AEM rubber, or Ethylene Acrylic Elastomer, is a high-performance synthetic rubber renowned for its exceptional balance of properties. It was engineered to withstand harsh environments where typical elastomers fail, offering a unique combination of heat resistance, oil resistance, and low-temperature flexibility. This guide will dive into what makes AEM a superior material.

Discover why industries like automotive and industrial manufacturing rely on AEM for critical components. We’ll explore its chemical composition, key advantages over other rubbers like EPDM and ACM, and its most common applications, including seals, gaskets, and high-performance hoses.

What is AEM Rubber?

AEM rubber, short for Ethylene Acrylic Elastomer, is a high-performance synthetic rubber created by combining ethylene and acrylic monomers. This unique copolymer structure is engineered to provide a superb balance of properties not found in many other common elastomers.

The ethylene component contributes excellent low-temperature flexibility and dynamic properties, while the acrylic groups are primarily responsible for the material’s strong resistance to hot oils and automotive fluids. This combination also results in a saturated backbone that imparts exceptional resistance to heat, ozone (weathering), and oxidation.

AEM Rubber Components

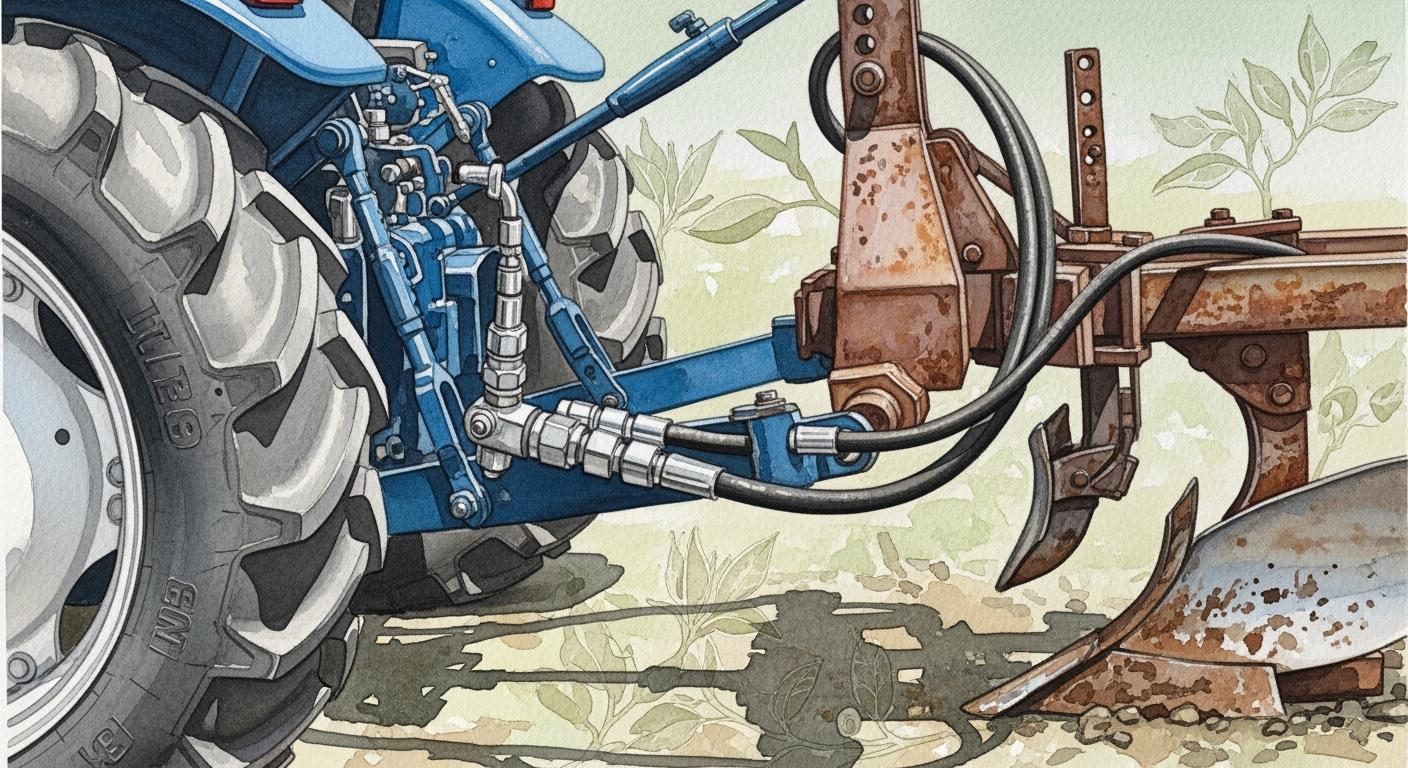

AEM rubber (Ethylene Acrylic Elastomer) is indispensable for components in harsh, dynamic environments, especially within the automotive powertrain. Its unique formulation provides superior resistance to heat, hot oils, and ozone, making it the perfect material for parts that must maintain sealing integrity and flexibility.

