Ready to delve into the fascinating world of rubber hose manufacturing? Join us as we explore the intricacies of the rubber hose extrusion process. From raw materials to finished products, we’ll uncover the steps involved in creating these essential components used in countless industries.

In this blog post, we’ll discuss:

- The extrusion process: A step-by-step breakdown of how rubber is transformed into hoses.

- Types of rubber hoses: Discover the diverse applications and characteristics of different rubber hose varieties.

- Key components of a rubber hose: Learn about the reinforcement layers, inner and outer tubes, and other essential elements.

- Quality control and testing: Understand the rigorous measures taken to ensure the safety and reliability of rubber hoses.

So, whether you’re a curious individual or a professional in the rubber industry, let’s embark on a journey through the world of rubber hose extrusion.

What is Rubber Extrusion?

Rubber extrusion is a manufacturing process used to create rubber products in continuous lengths. It involves forcing a rubber compound through a die of a specific shape under high pressure.

Here’s a simplified breakdown of the process:

- Compound Preparation: A rubber compound, consisting of natural or synthetic rubber, fillers, and other additives, is prepared.

- Extrusion: The compound is fed into an extruder, where a heated screw forces it through a die. The die’s shape determines the cross-section of the extruded product.

- Cooling and Curing: The extruded rubber is cooled and then cured, a process that hardens the rubber and gives it its desired properties.

Common rubber products created through extrusion include:

- Hoses (garden, industrial, automotive)

- Seals and gaskets

- Weatherstripping

- Tubing

- Profiles (for windows, doors, and other applications)

This process is efficient for producing long, consistent lengths of rubber products in various shapes and sizes.

Why is Rubber Extrusion Important?

Rubber extrusion is a crucial manufacturing process due to several key reasons:

- Versatility: It can produce a wide range of rubber products, from hoses and seals to gaskets and tubing, making it adaptable to various industries.

- Efficiency: The continuous nature of the process allows for high-volume production, reducing costs and lead times.

- Precision: With precise control over the extrusion process, manufacturers can create products with consistent dimensions and quality.

- Durability: Rubber products created through extrusion are known for their durability, resistance to harsh conditions, and long lifespan.

- Cost-effectiveness: Extrusion is often more cost-effective compared to other manufacturing methods, especially for large-scale production.

- Customization: The ability to customize rubber compounds and die shapes enables the production of products tailored to specific needs and applications.

In essence, rubber extrusion is essential for providing the versatile, durable, and cost-effective rubber products that are vital to many industries, from automotive and construction to medical and aerospace.

Here is a video showing you the rubber extrusion process.

Rubber Hose Extrusion Process for Hydraulic Hose Manufacturing

Hydraulic hoses are essential components in various industries, from construction and agriculture to manufacturing and mining. They are designed to withstand high pressures and harsh environments while efficiently transporting hydraulic fluids. The rubber hose extrusion process plays a vital role in the production of these durable and reliable components.

Compound Preparation:

Rubber Selection: The appropriate type of rubber is chosen based on the specific requirements of the hydraulic hose, such as pressure resistance, temperature tolerance, and chemical compatibility. Common rubber types include natural rubber, synthetic rubber (like nitrile, neoprene, and butyl), and rubber blends.

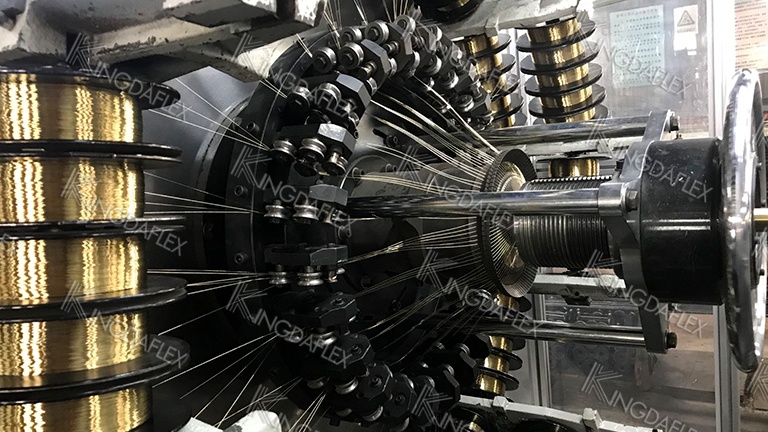

Reinforcement: Reinforcement materials, such as steel wire, textile braid, or synthetic fibers, are added to the rubber compound to provide strength and durability. These reinforcements are typically wound or braided around the rubber core.

