Measuring hydraulic hoses can seem daunting, but it’s a crucial skill for anyone working with hydraulic systems. Accurate measurements ensure proper function, prevent leaks, and extend the life of your equipment. This guide will walk you through the essential steps and techniques, making the process simple for beginners.

Whether you’re replacing a single hydraulic hose or planning a complex new system, understanding how to measure correctly is key to success. We’ll cover everything from determining overall length to identifying the right fitting types, so you can confidently tackle your next project with precision.

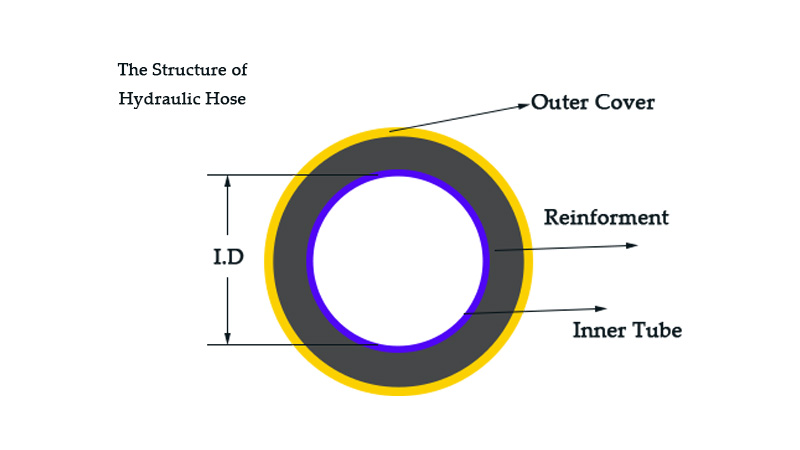

Hydraulic Hose Structure

Regularly, a hydraulic hose is designed with 3 different parts, including inner tube, reinforcement, and outer cover.

Hydraulic hose tube, inner tube, the inner part as the base

The inner hydraulic hose tube is made of oil-resistant or weather-resistant synthetic rubber material, and raw material for making hydraulic hose is basically important, to ensure the quality of the whole hydraulic hose pipe. So we pay much attention to selecting the raw material to ensure the quality of a hydraulic hose.

Reinforcement of Hydraulic hose

The reinforcement of the hydraulic hose is made of tensile steel wire spiral layers, stainless steel, and many other materials, and the reinforcement also matters, they are important to add much more strength and flexibility to the hydraulic hose. And hydraulic hoses can be divided into different types according to the hose reinforcement.

The hydraulic hose cover, the outer cover

The hydraulic hose cover is basically important to protect the hydraulic hose, giving a stable performance to the hydraulic hose pipe. And we can add certain materials to create the cover to protect the hydraulic hose, away from potential harm.

Strong cover can ensure the service life of a hydraulic hose, even if you need to assemble and use the hydraulic hose in an environment of high temperature, within the range of -22℃ to 120℃, or even lower or higher temperature.

The cover can be designed with higher performance to deal with all kinds of working environments, including high temperature, high pressure, much friction and etc.

How to Size A Hydraulic Hose?

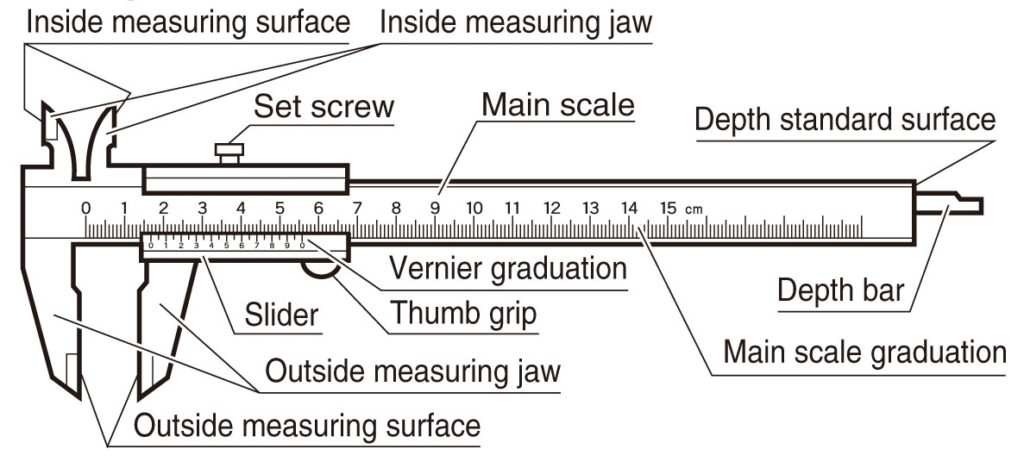

Measuring Tool:

The most accurate and precise measuring tool to measure the hydraulic hose is a vernier caliper, and we need to use the vernier caliper to measure the diameter of a hydraulic hose.

