Introduction

A hydraulic hose factory is a specialized manufacturing company that produces hydraulic hoses, which are used to transport hydraulic fluid from one component to another in hydraulic machinery. These hoses are designed to withstand high pressure and are made from materials that are resistant to wear and tear, such as synthetic rubber, thermoplastic, or Teflon.

In this blog post, we will discuss three important aspects of hydraulic hose factories: the manufacturing process, quality control, and customization options.

The Hydraulic Hose Manufacturing Process

Hydraulic hoses are an essential component of hydraulic machinery, and it is essential to understand the hydraulic hose manufacturing process to ensure that you get the best quality product. In this article, we will provide you with a step-by-step guide to the hydraulic hose manufacturing process.

Step 1: Material Selection

The first step in the manufacturing process is selecting the appropriate materials for the hydraulic hose. The materials used depend on the intended use of the hose. Common materials used include synthetic rubber, thermoplastic, or Teflon.

Step 2: Extrusion

Once the materials are selected, they are extruded into the desired shape and size. This process involves forcing the material through a die that shapes it into a tube. The tube is then cooled and cut to the desired length.

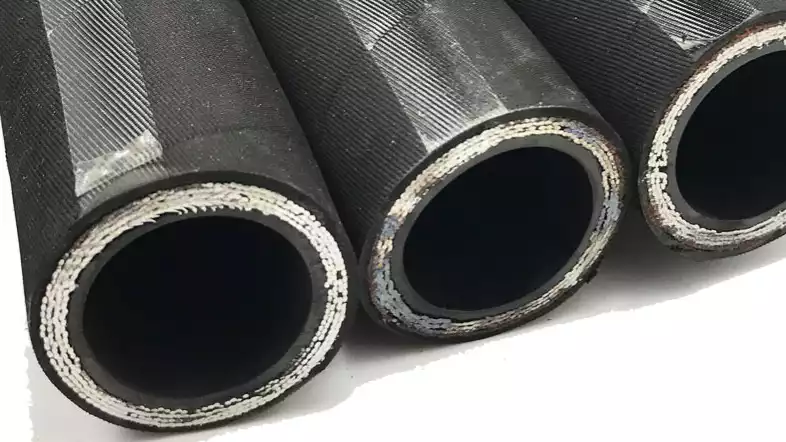

Step 3: Reinforcement

The next step is to reinforce the hose. The reinforcement layer is applied by wrapping wire or textile braid around the tube in a spiral pattern. This layer provides additional strength and durability to the hose.

Step 4: Covering

After the reinforcement layer, the hose is covered with a protective layer. This layer protects the hose from abrasion, weather, and other environmental factors. The covering material used depends on the intended use of the hose.

Step 5: Fitting

Finally, the hose ends are fitted with connectors, which allow them to be attached to the hydraulic machinery. The connectors are attached to the hose ends through a crimping process, which compresses the hose and connector together to create a seal.

Step 6: Quality Control

Quality control is an essential aspect of the hydraulic hose manufacturing process. The hose is tested for strength, durability, and resistance to wear and tear. Any defects or issues that arise during the manufacturing process are identified and addressed.

Quality Control

Quality control is an essential aspect of hydraulic hose manufacturing. A good hydraulic hose factory will have strict quality control measures in place to ensure that its products are of the highest quality. This includes testing the hoses for strength, durability, and resistance to wear and tear. The factory should also have a system in place for identifying and addressing any defects or issues that arise during the manufacturing process.

Customization Options

Hydraulic hoses are available in a wide range of sizes, shapes, and materials, and can be customized to meet the specific needs of the customer. A good hydraulic hose factory will offer a variety of customization options, such as different lengths, fittings, and colors. They should also be able to work with the customer to design a hose that is tailored to their unique requirements.

One important customization option is the length of the hose. Hydraulic hoses can be made in a wide range of lengths to meet the needs of different applications. Some hoses may need to be longer to reach certain components of machinery, while others may need to be shorter to fit in tight spaces.

Another customization option is the fittings used on the ends of the hose. Hydraulic hose fittings come in a variety of sizes and styles, and it is important to choose the right fitting to ensure that the hose functions properly. A good hydraulic hose factory will be able to provide a range of fittings to choose from, including JIC, NPT, and SAE.

Color coding is another customization option that can be useful for keeping track of different hoses in a system. For example, a hydraulic system may have hoses in different colors to indicate their function, such as blue for low-pressure hoses and red for high-pressure hoses.

Conclusion

In summary, hydraulic hoses are an essential component of hydraulic machinery, and as a good hydraulic hose factory, we will ensure our hydraulic hoses are manufactured well before loading to your side.

For more detailed info about the hydraulic hose factory, please feel free to contact us at any time.