At some point in time, every sandblasting machine owner or operator will have to replace their sandblast hose. It could be due to wear and tear or accidental damage.

Whatever the reason may be, it is essential to replace the sandblast hose as soon as possible to avoid any safety hazards and ensure the optimal performance of the sandblasting machine

In this guide, we will take you through the step-by-step process of replacing a sandblast hose, from identifying the problem to sourcing the right hose, and finally, installation.

When to Replace Sandblast Hose?

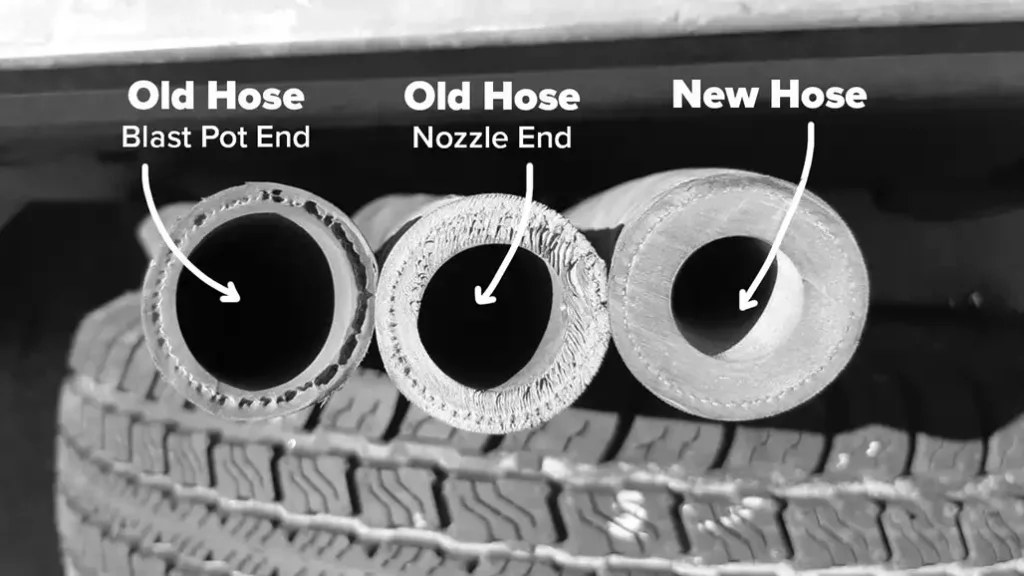

Sandblast hose should be replaced when it shows signs of wear and tear, punctures, or bursts. It is important to regularly inspect the sandblaster hose for any damage, especially at the ends where it connects to the sandblasting machine’s nozzle and compressor.

A leak or a puncture may not be noticeable at first glance but can pose a safety hazard if left unattended. A bursting hose is more visible and easier to identify, but it should be replaced immediately to avoid any potential injury or damage to the sandblasting machine.

In general, it is recommended to replace the sandblast hose every two years, even if there are no visible signs of wear and tear. This is to ensure the optimal performance and safety of the sandblasting machine.

Related: Why Your Hydraulic Hose Is Broken? Here Are Some Common Hydraulic Hose Damage Reasons

How to Replace Sandblast Hose?

Step 1: Identify the Problem

Before replacing the sandblast hose, you need to determine why you need to replace it. You could have a leak, a puncture, or a burst hose. A leak or a puncture can be caused by wear and tear, and it is not easy to notice at first glance. However, a burst hose is easier to identify as it will be visibly damaged and could pose a safety hazard.

