Have you ever wondered what goes into making those crucial lifelines of your hydraulic system? Hydraulic hoses are far more complex than simple tubes; they are engineered marvels, each layer meticulously crafted from specialized materials to ensure robust performance. Understanding their composition is key to appreciating their critical role.

From the inner tube that carries the fluid to the outer cover that withstands the elements, every material choice in a hydraulic hose’s construction serves a vital purpose. This blog will delve into the diverse materials used, explaining how they contribute to a hose’s ability to handle immense pressure, extreme temperatures, and harsh environments.

What is Hydraulic Hose Made of?

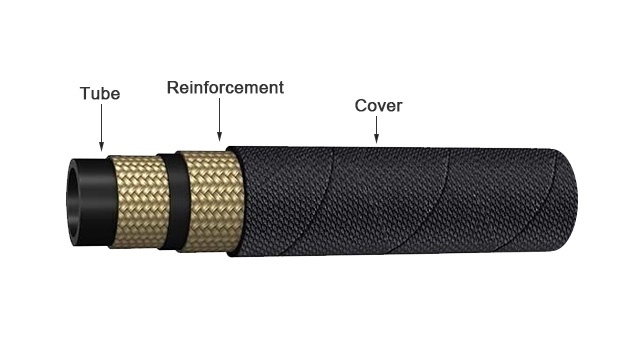

Hydraulic hoses are complex components, meticulously engineered to withstand the demanding conditions of hydraulic systems. As seen in the image, their construction typically involves three key layers: an inner tube, a reinforcement layer, and an outer cover, each made from specialized materials to ensure flexibility, pressure resistance, and protection.

Here’s a breakdown of common hydraulic hose materials:

- Tube (Inner Tube): This innermost layer is crucial as it’s in direct contact with the hydraulic fluid. Typically made of synthetic rubber (like nitrile, which offers excellent oil resistance), or sometimes thermoplastic, its primary function is to contain the fluid without degradation. It must be chemically compatible with the specific hydraulic fluid to prevent swelling, contamination, or breakdown.

- Reinforcement: This layer is the hydraulic hose’s strength, designed to withstand the immense internal pressure. As shown, it’s often comprised of braided or spiraled high-tensile steel wire, or sometimes textile fibers for lower-pressure applications. Multiple layers of reinforcement provide higher pressure ratings, preventing the hose from expanding or bursting under the system’s operational and surge pressures.

- Cover (Outer Cover): The outermost layer, as depicted, acts as a protective shield for the entire hose assembly. Commonly made from abrasion-resistant synthetic rubber compounds (like SBR or EPDM) or thermoplastic, its purpose is to protect the reinforcement layer from external damage. This includes safeguarding against abrasion, cuts, impacts, weathering (UV, ozone), and chemical exposure.

How Many Types of Hydraulic Hoses Are There?

-

SAE 100R14 / Teflon Hose(Inner Corrugated Tube)

SAE 100R14 / Teflon Hose(Inner Corrugated Tube) -

SAE 100R6 | Hydraulic Hose

SAE 100R6 | Hydraulic Hose -

SAE 100R15 | Hydraulic Hose

SAE 100R15 | Hydraulic Hose -

SAE 100R13 | Hydraulic Hose

SAE 100R13 | Hydraulic Hose -

SAE 100R12 | 4 Wire Spiral Hydraulic Hose

SAE 100R12 | 4 Wire Spiral Hydraulic Hose -

SAE 100R9 | Hydraulic Hose

SAE 100R9 | Hydraulic Hose -

SAE 100R8 | Thermoplastic Hydraulic Hose

SAE 100R8 | Thermoplastic Hydraulic Hose -

SAE 100R7 | Thermoplastic Hydraulic Hose

SAE 100R7 | Thermoplastic Hydraulic Hose -

SAE 100R4 | Hydraulic Suction Hose

SAE 100R4 | Hydraulic Suction Hose -

SAE 100R3 Textile Fiber Reinforced Hydraulic Hose

SAE 100R3 Textile Fiber Reinforced Hydraulic Hose -

SAE 100 R14 / Teflon Hose (Inner Smooth Tube)

