Hydraulic hoses are the arteries of machinery, transmitting fluid power that drives critical operations. Proper care and maintenance are essential to prevent leaks, ruptures, and downtime. Understanding the factors that affect hose longevity can save costs, improve efficiency, and ensure the reliability of your hydraulic systems.

Extending hydraulic hose life requires a combination of correct installation, routine inspection, and protective measures. By identifying wear patterns, maintaining proper pressure, and choosing high-quality hoses, you can reduce unexpected failures. Implementing practical strategies ensures your equipment performs optimally while maximizing the return on your investment in hydraulic components.

How to Extend Hydraulic Hose Life?

Extending the life of hydraulic hoses is essential for minimizing downtime and reducing maintenance costs. Proper handling, installation, and care significantly increase hose longevity. By implementing proven strategies, you can ensure safety, reliability, and optimal performance across all hydraulic systems, avoiding costly replacements.

- Proper Installation: Correctly routing and securing hoses prevents kinks, twists, and excessive bending. Ensure fittings are tight and compatible, avoiding strain on connection points. Proper installation reduces stress on the hose, prevents leaks, and improves fluid flow, ultimately extending the service life of your hydraulic components.

- Regular Inspection: Routine checks help identify wear, abrasion, or leaks before they escalate. Look for bulges, cracks, or fraying along the hose. Scheduled inspections allow timely replacements, preventing system failures, reducing downtime, and maintaining the overall efficiency and safety of your hydraulic machinery.

- Use of Protective Measures: Hydraulic hose sleeves, guards, and clamps shield hoses from external damage and environmental hazards. Protection against heat, chemicals, and sharp edges minimizes abrasion and degradation. These preventive measures safeguard your hoses, ensuring longer operational life and consistent hydraulic system performance.

- Maintain Proper Pressure and Temperature: Operating within recommended pressure and temperature ranges prevents excessive stress and hose fatigue. Avoid sudden spikes or extreme conditions that can weaken hose integrity. Maintaining stable conditions helps retain flexibility, prevents bursting, and ensures efficient, safe hydraulic operation.

- Clean Fluids and Systems: Contaminated hydraulic fluids accelerate internal hose wear and system damage. Regular fluid checks and filtration remove particles and debris. Clean systems reduce the risk of abrasion, corrosion, and blockages, prolonging hose life and enhancing the overall reliability of your hydraulic machinery.

Proper Hydraulic Hose Installation and Routing

Correct installation of hydraulic hoses is crucial for system safety, efficiency, and longevity. Improper routing or connection can lead to leaks, premature wear, or sudden failures. Following best practices ensures smooth fluid flow, minimizes stress on hoses, and maximizes performance across all hydraulic applications.

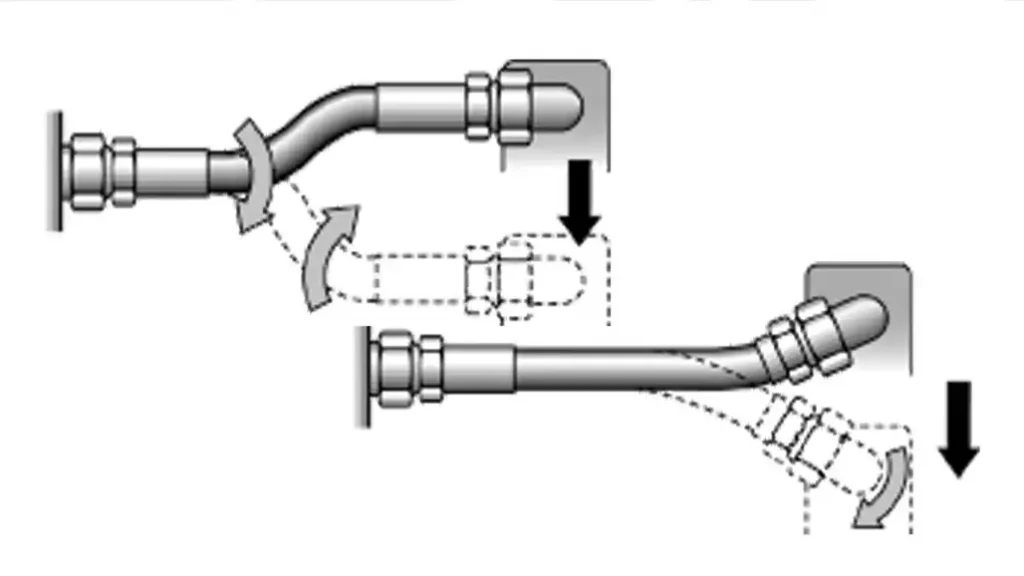

- Correct Hose Routing: Ensure hoses follow smooth, curved paths without sharp bends or twists, avoiding contact with moving parts, edges, or hot surfaces, which prevents kinking, chafing, and mechanical damage, extending hose life and maintaining consistent hydraulic performance.

- Secure Fittings and Connections: Tighten all fittings according to manufacturer specifications without over-torquing, verify compatibility of hose ends and connectors to prevent leaks, maintaining system integrity and reducing the risk of fluid loss, pressure drops, and sudden hose failures.

- Allow for Movement and Flexibility: Hoses should have enough slack to accommodate vibration, expansion, or motion of machinery, avoiding stretching or forcing hoses into position, which prevents stress points, minimizes fatigue, and ensures reliable performance under dynamic conditions.

