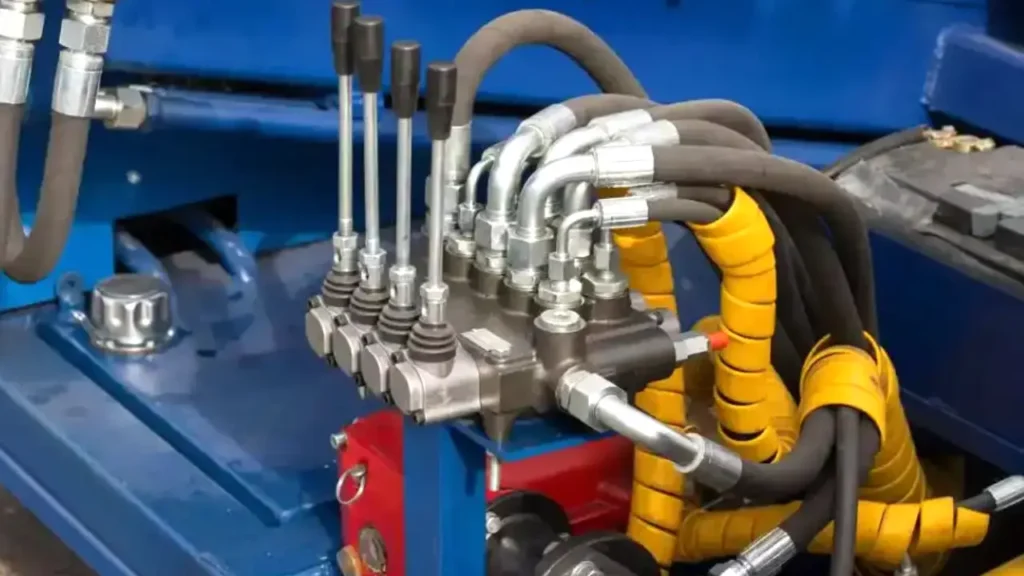

Understanding the difference between hydraulic hose burst pressure and working pressure is critical for safe and efficient system operation. Burst pressure indicates the maximum pressure a hose can withstand before failure, while working pressure represents the recommended operating limit, ensuring reliability and preventing accidents in hydraulic applications.

Selecting hoses with appropriate working and burst pressures is essential for durability and performance. Using hoses beyond their limits can lead to leaks, ruptures, and costly downtime. This blog explains the distinctions, factors affecting hose pressures, and tips for proper selection to maintain safety and efficiency in hydraulic systems.

What is Hydraulic Hose Burst Pressure?

Hydraulic hose burst pressure is the maximum internal pressure a hose can withstand before it ruptures or fails. It is a critical safety specification used to ensure hydraulic systems operate reliably without risking damage, leaks, or accidents under extreme conditions.

- Maximum Pressure Limit: Burst pressure represents the absolute upper limit of internal pressure a hose can endure. Exceeding this limit can cause sudden hose failure, posing safety risks and potential damage to surrounding equipment.

- Safety Factor Consideration: Manufacturers typically design hoses with a safety factor, meaning burst pressure is several times higher than the hose’s rated working pressure to ensure safe operation.

- Material and Construction Impact: The type of rubber, reinforcement layers, and braiding used in a hose directly influence its burst pressure, determining how much stress it can handle.

- Testing Standards: Burst pressure is determined through standardized testing procedures, ensuring hoses meet regulatory and industry requirements before being deployed in hydraulic systems.

- Application Relevance: Understanding burst pressure helps operators prevent over-pressurization, select suitable hoses, and maintain system safety, especially in high-pressure industrial or automotive hydraulic applications.

What is Hydraulic Hose Working Pressure?

Hydraulic hose working pressure is the maximum continuous pressure a hose can safely handle during regular operation. Staying within this limit ensures system efficiency, prevents hose failure, and maintains safety in industrial, automotive, and heavy-duty hydraulic applications. Understanding working pressure is key to proper hose selection.

- Working pressure, also called rated pressure, indicates the safe operational limit for a hydraulic hose, ensuring reliable fluid transfer without risking rupture or leaks during standard usage conditions.

- Importance: Adhering to working pressure prevents hose bursts, system downtime, and safety hazards. It protects both equipment and personnel while maintaining consistent performance across all hydraulic applications.

- Factors Affecting Working Pressure: Hose material, reinforcement layers, temperature, and fluid type influence working pressure. Correctly matching these parameters ensures optimal hose performance under continuous stress.

- Applications: Hydraulic hoses with rated working pressure are used in machinery, automotive systems, construction equipment, and industrial fluid transfer, providing safety and durability under high-pressure conditions.

- Maintenance Considerations: Regular inspection, avoiding over-pressurization, and storing hoses correctly help preserve their working pressure rating, extending lifespan and ensuring reliable operation.

Hydraulic Hose Burst Pressure vs Working Pressure

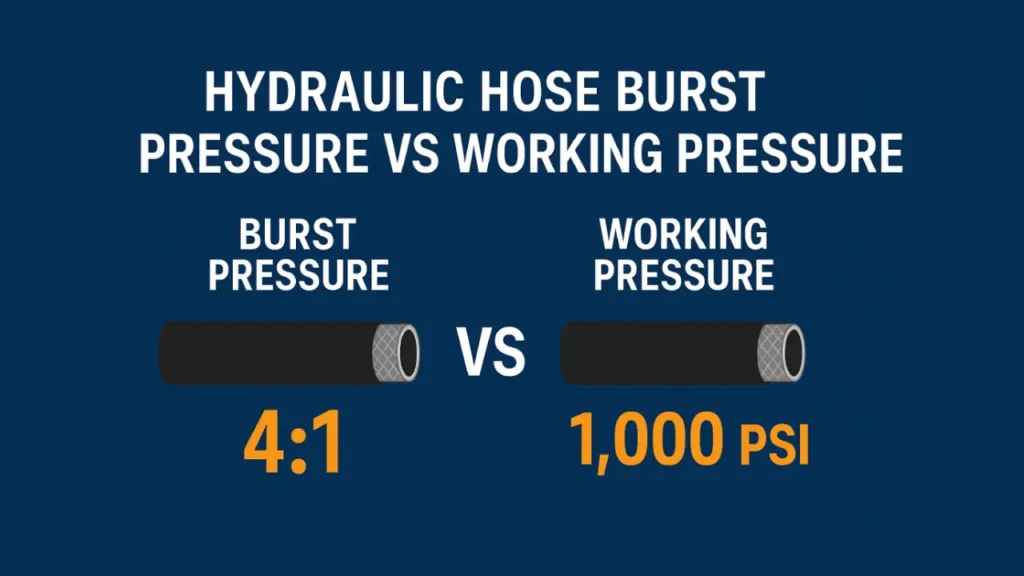

Hydraulic hoses are designed with both working pressure and burst pressure ratings to ensure safety and performance.

A 4:1 safety factor is commonly applied, meaning the hose’s burst pressure is four times its rated working pressure, providing a margin to prevent failures.

Definition and Purpose

Working pressure is the maximum pressure a hose can safely handle during normal operation, ensuring reliable performance. It defines the recommended limit to prevent damage, leaks, or system failure.

Burst pressure is the maximum pressure a hose can withstand before rupture occurs. It provides a safety margin, allowing hoses to handle unexpected pressure spikes without catastrophic failure, which is critical in hydraulic systems.

Safety Factor 4:1

The 4:1 safety factor means the burst pressure is four times the working pressure. For example, a hose rated at 1,000 PSI working pressure will have a burst pressure of 4,000 PSI, ensuring safety during sudden surges.

This ratio protects equipment and personnel from accidents caused by pressure spikes. It allows hydraulic systems to operate efficiently without constantly approaching dangerous pressure limits, balancing performance with safety.

Construction and Materials

Hydraulic hoses are made of reinforced rubber or thermoplastic materials with layers of textile or steel wire. This construction ensures they can withstand high pressures while maintaining flexibility for safe operation.

Reinforcement layers are critical for achieving the 4:1 safety factor. Properly engineered materials and construction techniques allow hoses to resist bursting under pressure, while still performing reliably under normal working conditions.

Applications and Importance

Hoses with a 4:1 safety factor are essential in industrial, automotive, and heavy machinery applications. They ensure that hydraulic systems can handle high-pressure operations safely without the risk of failure.

Properly rated hoses protect equipment, reduce downtime, and prevent accidents. Understanding the difference between burst and working pressure helps operators select hoses suitable for specific system requirements.

Maintenance and Compliance

Regular inspection, proper installation, and adherence to pressure ratings maintain hose safety. Over-pressurization or wear can reduce the effective burst pressure, compromising the 4:1 safety factor.

Compliance with manufacturer specifications and industry standards ensures hoses perform as intended. Proper maintenance preserves both working and burst pressure ratings, extending hose life and safeguarding hydraulic operations.

| Aspect | Working Pressure | Burst Pressure |

|---|---|---|

| Definition | Maximum safe operating pressure for normal use | Maximum pressure hose can withstand before failure |

| Purpose | Ensures safe, reliable system operation | Provides safety margin against pressure spikes |

| Safety Factor | Basis for 4:1 safety ratio calculation | Typically four times the working pressure |

| Construction | Reinforced rubber or thermoplastic for normal loads | Stronger reinforcement to resist rupture under extreme conditions |

| Applications | Daily hydraulic operations in machinery, automotive, and industrial systems | Emergency pressure situations or unexpected surges |

Conclusion

Knowing the difference between burst pressure and working pressure helps operators choose the right hydraulic hoses for their systems. Proper selection ensures hoses can handle expected loads safely while minimizing the risk of failure, damage, or downtime in industrial and automotive applications.

Regular inspection and adherence to pressure ratings extend hose life, maintain efficiency, and protect personnel from hydraulic accidents. Understanding these parameters also aids in selecting compatible fittings, connectors, and components for seamless system operation and long-term reliability.

For hydraulic hoses that meet both working and burst pressure requirements, get wholesale hydraulic hoses from Kingdaflex. We supply durable, reliable hoses designed for industrial, automotive, and heavy-duty hydraulic applications worldwide.