Picture this: It’s a peak production day at a mining site. A 50-ton excavator is digging into hard rock. Suddenly, a loud pop echoes through the site, followed by a spray of hot hydraulic fluid. The machine stops. Production halts.

For every hour that machine sits idle, thousands of dollars are lost.

As a hydraulic hose manufacturer with over 15 years of experience, we at Kingdaflex have noticed a distinct trend: Machines are getting stronger, and standard hoses can no longer keep up.

Modern hydraulic systems in construction, mining, and agriculture are running at higher pressures with faster cycle times. This creates “extreme impulse” conditions—a silent killer of standard hydraulic hoses. Today, we are diving deep into the world of high-pressure hydraulics and why upgrading to Spiral Wire Hoses (like the R13, R15, and 4SH) is not just an option, but a necessity.

The Science of “Extreme”: Pressure vs. Impulse

To understand why hoses fail, we must distinguish between static pressure and impulse.

Static Pressure is the constant force exerted by the fluid. Most standard hoses can handle their rated static pressure fine.

Impulse is the “heartbeat” of the machine. It is the rapid spike in pressure that occurs when a valve opens or a cylinder hits its limit. In modern heavy equipment, these spikes happen thousands of times a shift.

When a hose is subjected to high impulse, the wire reinforcement inside expands and contracts. Over time, this metal fatigue causes the wire to crack. Once the wire fails, the rubber tube bursts.

Standard braided hoses (like the 1SN or 2SN) are designed for flexibility and medium pressures. However, under the extreme pressure of modern hydrostatic transmissions (often exceeding 350-400 Bar), braided hoses simply expand too much. This is where Spiral Hoses enter the chat.

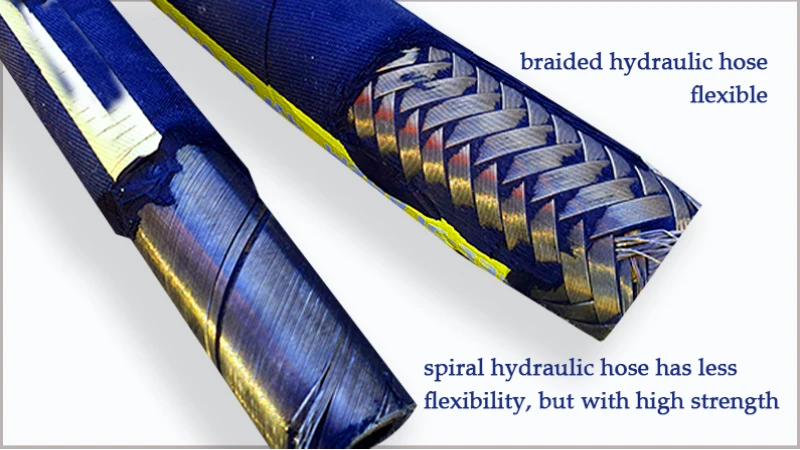

Braided vs. Spiral: Why the Structure Matters

The difference lies in the reinforcement.

- Braided Hoses (1SN, 2SN, R16, R17): These utilize a crisscross pattern of steel wire. They are flexible and great for general hydraulics, but under high pressure, the wires “scissor” against each other, creating friction and heat.

- Spiral Hoses (4SP, 4SH, R12, R13, R15): These hoses use 4 or 6 layers of high-tensile steel wire wrapped in alternating spirals.

Because the wires in a spiral hose are parallel (wrapped, not woven), they do not cross over each other. This results in:

- Higher Pressure Ratings: They can handle massive loads without expanding.

- Superior Impulse Life: They can withstand millions of pressure cycles compared to hundreds of thousands for braided hoses.

At Kingdaflex, we maintain strict quality control over our raw materials, ensuring that our high-tensile steel wires meet the stringent requirements of these spiral designs.

Kingdaflex High-Pressure Solutions: The “Big Three”

If you are dealing with heavy equipment (excavators, drill rigs, injection molding machines), you likely need one of the following three beasts. Let’s break down the specs from the Kingdaflex catalog to help you choose.

1. The Heavy Lifter: SAE 100R13

The SAE 100R13 is the gold standard for heavy-duty applications requiring constant high pressure and high impulse cycles.

- Construction: It features an oil-resistant synthetic rubber tube reinforced with four or six high-tensile steel wire spiral layers.

- Pressure Performance: What makes the R13 special is its Isobaric Rating. Unlike standard hoses where pressure drops as size increases, the Kingdaflex R13 maintains a massive working pressure of 350 Bar (5075 PSI) across all sizes, from 3/4″ all the way up to 2″.

- Temperature: It handles extremes from -40°C up to +120°C (with intermittent spikes to 125°C).

- Best For: Hydrostatic transmissions and heavy-duty earthmoving equipment.

2. The Ultimate Power: SAE 100R15

When 350 Bar isn’t enough, you need the SAE 100R15. This is the crown jewel of high-pressure hydraulics.

- Construction: Similar to the R13, it uses four or six spiral layers.

- Pressure Performance: This hose is built for the most severe loads. It offers a constant working pressure of 420 Bar (6090 PSI) across typically used sizes like 3/8″, 1/2″, 3/4″, and 1″.

- Reliability: With a burst pressure of 1680 Bar (24,360 PSI), it provides a 4:1 safety factor, ensuring operator safety even during massive pressure spikes.

- Best For: Modern mining excavators, heavy logging machinery, and high-performance industrial presses.

3. The European Standard: EN856 4SH

The 4SH is a staple in the European market and widely used globally for high-pressure systems.

- Construction: Four layers of high-tensile steel wire spirals.

- Pressure Performance: It offers extremely high working pressures, reaching 420 Bar for the 3/4″ size and 250 Bar for the large 2″ size.

- Durability: The cover is specifically compounded to be abrasion, ozone, and weather-resistant, making it ideal for outdoor construction sites.

Safety First: Protecting Your Assembly

Upgrading the hose is step one. Protecting it is step two.

In high-pressure applications, a pinhole leak can act like a water jet cutter—it is incredibly dangerous. Furthermore, abrasion is the number one cause of hose failure. Kingdaflex recommends pairing your high-pressure spiral hoses with the following protection:

- Fire Sleeve: Made of braided fiberglass coated with silicone rubber, this sleeve protects hoses from extreme heat (up to 260°C continuous, 1300°C instant). It prevents hoses from melting or catching fire in engine compartments.

- Nylon Protective Sleeve: This is crucial for operator safety. It is designed to contain fluid in the event of a burst or pinhole leak, protecting people and the environment. It also offers excellent abrasion resistance.

- Plastic Spiral Guard: Made of PP (Polypropylene), this wraps around the hose to protect it from rubbing against metal arms or rocks. It significantly extends the service life of the hose assembly.

Conclusion: Don’t Let Pressure Burst Your Profits

The shift toward higher pressure in the industrial world is not slowing down. Sticking with older, lower-rated braided hoses in high-impulse applications is a recipe for downtime and danger.

Whether you need the constant 5000 PSI power of the SAE 100R13, the extreme 6000 PSI capability of the SAE 100R15, or the rugged reliability of the EN856 4SH, Kingdaflex has the manufacturing capability and raw material quality to keep your machinery moving.

We continuously improve our manufacturing systems to meet these evolving needs, ensuring that when you install a Kingdaflex hose, you are installing peace of mind.

Ready to upgrade your hydraulic systems? We warmly invite you to explore opportunities for collaboration. Contact us today for a quote or technical consultation.