SAE 100 R14 / Teflon Hose (Inner Smooth Tube) -

SAE 100R5 | Fabric Covered Hydraulic Hose

SAE 100R5 | Fabric Covered Hydraulic Hose -

SAE 100R17 | Hydraulic Hose

SAE 100R17 | Hydraulic Hose -

SAE 100R16 | Hydraulic Hose

SAE 100R16 | Hydraulic Hose -

SAE 100R2A / DIN EN853 2ST

SAE 100R2A / DIN EN853 2ST -

SAE 100R1A/DIN EN853 1ST

SAE 100R1A/DIN EN853 1ST -

SAE 100R2AT / DIN EN853 2SN

SAE 100R2AT / DIN EN853 2SN -

SAE 100R1AT/ DIN EN853 1SN

SAE 100R1AT/ DIN EN853 1SN

While it might seem like there are countless hydraulic hose options, they are broadly categorized based on their construction and the specific applications they’re designed for, often adhering to industry standards like SAE International (Society of Automotive Engineers) J517. These standards define the hose’s working pressure, temperature range, fluid compatibility, and construction, simplifying selection. Understanding these primary types helps to narrow down the best fit for any hydraulic system.

Here are the main types of hydraulic hoses:

- Braided Hydraulic Hoses (SAE 100R1, 100R2, etc.): These are among the most common, featuring one or more layers of braided steel wire or textile reinforcement. Braided hoses offer a good balance of flexibility and pressure capability, making them suitable for a wide range of medium to high-pressure applications in industries like construction, agriculture, and manufacturing.

- Spiral Hydraulic Hoses (SAE 100R9, 100R12, 100R13, 100R15, etc.): Designed for very high and ultra-high pressure applications, these hoses utilize multiple layers (typically four or six) of spirally wound steel wire reinforcement. This construction provides superior strength and resistance to impulse pressures, making them ideal for heavy-duty equipment in mining, oil and gas, and large machinery where extreme pressures are encountered.

- Thermoplastic Hydraulic Hoses (SAE 100R7, 100R8, 100R18): These hoses use thermoplastic materials for both the inner tube and sometimes the outer cover, reinforced with synthetic fibers or non-metallic braids. They are known for being lightweight, highly flexible, and offering excellent chemical resistance and low-temperature performance. Thermoplastic hoses are often used in mobile equipment, aerial lifts, and non-conductive applications.

- PTFE (Teflon) Hydraulic Hoses (SAE 100R14): Featuring an inner tube made from Polytetrafluoroethylene (PTFE), these hoses offer exceptional chemical resistance and can withstand extreme temperatures, both high and low. Reinforced with stainless steel wire braid, PTFE hoses are chosen for applications involving corrosive fluids, steam, or where very wide temperature ranges are present, such as in chemical processing or food industries.

- Suction and ReturnHydraulic Hoses (SAE 100R4, 100R6): These hoses are designed for low-pressure applications, primarily to convey fluid back to the reservoir or for suction lines. They typically have textile reinforcement and often include a helical wire to prevent collapse under vacuum. Their construction prioritizes flexibility and larger diameters to accommodate higher flow rates at lower pressures.

What is the Standard for Hydraulic Hoses?

The standardization of hydraulic hoses is crucial for ensuring interchangeability, safety, and consistent performance across the global fluid power industry. Various international and regional organizations develop and maintain these standards, providing clear specifications for hose construction, materials, dimensions, pressure ratings, temperature ranges, and testing procedures. Adhering to these standards allows manufacturers to produce reliable products and enables users to select the correct hose for their specific application with confidence, preventing costly failures and ensuring system integrity.

Here are the primary standards for hydraulic hoses:

- SAE (Society of Automotive Engineers) Standards: These are perhaps the most widely recognized and used standards in North America and globally, particularly the SAE J517 series. This series defines specifications for various types of hydraulic hoses, such as SAE 100R1 (single wire braid), 100R2 (double wire braid), 100R4 (suction and return), 100R7 (thermoplastic), 100R9 (spiral wire), and 100R12 (high-pressure spiral wire). Each “R” designation specifies construction, working pressure, and material requirements.

- ISO (International Organization for Standardization) Standards: ISO is a global body that develops standards covering a vast range of products and services. For hydraulic hoses, ISO 1436 (rubber hoses with wire reinforcement), ISO 3949 (thermoplastic hoses), and ISO 11237 (compact wire spiral hoses) are highly significant. These ISO standards often align closely with, or are the basis for, regional and national standards, promoting international compatibility.