Step 2: Choose the Right Sandblast Hose

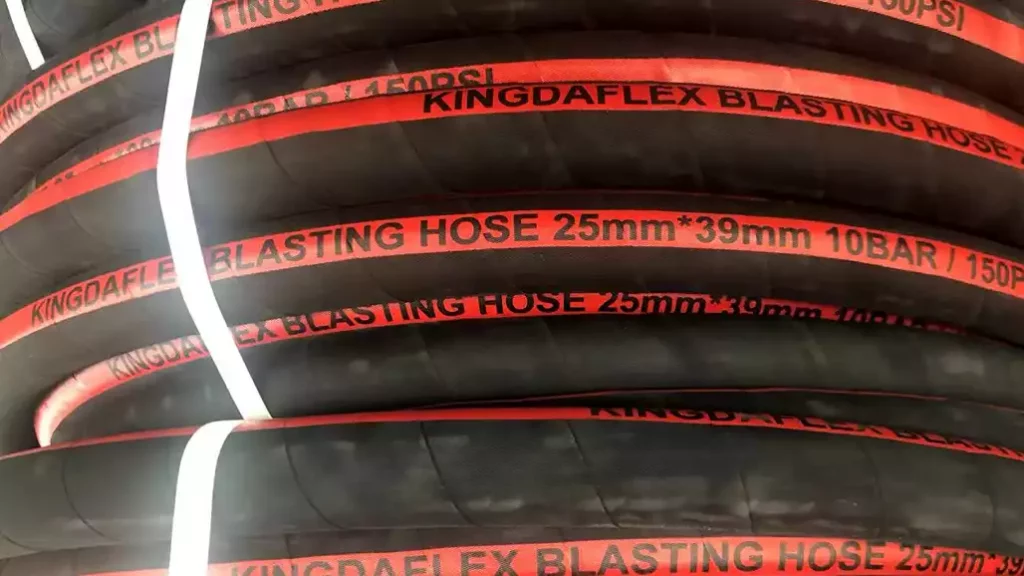

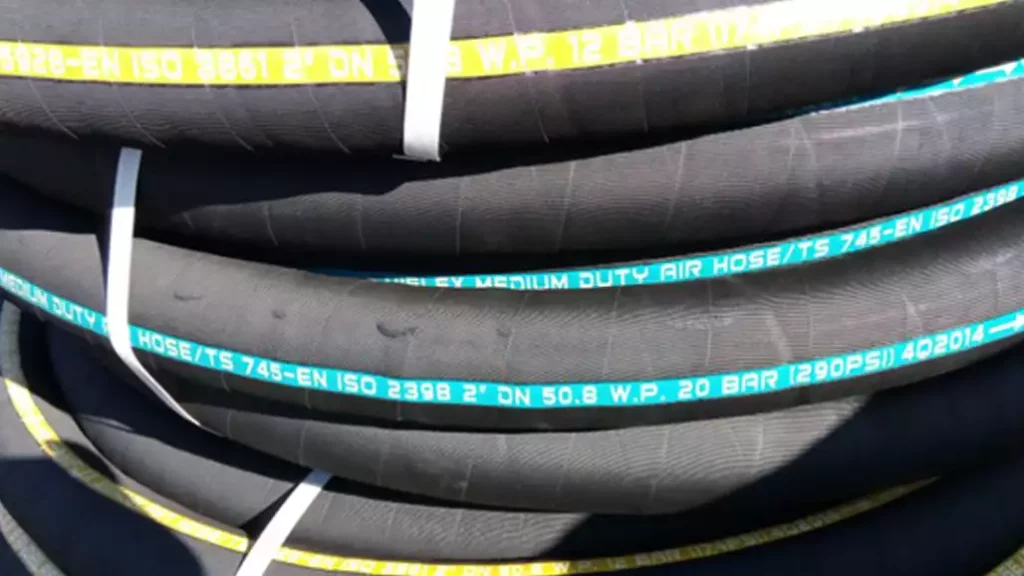

Once you have identified the problem before sandblast hose replacement, the next step is to choose the right sandblast hose. The type of hose you need will depend on the type of sandblasting machine you have and the type of abrasive material you use. There are various types of sandblast hoses available in the market, including rubber, PVC, and polyurethane hoses.

When choosing the right hose, consider the following factors:

- The size of the hose: Choose a hose that fits your sandblasting machine’s nozzle and compressor.

- The type of abrasive material: Different types of abrasive materials require different types of hoses. For example, if you use a steel shot, you need a hose with a high abrasion resistance.

- The working pressure: Choose a hose with a working pressure that matches your sandblasting machine’s pressure.

Step 3: Remove the Old Sandblast Hose

Before installing the new hose, you need to remove the old one. First, turn off the compressor and release any pressure in the sandblasting machine. Then, use a wrench or pliers to loosen the hose coupling and remove the hose from the nozzle and the compressor.

Step 4: Install the New Sandblast Hose

Once you have removed the old hose, it is time to install the new one. Here are the steps to follow:

- Attach the hose coupling to the sandblasting machine’s nozzle and the compressor. Use a wrench or pliers to tighten the coupling.

- Connect the hose to the coupling. Make sure that the hose is straight and aligned with the coupling.

- Turn on the compressor and test the new hose for any leaks or abnormal sounds.

Step 5: Maintenance Sandblast Hose

After replacing the sandblast hose, it is essential to maintain it regularly to prolong its lifespan and ensure that it performs optimally. Here are some tips for maintaining your sandblast hose:

- Inspect the hose regularly for any signs of wear and tear.

- Keep the hose clean and dry when not in use.

- Store the hose properly in a cool and dry place.

- Replace the hose immediately if you notice any signs of damage or wear.

How to Extend Blast Hose Service Life?

To extend the service life of a blast hose, there are several steps you can take:

- Choose the right hose material: Select a blast hose material that is durable and resistant to abrasion, cuts, and punctures. Common materials include natural rubber, synthetic rubber, and polyurethane.

- Proper storage: Store the blast hose in a cool, dry place away from direct sunlight and moisture. Avoid folding or crimping the hose as this can cause stress points that can lead to premature wear and tear.

- Regular inspection: Inspect the blast hose regularly for signs of wear and tear. Look for cracks, cuts, punctures, or any other damage that may compromise the integrity of the hose. Replace the hose immediately if you notice any signs of damage.

- Proper use: Use the blast hose as intended and avoid overstretching or bending it beyond its recommended limits. Follow the manufacturer’s recommendations for pressure, flow rate, and nozzle size to prevent excessive wear and tear.

- Maintain cleanliness: Keep the blast hose clean by flushing it with water after each use to remove any abrasive particles or debris. This will help prevent clogs and ensure that the hose maintains its flexibility and strength.

By following these steps, you can extend the service life of your blast hose, which can save you money in the long run by reducing the need for frequent replacements.

Related: Extending the Life of Your Hydraulic Hoses: Strategies and Solutions

Conclusion

In conclusion, replacing a sandblast hose is a simple process that requires a bit of knowledge and the right tools. It is essential to choose the right hose, remove the old hose carefully, install the new hose correctly, and maintain it regularly to prolong its lifespan and ensure optimal performance.

At Kingdaflex, we provide a wide range of sandblast hoses that are designed to meet your specific needs. Our hoses are durable, flexible, and designed to handle the toughest abrasive materials. Contact us today to learn more about our products and services.

Related: