If you work with hydraulic systems, you’re likely familiar with the crucial role that hydraulic hoses play in transmitting power and fluid between components.

These hoses endure a significant amount of pressure and must withstand various environmental conditions. However, like any mechanical component, hydraulic hoses have a limited lifespan.

In this blog post, we will explore the factors that influence the lifespan of hydraulic hoses and provide you with insights on how to maximize their longevity.

Hydraulic Hose Lifespan

The lifespan of a hydraulic hose is influenced by a complex interplay of factors, making it difficult to give a precise number of years.

The life expectancy of a hydraulic hose is a variable influenced by several key factors. Understanding these allows for better maintenance and preventative measures. Primarily, a hydraulic hose’s lifespan is affected by:

- Operating Pressure: Exceeding the hose’s rated pressure significantly shortens its lifespan.

- Temperature: Extreme temperatures, both high and low, can degrade hose materials.

- Fluid Compatibility: Using incompatible fluids can cause internal damage and premature failure.

- Environmental Conditions: Exposure to UV radiation, ozone, chemicals, and abrasion accelerates wear.

- Installation and Routing: Improper installation, including kinking or twisting, causes stress and reduces longevity.

- Maintenance: Regular inspections and preventative maintenance extend the hose’s service life

- Temperature Fluctuations: Extreme heat or cold can degrade the hose’s material, leading to cracks and brittleness.

- Physical Stress: Kinking, twisting, and abrasion from improper routing or installation significantly reduce hose life.

- Pulse frequency: High pulse frequency can rapidly fatigue the hose.

Therefore, extending a hydraulic hose’s life involves proactive steps. Regular inspections for signs of damage, proper installation techniques, and adherence to the hose’s operating parameters are crucial. Additionally, selecting hoses made from materials suitable for the intended application and environment is essential for maximizing their lifespan and ensuring safe operation.

How Long Do Hydraulic Hoses Last?

The longevity of hydraulic hoses can vary, influenced by several factors such as the hydraulic hose types, operating conditions, and maintenance frequency. Under normal circumstances, hydraulic hoses tend to endure for about 5 to 10 years on average.

Nevertheless, their lifespan can be curtailed by factors, like exposure to elevated temperatures, abrasion, and contact with chemicals. With time, hydraulic hoses deteriorate due to a range of causes, including:

- Aging: As hoses grow older, they lose flexibility and become more susceptible to cracking or rupturing.

- Wear and Tear: Hoses can degrade due to exposure to harsh surroundings, abrasive materials, and repetitive bending.

- Contamination: The inner lining of the hose can suffer damage from dirt, debris, and other contaminants, leading to leaks or failure.

- Improper Installation: Hoses that are not correctly installed may experience premature failure, often due to kinks, twists, or excessive bending. How to Install Hydraulic Hose? [Hydraulic Hose Installation Tips]

- Overpressure: Exceeding the recommended maximum pressure can result in the hose bursting or rupturing.

To avert equipment downtime, costly repairs, and potential safety risks, it is crucial to conduct regular inspections and replace hydraulic hoses as needed. Effective maintenance and proper handling practices are essential for prolonging the life of hydraulic hoses and ensuring they deliver peak performance.

Factors Affecting Hydraulic Hose

Quality of Materials

The quality of materials used in manufacturing hydraulic hoses greatly impacts their lifespan. High-quality hoses made from durable materials, such as synthetic rubber or thermoplastic, tend to last longer than those made from lower-grade materials. When purchasing hydraulic hoses, opt for reputable manufacturers known for their quality products.

Operating Conditions

The operating conditions in which hydraulic hoses are used can significantly affect their lifespan. Factors such as temperature extremes, exposure to chemicals, abrasion, and pressure fluctuations can cause wear and tear on hoses. Regularly inspect hoses for signs of damage and promptly replace them if necessary.

Maintenance and Inspection

Proper maintenance and regular inspections are essential for prolonging the lifespan of hydraulic hoses. Implement a routine maintenance schedule that includes inspections for leaks, signs of deterioration, and damaged fittings. Regularly clean the hoses to remove dirt and debris that could cause abrasion or clog the system.

