Understanding the relationship between megapascals (MPa) and pounds per square inch (PSI) is crucial for anyone working with hydraulic systems. These units of pressure are fundamental in specifying and managing hydraulic system performance, ensuring safety and efficiency. This blog will demystify these measurements, explaining their significance and how to convert between them.

Whether you’re dealing with hydraulic hoses, pumps, or other components, knowing how to translate MPa to PSI and vice versa allows for accurate system design, maintenance, and troubleshooting. We’ll explore the conversion formulas and provide practical examples to help you navigate these pressure measurements with confidence, ensuring your hydraulic systems operate reliably.

What Is MPA

MPA, or Megapascal, is a unit of pressure within the metric system. It represents one million pascals (Pa) and is commonly used in high-pressure hydraulic systems to quantify the force exerted per unit area. This unit is particularly prevalent in regions that adhere to the International System of Units (SI).

In hydraulic applications, MPA is used to specify the pressure ratings of hoses, fittings, and other components. It provides a standardized measurement for engineers and technicians to ensure system compatibility and safety. For instance, a hydraulic hose rated at 200 MPA indicates it can withstand very high pressures, ensuring reliable performance in demanding industrial settings.

What Is PSI

PSI, or pounds per square inch, is a unit of pressure commonly used in the United States and other regions that adhere to the imperial system. It’s particularly prevalent in applications involving relatively lower pressures, such as tire inflation, compressed air systems, and certain hydraulic applications where the force exerted per square inch is within a manageable range.

In hydraulic systems, PSI is used to specify the pressure ratings of hydraulic hoses, hydraulic fittings, and other components, especially in applications that don’t require the extreme pressures measured by MPA. It provides a straightforward measurement for technicians and engineers, allowing them to ensure system compatibility and safety. For instance, a hydraulic system operating at 500 PSI indicates a moderate pressure level, suitable for many industrial tasks.

MPA to PSI

MPA (Megapascal) and PSI (pounds per square inch) are both units of pressure, but they are used in different measurement systems. MPA is part of the metric system, while PSI is part of the imperial system. To convert MPA to PSI, you multiply the MPA value by 145.038. This conversion is crucial in hydraulic systems where components may be rated in either unit, ensuring compatibility and safety.

Understanding this conversion is essential for engineers and technicians working with hydraulic systems. It allows for accurate comparisons and selections of hydraulic hoses, fittings, and other components, regardless of the measurement system used. Errors in conversion can lead to system failures, leaks, and even hazardous situations, highlighting the importance of precise calculations.

MPA to PSI Conversion Chart

| MPA | PSI (Approximate) |

|---|---|

| 1 | 145 |

| 5 | 725 |

| 10 | 1,450 |

| 20 | 2,900 |

| 50 | 7,250 |

| 100 | 14,500 |

| 200 | 29,000 |

| 300 | 43,500 |

| 400 | 58,000 |

| 500 | 72,500 |

MPA to PSI Converter

The MPA to PSI converter is a tool designed to easily translate pressure measurements from megapascals (MPA) to pounds per square inch (PSI), essential for applications where both metric and imperial units are used. By inputting an MPA value, the converter performs the necessary calculation, multiplying the MPA by 145.038, to provide the equivalent PSI pressure.

This simplifies the process of converting MPA to PSI pressure, ensuring accuracy and preventing errors in hydraulic and industrial settings where precise pressure measurements are critical.

MPA to PSI Converter

MPA to PSI Conversion Table

An MPA to PSI conversion table provides a quick reference for converting pressure measurements between megapascals (MPA) and pounds per square inch (PSI). This table typically lists common MPA values alongside their corresponding PSI equivalents, simplifying the process of converting between these two pressure units.

