Safety is of paramount importance in any industrial setting, especially where high-pressure hydraulic systems are utilized. One significant hazard associated with such systems is hose whipping, which can lead to severe injuries or property damage.

In this article, we will explore the importance of hydraulic hose whip checks and how they contribute to maintaining a safe working environment.

What is Hose Whipping?

Whip checks for hydraulic hosesrefers to the uncontrolled movement and thrashing of a pressurized hydraulic hose when it becomes detached or fails.

This sudden release of energy can cause the hose to flail uncontrollably, potentially striking nearby objects or individuals, resulting in serious injuries or accidents.

The force generated by a whipping hose can be incredibly powerful, capable of causing severe harm or even death.

What Are Hydraulic Hose Whip Checks?

Bolted connections should be tightened using hydraulic tensioning with hydraulic tensioners and nuts. In important fasteners, hydraulic tensioning helps accomplish proper bolt loading by removing errors. Since 1986, HTI has been producing hydraulic tensioners, nuts, pumps, and accessories for tensioning.

The metal quick disconnect fitting on the ends of air hoses can sustain considerable damage if the hose is whipped around rapidly.

Hydraulic hose whip checks are safety devices designed to prevent or minimize the hazards associated with hose whipping incidents. They are typically comprised of strong cables or straps that connect the hose to the equipment, anchoring it securely.

Whip checks act as a fail-safe mechanism, restricting the movement of a pressurized hose in the event of detachment or failure. By restraining the hose’s movement, whip checks for hydraulic hose help prevent accidents and protect workers and equipment.

Why Are Hydraulic Hose Whip Checks Essential

Hydraulic systems operate under immense pressure, and a sudden hose failure can result in dangerous whip-like movements, endangering nearby personnel and equipment.

Hydraulic hose whip checks provide an essential layer of protection, significantly reducing the risk of injuries, property damage, hydraulic hose leaks, and downtime. By restraining hoses and containing potential hazards, these devices ensure a safer working environment.

The Kingdaflex Whip Checks are a type of retention mechanism created to stop uncontrollable hose flaying in the case of a fitting blowing off or an unintentional disconnect. Anyone nearby the machinery is at risk of severe damage or death due to the whipping of high pressure hoses.

The whip check installation is a life-saving precaution that can make the difference between a tragic event and a minor mishap. The Whip Check System’s primary purpose is to safeguard the lives of everyone who comes into contact with the machinery.

Types of Hydraulic Hose Whip Checks

Cable Whip Checks

Cable whip checks consist of steel cables with loops on both ends that are attached to the hose and equipment. These cables are strong and flexible, allowing limited movement while effectively restraining hose whipping. They are commonly used in various industries, including construction, mining, and oil and gas.

Nylon Whip Checks

Nylon whip checks are made from durable nylon webbing material. They feature loops on each end and are secured using quick-release buckles. Nylon whip checks are lightweight, non-conductive, and suitable for applications involving compressed air, water, and other fluids.

How Do Hydraulic Hose Whip Checks Work?

Hydraulic hose whip checks consist of strong cables, typically made from steel or other durable materials, that are fastened around the hoses using secure connections.

In the event of a hydraulic hose failure or sudden pressure surge, the whip checks prevent excessive movement by restraining the hose, thereby minimizing the potential for whipping, flailing, or causing harm.

How to Properly Install Hydraulic Hose Whip Checks

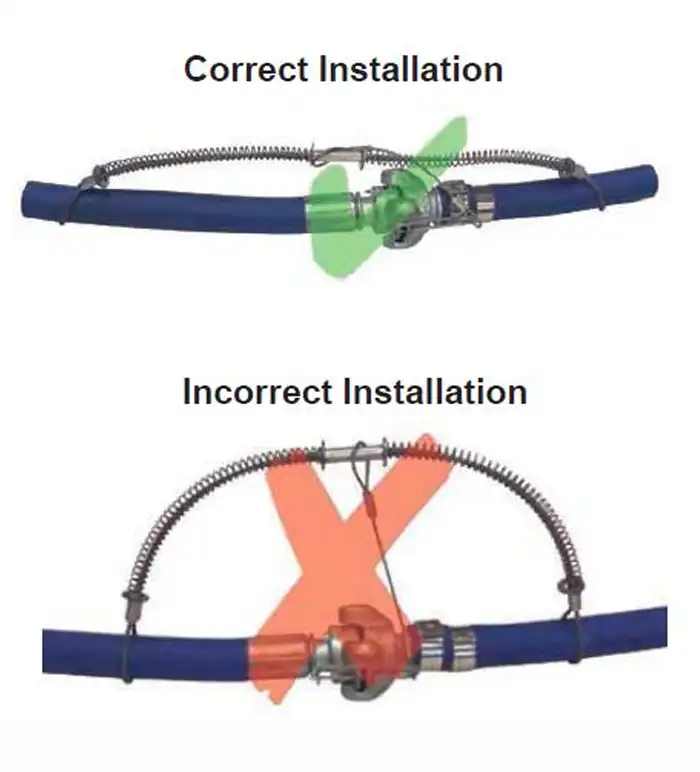

Proper installation of hydraulic hose whip checks is essential to maximize their effectiveness and ensure optimal safety. Follow these steps for correct installation:

Identify the appropriate locations along the hoses for whip check placement.