Here is the vernier caliper structure, and we use the outside measuring jaw to measure the size of the hydraulic hose O.D (Out Diameter); the inside measuring jaw to measure the size of the hydraulic hose I.D (Inner Diameter). Finally, we need to read the number given to two decimal points, to make it much more accurate.

And you can watch this short video to know how to measure the hydraulic hose using the vernier caliper.

Specifications for Hydraulic Hose Measurement

The sizing process is basically important to measure a hydraulic hose, which is the essential factor for you to select your desired hydraulic hose for your project.

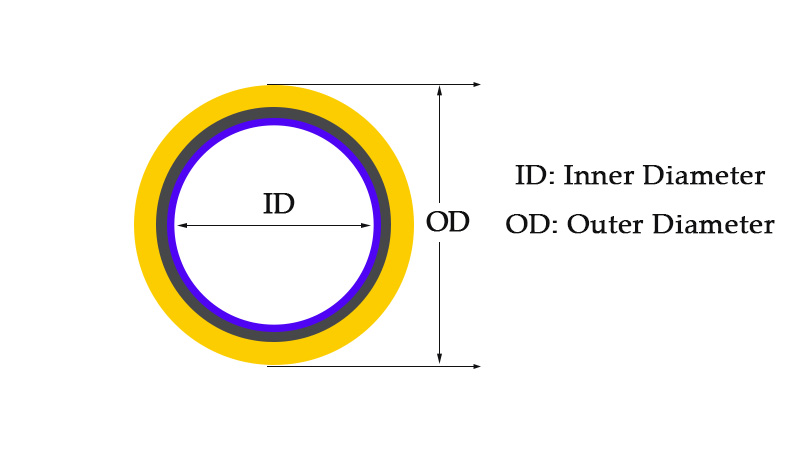

Here are some important sizing specifications for the hydraulic hose measurement, including ID, OD, and overall length.

- ID: Inner Diameter (or I.D, I.D.) is the span of the empty space in a circular hose cross-section that affects the flow velocity of the fluid within the hose. A hose with an oversized I.D. will result in sluggish system performance problems, while an undersized I.D. can cause excessive pressure drops, leaks, and system damage. So it’s important to get the accurate ID specification, and they are accurate to one decimal point.

- OD: Outer Diameter (or I.D, I.D.) measures the entire span of the hose cross-section, including the tube, reinforcement, and cover. The difference between the O.D. and I.D. is the thickness of the hose wall. Outer diameter is important for sizing industrial hoses to appropriate fittings and system components.

And OD mins ID equals the thickness of the hydraulic hose, so we don’t need to measure the size of the thickness of the hydraulic hose pipe.

Measure the Length of the Hydraulic Hose

How to measure hydraulic hose length?

The length of the hydraulic hose defines its maximum space reach between two end-points. Increasing length can also increase the pressure drop in the hydraulic hose system because hose length is a function of head loss due to friction.

It’s flexible for you to get your desired length of the hydraulic hose for you to assemble at ease, and here we have different lengths for your consideration, including 40 meters, 50 meters, 80 meters, 100 meters, and even random lengths. And we can also customize the length for your hydraulic hose project.

Our hydraulic hose manufacturer can work out the best plan for you, so please be free to contact us to get the details of the hydraulic hose.

And you can get the full table of the hydraulic hose specifications from our hydraulic hose product singe page, please kindly visit to find your desired hydraulic hose.

Here is a length converter, which can help you convert length unit.

Length Unit Converter

Get Hydraulic Hose Specifications

How to Measure Hydraulic Hose Diameter?

The diameter of a hydraulic hose is a critical measurement for ensuring a proper fit and optimal system performance. This guide will walk you through the essential steps to accurately determine the diameter of your hydraulic hose.

Step 1: Measure Outer Diameter

Use a ruler or tape measure to find the widest point of the hose’s outer cover. This measurement, taken from edge to edge, should be recorded in either inches or millimeters to ensure accuracy and proper sizing.

This method gives you the hose’s external dimension, which is crucial for determining clearance and compatibility with clamps or other components that secure the hose in place.

Step 2: Measure Crimped Fitting

If your hose has a crimped-on fitting, measure its diameter. The diameter of this fitting will be identical to the hose’s diameter at that specific connection point, providing a reliable measurement.

This approach is especially useful when the hose itself is difficult to measure due to its location or condition, offering an alternative way to determine the correct size.

Step 3: Consult Manufacturer Specifications

If you cannot measure the hose or fitting, the manufacturer’s specifications are your best resource. These documents provide precise dimensions and are essential for ensuring you select the correct replacement part.