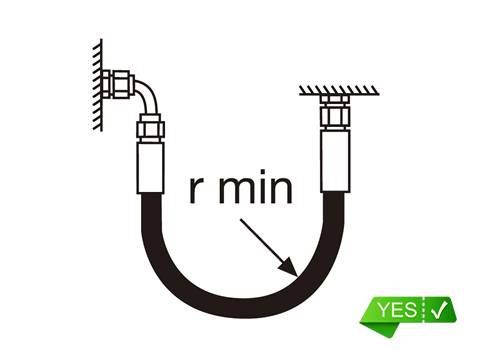

Flexibility and Bend Radius

Hydraulic hoses are designed to flex and bend to accommodate the movement of the hydraulic system. However, excessive bending, especially below the recommended bend radius, can lead to premature hydraulic hose failure. Always adhere to the manufacturer’s guidelines regarding the minimum bend radius and avoid over-stressing the hoses.

Installation Practices

Correct hydraulic hose installation procedures play a vital role in ensuring the longevity of hydraulic hoses. Improper installation, such as using incorrect fittings, overtightening connections, or inadequate support, can cause stress and damage to the hoses. Follow the manufacturer’s instructions carefully, and consult professionals if needed.

Usage Frequency

The frequency of use also affects the lifespan of hydraulic hoses. Hoses that are frequently exposed to high-pressure conditions and undergo constant cycles of pressure changes are more prone to wear and fatigue. Regularly monitor and replace hoses that are subjected to heavy use.

Hydraulic Hose Life Expectancy

What is the life expectancy of a hydraulic hose?

The lifespan of a hydraulic hose can vary significantly depending on several factors. While the average lifespan is often quoted as 5-10 years, this can be influenced by:

Operating Conditions:

- Temperature: Extreme temperatures, both hot and cold, can accelerate the degradation of the hose material.

- Pressure: High pressure can cause stress on the hose, leading to premature wear and tear.

- Abrasion: Contact with abrasive materials can cause the hose to wear down or develop cuts.

- Chemicals: Exposure to certain chemicals can weaken the hose material over time.

- Vibration: Constant vibration can cause fatigue and cracking in the hose.

Hose Construction:

- Material: The specific materials used in the hose construction, such as rubber or synthetic materials, can affect its durability.

- Reinforcement: The type and quality of reinforcement within the hose, such as steel wire or braided fabric, can influence its strength and resistance to wear.

Maintenance:

- Regular Inspections: Visual inspections should be conducted periodically to identify signs of wear, such as cracks, bulges, or leaks.

- Proper Installation: Incorrect installation techniques can shorten the hose’s lifespan.

- Storage: When not in use, hoses should be stored in a cool, dry place to prevent degradation.

Recommendations for Extending Hose Life:

- Follow Manufacturer Guidelines: Adhere to the manufacturer‘s recommendations for operating conditions, pressure limits, and maintenance.

- Use High-Quality Hoses: Invest in hoses from reputable manufacturers that meet or exceed industry standards.

- Avoid Overheating: Take steps to prevent the hose from overheating, such as using heat shields or routing it away from hot components.

- Proper Lubrication: Use the recommended lubricants to maintain hose flexibility and prevent premature wear.

By understanding these factors and implementing appropriate maintenance practices, you can significantly extend the life of your hydraulic hoses and reduce the risk of costly failures.

Would you like to know more about specific types of hydraulic hoses or maintenance techniques?

Hydraulic Hose Life Calculator

Unfortunately, there isn’t a straightforward, universal hydraulic hose life calculator. The lifespan of a hose depends on numerous factors, as discussed in our previous response. These factors can include:

- Operating conditions: Temperature, pressure, abrasion, chemicals, vibration

- Hose construction: Material, reinforcement

- Maintenance: Inspections, installation, storage

To accurately estimate the lifespan of a specific hose, a combination of factors and expert judgment is often required. This might involve:

- Collecting data: Gathering information about the hose’s operating conditions, including temperature ranges, pressure fluctuations, and exposure to chemicals.

