Hydraulic hoses are critical components in countless industries, powering machinery and equipment from construction sites to manufacturing plants. To ensure the safe and efficient operation of hydraulic systems, proper identification of hydraulic hoses is essential. This is where hydraulic hose labels come into play.

In this blog post, we’ll explore the significance of hydraulic hose labels, discussing their key features, benefits, and the importance of adhering to labeling standards.

We’ll also provide practical tips for selecting and applying the right labels for your hydraulic hoses.

What Are Hydraulic Hose Labels

Hydraulic hose labels are specialized tags or stickers that provide essential information about a hydraulic hose. These labels are typically attached to the hose itself or to a nearby component.

Common information included on hydraulic hose labels:

- Hose type: Specifies the type of hose, such as braided wire, textile braid, or spiral wire.

- Size: Indicates the inner diameter and outer diameter of the hose.

- Working pressure: Specifies the maximum pressure the hose can withstand.

- Temperature range: Indicates the temperature limits within which the hose can safely operate.

- Fluid compatibility: Lists the types of fluids the hose is compatible with.

- Date of manufacture: Provides the date the hose was produced.

- Manufacturer‘s information: Includes the manufacturer‘s name, logo, and contact information.

Hydraulic hose labels serve several important purposes, including:

- Identification: They allow for easy identification of different hoses within a hydraulic system, preventing mix-ups and ensuring correct routing.

- Safety: They provide essential information about the hose’s capabilities, helping to prevent accidents and ensure safe operation.

- Compliance: They help ensure compliance with industry standards and regulations, which can be crucial for safety and liability reasons.

- Maintenance: They provide valuable information for maintenance and inspection purposes, helping to identify hoses that may need replacement or repair.

Why Hydraulic Hose Labels Are Important?

Hydraulic hose labels are essential for several reasons:

- Identification: They allow for easy identification of different hoses within a hydraulic system, preventing mix-ups and ensuring correct routing.

- Safety: They provide essential information about the hose’s capabilities, helping to prevent accidents and ensure safe operation.

- Compliance: They help ensure compliance with industry standards and regulations, which can be crucial for safety and liability reasons.

- Maintenance: They provide valuable information for maintenance and inspection purposes, helping to identify hoses that may need replacement or repair.

By ensuring that all hydraulic hoses are clearly labeled, you can:

- Reduce downtime: Prevent equipment failures caused by incorrect hose routing or selection.

- Improve safety: Minimize the risk of accidents and injuries.

- Extend the lifespan of your equipment By following proper maintenance and inspection procedures.

- Comply with industry regulations: Avoid legal and financial penalties.

In short, hydraulic hose labels are an essential tool for ensuring the safe, efficient, and compliant operation of hydraulic systems.

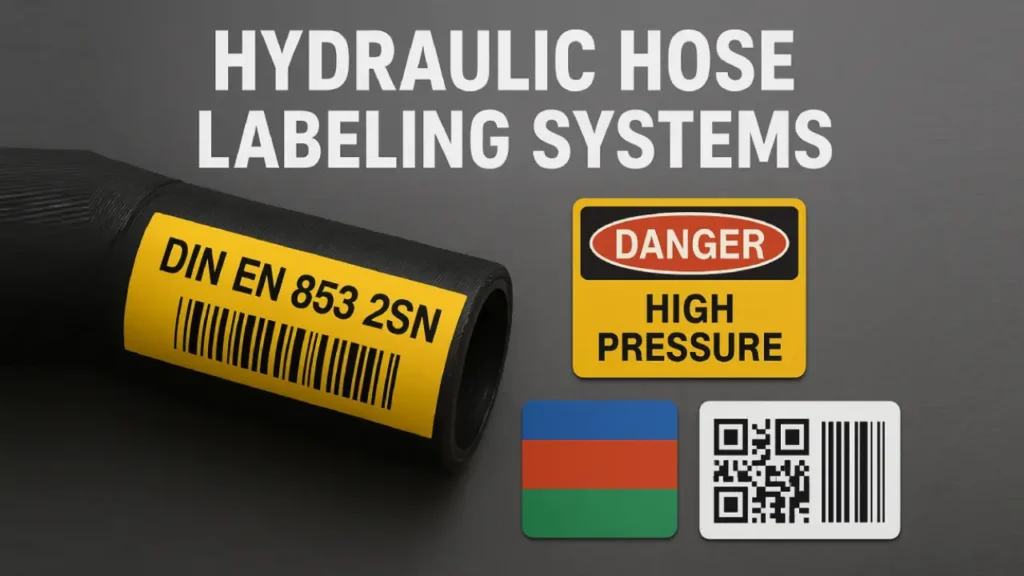

Hydraulic Hose Labeling Systems

Hydraulic hose labeling systems are essential for identifying, tracking, and managing hoses in industrial and hydraulic applications. Proper labeling ensures safety, reduces errors, and improves maintenance efficiency. These systems help operators quickly recognize hose types, pressure ratings, and service history, enhancing operational reliability.

- Durable Labels: Hydraulic hoses require labels that withstand high pressure, temperature fluctuations, and exposure to oils or chemicals. Durable labels maintain legibility over time, ensuring that hose information is easily readable, reducing the risk of improper usage or maintenance errors in demanding industrial environments.

- Color-Coding Systems: Many labeling systems use color codes to distinguish hose types, sizes, or fluid compatibility. This visual method allows operators to quickly identify the correct hose during assembly or repair, streamlining operations, and preventing costly downtime due to incorrect hose installation.