The most common applications for AEM take advantage of its balanced performance where other rubbers (like NBR or EPDM) might fail due to high temperatures or aggressive fluids. This includes seals and hoses where continuous contact with engine oil, transmission fluid, or hot air is expected.

- Turbocharger and Air Hoses: These components withstand high under-hood temperatures and exposure to oil vapor (blow-by gas). AEM’s heat resistance (up to 175 ℃ intermittent) and flexibility ensure long-term, reliable connections in the air management system.

- Engine and Transmission Seals: Used for shaft seals and O-rings, AEM resists the swelling and degradation caused by hot engine and transmission oils, ensuring minimal leakage. Its low-temperature flexibility also maintains a tight seal in cold-weather starts.

- Cylinder Head Cover Gaskets: AEM is excellent for static sealing against engine oils and blow-by condensates at high temperatures. Its good compression set resistance prevents the gasket from permanently flattening over time, maintaining seal pressure.

- Vibration Dampers and Mounts: Utilizing AEM’s outstanding dynamic properties and resistance to heat aging, these components isolate noise and vibration. The material retains its flexibility and damping capacity over a wide temperature range, ensuring consistent performance.

AEM Rubber Hose Advantages

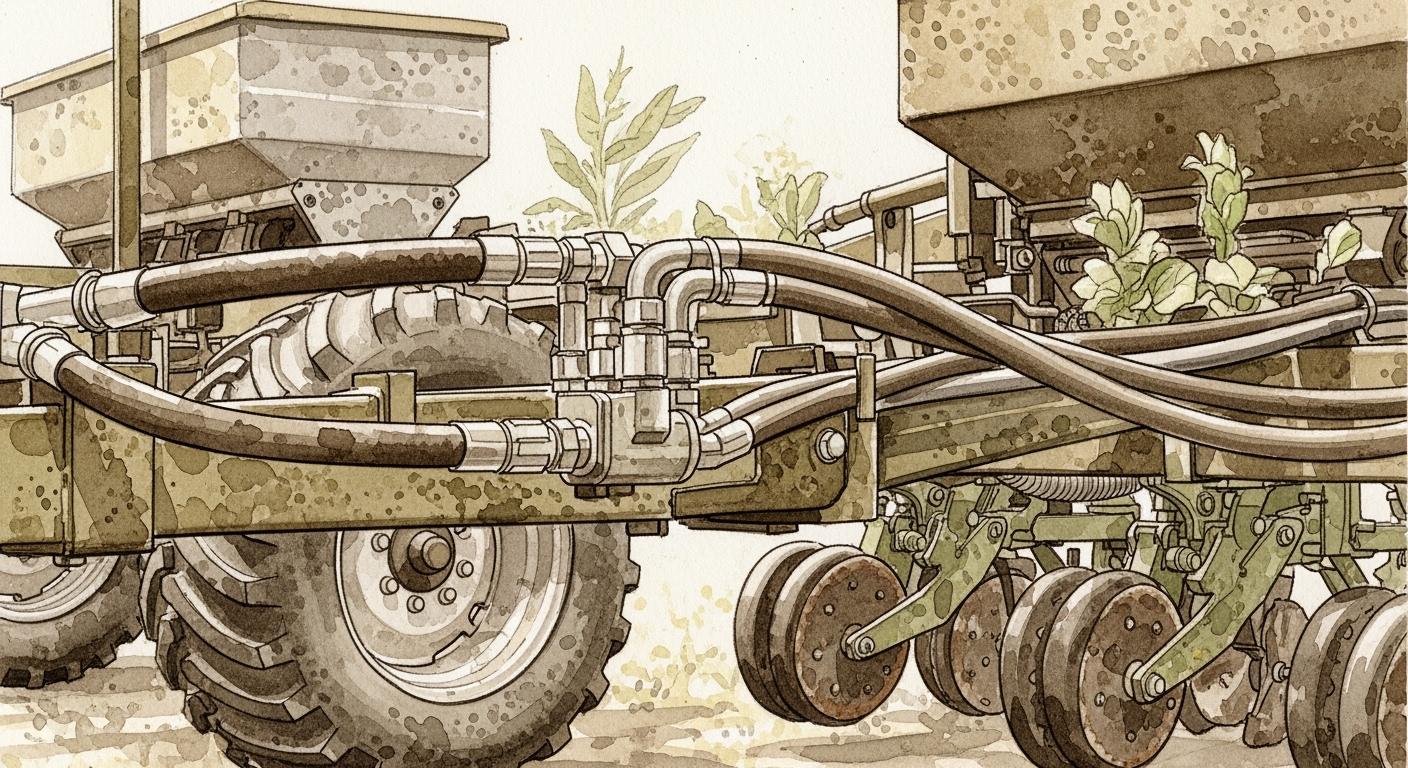

AEM (Ethylene Acrylic Elastomer) rubber hoses are engineered for demanding automotive and industrial applications where high heat, oil exposure, and long-term durability are critical. Their unique chemical structure offers a superior balance of resistance and dynamic flexibility that outperforms standard rubber types like EPDM and NBR in harsh environments.

AEM hoses provide a high-performance, cost-effective solution for systems that require reliable fluid transfer and air management under strenuous operating conditions.

- Exceptional Heat Resistance: AEM hoses maintain their physical properties and integrity at continuous operating temperatures up to 150℃. This feature is vital for turbocharger hoses and under-hood components where constant high heat would rapidly degrade conventional rubber materials.

- Superior Oil and Fluid Resistance: The acrylic component in AEM provides outstanding resistance to hot engine oil, synthetic transmission fluids (ATF), and lubricants. This prevents the hose from swelling, softening, or cracking, ensuring a long service life in oil transfer and cooling lines.

- Excellent Ozone and Weather Resistance: The saturated polymer backbone of AEM makes it highly resilient against ozone, UV light, and weathering. This is crucial for exterior-exposed hoses and prevents surface cracking or premature aging in the engine bay environment.

- Low-Temperature Flexibility and Dynamic Properties: AEM retains its flexibility down to approximately -40 ℃, preventing stiffening and cracking during cold starts. This ensures continuous sealing and reliable performance in dynamic applications, like vibration-dampening lines and air ducts.