Slide the whip check loops over each hose end, ensuring a snug fit.

Attach the ends of the whip check cables securely to adjacent structures or fixed points, such as fittings, equipment, or pipes.

Double-check the connections to confirm that the whip checks are properly secured and can effectively restrain hose movements.

Factors to Consider When Choosing Whip Checks

When selecting hydraulic hose whip checks for your specific application, it’s crucial to consider the following factors:

Working Pressure: Select whip checks that can withstand the maximum pressure of the hydraulic system.

Hose Size and Compatibility: Ensure that the whip checks are appropriate for the diameter and type of hydraulic hose being used. Select whip checks that match the size and diameter of your hoses for optimal performance.

Environmental Conditions: Consider the operating environment, such as temperature, moisture, and exposure to chemicals or abrasive substances.

Durability and Strength: Opt for high-quality whip checks that can withstand rigorous conditions and provide long-lasting reliability.

Compliance with Standards: Choose whip checks that meet industry safety standards and regulations.

Pressure Rating: Ensure that the whip checks you choose can handle the maximum pressure of your hydraulic system.

Material Durability: Consider the environment in which the whip checks will be used and choose materials that are resistant to corrosion, abrasion, and weathering.

Ease of Installation: Look for whip checks that are easy to install, allowing for quick and efficient implementation. How to Install Hydraulic Hose? [Hydraulic Hose Installation Tips]

The Benefits of Using Hydraulic Hose Whip Checks

Using hydraulic hose whip checks offers several notable benefits, including:

- Enhanced Safety: Whip checks protect against dangerous hose movements, reducing the risk of injuries and accidents.

- Damage Prevention: By preventing uncontrolled whipping, these devices help safeguard hoses, fittings, and other hydraulic system components from damage.

- Improved Equipment Longevity: Properly restrained hoses experience less stress and strain, resulting in longer service life for the entire hydraulic system.

- Reduced Downtime: Hose failures and subsequent downtime can be costly and disruptive. Whip checks mitigate these risks, ensuring uninterrupted operation and productivity.

- Compliance with Safety Regulations: Many industry standards and regulations mandate the use of hydraulic hose whip checks to ensure workplace safety and prevent accidents.

How to Properly Install Hydraulic Hose Whip Checks

Proper installation of hydraulic hose whip checks is essential to maximize their effectiveness and ensure optimal safety. Follow these steps for correct installation:

- Identify the appropriate locations along the hoses for whip check placement.

- Slide the whip check loops over each hose end, ensuring a snug fit.

- Attach the ends of the whip check cables securely to adjacent structures or fixed points, such as fittings, equipment, or pipes.

- Double-check the connections to confirm that the whip checks are properly secured and can effectively restrain hose movements.

FAQs (Frequently Asked Questions)

Are whip checks necessary for all hydraulic systems?

Yes, whip checks are recommended for all hydraulic systems to ensure the safety of workers and equipment in the event of hose failure or detachment.

Can whip checks be reused?

Whip checks should be regularly inspected for signs of wear or damage. If they are in good condition, they can be reused. However, if any defects are detected, they should be replaced immediately.

Are there any specific regulations regarding whip checks?

While specific regulations may vary across industries and regions, many safety standards and guidelines recommend the use of whip checks in high-pressure hydraulic systems.

Can whip checks restrict the movement of the hose during normal operation?

Whip checks are designed to allow limited movement of the hose while effectively restraining excessive movement that could lead to hose whipping. When properly installed, whip checks do not hinder the normal operation of the hydraulic system.

Can I use whip checks for other types of hoses, such as air or water hoses?

Whip checks are commonly used for hydraulic hoses but can also be utilized for other applications involving hoses under pressure, such as air hoses, water hoses, or certain types of industrial hoses. Ensure that the whip checks you choose are suitable for the specific hose type and application.

Do hydraulic hoses need whip checks?

Yes, hydraulic hoses generally require whip checks to ensure safety during operation. Whip checks are safety devices that help prevent the hose from flailing or whipping around uncontrollably in the event of a sudden pressure release or hose failure.