Skiving hydraulic hoses is a critical step in preparing hoses for fittings and assemblies. Proper skiving ensures a secure connection, leak-free operation, and optimal performance in hydraulic systems. Understanding the techniques and tools required helps technicians achieve consistent results while maintaining hose integrity and system safety.

This guide explains the step-by-step process for skiving hydraulic hoses, including selecting the right tools, measuring accurately, and cutting precisely. By following these best practices, users can improve assembly efficiency, reduce leaks, and extend hose service life in industrial, automotive, construction, and agricultural hydraulic applications.

Why Skiving Hydraulic Hoses?

Skiving hydraulic hoses is a crucial process that prepares hoses for fittings, ensuring leak-free connections, secure assembly, and optimal hydraulic system performance. Proper skiving prevents damage and extends hose life.

- Ensures Proper Fitting Connection – Skiving removes the outer cover and reinforcement layers to expose the inner tube, allowing the fitting to seat correctly for a secure, leak-free connection.

- Prevents Leaks and System Failures – Properly skived hoses fit tightly with couplings, reducing the risk of fluid leaks, pressure loss, and hydraulic system failures during operation.

- Maintains Hose Integrity – Skiving with correct tools and technique prevents cutting too deep or unevenly, preserving the hose’s structural strength and ensuring long-term reliability.

- Improves Assembly Efficiency – Skived hoses allow faster, more consistent assembly, reducing installation time, minimizing errors, and maintaining high-quality standards for industrial, automotive, and construction applications.

- Extends Hose Service Life – By ensuring secure connections and preventing wear or leaks, skiving contributes to longer hose lifespan and improved performance in demanding hydraulic systems.

How to Skive Hydraulic Hoses?

Skiving hydraulic hoses is essential for preparing hoses to fit securely with couplings. Proper technique ensures leak-free connections, prevents damage, and maintains hydraulic system performance. Following these seven steps guarantees consistent, safe, and reliable hose assembly for industrial, automotive, and construction applications.

Step 1: Select the Right Hose and Fitting

Choosing the correct hose type and compatible fitting is crucial. Ensure the hose pressure rating and size match the application requirements for a secure, efficient hydraulic system. Proper selection minimizes potential leaks and system failure during operation.

Verify that the hose length allows for routing without excessive bending. Check the fitting type, material, and connection style. Matching hose and fitting specifications ensures a precise, safe assembly while reducing maintenance needs and optimizing system performance.

Step 2: Gather Tools and Equipment

Collect all necessary tools before starting, including a skiving knife, measuring device, calipers, and safety gloves. Proper tools ensure clean cuts and precise exposure of the inner tube, critical for secure fitting installation.

Tools Needed:

- Skiving knife or hose skiving tool

- Measuring tape or ruler

- Calipers for precise measurement

- Safety gloves and protective eyewear

- Marker or chalk for hose marking

- Clean workspace or cutting mat

Ensure the workspace is clean and well-lit. Organizing tools and safety equipment in advance reduces errors, improves workflow efficiency, and protects both the hose and the operator from potential damage or injury.

Step 3: Measure and Mark Hose

Measure the section of hose to be skived accurately. Mark the area where the outer cover and reinforcement layers will be removed, ensuring proper fitting depth and alignment. Accurate marking prevents over-skiving or misalignment.

Double-check measurements to confirm correct length and alignment. Clear, precise marks guide cutting, maintaining hose integrity and providing a professional, leak-free assembly suitable for high-pressure hydraulic applications.

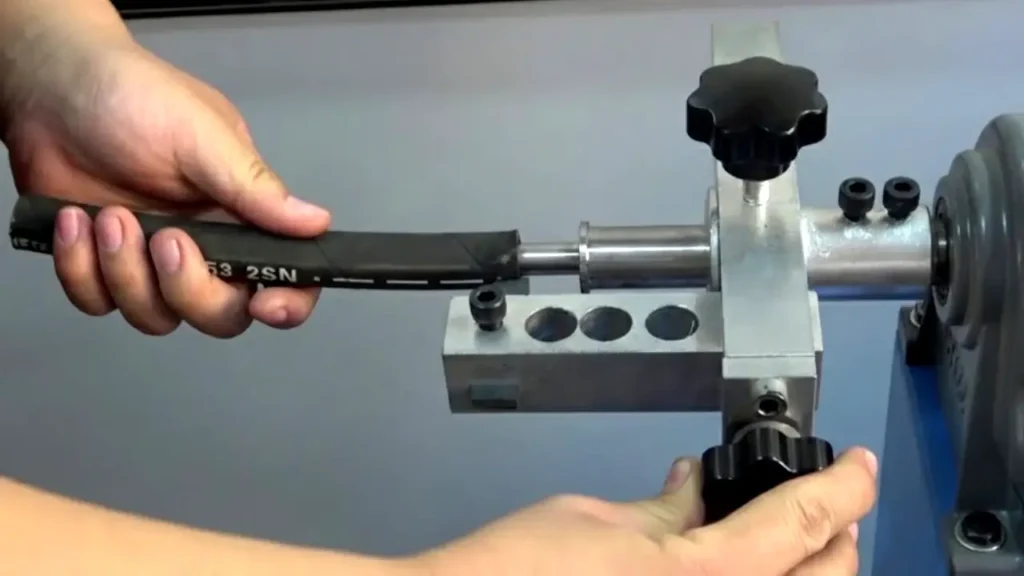

Step 4: Cut Outer Cover and Reinforcement

Use a skiving knife to carefully remove the outer cover and reinforcement layers. Avoid cutting too deep to prevent damage to the inner tube and maintain hose strength.

