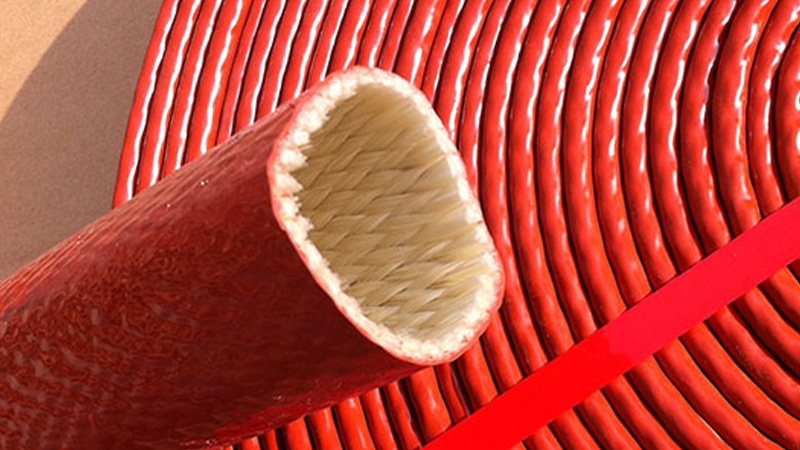

- Durable Construction: These sleeves combine abrasion resistance and flexibility with heat protection. Their woven fiberglass or reinforced coatings allow them to bend around curves and fit tight spaces, providing reliable coverage without compromising hose or cable routing.

- Extended Component Life: By reducing thermal and fire damage, fire rated sleeves help extend the lifespan of hoses, cables, and wiring. This results in fewer replacements, lower maintenance costs, and increased operational efficiency in high-risk environments.

Common Applications of Fire Rated Sleeves

Fire rated sleeves are essential for protecting hoses, cables, and wiring from heat, flames, and molten metal. Their durability and thermal resistance make them vital in industrial, automotive, aerospace, and manufacturing environments.

- Hydraulic Hoses: Protects hydraulic hoses in industrial machinery and vehicles from high temperatures and fire exposure, preventing leaks, system failure, and costly downtime while maintaining reliable hydraulic performance under extreme conditions.

- Fuel Lines: Shields fuel hoses from melting or fire hazards in engines, ensuring safe fuel delivery, preventing fire risks, and maintaining proper engine function even in high-heat environments.

- Electrical Wiring: Safeguards wiring and electrical cables in industrial and automotive systems from heat and flames, preventing short circuits, fire hazards, and operational interruptions while maintaining safety.

- Aerospace Applications: Used in aircraft to protect critical wiring, hydraulic lines, and control systems from extreme engine and environmental temperatures, ensuring operational reliability and passenger safety.

- Automotive Engine Compartments: Shields hoses, fuel lines, and electrical cables in engine compartments from high temperatures, reducing the risk of melting, fires, and damage while improving vehicle safety and performance.

- Welding Environments: Protects hoses, cables, and wiring near welding equipment from sparks, heat, and molten splashes, reducing fire risk, component damage, and ensuring a safe workplace.

- Metalworking Equipment: Provides thermal protection for hoses and cables in forges, furnaces, and metalworking machines, preventing damage from hot metal and maintaining consistent operation.

- Industrial Manufacturing: Guards machinery hoses and cables in factories exposed to high-temperature processes, ensuring operational efficiency, reducing maintenance costs, and enhancing workplace safety.

- Marine Applications: Protects hydraulic systems, fuel lines, and wiring on ships from engine heat, fire hazards, and harsh marine conditions, maintaining reliable performance in challenging environments.

- Oil & Gas Equipment: Shields hoses, cables, and pipelines in refineries, drilling rigs, and processing plants from high temperatures, flames, and fire risks, ensuring safety and uninterrupted operation.

- Railways: Protects hydraulic lines, wiring, and control systems in locomotives and railcars from heat, friction, and fire exposure, improving reliability and passenger safety.

- Power Plants: Safeguards critical cables and hoses in thermal and nuclear power plants from extreme heat, ensuring consistent operation and preventing fire hazards in high-risk areas.

- Construction Machinery: Shields hydraulic hoses, fuel lines, and electrical wiring on excavators, cranes, and heavy machinery from heat, fire, and abrasion, ensuring operational efficiency and reducing maintenance needs.