It is particularly useful in industries where both metric and imperial units are used, such as hydraulics, engineering, and manufacturing, ensuring accurate pressure readings and preventing errors in system design and operation.

| MPa | psi |

| 0 | 0 |

| 1 | 145.038 |

| 2 | 290.075 |

| 3 | 435.113 |

| 4 | 580.151 |

| 5 | 725.189 |

| 6 | 870.226 |

| 7 | 1015.26 |

| 8 | 1160.3 |

| 9 | 1305.34 |

| 10 | 1450.38 |

| 11 | 1595.42 |

| 12 | 1740.45 |

| 13 | 1885.49 |

| 14 | 2030.53 |

| 15 | 2175.57 |

| 16 | 2320.6 |

| 17 | 2465.64 |

| 18 | 2610.68 |

| 19 | 2755.72 |

| 20 | 2900.75 |

| 21 | 3045.79 |

| 22 | 3190.83 |

| 23 | 3335.87 |

| 24 | 3480.91 |

| 25 | 3625.94 |

| 26 | 3770.98 |

| 27 | 3916.02 |

| 28 | 4061.06 |

| 29 | 4206.09 |

| 30 | 4351.13 |

| 31 | 4496.17 |

| 32 | 4641.21 |

| 33 | 4786.25 |

| 34 | 4931.28 |

| 35 | 5076.32 |

| 36 | 5221.36 |

| 37 | 5366.4 |

| 38 | 5511.43 |

| 39 | 5656.47 |

| 40 | 5801.51 |

| 41 | 5946.55 |

| 42 | 6091.58 |

| 43 | 6236.62 |

| 44 | 6381.66 |

| 45 | 6526.7 |

| 46 | 6671.74 |

| 47 | 6816.77 |

| 48 | 6961.81 |

| 49 | 7106.85 |

| 50 | 7251.89 |

| 51 | 7396.92 |

| 52 | 7541.96 |

| 53 | 7687 |

| 54 | 7832.04 |

| 55 | 7977.08 |

| 56 | 8122.11 |

| 57 | 8267.15 |

| 58 | 8412.19 |

| 59 | 8557.23 |

| 60 | 8702.26 |

| 61 | 8847.3 |

| 62 | 8992.34 |

| 63 | 9137.38 |

| 64 | 9282.42 |

| 65 | 9427.45 |

| 66 | 9572.49 |

| 67 | 9717.53 |

| 68 | 9862.57 |

| 69 | 10007.6 |

| 70 | 10152.6 |

| 71 | 10297.7 |

| 72 | 10442.7 |

| 73 | 10587.8 |

| 74 | 10732.8 |

| 75 | 10877.8 |

| 76 | 11022.9 |

| 77 | 11167.9 |

| 78 | 11312.9 |

| 79 | 11458 |

| 80 | 11603 |

| 81 | 11748.1 |

| 82 | 11893.1 |

| 83 | 12038.1 |

| 84 | 12183.2 |

| 85 | 12328.2 |

| 86 | 12473.2 |

| 87 | 12618.3 |

| 88 | 12763.3 |

| 89 | 12908.4 |

| 90 | 13053.4 |

| 91 | 13198.4 |

| 92 | 13343.5 |

| 93 | 13488.5 |

| 94 | 13633.5 |

| 95 | 13778.6 |

| 96 | 13923.6 |

| 97 | 14068.7 |

| 98 | 14213.7 |

| 99 | 14358.7 |

| 100 | 14503.8 |

How to Identity Hydraulic Hose Pressure

Hydraulic hose pressure is critical for safe and efficient system operation. Identifying the correct pressure rating ensures hoses withstand operational demands without bursting. Accurate identification prevents equipment failure, reduces downtime, and improves system reliability.

Step 1: Check Hose Markings

Most hydraulic hoses have markings on the outer cover indicating pressure ratings. These markings include maximum working pressure, manufacturer details, and hose type. Inspecting them carefully allows quick identification of the hose’s capacity.

Hose markings are standardized to provide essential information for technicians. By reading these codes, you can determine the safe working limits and compatibility with your hydraulic system. Always cross-check with manufacturer documentation for accurate pressure verification.

