The maritime industry is a vital component of the global economy, with the shipping of goods and commodities being an essential part of international trade.

One of the critical components of this industry is dredging, which involves the removal of sediments and other debris from the seabed to maintain safe navigation for ships. Dredging hose plays a critical role in this process, and their importance cannot be overstated.

In this article, we will explore the significance of dredging hoses in the maritime industry and how they contribute to the success of this sector.

What Is Dredging Hose?

A dredging hose is a type of hose that is used in the dredging process. It is a flexible tube that is made from materials such as rubber, polyurethane, or PVC. These materials are chosen for their durability, flexibility, and resistance to abrasion, corrosion, and other environmental factors. Dredging hoses come in various sizes and lengths, depending on the specific application and the depth of the dredging operation.

What Is Dredging Hose Made of?

Dredging hoses are typically made of a combination of materials that provide durability, flexibility, and resistance to abrasion, chemicals, and other harsh conditions. The most common materials used in the construction of dredging hoses include synthetic rubber, reinforced with high-strength synthetic fibers or steel wire.

Some dredging hoses may also have a layer of foam or other material to improve buoyancy and prevent sinking. The specific materials used in a dredging hose can vary depending on the application and the environmental conditions in which it will be used.

The Importance of Dredging Hose in the Maritime Industry

The use of dredging hoses is essential in the maritime industry for several reasons:

1. Safe Navigation

One of the primary reasons for dredging is to ensure safe navigation for ships. Dredging hoses are used to remove sediments and other debris from the seabed, which can impede the movement of ships. By keeping shipping channels clear, dredging hoses help prevent accidents, collisions, and other maritime incidents that could result in loss of life, property damage, or environmental harm.

2. Environmental Protection

Dredging hoses also play a crucial role in protecting the environment. Sediments and other debris can have a negative impact on marine life, ecosystems, and water quality. By removing these materials, dredging hoses help mitigate the environmental impact of maritime activities.

3. Efficient Operations

Dredging hoses allow for efficient and effective dredging operations. The flexibility of the hoses allows for maneuverability in tight spaces, and their durability ensures they can withstand the harsh marine environment. This efficiency means that dredging operations can be completed quickly, reducing downtime and increasing productivity.

4. Cost Savings

Using dredging hoses can also lead to cost savings for the maritime industry. By allowing for efficient and effective dredging operations, companies can reduce the amount of time and resources needed for these activities. This reduction in costs can lead to increased profitability for companies and lower prices for consumers.

Why Is Dredging Important for the Maritime Industry?

Dredging plays a critical role in the maritime industry by maintaining navigable waterways, ports, and harbors. It ensures safe vessel movement, prevents sediment accumulation, and supports economic activities. Efficient dredging helps protect marine infrastructure and sustain maritime operations in both commercial and industrial sectors.

- Maintaining Navigable Channels: Dredging keeps shipping channels clear of sediment, sand, and silt. By preventing blockages, it allows large vessels to pass safely, reduces the risk of accidents, and ensures the smooth operation of ports and shipping lanes.

- Port Expansion and Development: Dredging supports harbor expansion and deepening projects. It allows for larger vessels, increases cargo capacity, and strengthens infrastructure. Regular dredging ensures ports remain competitive, efficient, and capable of handling growing maritime trade demands.

- Environmental Management: Proper dredging helps manage sediment buildup and prevent flooding. By controlling sediment movement, it reduces erosion, protects marine habitats, and maintains ecological balance while supporting safe and sustainable maritime operations.

- Infrastructure Protection: Dredging safeguards marine structures, such as piers, jetties, and breakwaters. Removing accumulated materials prevents structural damage, extends the lifespan of infrastructure, and minimizes maintenance costs for long-term maritime operations.

Types of Dredging Hose

Dredging hoses are available in a variety of types, each with specific features and applications. Some of the most common types of dredging hoses are:

Suction Dredging Hose

Suction dredging hoses are used to transport sediment-laden water from the dredging site to the dredger. They are designed to withstand high suction forces and are available in different sizes and lengths. Suction dredging hoses are typically made of rubber or PVC material and can be reinforced with steel wire to increase their strength.

Discharge Dredging Hose

Discharge dredging hoses are used to transport the dredged material from the dredger to the disposal site. They are designed to withstand high pressure and are available in different sizes and lengths. Discharge dredging hoses are typically made of rubber or PVC material and can be reinforced with steel wire to increase their strength.