- Automated Systems: Protects robotic arms, conveyor systems, and automated machinery from heat exposure, sparks, and molten metal, preventing equipment damage and maintaining safe factory operations.

- Emergency Vehicles: Keeps hydraulic systems, hoses, and electrical wiring safe in fire trucks and rescue vehicles, preventing heat-related damage and ensuring reliable performance during emergency operations.

Types of Fire-Rated Sleeves

Fire rated sleeves come in different types, each designed to meet specific requirements and fire safety standards. The two common types of fire rated sleeves are:

Metallic Fire Rated Sleeves

Metallic fire rated sleeves are typically constructed using stainless steel or galvanized steel. They provide excellent fire resistance and are known for their durability and strength. Metallic sleeves are often used in high-impact areas or where mechanical protection is required.

Fire Sleeve for Hydraulic Hose

Fire sleeves for hydraulic hoses are protective coverings designed to withstand high temperatures and provide an additional layer of safety.

They are typically made from flame-resistant materials, such as silicone, fiberglass, or aramid fibers, which offer excellent resistance to heat and flames. By covering hydraulic hoses with fire sleeves, the risk of fire incidents caused by heat exposure is significantly reduced.

Fire Rated Conduit Sleeve

Fire rated conduit sleeves are specialized components designed to protect electrical conduits by preventing the spread of fire, heat, and smoke through them. They are typically made of fire-resistant materials that can withstand high temperatures and maintain their structural integrity during a fire.

By incorporating fire rated conduit sleeves into electrical systems, the risk of fire propagation through conduits is significantly reduced.

Fire Rated Sleeves for Cables

Fire rated sleeves for cables are specialized components designed to prevent the spread of fire and smoke through cable penetrations in walls, floors, or ceilings.

They are constructed from fire-resistant materials, such as intumescent compounds or mineral fibers, which expand when exposed to high temperatures, creating a barrier that restricts the passage of flames and smoke.

Aeroquip Fire Sleeve

The Aeroquip Fire Sleeve is constructed using a combination of high-temperature resistant materials, such as silicone-coated fiberglass, to provide exceptional heat resistance and thermal hydraulic hose insulation.

This silicone-coated fire sleeve acts as a barrier between the hydraulic hose and external heat sources, preventing direct contact and shielding the hose from potential sparks or flames.

The key benefits of using the Aeroquip Fire Sleeve include:

- Heat resistance: The Aeroquip Fire Sleeve is designed to withstand high temperatures, protecting hydraulic hoses from heat-related damage and maintaining their integrity even in extreme operating conditions.

- Flame protection: The sleeve’s construction materials offer excellent resistance to flames, reducing the risk of fire incidents caused by heat exposure.

- Abrasion resistance: In addition to heat protection, the Aeroquip Fire Sleeve provides a layer of defense against abrasion, shielding hydraulic hoses from wear and tear caused by contact with rough surfaces or other components.

- Easy installation: The Aeroquip Fire Sleeve is designed for easy installation. It can be slipped over the hydraulic hose and secured in place using clamps or ties, ensuring a secure fit and optimal protection.

- Compatibility: The Aeroquip Fire Sleeve is available in various sizes to accommodate different types and sizes of hydraulic hoses, making it highly versatile and compatible with a range of applications.

When selecting the Aeroquip Fire Sleeve, it is essential to consider the temperature rating and size compatibility to ensure optimal protection for the hydraulic system. The sleeve should be chosen based on the maximum operating temperature of the hydraulic system and the diameter of the hose it will be used with.

Proper installation of the Aeroquip Fire Sleeve is crucial to ensure its effectiveness. It should be securely fastened and positioned to cover the entire length of the hydraulic hose, leaving no exposed areas vulnerable to heat or flames.

Choosing the Right Fire Rated Sleeves

Selecting the appropriate fire rated pipe sleeves for a specific application is crucial to ensure optimal fire protection. Consider the following factors when choosing fire rated sleeves:

- Fire rating requirements: Determine the required fire rating for the specific location or building.

- Penetration size: Consider the size and type of penetrations that need to be sealed.

- Compatibility: Ensure compatibility with the surrounding materials and firestop systems.

