When navigating the world of hydraulic hoses, you’ll inevitably encounter various specifications and acronyms. Among the most important is “DN.” Understanding what DN signifies is crucial for anyone involved in hydraulic systems, whether you’re selecting a replacement hose, designing a new system, or simply trying to comprehend technical datasheets.

This guide will demystify DN and explain its vital role, short for “Diameter Nominal,” is a standardized metric measurement that indicates the approximate internal diameter (ID) of a hydraulic hose. Unlike inches, which can sometimes refer to the hose’s outer diameter or a less precise measurement, DN provides a clear and consistent reference for the hose’s bore size. This standardization is key to ensuring proper flow rates and compatibility with fittings.

What is DN in Hydraulic Hose Sizes?

In hydraulic hose sizes, “DN” stands for Diameter Nominal, a standardized metric measurement that refers to the approximate internal diameter (ID) of the hose, expressed in millimeters. This designation is crucial for specifying the correct hose size for a given hydraulic system, as it directly influences the fluid’s flow rate and velocity.

- Metric Standard: DN is a metric-based system, providing a universal way to identify hose sizes, especially valuable in international contexts like in Qingdao, China, where metric units are standard.

- Internal Diameter: Crucially, DN refers to the internal bore of the hose, not its outer diameter. This is because the internal diameter dictates how much fluid can flow through the hose and at what speed.

- Flow Rate and Performance: Selecting the appropriate DN is essential for maintaining optimal flow rates, minimizing pressure drop, and preventing issues like overheating or cavitation within the hydraulic system.

How to Read Hydraulic Hose Numbers?

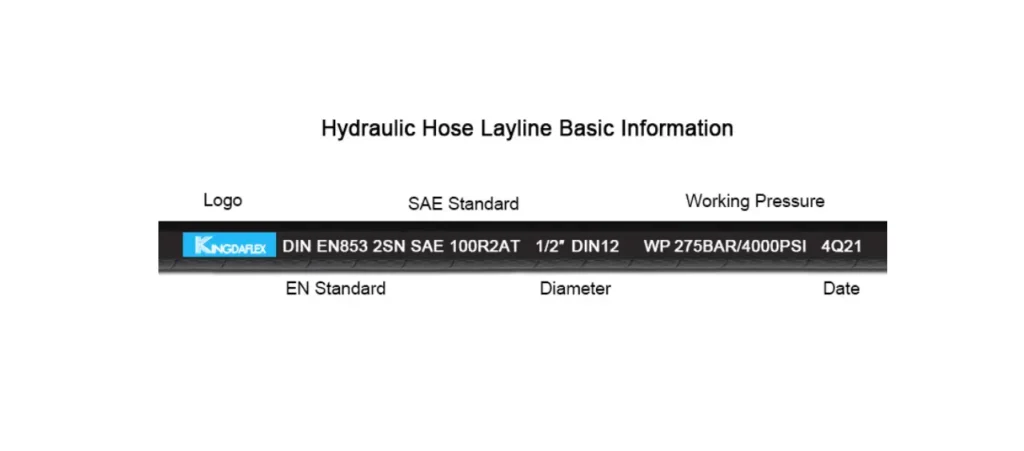

Understanding how to read hydraulic hose numbers is essential for proper system maintenance and design. These alphanumeric codes convey critical information about a hose’s size, material, pressure rating, and more. Deciphering them ensures you select the correct hose for optimal performance and safety.

Step 1: Identify the Hydraulic Hose Manufacturer and Series

The very first characters often indicate the hose manufacturer and the specific product series or family. This initial identification helps you reference the correct catalog or datasheet for detailed specifications. Knowing the series is crucial because it defines the hose’s core construction.

This initial hydraulic hose manufacturer and series code is your gateway to understanding the hose’s fundamental characteristics. Different manufacturers use unique systems, so familiarizing yourself with common industry codes or consulting a cross-reference guide is highly beneficial for accurate identification.

Step 2: Determine the Dash Size

Following the series information, you’ll typically find a “dash size,” which indicates the hose’s nominal inside diameter (ID) in sixteenths of an inch. For example, a “-08” dash size signifies a 8/16 inch, or 1/2 inch, internal diameter.

