Hydraulic hoses play an essential role in machinery and equipment that use hydraulic power. They transfer pressurized hydraulic fluid from one part of the machine to another, allowing it to function efficiently. However, like any other component, hydraulic hoses are subject to wear and tear, and they need to be replaced from time to time.

In this article, we’ll discuss five warning signs that your hydraulic hose needs to be replaced as soon as possible.

Hydraulic hoses are the arteries of any hydraulic system, and their proper functioning is crucial for the overall efficiency of the machinery or equipment. However, if not maintained correctly, they can cause serious problems, including costly downtime, increased repair costs, and potential safety hazards.

In this article, we’ll discuss the five warning signs that your hydraulic hose needs to be replaced immediately to prevent any damage to your machine and ensure the safety of your operators.

PS: You can get to know how to replace a hydraulic hose after identifying the warning signs to see what happens about the hydraulic hose failure.

Importance of Hydraulic Hoses

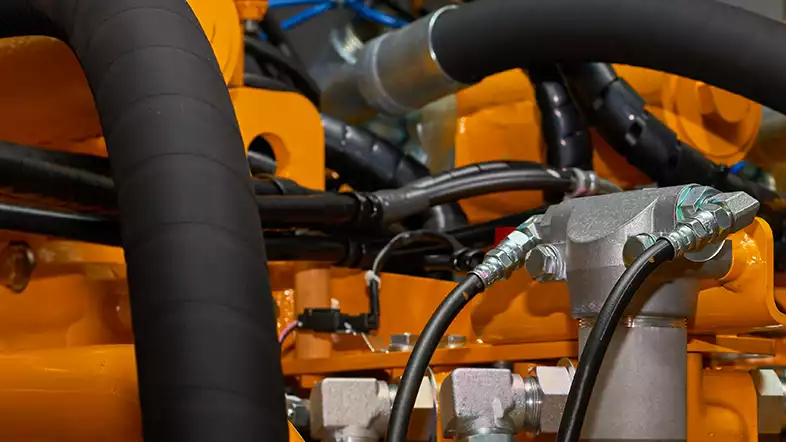

Hydraulic hoses are essential components of hydraulic systems, which are used in a wide range of machines and equipment, including construction machinery, agricultural equipment, industrial machinery, and vehicles.

Hydraulic hoses are responsible for transmitting hydraulic fluid, which is pressurized to move cylinders, motors, and other components of hydraulic systems.

The importance of hydraulic hoses lies in their critical role in ensuring the proper functioning of hydraulic systems. Hydraulic hoses must be designed to withstand high pressures, temperatures, and environmental conditions, while also maintaining flexibility to allow for the movement of the hydraulic fluid. Any failure in the hydraulic hose can cause a disruption in the flow of hydraulic fluid, leading to reduced efficiency, damage to the machine, or even safety hazards.

Moreover, hydraulic hoses are subject to wear and tear over time due to exposure to high pressures, temperature fluctuations, and environmental factors.

Therefore, regular maintenance, including inspection and replacement of hydraulic hoses, is essential to ensure the proper functioning of hydraulic systems and prevent any potential damage or safety hazards.

Hydraulic hoses are critical components of hydraulic systems that are responsible for transmitting hydraulic fluid and ensuring the proper functioning of machines and equipment. Their importance lies in their ability to withstand high pressures, temperatures, and environmental conditions while maintaining flexibility, and their regular maintenance is necessary to prevent any potential damage or safety hazards.

The Lifespan of Hydraulic Hoses

The lifespan of hydraulic hoses depends on several factors, including the type of hose, its quality, the application in which it is used, and how well it is maintained. Generally, hydraulic hoses have a lifespan of around five to ten years, but this can vary depending on these factors.

One of the primary factors affecting the lifespan of hydraulic hoses is the type of hose material used. Some materials, such as synthetic rubber and thermoplastics, are more durable and resistant to wear and tear, while others, such as natural rubber, have a shorter lifespan. The quality of the hose also plays a significant role in its lifespan, with high-quality hoses typically lasting longer than low-quality ones.