- Consulting manufacturer specifications: Referring to the manufacturer‘s guidelines for the specific hose type to determine its expected lifespan under ideal conditions.

- Considering maintenance practices: Assessing the frequency and quality of inspections, the effectiveness of lubrication, and the overall care of the hose.

- Using predictive maintenance techniques: Employing methods like vibration analysis or infrared thermography to monitor the hose’s condition and identify potential problems early.

While there may be software tools or online resources that can provide estimates based on certain parameters, these should be used as general guidelines rather than definitive predictions.

For a more accurate and reliable assessment, it’s often recommended to consult with a hydraulic hose specialist or engineer. They can evaluate your specific application, consider the relevant factors, and provide a more informed estimate of the hose’s expected lifespan.

Would you like to discuss a specific hydraulic hose application or explore some of the factors that influence hose life in more detail?

When Should a Hydraulic Hose Be Replaced

A hydraulic hose should be replaced when it shows signs of wear or degradation. These signs might include:

- Cracks or bulges are indications of internal damage that can lead to leaks or failure.

- Leaks: Any hydraulic fluid leakage is a sign of a problem and should be addressed promptly.

- Cuts or abrasions: These can weaken the hose and increase the risk of failure.

- Excessive wear or fraying: Over time, hoses can become worn or frayed, especially at the fittings.

- Age: Even if a hose appears to be in good condition, it may have reached the end of its expected lifespan.

It’s also important to follow the manufacturer‘s recommended replacement intervals. These intervals may vary depending on the specific hose type, operating conditions, and maintenance practices.

Regular inspections and preventive maintenance can help identify potential problems early and prevent catastrophic failures. By replacing hoses before they fail, you can avoid costly downtime, equipment damage, and potential safety hazards.

Would you like to know more about specific types of hydraulic hoses or maintenance practices?

How to Extend Hydraulic Hose Shelf Life

Extending the shelf life of hydraulic hoses is crucial for minimizing waste and ensuring their readiness for use. Proper storage and handling are key to preventing degradation and maintaining their integrity.

- Temperature Control:

- Store hoses in a cool, dry environment, ideally between 40°F and 80°F (4°C and 27°C).

- Avoid exposure to direct sunlight and extreme temperature fluctuations.

- Humidity Control:

- Maintain low humidity levels to prevent moisture from degrading the hose materials.

- Store hoses away from sources of moisture or condensation.

- Protection from Ozone and UV:

- Store hoses in a dark, well-ventilated area to minimize exposure to ozone and UV radiation, which can cause cracking and hardening.

- Consider using opaque packaging or storage containers.

Furthermore, proper handling and storage techniques are vital. Avoid kinking, twisting, or compressing hoses, as this can cause permanent damage. Store hoses in a relaxed, coiled state, and use appropriate racks or shelves to prevent them from resting on sharp edges or abrasive surfaces.

- Proper Coiling and Storage:

- Coil hoses loosely to prevent kinking or stress on the material.

- Store hoses horizontally on racks or shelves to avoid excessive bending.

- End Cap Protection:

- Use end caps or plugs to prevent contaminants from entering the hose.

- This is especially important to prevent the drying of internal hose liners.

- Regular Inspections:

- Rotate stock, and inspect hoses periodically for signs of damage or degradation, even when in storage.

- Document inspection dates, and findings.

By implementing these best practices, you can significantly extend the shelf life of your hydraulic hoses, ensuring their reliability and performance when needed.

Conclusion

Hydraulic hoses are critical components in hydraulic systems, and understanding their lifespan is essential for maintaining optimal performance and preventing unexpected failures.

By considering the quality of materials, operating conditions, maintenance practices, flexibility, installation, and usage frequency, you can significantly extend the lifespan of your hydraulic hoses. Regular inspections, proper maintenance, and adherence to manufacturer guidelines will help ensure the safe and efficient operation of your hydraulic system.

Remember, a proactive approach to hose lifespan can save you time, money, and potential downtime in the long run.

Need high-quality hydraulic hoses at wholesale prices?

Look no further than Kingdaflex! Contact us today to learn more about our extensive selection and competitive pricing. Get your order started and experience the Kingdaflex difference.