This dash size is a critical measurement for ensuring adequate fluid flow and preventing pressure drops within your hydraulic system. Selecting the correct ID is paramount for maintaining system efficiency and preventing damage due to insufficient or excessive fluid velocity.

Step 3: Understand the Pressure Rating

The hose number will also include a code or set of numbers indicating its maximum working pressure. This is often expressed in PSI (pounds per square inch) or Bar. It’s vital never to exceed this rating during operation to prevent hose rupture.

Adhering to the stated pressure rating is a fundamental safety measure in hydraulic systems. Over-pressurizing a hose can lead to catastrophic failure, causing injury, equipment damage, and significant downtime. Always select a hose with a pressure rating that exceeds your system’s maximum operating pressure.

Step 4: Recognize the Material and Construction

Other segments of the hose number might specify the hydraulic hose’s material composition (e.g., synthetic rubber, thermoplastic), the number of reinforcement layers (e.g., one-wire, two-wire braid), and the type of cover. This information indicates durability and application suitability.

The internal and external construction materials dictate the hose’s resistance to abrasion, chemicals, and environmental factors. Understanding these details helps you choose a hose that will withstand the specific conditions of your operating environment, extending its lifespan.

Step 5: Note the Length and End Connections

While not always directly part of the imprinted hose number itself, the overall length and the type of end connections (fittings) are crucial for ordering and installation. These are typically specified separately when purchasing.

The correct length prevents unnecessary bends and tension, while compatible end fittings ensure a secure, leak-free connection to your hydraulic components. Always confirm both length and fitting specifications carefully before installation to avoid costly errors.

How is a Hydraulic Hose Measured?

Accurately measuring a hydraulic hose is critical for ensuring proper fit, function, and system integrity. It’s not just about length; internal diameter and even fitting types play a vital role. Taking precise measurements prevents leaks, optimizes flow, and prolongs the lifespan of your hydraulic system.

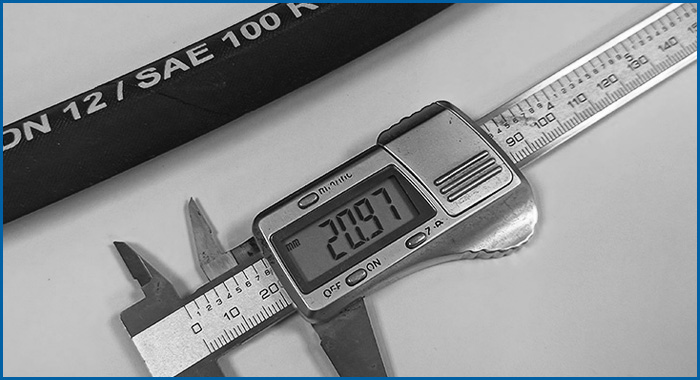

Step 1: Measure the Inner Diameter (ID)

The most crucial measurement for a hydraulic hose is its Inner Diameter (ID). This refers to the open space inside the hose through which the hydraulic fluid flows. Use a specialized ID gauge or the inside jaws of a caliper for an accurate reading.

The ID directly impacts the fluid’s flow rate and velocity. An undersized ID can lead to excessive pressure drop and heat generation, while an oversized ID might result in sluggish system performance. Always confirm the ID matches your system’s flow requirements.

Step 2: Determine the Dash Size

The measured Inner Diameter is often converted into a “dash size.” This is a standardized numbering system where each dash represents 1/16th of an inch. For instance, a 1/2-inch ID hose would be a -08 dash size (8/16ths of an inch).

Understanding dash sizes simplifies hose ordering and ensures consistency across different manufacturers. Many hydraulic hose specifications and fitting charts rely on this dash size system, making it an essential conversion for proper component matching.