Another factor that affects the lifespan of hydraulic hoses is the application in which they are used. Hoses that are subject to frequent and extreme pressure cycles, high temperatures, or exposure to harsh chemicals and environmental conditions are more likely to experience wear and tear, reducing their lifespan.

Proper maintenance can also help prolong the life of hydraulic hoses. Regular inspection and replacement of hoses as soon as any signs of wear and tear appear can prevent further damage and potential safety hazards. Pressure testing can also help identify any leaks or damage in the hoses and ensure they are functioning correctly.

In summary, the lifespan of hydraulic hoses varies depending on several factors, including the type and quality of the hose, the application in which it is used, and how well it is maintained. By understanding these factors and performing regular maintenance, you can ensure the longevity of hydraulic hoses and prevent any potential damage or safety hazards.

Warning Signs to Tell You to Replace Hydraulic Hose

To avoid any unexpected breakdowns or safety hazards, it is crucial to be aware of the following warning signs that your hydraulic hose needs to be replaced:

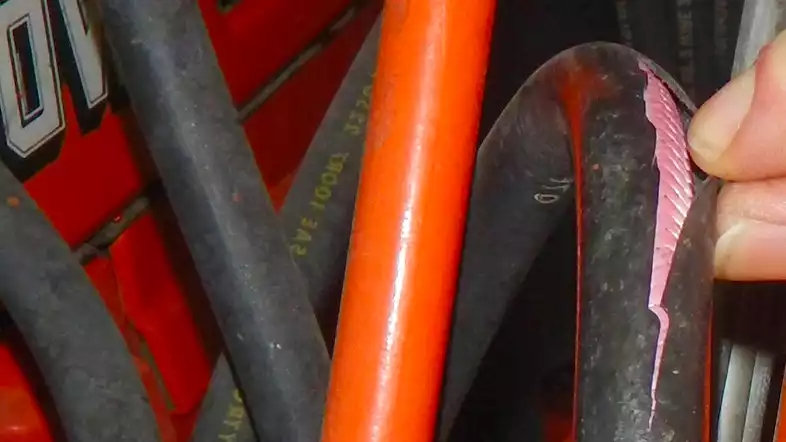

Cracks and Abrasions

If you notice any cracks or abrasions on the surface of the hose, it is a clear indication that the hose needs to be replaced. These cracks can be caused by external factors, including exposure to extreme temperatures or chemicals, and can cause hydraulic fluid to leak.

Leaking Hydraulic Fluid

Leaking hydraulic fluid is one of the most apparent signs that your hydraulic hose needs to be replaced. You need to pay much more attention to the hydraulic hose leaking problems. If you notice any fluid dripping from the hose or puddles of fluid around the machinery, it is essential to shut down the machine immediately and replace the hose.

Hydraulic hoses are designed to contain high-pressure fluids within the system. When a hose begins to leak, it can cause fluid loss, which can lead to a reduction in pressure and efficiency, and in some cases, even catastrophic failures. Leaks can also lead to safety hazards by exposing workers to hazardous chemicals, causing slips, trips, and falls. Identifying and fixing leaks early is critical to maintaining the safety and integrity of the hydraulic system.

Reduced Flexibility

A hydraulic hose that has lost its flexibility is another sign that it needs to be replaced. The hose should be flexible enough to bend without cracking or breaking. If it feels stiff or brittle, it may be time for a replacement.

Hydraulic hoses are designed to be flexible to allow for smooth movement and operation of the hydraulic system. However, over time, the constant pressure and exposure to environmental factors can cause the hose to lose its flexibility. This can result in a variety of issues such as kinks, twists, and other deformations that can impede the proper functioning of the hydraulic system.

Reduced flexibility can also lead to cracking or splitting of the hose, which can result in leaks and safety hazards. It’s important to inspect hydraulic hoses regularly for any signs of reduced flexibility and replace them as soon as possible to prevent any further damage or safety hazards. In addition, proper installation and routing of hydraulic hoses can help prevent damage to the hose and maintain its flexibility over time.

Bulging or Kinking

Bulging or kinking of the hose is another clear indication that it needs to be replaced. Bulging can occur due to the pressure of the hydraulic fluid while kinking can be caused by bending the hose beyond its recommended bend radius.

