Hydraulic hoses are vital components in numerous industrial and mobile applications, facilitating the transfer of hydraulic fluid under high pressure. Their flexibility and durability enable the operation of heavy machinery and equipment across diverse sectors. Understanding their construction, types, and applications is crucial for ensuring efficient and safe hydraulic system performance.

This guide provides a comprehensive overview of hydraulic hoses, covering their fundamental characteristics, material composition, and the various standards they adhere to. We will explore the distinctions between different hose types, such as braided and spiral, and delve into the factors that influence their selection for specific applications. Proper hose selection is key to maximizing system efficiency and longevity.

What Is A Hydraulic Hose?

-

SAE J1402 Air Brake Hose

SAE J1402 Air Brake Hose -

SAE J1401 Hydraulic Brake Hose

SAE J1401 Hydraulic Brake Hose -

SAE J188 Power Steering Hose

SAE J188 Power Steering Hose -

SAE 100R14 / Teflon Hose(Inner Corrugated Tube)

SAE 100R14 / Teflon Hose(Inner Corrugated Tube) -

SAE 100R6 | Hydraulic Hose

SAE 100R6 | Hydraulic Hose -

SAE 100R15 | Hydraulic Hose

SAE 100R15 | Hydraulic Hose -

SAE 100R13 | Hydraulic Hose

SAE 100R13 | Hydraulic Hose -

SAE 100R12 | 4 Wire Spiral Hydraulic Hose

SAE 100R12 | 4 Wire Spiral Hydraulic Hose -

SAE 100R9 | Hydraulic Hose

SAE 100R9 | Hydraulic Hose -

SAE 100R8 | Thermoplastic Hydraulic Hose

SAE 100R8 | Thermoplastic Hydraulic Hose -

SAE 100R7 | Thermoplastic Hydraulic Hose

SAE 100R7 | Thermoplastic Hydraulic Hose -

SAE 100R4 | Hydraulic Suction Hose

SAE 100R4 | Hydraulic Suction Hose -

SAE 100R3 Textile Fiber Reinforced Hydraulic Hose

SAE 100R3 Textile Fiber Reinforced Hydraulic Hose -

SAE 100 R14 / Teflon Hose (Inner Smooth Tube)

SAE 100 R14 / Teflon Hose (Inner Smooth Tube) -

SAE 100R5 | Fabric Covered Hydraulic Hose

SAE 100R5 | Fabric Covered Hydraulic Hose -

SAE 100R17 | Hydraulic Hose

SAE 100R17 | Hydraulic Hose -

SAE 100R16 | Hydraulic Hose

SAE 100R16 | Hydraulic Hose -

SAE 100R2A / DIN EN853 2ST

SAE 100R2A / DIN EN853 2ST -

SAE 100R1A/DIN EN853 1ST

SAE 100R1A/DIN EN853 1ST -

SAE 100R2AT / DIN EN853 2SN

SAE 100R2AT / DIN EN853 2SN -

SAE 100R1AT/ DIN EN853 1SN

SAE 100R1AT/ DIN EN853 1SN

A hydraulic hose is a flexible, reinforced conduit designed to transport hydraulic fluid under high pressure within a hydraulic system. These hoses are critical components in a wide range of machinery and equipment, enabling the transfer of power and facilitating mechanical movement. They are engineered to withstand the demanding conditions of hydraulic applications, including high pressures, temperature variations, and mechanical stress.

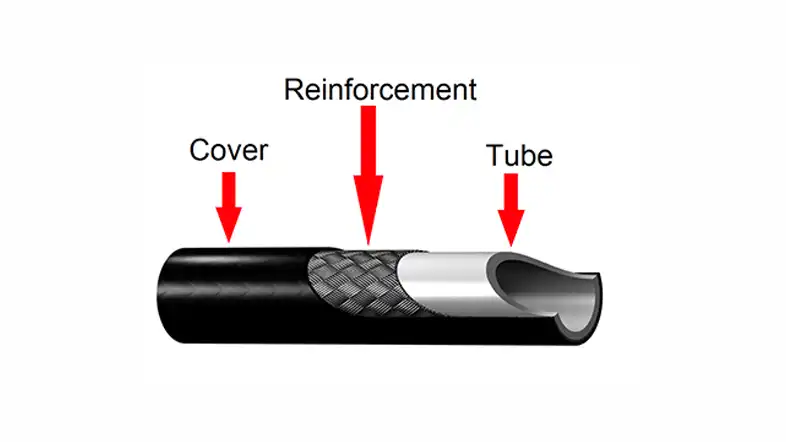

Constructed from multiple layers, hydraulic hoses typically consist of an inner tube, reinforcement layers, and an outer cover. The inner tube is made of a fluid-compatible material, often synthetic rubber or thermoplastic. The reinforcement layers, which can be braided or spiral wound from steel wire, textile, or synthetic fiber, provide the hose’s strength and pressure resistance. The outer cover protects the reinforcement layers from abrasion, weather, and other environmental factors, ensuring the hose’s longevity and reliability.