- EN (European Norm) Standards: These standards are developed by CEN (European Committee for Standardization) and are widely used within Europe. Many EN standards for hydraulic hoses are harmonized with corresponding ISO standards. Examples include EN 853 (rubber hoses with wire braid, similar to SAE 100R1/R2) and EN 856 (rubber hoses with spiral wire reinforcement, similar to SAE 100R9/R12/R13).

- DIN (Deutsches Institut für Normung) Standards: While often superseded or harmonized with EN standards in Europe, DIN standards still represent a foundational set of specifications, particularly originating from Germany. DIN 20022 and DIN 20023 are examples that define various types of hydraulic hoses, often aligning with their SAE or ISO equivalents.

- BS (British Standards) Standards: Developed by the BSI (British Standards Institution), these standards are primarily used in the UK. Like DIN, many BS hydraulic hose standards have been aligned with EN and ISO standards to promote international consistency.

- AS (Australian Standards) Standards: These standards are developed by Standards Australia. Similar to other national standards bodies, AS often adopts or adapts ISO and EN standards for hydraulic hoses, ensuring local industry compliance and safety.

How to Make Hydrualic Hoses in Manufacturer?

Manufacturing hydraulic hoses is a precise, multi-stage process involving specialized machinery and skilled technicians. Each step is critical in ensuring the hose meets stringent performance and safety standards, from raw material preparation to the final inspection.

Step 1: Material Preparation

This initial phase involves preparing the raw materials. Rubber compounds for the inner tube and outer cover are precisely mixed to achieve desired properties like flexibility, chemical resistance, and abrasion resistance. Steel wire for reinforcement is also prepped, ensuring it meets tensile strength specifications before being fed into the production line.

Step 2: Inner Tube Extrusion

The prepared rubber or thermoplastic compound is fed into an extruder. Under heat and pressure, it’s forced through a die to form a seamless inner tube. This tube’s consistency and specified inner diameter are crucial, as it will directly contact the hydraulic fluid and must maintain its integrity under operational conditions.

Step 3: Reinforcement Application

After the inner tube, the reinforcement layers are applied. For braided hoses, steel wire is woven around the tube. For spiral hoses, wire is wound in multiple precise layers. This step is vital for the hose’s pressure rating, as the reinforcement provides the strength to withstand the high internal pressures of hydraulic systems.

Step 4: Outer Cover Extrusion

Once the reinforcement is in place, another extrusion process applies the outer cover. This protective layer encases the entire assembly, shielding the reinforcement from external damage like abrasion, cuts, impacts, and environmental factors such as UV radiation and ozone. Its composition contributes significantly to the hose’s longevity.

Step 5: Curing (Vulcanization)

For rubber hoses, the assembled hose then undergoes a curing process, often called vulcanization, in an autoclave or curing oven. This involves applying heat and pressure to chemically cross-link the rubber polymers. Curing gives the rubber its permanent elasticity, strength, and durability, ensuring it maintains its shape and performance.

Step 6: Branding and Finishing

After curing, the hydraulic hose is often branded with essential information like hydraulic hose manufacturer, hose type, size, and pressure rating for traceability. Finishing steps may include cutting to specific lengths and preparing ends for fitting attachment. This ensures proper identification and facilitates correct usage in various hydraulic applications.

Step 7: Quality Control and Testing

The final and critical stage involves rigorous hydraulic hose quality control. Each batch, or even individual hoses, undergoes extensive testing. This includes pressure testing (proof and burst tests), impulse testing (repeated pressure cycles), and dimensional checks to ensure the hose meets all relevant industry standards and performance specifications before leaving the factory.

Conclusion

The sophisticated construction of hydraulic hoses, leveraging a variety of specialized materials, is what enables them to withstand the rigorous demands of modern hydraulic systems. Each layer—from the fluid-compatible inner tube to the pressure-resisting reinforcement and the protective outer cover—plays an indispensable role in ensuring system reliability, safety, and longevity.

Understanding “What is hydraulic hose made of?” illuminates why material selection isn’t just a detail, but a foundational decision. The choice of synthetic rubber, thermoplastic, steel wire, or even specialized materials like PTFE directly impacts performance, durability, and your overall operational efficiency. It’s an investment in uninterrupted work.

For all your hydraulic hose requirements, from standard applications to the most demanding environments, trust Kingdaflex. We provide a comprehensive selection of wholesale hydraulic hoses, expertly manufactured from the highest quality materials to guarantee superior performance. Get wholesale hydraulic hoses from our Kingdaflex today and power your systems with confidence.