Bulging occurs when the hose expands beyond its normal size, typically due to an increase in pressure within the hose. This can cause the hose to become misshapen and put stress on the fittings and connectors, leading to leaks or even ruptures.

Kinking occurs when the hose is bent or twisted beyond its bend radius, causing a blockage in the flow of hydraulic fluid. This can cause a reduction in the efficiency of the hydraulic system, leading to slow or weak movements. Kinking can also cause the hose to become damaged, leading to leaks and safety hazards.

Both bulging and kinking can occur due to a variety of reasons such as improper installation, wear and tear, or damage to the hose. It’s important to inspect hydraulic hoses regularly for any signs of bulging or kinking and replace them as soon as possible to prevent any further damage or safety hazards. In addition, proper installation and routing of hydraulic hoses can help prevent bulging or kinking over time.

Discoloration and Brittleness

Discoloration can occur due to a variety of factors such as exposure to sunlight, heat, or chemicals. Over time, constant exposure to these environmental factors can cause the hose to change color, indicating that it has started to degrade. Discoloration can also be an indication of high temperatures within the hydraulic system, which can cause the hose to become brittle and crack.

Brittleness occurs when the hose becomes rigid and breaks easily. This can be caused by exposure to high temperatures or chemicals, as well as normal wear and tear. A brittle hose is more likely to fail under pressure, leading to leaks and safety hazards.

It’s important to inspect hydraulic hoses regularly for any signs of discoloration or brittleness and replace them as soon as possible to prevent any further damage or safety hazards. In addition, proper maintenance of the hydraulic system, such as regular cleaning and avoiding exposure to extreme temperatures and chemicals, can help prevent discoloration and brittleness over time.

Why Timely Hydraulic Hose Replacement Is Necessary

Ignoring the warning signs and delaying the replacement of hydraulic hoses can lead to serious consequences. A failed hydraulic hose can cause damage to the machine, leading to costly downtime and repair costs. It can also result in safety hazards, including fires, explosions, or injuries to operators.

Moreover, a failed hydraulic hose can cause hydraulic fluid to leak, resulting in environmental pollution and fines. It is, therefore, essential to replace hydraulic hoses as soon as any warning signs appear to prevent any damage to your machine and ensure the safety of your operators.

FAQs

Q1. How often should hydraulic hoses be replaced?

The lifespan of hydraulic hoses varies depending on various factors, including the type of hose, its quality, and how well it is maintained. However, in general, hydraulic hoses have a lifespan of around five to ten years. It is recommended to inspect hydraulic hoses regularly and replace them as soon as any warning signs appear.

Q2. Can I repair a hydraulic hose instead of replacing it?

Repairing a hydraulic hose is not recommended as it can compromise the integrity of the hose and lead to further damage or safety hazards. It is always recommended to replace the hydraulic hose as soon as any warning signs appear.

Q3. Can I use any hydraulic hose to replace a damaged one?

No, it is essential to use the same type and size of hydraulic hose as the damaged one to ensure proper functioning and prevent any safety hazards. Using an incorrect hose can cause leaks, pressure loss, or damage to the machine.

Q4. Can I visually inspect hydraulic hoses to detect any warning signs?

Yes, it is recommended to visually inspect hydraulic hoses regularly to detect any warning signs, including cracks, abrasions, leaks, reduced flexibility, bulging, kinking, discoloration, and brittleness. However, it is also essential to perform regular maintenance, including pressure testing and replacement of hydraulic hoses.

Q5. How can I ensure the longevity of hydraulic hoses?

To ensure the longevity of hydraulic hoses, it is essential to perform regular maintenance, including visual inspection, pressure testing, and replacement of hoses as soon as any warning signs appear. Proper installation, including ensuring the correct routing and bend radius, can also help prolong the life of hydraulic hoses.

Conclusion

Hydraulic hoses play a crucial role in the proper functioning of machines and equipment that rely on hydraulic power. It is, therefore, essential to ensure their proper functioning and timely replacement as soon as any warning signs appear.

By being aware of the warning signs discussed in this article and performing regular maintenance, you can prevent any damage to your machine and ensure the safety of your operators.