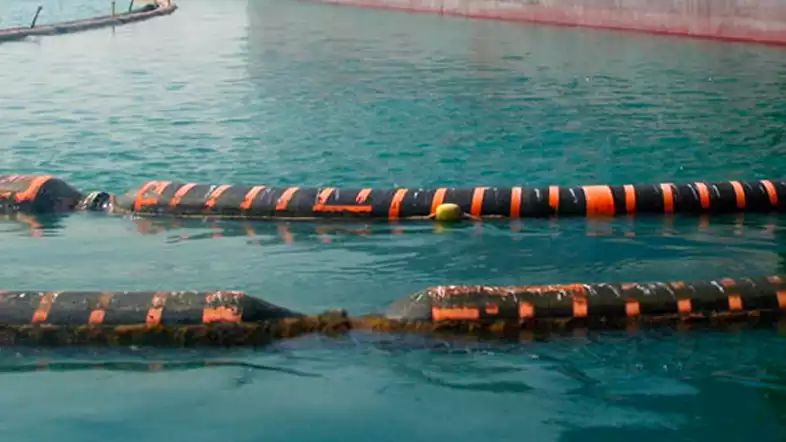

Floating Dredging Hose

Floating dredging hoses are used to transport sediment-laden water from the dredging site to the disposal area. They are designed to float on water and can be equipped with flotation devices to increase their buoyancy. Floating dredging hoses are typically made of rubber or PVC material and can be reinforced with steel wire to increase their strength.

Armored Dredging Hose

Armored dredging hoses are designed to withstand harsh environmental conditions, such as sharp rocks and debris, that can cause abrasion and puncture damage. They are typically made of reinforced rubber or PVC material and can be equipped with a steel wire helix for added strength.

Corrugated Dredging Hose

Corrugated dredging hoses are designed to be flexible and easy to maneuver in tight spaces. They are typically made of rubber or PVC material and can be reinforced with steel wire to increase their strength. Corrugated dredging hoses are ideal for use in shallow waters and tight spaces.

Wear-Resistant Dredging Hose

Wear-resistant dredging hoses are designed to withstand abrasive materials, such as sand and gravel, that can cause rapid wear and tear. They are typically made of reinforced rubber material and can be equipped with a steel wire helix for added.

Self-Floating Dredging Hose

Self-floating dredging hoses are designed to float on water without the need for additional flotation devices. They are typically made of reinforced rubber material and can be equipped with a steel wire helix for added strength. Self-floating dredging hoses are ideal for use in deep waters where buoyancy is crucial.

Heat-Resistant Dredging Hose

Heat-resistant dredging hoses are designed to withstand high-temperature materials, such as hot tar and asphalt, that can cause a rapid deterioration in standard hoses. They are typically made of reinforced rubber material and can be equipped with a steel wire helix for added strength. Heat-resistant dredging hoses are ideal for use in road construction and maintenance projects.

Factors to Consider When Choosing a Dredging Hose

Choosing the right dredging hose is essential for safe and efficient operations. Factors such as material, size, pressure rating, and environmental conditions determine performance and lifespan. Selecting the correct hose ensures reliable slurry transfer, reduces maintenance, and supports smooth dredging operations in challenging marine and industrial environments.

- Hose Material: Consider the type of material used for the hose’s inner tube and outer cover. We ensure materials can handle abrasive slurry, chemical exposure, and varying temperatures, providing durability, flexibility, and long-lasting performance for different dredging applications.

- Diameter and Length: Choose the proper hose diameter and length to match your dredging equipment and project needs. We ensure the hose allows optimal flow rate, minimal pressure loss, and easy handling while navigating complex project layouts efficiently.

- Pressure and Vacuum Ratings: Check the hose’s pressure and vacuum limits to ensure it can withstand operational conditions. We help select hoses capable of handling high-pressure slurry transfer and suction operations without collapsing or causing safety hazards.

- Environmental Conditions: Consider operating environments such as marine, freshwater, or industrial settings. We select hoses resistant to UV exposure, abrasion, chemicals, and temperature fluctuations, ensuring consistent performance and reliability in demanding conditions.