- Environmental conditions: Consider factors such as moisture, temperature, and chemical exposure.

Installation Process of Fire Rated Sleeves

Proper installation is essential to ensure the effectiveness offire-rated sleeves piping. The installation process typically involves the following steps:

Preparing the Opening

Prepare the opening by cleaning and removing any obstructions. Ensure the penetration is properly sized and aligned with the manufacturer’s specifications.

Inserting the Fire Rated Sleeve

Carefully insert the fire rated sleeve into the opening, ensuring a tight fit. Follow the manufacturer’s instructions for any specific installation requirements.

Securing and Sealing the Sleeve

Secure the fire rated sleeve in place using appropriate fixing methods. Seal any gaps between the sleeve and the surrounding wall or floor using fire-resistant sealants or intumescent materials.

Maintenance and Inspection of Fire Rated Sleeves

Regular maintenance and inspection of fire-rated sleeves piping are essential to ensure their continued effectiveness. Here are some key considerations:

- Inspect for any signs of damage, wear, or corrosion.

- Verify that penetrations remain sealed and intact.

- Ensure that firestop materials are in good condition.

- Conduct regular testing to confirm the fire resistance of the sleeves.

Compliance with Fire Safety Regulations

Fire rated sleeves play a crucial role in complying with fire safety regulations and building codes. It is important to consult local fire safety authorities and adhere to relevant standards and guidelines to ensure proper installation and compliance.

Benefits of Using Fire Rated Sleeves

Using fire rated sleeves in your building or structure offers several advantages, including:

- Enhanced fire safety: Fire rated sleeves help prevent the spread of fire, smoke, and toxic gases, providing additional time for evacuation and reducing the risk of injuries or fatalities.

- Code compliance: Installing fire-rated sleeves piping ensures compliance with fire safety regulations and standards, avoiding potential penalties or legal issues.

- Property protection: Fire rated sleeves help protect the structural integrity of buildings, minimizing damage caused by fire.

- Peace of mind: Knowing that effective fire protection measures are in place provides peace of mind for building occupants, owners, and managers.

Considerations When Using Fire Rated Sleeves

While fire rated sleeves offer significant fire protection benefits, it is important to consider the following:

- Compatibility with other fire protection systems: Ensure that fire rated sleeves are compatible with other fire protection systems in place, such as fire doors, fire alarms, and sprinkler systems, to ensure a comprehensive fire safety strategy.

- Regular inspections and maintenance: Schedule regular inspections and maintenance to ensure that fire rated sleeves remain in good condition and are functioning as intended. This includes checking for any signs of damage, wear, or degradation.

- Upgrading existing installations: If your building has older fire protection systems in place, consider upgrading to newer and more advanced fire rated sleeves that meet the latest fire safety standards and regulations.

- Professional installation: It is recommended to have fire rated sleeves installed by trained professionals who have expertise in fire safety systems. This ensures proper installation and maximizes the effectiveness of the sleeves.

Conclusion

Fire rated sleeves are crucial components in fire safety systems, providing effective protection against the spread of fire and smoke through penetrations in walls and floors. By sealing these openings, fire rated sleeves help prevent the loss of lives and property during a fire incident. It is essential to choose the right type of fire rated sleeves, ensure proper installation, and conduct regular inspections to maintain their effectiveness over time.

By investing in fire rated sleeves and implementing comprehensive fire protection measures, building owners and occupants can have peace of mind knowing that they have taken important steps to enhance fire safety.

Conclusion

Fire rated sleeves are a vital safety solution for protecting hoses, cables, and wiring in heat-prone environments. Their ability to withstand flames and extreme temperatures makes them indispensable in industrial, automotive, and aerospace applications. Investing in the right sleeve ensures safety, reliability, and prolonged component life.

Proper selection, installation, and maintenance of fire rated sleeves maximize their effectiveness. By considering material, size, and temperature resistance, you can ensure optimal protection for your critical systems. Routine inspection and replacement further enhance safety and prevent potential hazards caused by wear or damage.

For reliable, cost-effective fire rated sleeves, get wholesale solutions from Kingdaflex. We offer a wide range of sizes and materials to meet diverse industrial needs. Our sleeves provide dependable thermal protection, helping your operations stay safe and efficient while minimizing downtime and component failures.