Step 2: Consult Hydraulic Hose Manufacturer Specifications

Manufacturers provide detailed pressure specifications in product catalogs or datasheets. Checking these ensures that the hose selected matches the system’s requirements, avoiding mismatches that can lead to leaks or hose failure.

Specification sheets also include burst pressure, temperature limits, and compatible fluids. This information helps operators confirm the hose’s suitability for specific applications and ensures safe, long-term operation under expected pressure conditions.

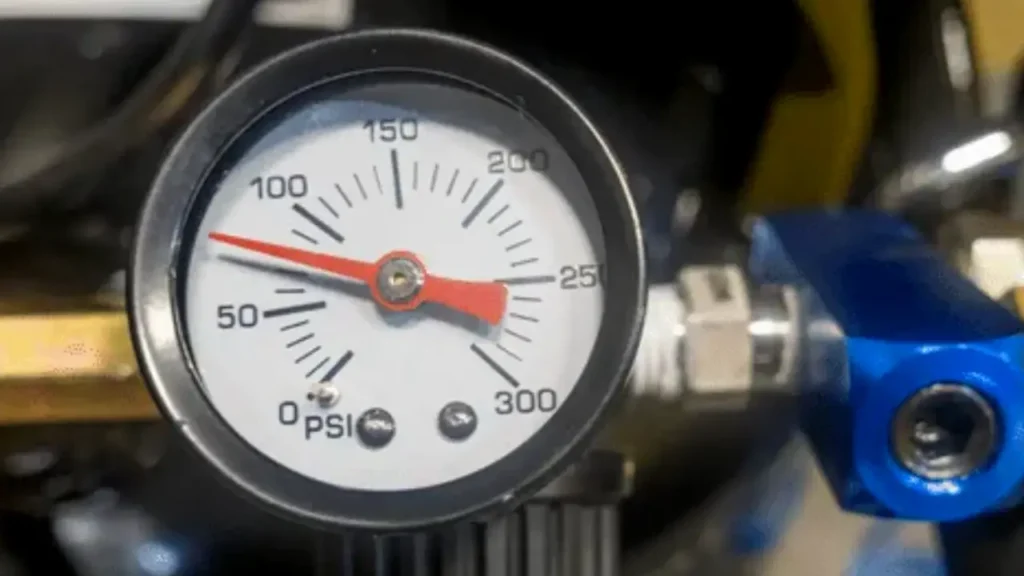

Step 3: Measure System Operating Pressure

Using pressure gauges or sensors, measure the hydraulic system’s operating pressure. Comparing it to the hose’s rated working pressure confirms whether the hose can handle current system conditions safely.

Regular monitoring of system pressure allows early detection of overpressure events or fluctuations. Measuring under normal operating conditions ensures accurate assessment, reducing the risk of hose rupture and protecting both equipment and personnel.

Step 4: Verify Hose Material and Construction

Different hose materials and reinforcement layers affect pressure capacity. Identify whether the hose uses wire braid, spiral, or textile reinforcement, as this determines its working and burst pressure capabilities.

Material compatibility with hydraulic fluid is also important. Selecting hoses with the correct construction ensures pressure resistance and longevity, preventing failures caused by pressure spikes, abrasion, or chemical degradation.

Conclusion

In conclusion, understanding the relationship between MPA and PSI is vital for ensuring the safety and efficiency of hydraulic systems. Accurate conversions prevent over-pressurization, which can lead to system failures and hazardous conditions. Proper pressure management extends the lifespan of hydraulic components and maintains optimal system performance.

Grasping these pressure units allows for precise selection of hydraulic hoses and fittings, ensuring compatibility and reliability. Regular monitoring and accurate conversions are crucial for preventing leaks and maintaining system integrity. A thorough understanding of MPA and PSI empowers informed decisions, enhancing system safety and productivity.

For a comprehensive selection of high-quality hydraulic hoses and expert guidance, choose Kingdaflex. We offer wholesale solutions with diverse sizes and pressure ratings to meet your specific project needs. Contact us today to explore our product offerings and ensure your hydraulic systems operate with maximum efficiency and safety.