Peristaltic pumps are a great choice for many applications due to their ability to handle a wide range of fluids gently and without contamination. At the heart of a peristaltic pump’s function is the flexible tubing, which is constantly compressed and released. This repetitive action is key to its operation but also the primary source of wear.

The durability of your peristaltic pump hinges almost entirely on the life of its tubing. Understanding how to properly maintain this critical component is essential for preventing costly downtime and ensuring a long service life for your pump. This guide will provide practical tips and best practices to help you get the most out of your pump tubing.

What is a Peristaltic Pump?

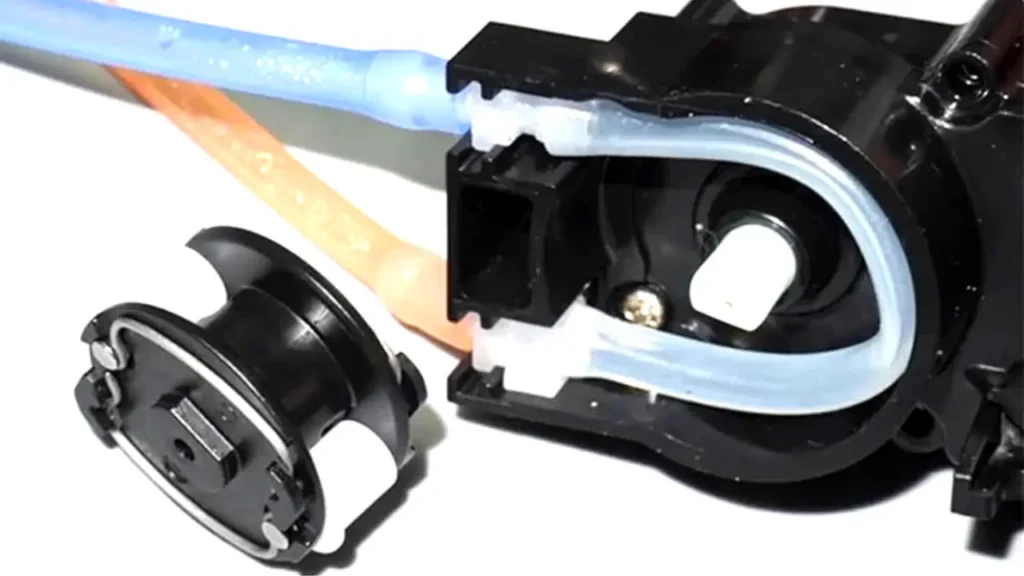

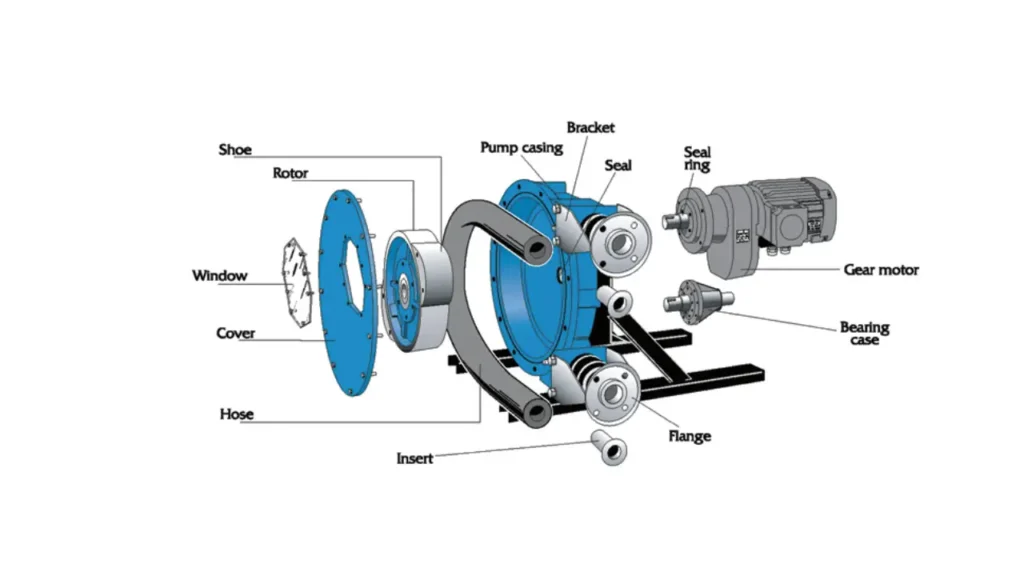

A peristaltic pump is a type of positive displacement pump that uses a series of rollers or “shoes” to move fluid through a flexible tube. The fluid is contained entirely within the tube, which is squeezed by the rollers against a circular casing.

