We are the hydraulic hose manufacturer to provide multiple types of hydraulic hose in the market. Today I am here to share with you guys about the 2-wire hydraulic hose.

In this guide, I am happy to share with you all about the steel wire hydraulic hose, including steel wire braided hydraulic hose and steel wire spiral hydraulic hose.

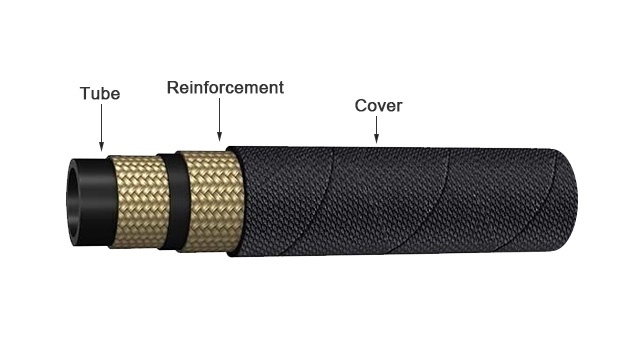

2-Wire Hydraulic Hose Structure

The hydraulic hose is structured with three different parts, inner tube, reinforcement, and outer cover. The wire is used to create the reinforcement layer of the hydraulic hose. And here are two types of hydraulic hose, based on the manufacturing craftsmanship, they are spiral hydraulic hose and braided hydraulic hose. And spiral & braided hydraulic hose is basically different in the reinforcement.

A 2-wire hydraulic hose structure is designed to handle medium to high-pressure hydraulic applications, and its construction typically includes the following layers:

- Inner Tube (Core):

This is the innermost layer that comes into direct contact with the hydraulic fluid. It’s usually made from synthetic rubber or thermoplastic materials, chosen for their compatibility with various hydraulic fluids and their ability to withstand the fluid’s temperature and chemical properties.

- First Reinforcement Layer (Wire Braid):

This layer consists of a woven or braided layer of high-tensile steel wire. It provides the initial structural support, helping the hose withstand internal pressure.

- Second Reinforcement Layer (Wire Braid):

An additional layer of high-tensile steel wire braiding, interwoven over the first layer. This second layer further enhances the hydraulic hose’s strength and pressure-bearing capacity, significantly increasing its overall durability.

- Outer Cover (Jacket):

The outermost layer, typically made from synthetic rubber or another abrasion-resistant material. It protects the reinforcement layers from external damage, such as abrasion, weathering, and chemical exposure. This layer also contributes to the hose’s overall flexibility and durability.

And the braided hydraulic hose can be classified into 1 wire braided hydraulic hose, 2 wire braided hydraulic hose, 3 wire braided hydraulic hose, 4 wire braided hydraulic hose, 6 wire braided hydraulic hose and etc. And the hydraulic hose with 1 wire reinforcement can work well in very low to high temperatures with the range of -40°C to +100°C, and even the maximum temperature can be up to +125°C.

Here, the hydraulic hose reinforcement is made of steel wire, with different layers to create different strengths, and more wires can be added much more strength to the whole hydraulic hose.

And we have different wire layers as the reinforcement to make braided hydraulic hoses.

- 1 wire hydraulic hose (wire braided hydraulic hose)

- 2 wire hydraulic hose (wire braided hydraulic hose)

- 4 wire hydraulic hose (wire spiral hydraulic hose)

- 6 wire hydraulic hose (wire spiral hydraulic hose)

It’s flexible for you to choose the proper wire braided hydraulic hose for your hydraulic project.

What Does 2 Wire Mean on a Hydraulic Hose?

When a hydraulic hose is described as “2 wire,” it refers to the hydraulic hose’s reinforcement layer, specifically indicating that it has two layers of wire braiding. This reinforcement is crucial for the hose’s ability to withstand high pressures. The wire braiding is typically made of steel and is interwoven around the inner tube of the hose, providing structural integrity and preventing the hose from expanding or bursting under pressure.

The two layers of wire braiding provide increased strength compared to hoses with single wire braiding or textile reinforcement. This makes 2-wire hoses suitable for medium to high-pressure hydraulic applications.

The specific pressure rating of a 2-wire hose will vary depending on the wire’s gauge, the braid’s pattern, and the hose’s overall construction, but it generally signifies a robust and durable hose capable of handling demanding hydraulic tasks.