What Is A Hydraulic Hose Made of?

Hydraulic hoses are complex structures designed to handle high-pressure fluid transfer. Their construction involves multiple layers, each serving a specific purpose to ensure durability and performance. Understanding these layers is crucial for selecting the right hose for your application. The materials and manufacturing processes are carefully chosen to withstand the demanding conditions of hydraulic systems.

Hydraulic Hose Construction

Inner Tube:

The inner tube, made of synthetic rubber or thermoplastic, is the innermost layer that comes into direct contact with the hydraulic fluid. It must be compatible with the fluid to prevent degradation and ensure smooth flow. The inner tube’s material is selected to resist chemical reactions and maintain flexibility under varying temperatures and pressures, ensuring the hose’s longevity and performance.

Reinforcement layers, typically braided or spiral wound from steel wire, textile, or synthetic fiber, provide the hose’s strength and pressure resistance. These layers are designed to withstand the high pressures exerted by the hydraulic fluid, preventing the hose from bursting or expanding. The type and number of reinforcement layers determine the hose’s pressure rating and overall durability, crucial for heavy-duty applications.

Outer Cover:

The outer cover, made of synthetic rubber or thermoplastic, protects the reinforcement layers from abrasion, weather, and other environmental factors. This layer ensures the hose’s longevity and reliability in harsh working conditions. The outer cover is designed to resist damage from UV radiation, ozone, and physical wear, safeguarding the internal layers and maintaining the hose’s structural integrity.

What Are Hydraulic Hoses Used For

Hydraulic hoses are indispensable components in various industries, facilitating the transfer of hydraulic fluid under high pressure. Their versatility and durability make them essential for powering machinery and equipment. Here are some of the key applications of hydraulic hoses:

Construction Equipment

Hydraulic hoses are integral to the operation of construction equipment such as excavators, bulldozers, and cranes. These hoses enable the movement of heavy machinery components, allowing for precise control and powerful performance. They withstand the demanding conditions of construction sites, including high pressures and abrasive environments.

Agricultural Machinery

In agriculture, hydraulic hoses are used in tractors, harvesters, and other farm equipment to power various functions like lifting, steering, and implement control. These hoses ensure efficient operation in diverse agricultural settings, contributing to increased productivity and reduced manual labor. They are designed to resist the effects of weather, chemicals, and mechanical stress.

Industrial Applications

Hydraulic hoses are widely used in industrial settings for powering machinery in manufacturing, mining, and material handling. They facilitate the operation of hydraulic presses, lifts, and conveyors, enabling smooth and efficient production processes. These hoses are engineered to handle high pressures and extreme temperatures, ensuring reliable performance in demanding industrial environments.

Automotive Industry

In the automotive industry, hydraulic hoses are used in power steering systems, braking systems, and hydraulic lifts. They ensure reliable fluid transfer, contributing to vehicle safety and performance. These hoses are designed to withstand the varying temperatures and pressures encountered in automotive applications, ensuring long-term durability and efficiency.

Hydraulic Hose Application Comparison Table

| Application | Key Uses | Environmental Demands | Key Benefits |

| Construction Equipment | Excavators, bulldozers, cranes; movement of heavy machinery components. | High pressures, abrasive environments, temperature variations. | Precise control, powerful performance, durable construction. |

| Agricultural Machinery | Tractors, harvesters; lifting, steering, implement control. | Weather exposure, chemical exposure, mechanical stress. | Efficient operation, increased productivity, reduced manual labor. |

| Industrial Applications | Hydraulic presses, lifts, conveyors; manufacturing, mining, material handling. | High pressures, extreme temperatures, demanding working environments. | Smooth production processes, reliable operation, high performance. |

| Automotive Industry | Power steering systems, braking systems, hydraulic lifts. | Varying temperatures, pressure variations, fluid compatibility. | Reliable fluid transfer, enhanced safety, efficient performance. |

Types of Hydraulic Hose

Hydraulic hoses come in various types, each designed to meet specific application requirements based on pressure, temperature, and fluid compatibility. Understanding these types is crucial for selecting the right hose for your hydraulic system. Here are some common types of hydraulic hoses:

Rubber Hydraulic Hoses

Rubber hydraulic hoses are widely used due to their flexibility and ability to handle high pressures. They consist of a synthetic rubber inner tube, multiple layers of reinforcement (braided or spiral), and a synthetic rubber outer cover. These hoses are suitable for a broad range of hydraulic fluids and operating conditions, making them versatile for many applications.