This “peristaltic” action, which mimics the muscle contractions in the human digestive tract, creates a vacuum that pulls fluid into the pump and then pushes it out, providing a continuous and controlled flow. The primary advantage is that the fluid never touches any of the pump’s mechanical components, making it ideal for sterile, corrosive, or abrasive fluids.

What is Peristaltic Pump Made of?

Peristaltic pumps are specialized devices designed to transfer fluids without contamination. They operate by compressing a flexible tube, moving liquid through precise peristaltic action. Understanding what these pumps are made of helps in selecting the right type for chemical, medical, or industrial applications.

- Pump Head: Made from stainless steel, aluminum, or polypropylene, the pump head houses rollers or shoes that compress the tubing, ensuring smooth operation, resisting wear, and maintaining consistent flow without leaks during continuous cycles.

- Flexible Tubing: Usually made of silicone, PVC, or Santoprene, the tubing is flexible, chemical-resistant, and FDA-approved. Its elasticity allows efficient fluid displacement and durability under repeated compression for long-lasting pump performance.

- Rollers or Shoes: Constructed from stainless steel, ceramic, or reinforced plastic, rollers compress the tubing to create peristaltic motion, minimizing friction and wear while maintaining accurate flow rates over time.

- Pump Housing: Made from stainless steel, aluminum, or reinforced plastic, the housing protects internal components, resists corrosion and impact, and ensures safe operation in industrial, laboratory, or medical settings.

- Drive System: Composed of electric motors, gearboxes, or belt systems using steel, aluminum, or high-strength plastics, the drive powers the rollers, ensuring smooth, precise, and variable fluid transfer control.

Peristaltic Pump Applications

Peristaltic pumps are used across a wide variety of industries due to their ability to handle sensitive, abrasive, or corrosive fluids without cross-contamination. Because the fluid is contained within a flexible tube, these pumps are perfect for applications where hygiene and precision are critical.

They are a staple in laboratories and manufacturing, and their versatility allows them to handle anything from delicate biological samples to thick, abrasive slurries with solids. Their simple design makes them low-maintenance and easy to operate in many different environments.

- Medical and Pharmaceutical: Ideal for dialysis machines, heart-lung bypass pumps, and dispensing sterile fluids, where preventing contamination is essential.

- Food and Beverage: Used for accurately dispensing sauces, syrups, or juices, and for handling delicate products that shouldn’t be damaged by traditional pump mechanisms.

- Water and Wastewater Treatment: Effective for dosing chemicals like chlorine or lime into water systems, as they can handle abrasive chemicals and sludges without wear to the pump.

- Chemical Processing: Suited for transferring harsh or corrosive chemicals and for metering precise amounts of reagents in a safe, sealed manner.

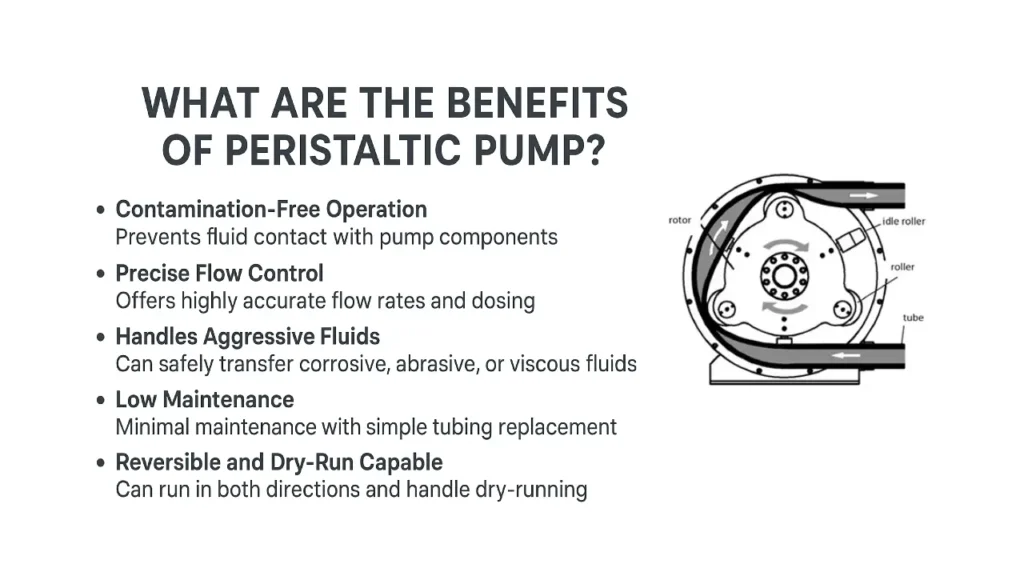

What Are the Benefits of Peristaltic Pump?