You can also consult a hydraulic hose supplier. They have access to product databases and can help you identify the correct hose diameter based on your system’s requirements.

Step 4: Understand Nominal vs. Actual Diameter

Be aware that a hydraulic hose’s nominal diameter is not always the same as its actual diameter. Always physically measure the hose or fitting to confirm the exact size needed for your application.

This distinction is important to avoid a mismatch. A nominal size is often an approximation, so a precise measurement is the only way to guarantee a perfect fit.

Step 5: Measure Outer, Not Inner, Diameter

When dealing with a hose that has an inner tube and multiple reinforcement layers, always measure the outer diameter. This is the correct dimension to use for compatibility with fittings and connectors.

Ignoring the outer layers and measuring the inner tube’s diameter will lead to an incorrect size selection, causing potential leaks or system failures.

Step 6: Handle Irregular Shapes

For hoses with irregular shapes, such as a spiral wire hose, you should measure the diameter at the widest point of the spiral. This ensures you account for its full external dimension.

This method is necessary to accommodate the unique construction of such hoses and to guarantee a proper fit within any constraints or mounting hardware.

Step 7: Verify with Specifications

Once you have your measurement, compare it against the manufacturer’s specifications. This final step confirms that your measured size corresponds to an available and correct product.

You can also consult a hydraulic hose supplier with your measurement. They can help you cross-reference it to determine the exact size and part number you need.

By following these steps, you should be able to accurately measure the diameter of a hydraulic hose, ensuring that you purchase the correct size for your system.

How to Measure Hydraulic Hose Size

Hydraulic hose size is characterized by two main measurements:

- Inner Diameter (ID): This is the most crucial measurement and refers to the open space within the hose where the fluid flows. It’s typically specified in inches or millimeters.

- Overall Length: This is the total length of the hose assembly, from end to end, including the fittings.

Here’s a breakdown of how to measure each:

Measuring Inner Diameter (ID):

- There are two common ways to express ID:

- Inches: This is the most common method in North America. You’ll need a ruler or caliper to measure the straight distance across the inner opening of the hose.

- Dash Size: This system uses fractions based on inches. For example, a 1/2″ ID hose would be designated as “-8” (8/16ths of an inch).

Measuring Overall Length:

- Measure the total length of the hose assembly, not including the crimped part of the fittings.

- For hoses with straight fittings, measure from the sealing surface to sealing surface.

- For hoses with elbow fittings, measure to the centerline of the elbow.

Additional Tips:

- When replacing a hose, it’s best to use the old hose as a reference for both ID and length.

- Consult the manufacturer‘s specifications for your specific equipment to ensure you’re using the correct hose size.

- Some resources like hydraulic hose nomograph charts can help determine the appropriate hose size based on factors like flow rate and desired flow velocity. However, consulting a professional is recommended for critical applications.

Remember: Using the right size hose is crucial for optimal performance and safety in your hydraulic system. An undersized hose can restrict flow and lead to pressure drops, while an oversized hose can be bulky and more expensive.

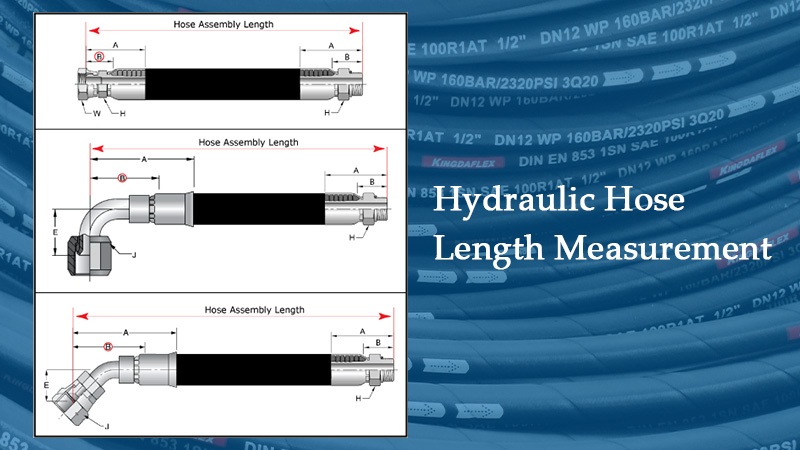

How to Measure Hydraulic Hose Length

Here’s how to measure the length of a hydraulic hose assembly, ensuring you get the right size for your needs:

What to Measure:

There are two main lengths to consider when dealing with hydraulic hose assemblies:

- Overall Length: This is the total length of the entire assembly, measured from end to end, including the fittings. This is the most common measurement used when ordering or replacing a pre-made hose assembly.

