Hydraulic systems are the backbone of countless industries, powering everything from heavy machinery on construction sites to intricate medical equipment. At the heart of these systems lies a critical component: the hydraulic suction hose.

This guide will delve into the intricacies of hydraulic suction hoses, exploring their crucial role, construction, selection criteria, and best practices for maintenance and replacement.

We’ll cover key aspects like hose materials, reinforcement, and compatibility with various hydraulic fluids. Whether you’re a seasoned hydraulics expert or simply curious about this vital component, this comprehensive guide will equip you with the knowledge you need to make informed decisions and ensure optimal performance of your hydraulic systems.

What Is Hydraulic Suction Hose

A hydraulic suction hose is a specialized type of hose used to transport hydraulic fluid from a reservoir to a hydraulic pump.

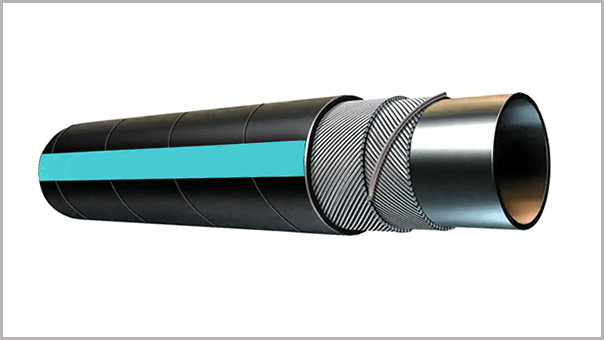

Compared with other hydraulic hoses, SAE 100R4 hydraulic suction hose is designed differently, with the stainless steel wire is embedded in the reinforced layer.

This is the structure of the hydraulic suction hose.

Tube: Oil-resistant synthetic rubber (same with other hydraulic hoses)

Reinforcement: High tensile cords and helix steel wire (the helix steel wire is specially designed for hydraulic suction & discharge hose)

Cover: Oil and weather-resistant synthetic rubber (same with other hydraulic hoses)

Hydraulic suction hoses are not susceptible to cavitation. False

Cavitation is a significant concern for hydraulic suction hoses. When the fluid pressure within the hose drops below the vapor pressure of the fluid, it can cause the formation of vapor bubbles. These bubbles can collapse violently, generating shock waves that can damage the hose lining and reduce its lifespan.

Hydraulic suction hoses are designed to withstand the effects of suction. True

Suction hoses experience significant internal pressure changes due to the vacuum created by the pump. They must be able to withstand this negative pressure without collapsing or imploding. Special construction techniques, such as thicker walls and reinforced layers, are used to ensure suction hoses maintain their shape and integrity under suction conditions.

Helical Hydraulic Hose

The helical hydraulic hose is also one type of hydraulic hose in the hose industry. The suction hose is coiled with a layer of stainless steel wire, so it is also the helical hose (helically coiled with the stainless steel wire). So that you can find the helically coiled reinforcement in the suction hydraulic hose. And the use of helical reinforcement can prevent collapse under vacuum working conditions.

What Is Hydraulic Suction Hose Used for

Hydraulic suction hoses are specifically designed to transport fluids from a reservoir or source to a hydraulic pump.

Here are their key uses:

Conveying Fluids:

- They transfer hydraulic fluids (like oils) from reservoirs to the inlet ports of hydraulic pumps.

- They can also be used to transport other liquids, depending on the hose’s material compatibility.

Withstanding Vacuum:

- The primary function is to withstand the negative pressure (vacuum) created by the suction action of the hydraulic pump.

- They must maintain their shape and prevent collapse under these conditions.

- Found in various hydraulic systems across industries:

- Construction equipment (excavators, loaders)

- Agricultural machinery

- Industrial machinery

- Mobile equipment

Key Features:

- Reinforced Construction: Often have multiple layers of reinforcement (wire, fabric) to maintain shape and prevent collapse under vacuum.

- Specific Materials: Constructed from materials resistant to hydraulic fluids, abrasion, and the effects of suction.

In essence, hydraulic suction hoses play a crucial role in ensuring the proper functioning of hydraulic systems by reliably conveying fluids from the reservoir to the pump.

SAE 100R4 Hydraulic Suction Hose

SAE 100R4 is the hydraulic suction hose, it is designed to be a textile reinforced hydraulic hose. You can see that the reinforcement of the hydraulic suction hose consists of spiral steel wire.

The inner tube of this suction hose hydraulic hose is manufactured with Nitrile rubber material, which has excellent oil resistance so that you can apply this suction hydraulic hose to convey all oil-based, petroleum-based hydraulic fluids. And the inner tube can’t be corroded due to the Nitrile rubber performance.

The hydraulic suction hose should work under high pressure, so that the reinforced layer is designed with the spiral steel wire, to add much strength making it durable and stable during its service life.