What Is 1 Wire Hydraulic Hose? (Single Wire Hydraulic Hose)

1 wire hydraulic hose, also called 1-wire braided hydraulic hose, single wire hydraulic hose, is the braided hydraulic hose reinforced with one layer of stainless steel wire. The single wire braided hydraulic hose, made of oil-resistant synthetic rubber material with a single layer of steel wire reinforcement.

You can get to know if a hydraulic hose is a 1 wire hydraulic hose, by reading from the hydraulic hose cover printing mark. This EN857 1SC is the 1 wire hydraulic hose.

Here are 1 wire hydraulic hose below:

3/8 2 Wire Hydraulic Hose

A 3/8 2-wire hydraulic hose refers to a hose with an inner diameter (ID) of 3/8 inch and two layers of high-tensile steel wire braiding for reinforcement. This configuration is designed to handle medium to high-pressure hydraulic applications, providing a balance of flexibility and strength. The 3/8-inch ID is suitable for applications requiring moderate fluid flow, while the 2-wire reinforcement ensures the hose can withstand significant pressure without expanding or bursting.

Kingdaflex offers high-quality 3/8 2-wire hydraulic hoses that meet stringent industry standards. These hoses are engineered to provide reliable performance in demanding environments, ensuring durability and longevity. We focus on quality construction and materials, providing hoses that ensure optimal functionality.

Inner Diameter (ID):

3/8 inch, providing a moderate flow rate suitable for various hydraulic applications.

Reinforcement:

Two layers of high-tensile steel wire braiding, offering superior strength and pressure resistance.

Materials:

High-quality synthetic rubber or thermoplastic inner tube, compatible with various hydraulic fluids.

Durable outer cover, resistant to abrasion, weathering, and chemical exposure.

Applications:

Suitable for medium to high-pressure hydraulic systems in industrial, construction, and agricultural machinery.

Ideal for applications requiring flexibility and robust pressure handling.

2 Wire Hydraulic Hose Rating

2-wire hydraulic hoses are known for their higher pressure ratings compared to 1-wire hoses. The specific pressure rating can vary depending on the exact type and size of the hose. However, they typically handle pressures in the range of 3,000 to 6,000 PSI.

It’s important to note that the pressure rating is just one factor to consider when selecting a hydraulic hose. Other factors include:

- Temperature range: 2-wire hoses generally have a wider temperature range than 1-wire hoses.

- Flexibility: 2-wire hoses are typically less flexible than 1-wire hoses.

- Weight: 2-wire hoses are generally heavier than 1-wire hoses.

- Cost: 2-wire hoses are generally more expensive than 1-wire hoses.

When selecting a hydraulic hose, it’s important to consider all of these factors to ensure that the hose is suitable for the specific application.

1 Wire vs 2 Wire Hydraulic Hose

The primary difference between 1-wire and 2-wire hydraulic hoses lies in their construction and resulting capabilities.

1-Wire Hydraulic Hose

- Construction: Reinforced with a single layer of steel wire braid.

- Advantages:

- More flexible

- Lighter weight

- Lower cost

- Disadvantages:

- Lower pressure rating

- Less durable

- Lower temperature range

2-Wire Hydraulic Hose

- Construction: Reinforced with two layers of steel wire braid.

- Advantages:

- Higher pressure rating

- More durable

- Wider temperature range

- Disadvantages:

- Less flexible

- Heavier

- Higher cost

When to Use Which Wire Hydraulic Hose?

The choice between 1-wire and 2-wire hoses depends on the specific application and its requirements.

1-Wire Hoses are suitable for:

- Low-pressure applications

- Applications where flexibility is a priority

- Applications with moderate temperature fluctuations

2-Wire Hoses are ideal for:

- High-pressure applications

- Applications in harsh environments

- Applications with extreme temperature fluctuations

While 1-wire hoses offer flexibility and cost-effectiveness, 2-wire hoses provide superior performance in terms of pressure, durability, and temperature resistance.

It’s crucial to consult with a hydraulic hose specialist to determine the most suitable hose for your specific needs. Factors such as pressure, temperature, fluid compatibility, and environmental conditions should be carefully considered.

What Is 4 Wire Hydraulic Hose?