Work slowly and evenly around the hose circumference. Smooth, uniform removal ensures the fitting seats properly, prevents leaks, and guarantees that the hose can handle operational pressure without failure.

Step 5: Inspect the Skived Area

Check the skived section for smoothness, evenness, and any accidental cuts. The area should be clean and ready to accept the fitting, ensuring proper sealing and connection reliability.

Remove any debris or frayed material from the skived section. A clean, inspected surface prevents installation issues, leaks, and potential hose damage during assembly, providing long-term system reliability.

Step 6: Install the Fitting

Carefully insert the fitting into the skived hose end. Ensure proper alignment, full seating, and engagement with the inner tube. Proper installation prevents leaks and mechanical failures.

Rotate or twist slightly if needed to align the fitting. Confirm the fitting is secure and seated correctly, maintaining hose integrity and supporting high-pressure operation without compromising safety or performance.

Step 7: Test and Secure the Assembly

After installation, test the hose assembly under pressure to check for leaks or misalignment. Ensure clamps or supports secure the hose in place for safe operation.

Observe the assembly during initial operation. Confirm proper fluid flow, leak-free connections, and stability under system pressure, verifying that the skiving and installation process was successful and the hydraulic hose is ready for long-term use.

What Types of Hydraulic Hoses Need to Skive

Not all hydraulic hoses require skiving, but hoses designed for high-pressure fittings, reusable assemblies, or leak-sensitive applications typically do. Skiving prepares the hydraulic hose end for proper fitting installation, ensuring secure connections, leak prevention, and long-lasting performance in demanding industrial, automotive, and construction environments.

- High-Pressure Hydraulic Hoses (e.g., SAE 100R1, SAE 100R2) – Skiving exposes the inner tube to ensure fittings seat securely under extreme pressure conditions.

- Reusable Hydraulic Hoses – Hydraulic hoses designed for repeated fitting installation and removal require precise skiving for proper engagement.

- Thermoplastic Hydraulic Hoses (4SH Thermoplastic Hydraulic Hose) – Skiving removes outer layers, allowing fittings to properly attach without damaging the hydraulic hose material.

- Multi-Layer Reinforced Hydraulic Hoses (e.g., SAE 100R12, R13) – Hydraulic hoses with textile or wire reinforcement require skiving to expose the inner tube for secure fitting.

- Industrial and Automotive Hydraulic Hoses (general use hoses for machinery, construction, or vehicles) – Skiving ensures leak-free connections for critical applications where system reliability and safety are paramount.

Skive vs Non-skive Hydraulic Hose

Hydraulic hoses can be classified as skive or non-skive depending on whether the hose end is prepared for fitting installation. Skive hoses require the outer layers to be removed, while non-skive hoses allow fittings to attach without this step. Understanding the differences ensures correct assembly, safety, and system performance.

- Skive Hydraulic Hoses – These hoses require the outer cover and reinforcement layers to be carefully removed before fitting installation, allowing precise seating and leak-free connections for high-pressure and reusable applications.

- Non-Skive Hydraulic Hoses – Non-skive hoses feature specially designed fittings that attach without removing layers. They reduce assembly time, simplify installation, and maintain reliable performance under standard operating pressures, making them ideal for many general hydraulic systems.

- Advantages of Skive Hoses – Skive hoses allow for maximum fitting engagement and secure connections, making them suitable for high-pressure, leak-sensitive, and industrial-grade hydraulic applications requiring extended service life.

- Advantages of Non-Skive Hoses – Non-skive hoses offer quick installation, reduced labor, and consistent performance. They eliminate the need for specialized skiving tools, making them efficient for field or workshop assembly with moderate-pressure systems.

Tips for Skiving Hydraulic Hoses

Skiving hydraulic hoses requires precision, the right tools, and careful attention to detail to ensure leak-free fittings and long-lasting performance. Following best practices reduces errors, prevents hose damage, and improves overall hydraulic system reliability.

- Use Proper Tools – Always use a dedicated skiving knife or hose skiving tool. Proper tools ensure clean cuts, preserve the inner tube, and prevent accidental damage during the skiving process.

- Measure Accurately – Mark the hydraulic hose precisely before skiving. Accurate measurement ensures correct fitting engagement, prevents over-skiving, and maintains the hose’s structural integrity and long-term performance.

- Work Slowly and Evenly – Remove the outer layers gradually and uniformly. Controlled, even skiving prevents cutting too deep, reduces fraying, and ensures a smooth surface for proper fitting installation.

- Inspect the Skived End – After skiving, check the hydraulic hose end for smoothness and any accidental damage. A clean, inspected surface ensures reliable seating and leak-free operation of the hose assembly.

- Maintain a Clean Workspace – Keep the work area free from debris and contaminants. A clean environment prevents dirt from entering the hydraulic hose, ensuring proper fitting installation and long-lasting system performance.

Conclusion

Proper skiving of hydraulic hoses is essential for creating secure, reliable assemblies. Following correct techniques ensures hoses fit fittings precisely, preventing leaks and mechanical failures. Consistent skiving practices enhance system efficiency, reduce maintenance costs, and improve safety across industrial, automotive, and construction hydraulic operations.

Using the right tools and careful preparation during skiving minimizes hose damage and ensures long-term performance. Measuring accurately, cutting evenly, and inspecting skived ends help maintain hose integrity. These steps reduce the risk of downtime, increase reliability, and provide smooth fluid transfer in high-pressure hydraulic systems.

At Kingdaflex, we provide wholesale hydraulic hoses suitable for precise skiving and assembly. Our hoses deliver durability, pressure resistance, and reliable performance across various applications. Partner with Kingdaflex today to get hydraulic hoses tailored for industrial, automotive, construction, and agricultural hydraulic systems at competitive wholesale prices.