Additives: Various additives are incorporated into the compound to enhance properties like elasticity, abrasion resistance, and UV protection.

Rubber Extrusion Process:

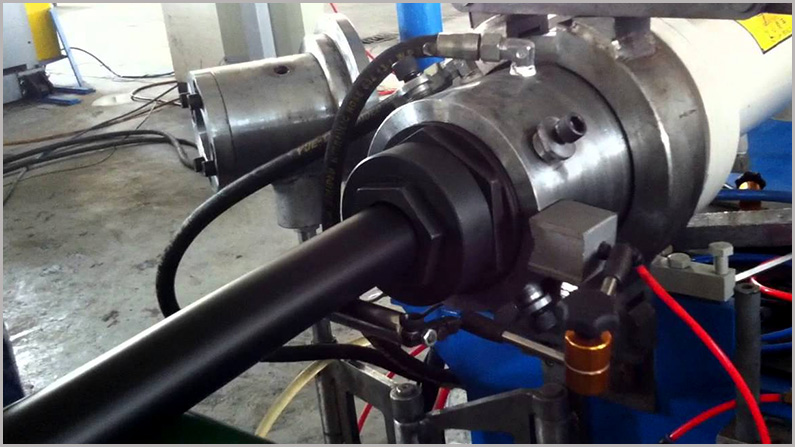

Die: A specially designed die with the desired hose cross-section is fitted into the extruder.

Compound Feeding: The prepared rubber compound is fed into the extruder, where a heated screw forces it through the die.

Shape Formation: As the compound passes through the die, it takes on the shape of the hose.

Curing:

Curing Chamber: The extruded hose is immediately transferred to a curing chamber.

Heat and Pressure: The hose is subjected to heat and pressure, which causes the rubber to vulcanize (cure) and form strong chemical bonds. This process gives the hose its final properties.

Testing and Inspection:

Quality Control: The cured hoses undergo rigorous testing to ensure they meet specific standards for burst pressure, tensile strength, and other performance parameters.

Inspection: Visual inspections are conducted to check for defects like cracks, blisters, or uneven wall thickness.

Key Components of Hydraulic Hoses

- Inner Tube: The inner tube is made of a rubber compound that is resistant to the hydraulic fluid being transported. It must also be smooth to minimize fluid resistance.

- Reinforcement Layers: These layers provide strength and support to the hose, preventing it from bursting under high pressure. They can be made of steel wire, textile braid, or synthetic fibers.

- Outer Cover: The outer cover protects the hose from abrasion, weathering, and other environmental factors. It is typically made of a tough rubber compound.

Types of Hydraulic Hoses

- Braided Wire Hose: Reinforced with steel wire braid, these hoses are highly durable and suitable for high-pressure applications.

- Textile Braid Hose: Reinforced with textile braid, these hoses are more flexible than wire braid hoses but may not be as strong.

- Spiral Wire Hose: Reinforced with a spiral steel wire, these hoses are lightweight and have good flexibility.

- Thermoplastic Hose: Made of thermoplastic materials, these hoses are lightweight, flexible, and resistant to chemicals.

The rubber hose extrusion process is a critical step in the manufacturing of hydraulic hoses, ensuring that these essential components meet the demanding requirements of various industries.

By carefully selecting materials, controlling the extrusion process, and conducting thorough testing, hydraulic hose manufacturers can produce hydraulic hoses that are reliable, durable, and capable of withstanding the challenges of demanding applications.

Conclusion

The rubber hose extrusion process is a complex yet fascinating manufacturing technique that enables the production of a wide range of essential products, including hydraulic hoses. From compound preparation to curing and testing, each stage plays a vital role in ensuring the quality and performance of these hoses.

Hydraulic hoses are indispensable components in various industries, providing reliable and efficient fluid transfer solutions. By understanding the rubber hose extrusion process, we gain a deeper appreciation for the craftsmanship and technology involved in creating these critical components.

Are you in need of high-quality hydraulic hoses for your specific application? Look no further! Our experienced hydraulic hose manufacturer offers a wide range of custom and standard hoses to meet your exact requirements.

Contact us today 0086-18653246929 or email us [email protected] discuss your needs and receive a personalized quote. Let us help you optimize your hydraulic systems with our premium hydraulic hoses.