Peristaltic pumps are versatile and efficient fluid transfer devices widely used in medical, laboratory, and industrial applications. Their unique design prevents contamination and allows precise flow control. Understanding the benefits of peristaltic pumps helps in selecting the right solution for clean, accurate, and reliable fluid handling.

- Contamination-Free Operation: Peristaltic pumps prevent fluid contact with pump components because liquid only touches the tubing. This ensures sterile and contamination-free transfer, making them ideal for pharmaceuticals, food processing, and sensitive laboratory applications, where hygiene and safety are critical.

- Precise Flow Control: These pumps offer highly accurate flow rates and dosing, controlled by roller speed or tube size. Their consistent performance is essential for applications requiring exact measurements, such as chemical dosing, laboratory experiments, and medical fluid delivery.

- Handles Aggressive Fluids: Peristaltic pumps can safely transfer corrosive, abrasive, or viscous fluids. The tubing material can be selected according to chemical compatibility, making them suitable for harsh chemicals, slurries, and solutions without damaging the pump or causing leaks.

- Low Maintenance: Since only the tubing experiences wear, maintenance is minimal. Replacing the tubing is simple and quick, reducing downtime and costs. The pump head and drive system remain protected, ensuring long-term reliability and durability with minimal servicing.

- Reversible and Dry-Run Capable: These pumps can run in both directions and handle dry-running without damage. This flexibility supports versatile applications, easy system flushing, and safe operation in environments where fluid supply may be interrupted temporarily.

How to Protect Your Peristaltic Pump?

Protecting your peristaltic pump is essential for ensuring long-term performance and minimizing maintenance costs. Following a few simple steps can dramatically extend the life of your pump’s most critical component: the tubing. These practices will prevent premature wear and keep your operations running smoothly.

Select the Right Tubing

Choosing the correct tubing material is the most crucial step. It must be compatible with the fluid you are pumping and able to withstand the required pressure and temperature. The wrong material can quickly degrade, leading to failure and contamination.

Different applications demand specific tubing properties. For instance, chemically resistant tubing is needed for corrosive substances, while food-grade tubing is required for sterile applications. Consulting a compatibility chart ensures you make the right choice, protecting both the pump and the pumped medium.

Ensure Proper Installation

Correct installation is vital to prevent uneven wear. The tubing must be properly seated in the pump head without twists or kinks. A twisted tube can create uneven pressure, leading to localized stress and premature failure.

Always ensure the pump head is securely closed and that the rollers apply consistent compression. Misalignment or improper tension can cause the tube to wear down unevenly, shortening its lifespan and potentially leading to a rupture during operation.

Regular Maintenance and Inspection

Routine maintenance is key to proactive protection. Regularly inspect the tubing for signs of wear, such as cracking, discoloration, or a loss of elasticity. Catching these issues early allows for timely replacement before a failure occurs.

Additionally, keep the pump head and rollers clean to prevent debris from causing damage to the tubing. Periodically check the rollers and bearings for smooth operation, as worn components can put extra stress on the tubing, accelerating its degradation.

Why Choose Kingdaflex Peristaltic Pump?

Kingdaflex peristaltic pump hoses are engineered for superior performance and durability, making them a top choice for a wide range of industrial applications. They are designed to withstand the high pressures and abrasive nature of many different fluids, ensuring a longer service life and reducing the frequency of costly replacements.

Kingdaflex’s commitment to quality materials and strict manufacturing standards results in hoses that provide a reliable and efficient solution for your pumping needs.

- Exceptional Durability: Made with high-quality, abrasion-resistant materials to ensure long operational life even in heavy-duty applications.

- Versatile and Flexible: Compatible with a variety of peristaltic pump models and can handle a wide range of fluids, from viscous and corrosive chemicals to food products.

- Reduced Maintenance: The robust design and resistance to wear and tear minimize the need for frequent replacement, saving time and maintenance costs.

- Precise and Consistent Flow: The hoses are designed to provide accurate and repeatable flow rates, which is crucial for applications that require precise metering and dosing.

Conclusion

Ultimately, extending the life of your peristaltic pump’s tubing is about proactive care and making informed choices. By selecting the right tubing material for your specific application, ensuring correct installation, and adhering to a consistent maintenance schedule, you can significantly reduce wear and tear. These practices will not only save you money but also improve the reliability of your pumping operations.

Remember, the quality of the tubing you use directly impacts both the performance and longevity of your pump. Investing in high-grade, durable tubing designed for the rigorous demands of peristaltic pumping is a non-negotiable step toward preventing premature failure and maintaining the integrity of your process. Don’t compromise on this crucial component.

For all your peristaltic pumping needs, including a wide selection of top-quality tubing, trust Kingdaflex. Our wholesale peristaltic pump hoses are engineered for exceptional durability and chemical resistance, ensuring your pump runs efficiently and reliably. Contact us today to find the perfect tubing solution for your application.