Reinforced hydraulic hoses play a critical role in hydraulic systems by providing the strength and durability required to handle the high-pressure fluid transfer.

In this blog, we will explore the benefits of using reinforced hydraulic hoses and the different types available.

What Is Hydraulic Hose Reinforcement?

Hydraulic hose reinforcement is a layer or multiple layers of material added to the inner tube of a hydraulic hose to provide additional strength and durability. The purpose of reinforcement is to improve the hose’s ability to withstand high pressure, temperature, and other environmental factors that can cause degradation over time.

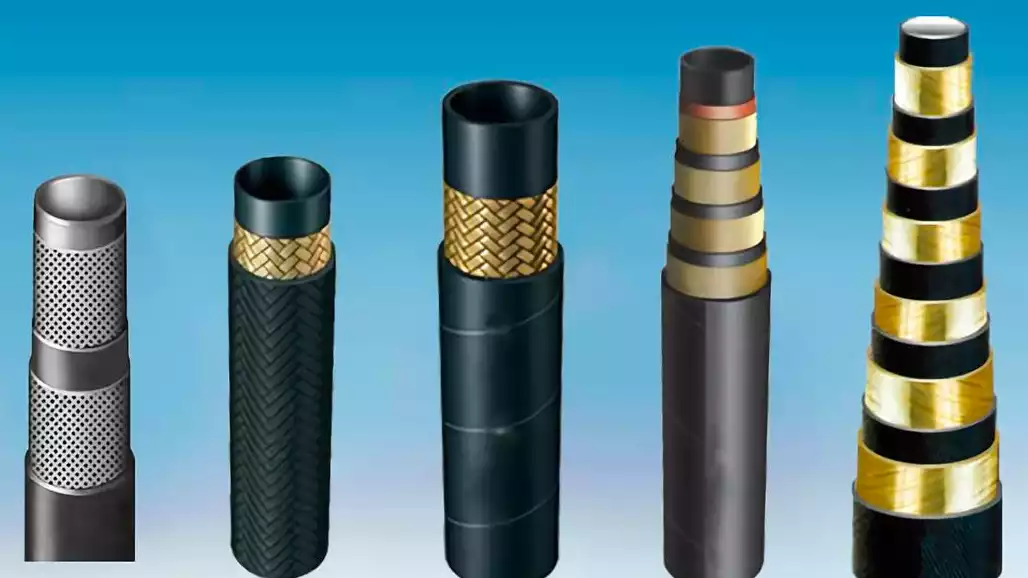

There are several types of hydraulic hose reinforcement materials, including wire-braid, spiral-wire, textile-braid, and thermoplastic. The choice of reinforcement material will depend on the specific requirements of the hydraulic system, including pressure, temperature, fluid compatibility, and flexibility.

Reinforced hydraulic hoses are commonly used in industrial, construction, and agricultural applications where high-pressure fluid transfer is required. By adding reinforcement, hydraulic hoses can handle higher pressures, maintain their shape under pressure, and resist bursting, kinking, and other forms of degradation.

So the hydraulic hose reinforcement is a critical component of hydraulic systems that provides the strength and durability required to handle high-pressure fluid transfer and withstand harsh environmental conditions.

Types of Reinforced Hydraulic Hose

Here are many different types of reinforced hydraulic hoses in the market, take a look at them now.

Wire-Braid and Spiral-Wire Reinforced Hoses

Wire-braid and spiral-wire reinforced hoses are two of the most common types of steel reinforced hydraulic hoses. These hoses are made with a reinforcement layer that provides extra strength and durability, making them ideal for high-pressure applications. Related: What Are Differences Between Spiral vs Braided Hydraulic Hose?

Wire-braid hoses feature a wire-braid reinforcement layer, while spiral-wire hoses feature a spiral-wire reinforcement layer. Both types offer improved strength and durability compared to traditional hydraulic hoses.

Textile-Braid Reinforced Hoses

Textile-braid reinforced hoses are made with a textile braid reinforcement layer and are ideal for low to medium-pressure applications. They offer excellent flexibility and are commonly used in hydraulic systems that require tight bend radii. Textile-braid reinforced hoses are often made with a durable and flexible material, making them easy to install and maneuver.

Thermoplastic Hoses

Thermoplastic hoses are made with a thermoplastic inner tube and reinforcement layer, making them resistant to high temperatures and harsh environments. They are commonly used in applications where high-pressure and high-temperature resistance is required. Thermoplastic hoses are often used in hydraulic systems that require a lightweight and flexible hose that can withstand harsh conditions.

The Benefits of Reinforced Hydraulic Hoses

Reinforced hydraulic hoses offer several benefits, including:

- Improved Durability: Reinforced hoses are designed to handle high-pressure fluid transfer and are made with materials that provide extra strength and durability.

- Increased Pressure Capacity: Reinforced hoses can handle higher pressures compared to traditional hydraulic hoses, making them ideal for high-pressure applications.

- Enhanced Flexibility: Some types of reinforced hoses, such as textile-braid reinforced hoses, offer excellent flexibility, making them easier to install and maneuver in tight spaces.

- Improved Resistance to Harsh Environments: Reinforced hoses, such as thermoplastic hoses, are designed to withstand harsh environments and high temperatures, making them ideal for use in harsh industrial settings.