- Cut Length: This is the length of the hose itself, not including the fittings. It’s relevant if you’re building your own hose assembly or need to know the exact hose length before crimping on the fittings.

Measuring Overall Length:

- This is a straightforward measurement.

- Lay the hose assembly flat on a level surface.

- Use a tape measure to measure the distance from the sealing surface of one fitting to the sealing surface of the other fitting.

- For straight fittings, measure from the end of the threads (if male) or the sealing surface (if female or flanged).

- For elbow fittings, measure to the centerline of the sealing surface on the elbow.

- Don’t pull the hose taut while measuring.

Measuring Cut Length:

- This requires some knowledge of the specific hose fitting you’re using.

- Consult the fitting manufacturer‘s specifications or data sheet. They will typically provide a dimension labeled as “cut-off length” or “ferrule length“. This value represents the distance from the bottom of the ferrule (the metal ring that grips the hose) to the sealing surface of the fitting.

- Once you have the cut-off length, subtract it from the Overall Length you measured previously for each fitting. This will give you the Cut Length of the hose itself.

Here are some additional tips for accurate measurement:

- Use a quality tape measure with good markings.

- Consider using a straight edge to ensure your measurement is aligned with the hose centerline.

- Double-check your measurements before finalizing your order or cutting the hose.

- If you’re unsure about anything, consult a professional hydraulics specialist for guidance.

By following these steps and understanding the difference between OAL and COL, you can accurately measure your hydraulic hose length and ensure a proper fit for your application.

How to Convert MM to Inches (“)

To convert millimeters (mm) to inches (“), you can use the following conversion factor:

1 inch = 25.4 millimeters

So, to convert from mm to inches, divide the number of millimeters by 25.4.

For example, to convert 100 mm to inches:

100 mm ÷ 25.4 mm/inch = 3.937 inches

Here is the hydraulic hose size chart converting MM to Inches (“). Welcome to consult the our hydraulic hose manufacturer’s specifications for the most accurate information.

Millimeter-to-Inch Conversion Table for Hydraulic Hose Lengths

| Millimeter (mm) | Inch (“) |

|---|---|

| 2 mm | 3/32″ |

| 3 mm | 1/8″ |

| 4 mm | 5/32″ |

| 5 mm | 3/16″ |

| 6.5 mm | 1/4″ |

| 7 mm | 9/32″ |

| 8.0 mm | 5/16″ |

| 9.5 mm | 3/8″ |

| 11 mm | 7/16″ |

| 13 mm | 1/2″ |

| 16 mm | 5/8″ |

| 19 mm | 3/4″ |

| 22 mm | 7/8″ |

| 25 mm | 1″ |

| 28 mm | 1 1/8″ |

| 30 mm | 1 3/16″ |

| 32 mm | 1 1/4″ |

| 35 mm | 1 3/8″ |

| 38 mm | 1 1/2″ |

| 40 mm | 1 5/8″ |

| 45 mm | 1 3/4″ |

| 48 mm | 1 7/8″ |

| 51 mm | 2″ |

| 54 mm | 2 1/8″ |

| 57 mm | 2 1/4″ |

| 60 mm | 2 3/8″ |

| 63 mm | 2 1/2″ |

| 65 mm | 2 9/16″ |

| 68 mm | 2 11/16″ |

| 70 mm | 2 3/4″ |

| 76 mm | 3″ |

| 80 mm | 3 1/8″ |

| 83 mm | 3 1/4″ |

| 90 mm | 3 1/2″ |

| 102 mm | 4″ |

| 114 mm | 4 1/2″ |

| 127 mm | 5″ |

| 152 mm | 6″ |

Conclusion

By following the steps outlined in this blog, you’ve gained the knowledge and confidence to measure a hydraulic hose for replacement or custom assembly accurately. Remember, a precise measurement is crucial for ensuring your hydraulic system operates efficiently and safely.

Taking the Next Step with Us!

Now that you’re equipped with the know-how, avoid the hassle of searching for the perfect hose! Kingdaflex.com offers a wide range of high-quality hydraulic hoses in various sizes and pressure ratings.

Here’s how we can simplify your hydraulic needs:

- Customizable Solutions: Don’t see the exact size or fit you require? We offers custom hydraulic hose assemblies tailored to your specific application.

- Durable Materials: Their hoses are built with top-grade materials to withstand demanding pressures and temperatures.

- Expert Assistance: Our hydraulic specialists is always happy to answer your questions and guide you toward the best hose solution.

Ready to streamline your hydraulic system?

Head over to Kingdaflex.com today and explore their selection of high-performance hoses. Get a custom quote or browse their pre-made assemblies to find the perfect fit for your needs!