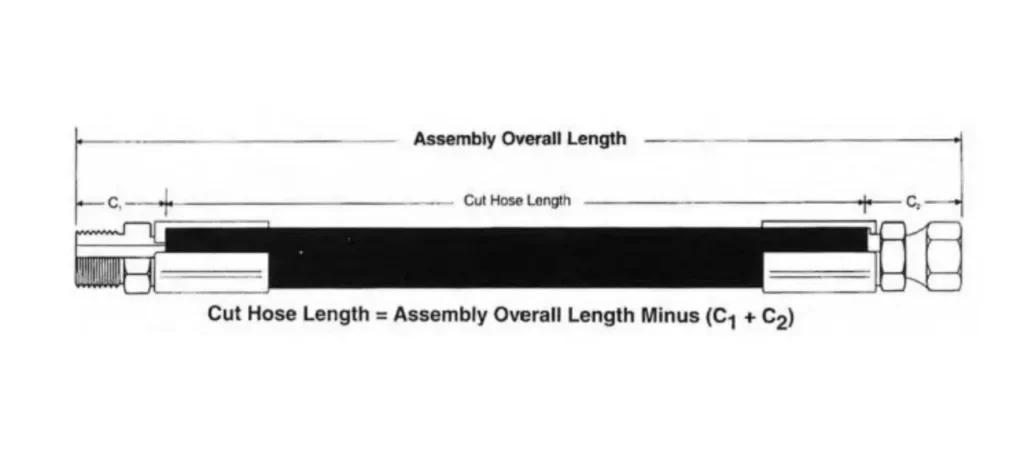

Step 3: Measure the Overall Length

The overall length of a hydraulic hose assembly includes the hose itself and its attached fittings. For hoses with straight fittings, measure from the sealing surface of one fitting to the sealing surface of the other.

For hoses with elbow fittings, measure to the centerline of the elbow. Accurate length measurement is crucial to avoid stretching or kinking the hose during installation, which can lead to premature failure and compromised system performance.

Step 4: Identify Fitting Types and Orientations

While not a “measurement” in the traditional sense, correctly identifying the type and orientation of the end fittings is paramount. This includes thread type (e.g., NPT, JIC, ORB), size, and whether it’s male or female, straight, or angled.

Mismatched fittings are a common cause of leaks and system malfunction. Always verify the fitting specifications, including any specific angles or orientations required, to ensure a perfect and secure connection to your hydraulic components.

Hydraulic Hose DN vs SN

When working with hydraulic hoses, understanding the various abbreviations and standards is crucial. Two common designations you might encounter are “DN” and “SN.” While both relate to hydraulic hose specifications, they describe different aspects of the hose’s characteristics. Knowing the distinction ensures you select the right hose for your application.

DN: Diameter Nominal

DN stands for “Diameter Nominal” and is a metric standard that specifies the approximate internal diameter (ID) of a hydraulic hose in millimeters. It provides a standardized way to denote the hose’s bore size, which is critical for determining fluid flow rates and velocities within the system.

This measurement is fundamental for fluid dynamics calculations and ensuring the hose can handle the required volume of hydraulic fluid without excessive pressure drop or turbulence. A larger DN indicates a larger internal bore, allowing for higher flow capacities.

SN: Steel Wire Braid Reinforcement (EN 853 Standard)

“SN” typically refers to a type of hydraulic hose construction under the EN 853 standard, specifically indicating the number of steel wire braids used as reinforcement. For example, “1SN” signifies one steel wire braid, while “2SN” denotes two steel wire braids.

This designation is directly related to the hose’s pressure rating and flexibility. Hoses with more reinforcement layers (e.g., 2SN) can withstand higher operating pressures but are generally less flexible than those with fewer layers (e.g., 1SN).

Primary Function

DN’s primary function is to define the hydraulic hose’s size in terms of internal flow capacity. It helps engineers and technicians select hoses that can adequately transport the required volume of hydraulic fluid without creating excessive resistance or pressure drops.

SN’s primary function is to describe the hydraulic hose’s construction and reinforcement level, which directly relates to its pressure-handling capability and flexibility characteristics. It informs the user about the hose’s structural integrity and suitability for high-pressure applications.

Measurement Unit

DN is always expressed in millimeters (mm), adhering to international metric standards. This makes it a globally recognized and consistent measurement for hose sizing, facilitating clear communication and component compatibility across different regions like Qingdao, China.