The Importance of Hydraulic Hose Reinforcement

Here you can know the importance of hydraulic hose reinforcement for hydraulic systems.

Hydraulic hose reinforcement is important because it provides the necessary strength and durability for high-pressure fluid transfer in hydraulic systems. The reinforcement layer helps to prevent hose failure, bursting, kinking, and other forms of degradation, which can cause leaks, system downtime, and even safety hazards.

- Increased Pressure Capacity: Reinforcement allows hydraulic hoses to handle higher pressure compared to traditional hoses without reinforcement, making them ideal for high-pressure applications.

- Improved Durability: Reinforcement materials are designed to withstand high pressure, temperature, and environmental factors that can cause degradation over time, resulting in a longer lifespan for the hydraulic hose.

- Improved Resistance to Harsh Environments: Reinforced hoses, such as thermoplastic hoses, are designed to withstand harsh environments and high temperatures, making them ideal for use in harsh industrial settings.

- Enhanced Flexibility: Some types of reinforced hoses, such as textile-braid reinforced hoses, offer excellent flexibility, making them easier to install and maneuver in tight spaces.

- Increased Safety: Reinforced hoses are designed to handle high pressure without bursting or failing, reducing the risk of leaks and other safety hazards.

Choosing the Right Reinforced Hydraulic Hose

Choosing the right reinforced hydraulic hose is essential for ensuring the efficient and safe operation of your hydraulic system. The right hose will depend on several factors, including pressure requirements, fluid compatibility, temperature, and operating environment. Here are some key considerations when selecting the right reinforced hydraulic hose:

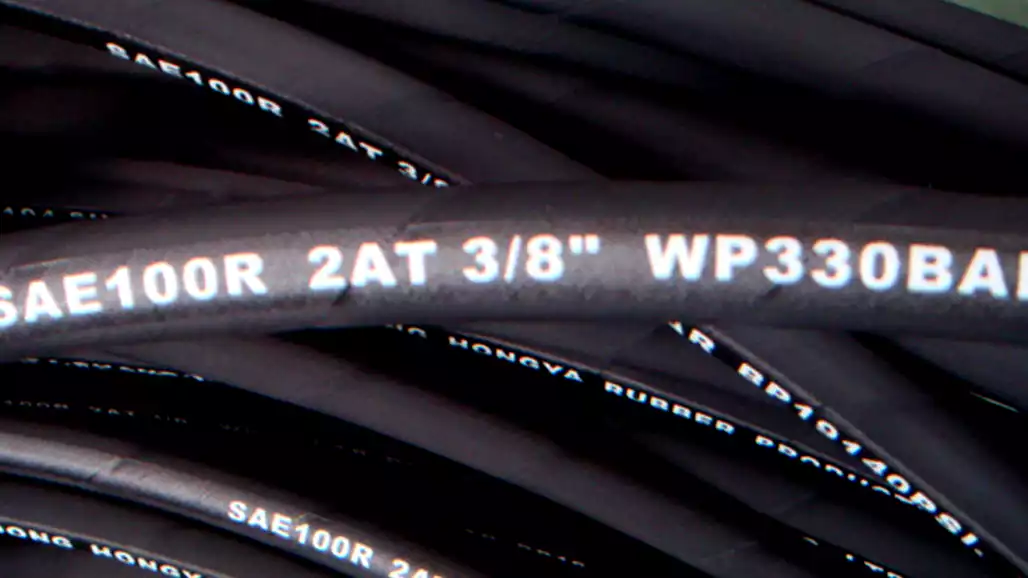

- Pressure Requirements: The pressure rating of the hose must be able to handle the highest operating pressure of the hydraulic system. The hose should also be able to withstand occasional spikes in pressure.

- Fluid Compatibility: The hose must be compatible with the type of fluid being transferred. This includes compatibility with the chemical properties of the fluid, as well as with the temperature and pressure requirements.

- Temperature: The hose must be able to withstand the temperature range of the fluid being transferred and the temperature of the operating environment. Some hoses are designed to handle extreme temperatures, while others are suitable for low-temperature applications.

- Operating Environment: The hose must be able to withstand the environmental conditions it will be subjected to, including exposure to chemicals, UV radiation, and physical damage.

- Flexibility: The hose must be flexible enough to accommodate the movement of the hydraulic system, while also providing the necessary reinforcement for high-pressure applications.

- Hose Length: The length of the hose must be appropriate for the specific application, and any fittings must be compatible with the hose.

Once you have considered these factors, you can then select the type of reinforcement material, such as wire-braid, spiral-wire, textile-braid, or thermoplastic, based on the specific requirements of your hydraulic system.

In summary, choosing the right reinforced hydraulic hose requires careful consideration of several key factors, including pressure requirements, fluid compatibility, temperature, operating environment, flexibility, and hose length. By selecting the right hose, you can ensure the efficient and safe operation of your hydraulic system.

Final Thoughts

In conclusion, reinforced hydraulic hoses are an essential component of hydraulic systems and provide the strength and durability required for high-pressure fluid transfer. With the right type of reinforced hose, you can improve the efficiency and lifespan of your hydraulic system.