- Use Protective Sleeves or Guards: Install abrasion-resistant sleeves, clamps, or guards where hoses may contact surfaces or face environmental hazards, reducing wear, cuts, and chemical exposure, safeguarding the hose and preventing premature failures while enhancing system efficiency.

- Follow Manufacturer Guidelines: Always adhere to hose specifications, pressure ratings, and installation instructions, avoiding usage outside recommended limits that can cause leaks or ruptures, ensuring optimal system performance and prolonging the service life of hydraulic components.

Hydraulic Hose Protector

Protective covers, such as polyethylene spiral wrap, spiral hydraulic hose protector, and fire sleeve, can be used to extend the life of hydraulic hoses by shielding them from external damage. Abrasion is one of the most common causes of hydraulic hose failure, and it can occur when hoses rub against each other or surrounding surfaces.

By using protective covers, it is possible to reduce the risk of abrasion and prevent damage to the hose. The spiral wrap acts as a barrier, protecting the hose from contact with other components and external surfaces.

In addition to preventing abrasion, protective covers can also offer other benefits such as reducing the risk of kinking, crushing, and impact damage. They are also relatively inexpensive and easy to install, making them a cost-effective solution for extending the life of hydraulic hoses.

Regular Hydraulic Hose Maintenance

A hydraulic hose is an important component of hydraulic systems, as it carries the fluid used to transmit power. Regular maintenance of hydraulic hoses is essential to ensure their longevity and to prevent unexpected failures. Here are some of the key steps involved in maintaining hydraulic hoses:

- Inspection: Regularly inspect the hoses for signs of damage, such as cracks, cuts, bulges, or leaks. If any of these are found, the hose should be replaced immediately.

- Cleaning: Keep the hoses clean and free of dirt and debris. Dirt and debris can cause abrasion, which can lead to premature failure of the hose.

- Routing: Ensure that the hoses are properly routed, with adequate support to prevent kinking or twisting. Hoses that are not properly supported can experience excessive wear and tear.

- Tightening: Check the fittings and connections for proper tightness. Loose connections can result in leaks and loss of hydraulic fluid.

- Flushing: Flush the hydraulic system periodically to remove any contaminants that may have accumulated over time.

- Replacing of hydraulic hose: Replace hoses that are showing signs of wear and tear, or that have been in service for a long period of time.

Use High-Quality Hydraulic Hose

Using high-quality hydraulic hoses is important for several reasons:

- Durability: High-quality hydraulic hoses are made from durable materials and are designed to withstand the pressure, temperature, and fluid compatibility requirements of the hydraulic system. This helps to extend the life of the hose and reduce the risk of failure.

- Leak resistance: High-quality hydraulic hoses are less likely to leak, which can reduce the risk of contamination of the hydraulic fluid and prevent system failures.

- Improved performance: High-quality hydraulic hoses have better flow characteristics and are less likely to kink or deform, which can result in improved system performance.

- Cost savings: While high-quality hydraulic hoses may have a higher upfront cost, they can ultimately result in cost savings by reducing the need for frequent replacements and avoiding costly system failures.

Kingdaflex offers a qualified hydraulic hose, as a leading hydraulic hose manufacturer in China, each hydraulic hose will be inspected strictly to ensure all things are best before loading to the container.

Proper Application

Choosing the proper hydraulic hose for your application is crucial to ensure the safety, reliability, and efficiency of your hydraulic system.

Here are some factors to consider when selecting a hydraulic hose:

Pressure rating:

The hydraulic hose must be rated for the maximum operating pressure of the system. This information can be found in the manufacturer’s specifications or by consulting with a hydraulic hose expert.

Temperature:

The hydraulic hose must be able to handle the temperature range of the fluid and the environment in which it will be used. Some hoses are designed to handle high temperatures, while others are designed for low temperature applications.

Fluid compatibility:

The hydraulic hose must be compatible with the type of fluid used in the system. Different types of fluid can have different chemical properties that can affect the hose material, so it is important to choose a hose that is compatible with the fluid in use.

Size:

The size of the hydraulic hose must match the size of the fittings and components in the system. This will ensure a proper fit and prevent leaks.

Bend radius:

The hydraulic hose bend radius of the hydraulic hose must be taken into consideration, as hoses with a tight bend radius can be more prone to kinking and collapse.

By considering these factors, you can select the proper hydraulic hose for your application and ensure the longevity, safety, and efficiency of your hydraulic system.

Conclusion

Extending the life of hydraulic hoses is both a practical and economical strategy. By adopting proper installation techniques, regular inspections, and using high-quality hoses, you minimize equipment downtime and maintenance costs. Proactive care ensures your hydraulic system operates safely and efficiently over the long term.

Protective measures, such as using hose guards, avoiding sharp bends, and maintaining clean fluids, play a crucial role in hose longevity. These strategies prevent premature wear, reduce leak risks, and enhance overall system performance. Consistent attention to these details can dramatically increase the service life of your hydraulic hoses.

For businesses looking for reliable, durable hydraulic hoses, Kingdaflex offers high-quality wholesale solutions. Our hoses are designed to withstand demanding industrial applications, ensuring safety, efficiency, and long-term performance. Trust Kingdaflex to supply the components that keep your machinery running smoothly.