SAE 100R4 Hydraulic Suction Hose

Hydraulic Suction Hose Sizing

|

DN | Size | SAE | Inside

Ø mm | Outside

Ø mm | Working

Pressure | Burst

Pressure | Bend Radius | Weight |

Length | ||||

|

mm | Inch | Dash | Min | Max | Max | Bar | Psi | Bar | Psi | mm | Kg/m |

m | |

|

19 | 19 | 3/4 | -12 | 18.2 | 19.8 | 34.9 | 21 | 305 | 84 | 1210 | 125 | 0.92 | 40 |

| 25 | 25 | 1 | -16 | 24.6 | 26.2 | 41.3 | 17 | 250 | 70 | 1015 | 150 | 1.10 | 40 |

| 32 | 32 | 1 1/4 | -20 | 30.6 | 33.0 | 50.8 | 14 | 200 | 56 | 810 | 200 | 1.30 | 40 |

| 38 | 38 | 1 1/2 | -24 | 36.9 | 39.3 | 57.2 | 10.5 | 150 | 42 | 610 | 255 | 1.80 | 40 |

| 51 | 51 | 2 | -32 | 49.2 | 52.4 | 69.9 | 7 | 100 | 28 | 410 | 300 | 2.23 | 40 |

| 63 | 63 | 2 1/2 | -40 | 61.9 | 65.1 | 82.6 | 4 | 60 | 17 | 250 | 355 | 3.23 | 40 |

| 76 | 76 | 3 | -48 | 74.6 | 77.8 | 95.3 | 4 | 60 | 16 | 230 | 460 | 4.25 | 40 |

| 89 | 89 | 3 1/2 | -56 | 87.3 | 90.5 | 107.9 | 3 | 40 | 12.5 | 180 | 530 | 5.05 | 40 |

| 102 | 102 | 4 | -64 | 100.0 | 103.2 | 120.7 | 2.5 | 40 | 10 | 145 | 610 | 5.60 |

40 |

If want to know more about the hydraulic suction hose sizing and related specifications, please ask us now.

Hydraulic Hose Catalogue from Kingdaflex you can view our hydraulic hose catalog for some detailed info about the hydraulic suction hose.

Properly sizing a hydraulic suction hose is crucial for optimal system performance and longevity.

Here are the key factors to consider:

1. Flow Rate:

- Determine the required flow rate (GPM – Gallons Per Minute) of the hydraulic system. This information is usually found in the pump’s specifications.

- Flow rate directly influences the necessary hose diameter. Higher flow rates generally require larger diameter hoses to prevent excessive fluid velocity.

2. Fluid Velocity:

Maintain an appropriate fluid velocity within the hose.

- Too high a velocity: Can cause cavitation (formation of vapor bubbles within the fluid), leading to noise, vibration, and reduced pump efficiency.

- Too low a velocity: Can increase the risk of air entrainment (incorporation of air into the fluid stream), reducing system performance and potentially damaging the pump.

- Recommended fluid velocities for suction lines typically range from 2 to 6 feet per second.

3. Hose Length:

- Longer hoses increase the potential for pressure drop due to friction.

- Consider the total length of the suction line. Longer lines may require larger diameter hoses to compensate for increased pressure losses.

4. Suction Lift:

- Suction lift refers to the vertical distance between the fluid level in the reservoir and the pump inlet.

- Higher suction lifts require larger diameter hoses to minimize pressure losses and ensure adequate fluid flow.

5. Fluid Type and Viscosity:

- The type of fluid (e.g., mineral oil, synthetic oil) and its viscosity can affect flow characteristics.

- Consult hose manufacturer guidelines for specific fluid compatibility and viscosity recommendations.

6. Vacuum Rating:

- Ensure the hose’s vacuum rating exceeds the expected negative pressure within the suction line.

7. Temperature and Pressure:

- Consider the operating temperature range of the fluid and any potential pressure fluctuations.

- Select a hose that can withstand the expected temperature and pressure conditions.

8. Environmental Factors:

- Take into account the environmental conditions the hose will be exposed to, such as abrasion, chemicals, and extreme temperatures.

- Choose a hose with appropriate material and construction to withstand these conditions.

9. Hose Manufacturer Guidelines:

- Consult our Kingdaflex hose manufacturer’s guidelines and selection charts for specific recommendations based on your application requirements.

10. Safety Factors:

- Always err on the side of caution and select a slightly larger hose diameter than the minimum calculated size.

By carefully considering these factors, you can select the appropriate size and type of hydraulic suction hose for your specific application, ensuring efficient and reliable system operation.

Conclusion

Choosing the right hydraulic suction hose is critical for the optimal performance and longevity of your hydraulic system. By understanding the factors influencing hose selection, conducting thorough inspections, and implementing proper maintenance practices, you can minimize downtime, reduce repair costs, and ensure the safety and efficiency of your equipment.

Ready to upgrade your hydraulic system with high-quality suction hoses?

Kingdaflex offers a wide range of durable and reliable hydraulic suction hoses at competitive wholesale prices.

Contact us today for a free consultation and discover the best solutions for your specific needs.