Thermoplastic Hydraulic Hoses

Thermoplastic hydraulic hoses are made from synthetic polymers, offering excellent chemical resistance and flexibility. They are lightweight and suitable for medium to high-pressure applications. These hoses are often used in applications where cleanliness and chemical compatibility are crucial, such as in food processing and chemical industries.

Teflon Hydraulic Hoses

Teflon (PTFE) hydraulic hoses are designed for extreme temperature and chemical resistance. They can handle a wide range of fluids, including corrosive chemicals and high-temperature oils. These hoses are commonly used in aerospace, chemical processing, and high-temperature applications where reliability and durability are paramount.

Wire Braid Hydraulic Hoses

Wire braid hydraulic hoses are reinforced with one or more layers of braided steel wire. This construction provides excellent pressure resistance and durability, making them suitable for medium to high-pressure applications. These hoses are commonly used in multiple layers of spiraled steel wire, providing maximum pressure resistance. They are designed for very high-pressure applications, such as heavy-duty construction equipment and mining machinery. These hoses offer superior strength and durability in extreme operating conditions.

Hydraulic Hose Type Comparison Table

| Hose Type | Material | Pressure Rating | Key Applications |

| Rubber Hydraulic Hoses | Synthetic rubber inner tube, braided/spiral reinforcement, synthetic rubber cover. | Medium to High | Construction, agriculture, industrial machinery. |

| Thermoplastic Hydraulic Hoses | Synthetic polymers inner tube and cover, fiber reinforcement. | Medium to High | Food processing, chemical industries, applications requiring cleanliness. |

| Teflon Hydraulic Hoses | PTFE inner tube, braided reinforcement. | Extreme High | Aerospace, chemical processing, high-temperature applications. |

| Wire Braid Hydraulic Hoses | Synthetic rubber inner tube, braided steel wire reinforcement, synthetic rubber cover. | Medium to High | Construction, agriculture, industrial applications requiring robust performance. |

| Wire Spiral Hydraulic Hoses | Synthetic rubber inner tube, spiraled steel wire reinforcement, synthetic rubber cover. | Very High | Heavy-duty construction, mining, extreme pressure applications. |

Hydraulic Hose Standards

Hydraulic hoses adhere to various industry standards to ensure quality, safety, and compatibility across different applications. These standards define the performance, construction, and testing requirements for hydraulic hoses. Understanding these standards is crucial for selecting the right hose for your hydraulic system. Here are some of the key hydraulic hose standards:

SAE Standards

The Society of Automotive Engineers (SAE) standards are widely used in the automotive and industrial sectors. SAE standards specify the dimensions, pressure ratings, and performance requirements for hydraulic hoses. These standards ensure that hoses meet the necessary criteria for safe and reliable operation in various applications, from automotive brake lines to heavy machinery.

DIN Standards

The Deutsches Institut für Normung (DIN) standards are prevalent in European and international markets. DIN standards provide detailed specifications for hydraulic hoses, including dimensions, pressure ratings, and testing procedures. These standards ensure that hoses comply with stringent quality requirements, making them suitable for demanding hydraulic applications.

ISO Standards

The International Organization for Standardization (ISO) standards are globally recognized and provide comprehensive guidelines for hydraulic hoses. ISO standards cover various aspects, including hose construction, testing, and performance requirements. These standards promote uniformity and compatibility across different manufacturers and regions, ensuring that hydraulic hoses meet international quality and safety standards.

EN Standards

European Norms (EN) standards are developed by the European Committee for Standardization (CEN). These standards are harmonized with ISO standards and provide specific requirements for hydraulic hoses used within the European Union. They ensure that hoses meet stringent safety and performance criteria, promoting reliability and compatibility in European applications.

Hydraulic Hose Standard

| Standard | Geographic Focus | Key Aspects | Benefits |

| SAE Standards | North America, Industrial Sectors | Dimensions, pressure ratings, performance requirements. | Ensures compatibility and safe operation in automotive and industrial applications. |

| DIN Standards | European, International | Dimensions, pressure ratings, testing procedures. | Stringent quality requirements, reliability in demanding hydraulic applications. |

| ISO Standards | Global | Hose construction, testing, performance requirements. | Uniformity and compatibility, international quality and safety standards. |

| EN Standards | European Union | Specific safety and performance requirements, harmonized with ISO. | Reliability and compatibility in European applications, high safety standards. |

How to Manufacture Hydraulic Hoses

Manufacturing hydraulic hoses involves a series of precise steps to ensure they meet stringent quality and performance standards. This process requires careful selection of materials and adherence to specific manufacturing techniques. Here’s a breakdown of the key steps in hydraulic hose manufacturing:

Step 1: Material Preparation

The manufacturing process begins with the selection and preparation of raw materials. This includes synthetic rubber or thermoplastic for the inner tube and outer cover, as well as steel wire, textile, or synthetic fiber for the reinforcement layers. These materials are inspected for quality and prepared for the subsequent manufacturing stages.