The 4 wire hydraulic hose is made of 4-layer steel wire reinforcement and separated by the synthetic rubber material, making the hydraulic hose much stronger with hardness. And 4-wire braided hydraulic hose suitable to be used for hydraulic fluids transmission.

Application: Medium and high-pressure circuit with restricted installation space

Standard: SAE 100R12

Inner layer: Oil resistant synthetic rubber

Insert: Four maximum-strength steel wire spiral layers

Outer layer: Synthetic rubber with high temperature, ozone, and weather resistance

Colour: Black

Temp.min : – 40 ℃

Temp.max: + 121 ℃

Media: Mineral oil, Polyglycol based oil, Water (0°C to + 70°C), Water-oil emulsions.

Here are the 4-wire hydraulic hose below:

Four Steel Wire Spiral Hose Hydraulic R12

A four steel wire spiral hydraulic hose, specifically the SAE 100R12 type, is a high-performance hose designed for demanding hydraulic applications. It’s characterized by its robust construction and ability to handle high pressures and harsh environments.

Key Features:

- Four Spiral Steel Wire Reinforcement: This provides exceptional strength and durability, enabling the hose to withstand high pressures without compromising its integrity.

- High-Pressure Rating: Typically rated for pressures up to 4,000 PSI, making it suitable for heavy-duty equipment and machinery.

- Temperature Resistance: Designed to operate in a wide temperature range, from -40°F to +212°F, ensuring reliable performance in various conditions.

- Oil and Weather Resistance: The hose’s outer cover is made of a durable, abrasion-resistant material that is resistant to oil, fuel, and weathering, prolonging its lifespan.

- Flexibility: Despite its robust construction, the hose offers a good degree of flexibility, allowing for easy installation and routing in confined spaces.

Applications:

- Construction equipment

- Agricultural machinery

- Mining equipment

- Industrial machinery

- Mobile hydraulic systems

Benefits:

- Enhanced Safety: The robust construction reduces the risk of hose failure, minimizing potential hazards.

- Increased Productivity: Reliable performance and durability minimize downtime, improving overall productivity.

- Cost-Effective: The long lifespan and resistance to wear and tear reduce the need for frequent replacements, saving costs in the long run.

When choosing a four steel wire spiral hydraulic hose, consider the following factors:

- Pressure Rating: Ensure the hose’s pressure rating is sufficient for your application.

- Temperature Range: Select a hose that can withstand the temperature extremes in your operating environment.

- Fluid Compatibility: Verify that the hose is compatible with the hydraulic fluid you’re using.

- Hose Length and Diameter: Choose the appropriate length and diameter to meet your specific needs.

- Fittings: Select compatible fittings to ensure a secure and leak-free connection.

By carefully considering these factors, you can select the right four steel wire spiral hydraulic hose to optimize your hydraulic system’s performance and reliability.

What Is 6 Wire Hydraulic Hose?

The 6-wire hydraulic hose is reinforced with 6-wire steel, as the strong media to add so much strength to the hydraulic hose.

Recommended For: Extremely high-pressure hydraulic oil lines. The extra high working pressures and excellent impulse life, when tested to SAE 100R13 test conditions, result in, increased service life and minimize equipment downtime. Meets or exceeds the performance requirements of SAE 100R13, AS 3791 100R13, EN 856 Type R13, ISO 3862 Type R13.

Tube: Black, oil-resistant synthetic rubber.

Reinforcement: Six alternating layers of spiraled high tensile steel wire.

Cover: Black, oil-resistant, and abrasion-resistant synthetic rubber.

Temperature Range: From -40oC to +121oC (-40oF to +250oF).

Here are the 6-wire hydraulic hose below:

Conclusion

In conclusion, understanding the 2-wire hydraulic hose structure is crucial for selecting the right hose for medium to high-pressure applications. The double wire braiding provides the necessary strength and durability, ensuring reliable performance in demanding environments. Proper selection prevents system failures and enhances overall safety.

The 2-wire hose, with its robust construction, offers a balance of flexibility and pressure resistance, making it a versatile choice for various hydraulic systems. Knowing its specifications and applications ensures you choose a hose that meets your system’s needs and maintains its integrity.

For high-quality, reliable hydraulic hoses, choose Kingdaflex. We offer wholesale solutions tailored to your specific requirements. Contact us today to explore our extensive range and ensure your hydraulic systems operate with maximum efficiency and safety.