SN is not a measurement unit itself but rather a classification or designation within the EN 853 standard, indicating the number of steel wire reinforcement layers. It describes a feature of the hose’s construction rather than a quantifiable dimension.

Impact on Performance

DN directly impacts the flow rate, fluid velocity, and pressure drop within a hydraulic system. An incorrectly sized DN can lead to reduced system efficiency, overheating, and potential damage to components due to inadequate or excessive flow.

SN impacts the maximum working pressure and flexibility of the hose. A higher SN number (e.g., 2SN vs. 1SN) generally means a higher pressure rating but a larger minimum bend radius. This trade-off is crucial for application-specific hose selection.

Standards Association

DN is broadly associated with ISO (International Organization for Standardization) and EN (European Norm) standards for hydraulic hose sizing. It is a fundamental part of how hose dimensions are universally categorized.

SN is specifically associated with the EN 853 European Standard for hydraulic hoses. This standard outlines the specifications for steel wire reinforced hoses, including 1SN and 2SN types, detailing their construction, dimensions, and performance requirements.

Differences between Hydraulic Hose DN and SN:

| Feature | DN (Diameter Nominal) | SN (Steel Wire Braid Reinforcement) |

| What it describes | Approximate Internal Diameter (ID) | Type of hydraulic hose construction, specifically steel wire braids |

| Purpose | Determines fluid flow capacity and hose size | Defines pressure rating and flexibility |

| Measurement Unit | Millimeters (mm) | Classification/designation (e.g., 1SN, 2SN) |

| Primary Impact | Flow rate, fluid velocity, pressure drop | Max working pressure, bend radius |

| Associated Standard | ISO, EN standards for hose sizing | EN 853 standard |

SNK Hydraulic Hose

While “SN” generally refers to steel wire braided hydraulic hoses conforming to the EN 853 standard (e.g., 1SN for one braid, 2SN for two braids), the designation “SNK” is a more specific term often used by certain hydraulic hose manufacturers, such as Semperit (e.g., SEMPERPAC 1SNK, 2SNK) or STAUFF (e.g., STAUFFPAC 2 SNK).

These “K” versions typically signify a compact construction with a reduced bend radius while still meeting or exceeding the pressure requirements of their equivalent SN standard. This makes them ideal for applications where space is limited or tighter routing is necessary, offering higher pressure capabilities than standard hoses of similar reinforcement, but with enhanced flexibility.

- Compact Construction: SNK hoses are engineered for a smaller outside diameter compared to standard SN hoses with the same internal diameter and pressure rating.

- Reduced Bend Radius: This compact design allows SNK hoses to be bent more sharply without compromising performance or integrity, facilitating installation in confined spaces.

- Higher Pressure Rating (often): Despite their compact nature, SNK hoses often offer an equivalent or even higher working pressure than their standard SN counterparts due to optimized reinforcement layers.

- Manufacturer Specific: “SNK” is often a proprietary or series-specific designation by certain manufacturers, so specifications can vary slightly between brands.

- Application Focus: They are particularly suited for mobile hydraulics, construction equipment, and other machinery where space constraints and demanding routing are common challenges.

Conclusion

Grasping the concept of DN is fundamental for anyone working with hydraulic hoses. It’s not just an arbitrary number; it’s a critical specification that directly impacts flow rate, pressure capability, and the overall efficiency and safety of your hydraulic system. By correctly interpreting DN, you can ensure that your hydraulic hose perfectly matches the demands of your application, preventing costly errors, downtime, and potential system failures.

Accurate hose selection based on DN also contributes to the longevity of your hydraulic components. An undersized hose can lead to excessive heat buildup and pressure drops, while an oversized one might be unnecessarily expensive and unwieldy. Paying close attention to DN ensures optimal fluid velocity and minimizes energy loss, making your operations more efficient and sustainable in the long run.

For all your hydraulic hose needs, remember the importance of correct sizing and quality. At Kingdaflex, we offer a wide range of wholesale hydraulic hoses with clearly defined DN specifications, ensuring you find the perfect fit for any application. Don’t compromise on performance or safety; get wholesale hydraulic hoses from Kingdaflex and experience the difference that precise engineering makes.