- Flexibility and Bend Radius: Evaluate the hose’s flexibility and minimum bend radius for tight spaces or complex routing. We ensure hoses maintain smooth flow without kinking, reduce operational risks, and make installation and handling easier on-site.

Dredging Hose Applications

Dredging hoses are versatile tools used in various marine, industrial, and civil engineering projects. They efficiently transfer slurry, sand, silt, and other dredged materials, ensuring smooth operations and reducing downtime. Their durability, flexibility, and resistance to abrasive materials make them essential for demanding dredging and material-handling tasks.

- Marine Dredging: Used in coastal, offshore, and harbor dredging projects, these hoses transfer sand, silt, and slurry efficiently. We ensure they withstand harsh marine conditions, high pressures, and abrasive materials, providing reliable performance while supporting navigation, port maintenance, and safe vessel operations.

- River and Canal Maintenance: Applied in rivers, canals, and lakes, dredging hoses remove sediment, maintain navigable waterways, and prevent flooding. We design hoses to navigate narrow or winding channels, resist abrasion, and ensure efficient slurry transfer, improving waterway safety and operational efficiency.

- Land Reclamation Projects: Essential in land reclamation, these hoses transport dredged materials to construction or filling sites. We ensure hoses handle high volumes of slurry, maintain smooth flow, and provide durability for large-scale civil engineering projects, enabling faster, safer, and more efficient reclamation.

- Industrial and Mining Applications: Used in mining or industrial sites to transfer slurry, tailings, or waste materials. We design hoses to withstand chemical exposure, heavy abrasion, and continuous flow, ensuring long-lasting performance while minimizing maintenance and operational interruptions.

- Flood Control and Environmental Projects: Dredging hoses help remove sediments and manage waterways during flood control or environmental restoration. We provide hoses capable of handling abrasive and contaminated materials safely, supporting ecological preservation, infrastructure protection, and disaster mitigation projects effectively.

Maintenance of Dredging Hose

Proper maintenance of dredging hoses ensures long-lasting performance, safety, and operational efficiency. Regular inspection, cleaning, and handling prevent wear, leaks, and damage. Maintaining hoses correctly reduces downtime, extends lifespan, and improves reliability, making your dredging operations smoother and more cost-effective in challenging marine and industrial environments.

- Regular Inspection: Inspect hoses frequently for signs of wear, cracks, or leaks. We recommend checking inner tubes, outer covers, and fittings to detect potential issues early. Timely inspections prevent operational failures, reduce repair costs, and ensure consistent slurry transfer during demanding dredging tasks.

- Cleaning and Flushing: Clean hoses after each operation to remove sediment, slurry, or debris. We provide guidance on proper flushing methods to prevent material buildup, reduce abrasion, and maintain optimal flow, ensuring your hoses remain efficient and safe for long-term use.

- Proper Storage: Store hoses in a dry, cool, and shaded area when not in use. We advise avoiding sharp bends, kinks, or exposure to sunlight and chemicals, which can weaken the hose structure and reduce lifespan. Proper storage ensures durability and reliability.

- Handling and Transportation: Handle hoses carefully during installation, removal, and transport. We recommend using appropriate equipment and avoiding dragging or twisting. Proper handling minimizes damage, prevents kinks, and maintains the hose’s structural integrity, ensuring safe and efficient operation.

- Pressure and Usage Monitoring: Monitor hose pressure and operational limits during use. We ensure hoses are not exposed to excessive pressure, vacuum, or abrasive loads. Keeping usage within recommended limits prevents failures, enhances safety, and prolongs the hose’s performance under continuous dredging operations.

Conclusion

Dredging hoses play a vital role in the maritime industry by ensuring safe, efficient, and continuous transport of slurry, sand, silt, and other materials. Their durability, flexibility, and resistance to harsh conditions make them indispensable for port maintenance, dredging projects, and coastal operations.

Proper selection, maintenance, and use of dredging hoses help prevent operational downtime, reduce costs, and extend equipment lifespan. By choosing hoses suited to specific project requirements, maritime operators can maintain navigable waterways, support infrastructure development, and protect vessels and marine environments from sediment-related hazards.

For reliable and high-performance dredging hoses, get wholesale dredging hoses from Kingdaflex. We provide hoses designed for various marine, industrial, and reclamation projects, ensuring durability, smooth slurry transfer, and long-lasting performance to support all your dredging operations.