Step 2: Inner Tube Extrusion

The inner tube is formed through an extrusion process, where the chosen material is heated and forced through a die to create a continuous tube. The dimensions and specifications of the inner tube are carefully controlled to ensure consistency and quality. This step establishes the foundation for the hose’s fluid-carrying capacity.

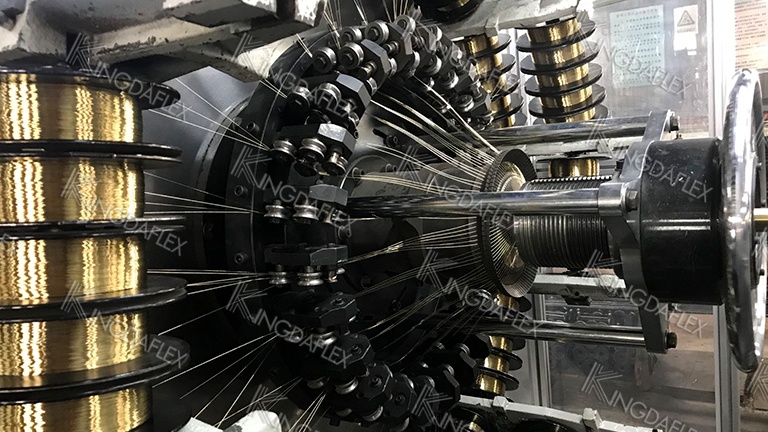

Step 3: Reinforcement Layer Application

Reinforcement layers are applied over the inner tube to provide the hose’s strength and pressure resistance. This can involve braiding or spiraling steel wire, textile, or synthetic fiber around the inner tube. The number and type of reinforcement layers are determined by the hose’s pressure rating and application requirements.

Step 4: Outer Cover Extrusion

The outer cover is applied over the reinforcement layers, providing protection from abrasion, weather, and other environmental factors. This layer is typically extruded from synthetic rubber or thermoplastic, ensuring a durable and protective outer surface. The outer cover’s material is selected to withstand the specific conditions of the hose’s intended application.

Step 5: Vulcanization or Curing

After the layers are assembled, the hose undergoes a vulcanization or curing process. This involves applying heat and pressure to bond the layers together, creating a cohesive and durable structure. The curing process ensures the hose’s integrity and performance under high-pressure conditions.

Step 6: Testing and Inspection

The final step involves rigorous testing and inspection to ensure the hydraulic hoses meet industry standards and customer specifications. This includes pressure testing, dimensional checks, and visual inspections. Hoses that pass these tests are then marked, packaged, and prepared for distribution.

Braided Hydraulic Hose vs Spiral

Understanding the differences between braided and spiral hydraulic hoses is crucial for selecting the right hose for your specific application. Both types offer distinct advantages and are designed for different pressure and flexibility requirements. Here’s a breakdown of their key characteristics:

Braided Hydraulic Hoses

Braided hydraulic hoses are reinforced with layers of braided wire, typically steel, over the inner tube. This construction provides excellent flexibility and moderate pressure resistance, making them suitable for applications where flexibility is paramount. Braided hoses are commonly used in medium-pressure hydraulic systems, such as those found in automotive and industrial machinery.

Spiral Hydraulic Hoses

Spiral hydraulic hoses are reinforced with multiple layers of spiraled wire, also typically steel, around the inner tube. This design offers superior pressure resistance and durability, making them ideal for high-pressure applications. Spiral hoses are commonly used in heavy-duty hydraulic systems, such as those found in construction and mining equipment, where extreme pressures and demanding conditions are prevalent.

Conclusion

In summary, hydraulic hoses are indispensable in modern hydraulic systems, enabling the transfer of power through fluid under high pressure. Their construction, materials, and adherence to industry standards ensure reliability and safety across various applications. Proper selection and maintenance are paramount for optimal performance. Understanding the differences between hose types, like braided and spiral, allows for application-specific choices.

The robustness of hydraulic hoses stems from their multi-layered design, encompassing an inner tube, reinforcement layers, and an outer cover, each serving a critical function. This construction allows them to withstand extreme pressures and environmental conditions. Regular inspections and timely replacements are essential to prevent system failures and ensure operational safety.

For high-quality wholesale hydraulic hoses that meet stringent industry standards, request a quote from Kingdaflex today. We offer a diverse range of durable and reliable hoses, tailored to your specific hydraulic system requirements. Contact us to discuss your needs and benefit from our expert service and competitive pricing.