AEM Rubber Hose Applications

AEM rubber hoses (Ethylene Acrylic Elastomer, like Vamac®) are selected for critical fluid and air transfer systems that operate under the most aggressive conditions. Their unique blend of thermal stability and resistance to various automotive fluids makes them indispensable for maximizing the reliability and lifespan of modern engines.

Engineers specify AEM to prevent component failure, a key concern in high-performance and high-mileage vehicle designs.

- Turbocharger and Air Intake Hoses: Used as flexible connectors in turbocharged systems to transport hot, pressurized air and oil vapor. AEM’s excellent heat resistance (up to 175 ℃ short-term) and oil resistance prevent the hose from softening, swelling, or bursting under high-stress turbo conditions.

- Transmission Oil Cooler Lines: Employed for hoses that manage the flow of hot automatic transmission fluid (ATF) between the transmission and the oil cooler. AEM resists the aggressive chemical additives and high temperatures of ATF, ensuring a long-lasting, leak-proof connection for the life of the vehicle.

- Crankcase Ventilation (PCV/Blow-by) Hoses: These hoses manage oil mist, combustion byproducts, and acidic condensates within the engine’s ventilation system. AEM’s resistance to ozone, oil, and acid blow-by prevents premature cracking or hardening, which is a common failure point for standard rubber materials.

- Heavy-Duty Cooling System Hoses: Used for radiator and heater hoses, often paired with aramid fiber reinforcement, in heavy-duty engines. AEM provides superior long-term performance and chemical resistance to coolants and high temperatures compared to conventional EPDM, particularly in demanding industrial and commercial vehicles.

Conclusion

AEM rubber is truly an essential, high-performance material in modern engineering, filling a crucial gap between more expensive fluoroelastomers and standard rubbers. Its standout characteristics—excellent resistance to hot oil, extreme heat, and ozone—make it indispensable for demanding applications within the engine and powertrain. Understanding AEM is key to material selection.

Ultimately, choosing AEM means investing in durability and reliability, especially for components that must endure continuous high temperatures and aggressive automotive fluids. By offering a superior operating temperature range and flexibility compared to other heat-resistant options, AEM reduces maintenance costs and extends the service life of critical parts in vehicles and machinery.

For reliable industrial and automotive applications, having access to high-quality rubber products is non-negotiable. Don’t compromise on performance or safety. Partner with us for your supply needs—you can get wholesale rubber hoses from our Kingdaflex that meet the highest standards of AEM and other premium elastomers.