- Barcoding and QR Codes: Modern hydraulic hose labeling incorporates barcodes or QR codes for digital tracking. Scanning these codes provides instant access to hose specifications, maintenance records, and usage history, improving inventory management and enabling predictive maintenance practices for enhanced system reliability.

- Customizable Labels: Labeling systems allow customization to include company logos, part numbers, and operational instructions. Custom labels ensure consistency across equipment and make it easier for maintenance teams to follow standard operating procedures, enhancing workplace safety and operational efficiency.

- Automated Labeling Machines: Advanced labeling systems use automated machines to apply labels precisely and efficiently. Automation reduces human error, ensures consistent placement, and speeds up the production or assembly process, making it ideal for high-volume hydraulic hose manufacturing environments.

Hydraulic Hose Labeling Process

Labeling hydraulic hoses is crucial for safety, maintenance, and efficiency in various industries. Here’s the hydraulic hose labeling process (epilogue of the hydraulic hose manufacturing) including information on labeling machines:

Hydraulic Hose Labeling Methods:

Hydraulic Hose Tags:

- Metal Tags: Durable and resistant to harsh environments. They can be stamped, embossed, or photo-anodized with information.

- Cable Tie Tags: Plastic or metal cable ties with attached labels.

- Tags with Wire: Metal or plastic tags attached with wire.

Hydraulic Hose Labels:

- Adhesive Labels: Durable labels that adhere directly to the hose. These are often made from materials resistant to oil, chemicals, and UV radiation.

- Self-Laminating Labels: These labels have a clear over laminate that protects the printed information.

Hydraulic Hose Marking:

Spiral Marking: Plastic spiral wraps that are placed around the hose. These can be color-coded for easy identification.

Shrink Sleeves: Sleeves that shrink to fit tightly around the hose when heated.

Hydraulic Hose Labeling Machines:

Thermal Transfer Printers:

- These printers are commonly used to create durable labels with variable data, such as barcodes, QR codes, and text.

- They offer high-resolution printing and can handle various label materials.

Label Applicators:

- Automated label applicators can streamline the labeling process, especially in high-volume applications.

- These machines apply labels quickly and accurately.

Embossing/Stamping Machines:

- Used for creating durable metal tags with raised or indented characters.

Key Considerations:

Durability: Labels must withstand harsh environmental conditions, including exposure to oil, chemicals, temperature extremes, and UV radiation.

Clarity: Information on labels must be clear, legible, and easy to understand.

Compliance: Ensure that labeling practices comply with relevant industry standards and regulations.

Information to include:

- Part number

- Date of manufacture

- Pressure rating

- Temperature rating

- Fluid type

- Company information

- QR or barcodes for digital information retrieval.

By implementing a comprehensive hydraulic hose labeling process, businesses can enhance safety, improve maintenance practices, and ensure efficient operations.

Hydraulic Hose Identification Labels

Hydraulic hose identification labels play a critical and often underestimated role in industrial and mobile fluid power applications. These durable tags are essential for both safety compliance and efficient system maintenance, acting as the permanent “DNA” of the hose assembly. They consistently provide clear, non-fading specifications necessary for proper replacement and minimize the risk of costly errors, particularly where extreme pressure or temperature is involved.

🏷️ The Importance of Hose Labels

Hydraulic hose identification labels are small but crucial safety and maintenance tools in any fluid power system. They provide essential, at-a-glance information for quick and accurate replacement, reducing costly downtime and ensuring the correct hose is used. Relying solely on memory or faded hose layline markings is a recipe for system failure and safety hazards.

- Label content is paramount: A good label typically includes the hose manufacturer, part number, date of assembly, and maximum working pressure. This complete data ensures technicians can precisely replicate the failed assembly, maintaining the system’s operational integrity and design specifications.

🔍 Ensuring Proper Replacement

Labels offer the most reliable method for confirming the specifications of a hose assembly. They act as a permanent record of the original component, which is vital because the hose’s exterior layline can often become abraded, dirty, or unreadable over time in harsh operating environments. Accurate labeling is key for compliance.

- Preventing catastrophic failure: Matching the label information—especially the working pressure and fluid compatibility—is critical to prevent installing an under-specified hose. Using a lower-rated hose can lead to immediate bursts, property damage, and severe injury, highlighting the label’s safety function.

🛠️ Streamlining Maintenance and Inventory

Standardized labeling procedures significantly streamline maintenance and inventory management. When a failure occurs, the label allows the technician to immediately identify and pull the correct replacement from stock or quickly order a duplicate, minimizing the Mean Time to Repair (MTTR). This efficiency directly impacts productivity.

- Organized stock management: Implementing a consistent labeling system aids in efficient inventory practices. It allows maintenance teams to track hose usage, forecast future needs, and maintain optimal stock levels for critical assemblies, avoiding sudden shortages that can halt production lines for extended periods.

How to Identify Hydraulic Hose?

Proper identification of hydraulic hoses is crucial for safety and efficient operation. Here’s a breakdown of the key factors to consider:

1. Visual Inspection:

- Hose Type: Examine the hose’s construction to determine if it’s braided wire, textile braid, spiral wire, or thermoplastic.

- Color: Some hoses have specific colors to indicate their intended use or fluid compatibility.

- Reinforcement: Check for visible reinforcement layers, such as steel wire or textile braid.

2. Label Information:

- Manufacturer: Look for the manufacturer‘s name or logo.

- Size: Identify the hose’s inner diameter (ID) and outer diameter (OD).

- Working Pressure: Determine the maximum pressure the hose can withstand.

- Temperature Range: Check the temperature limits within which the hose can safely operate.

- Fluid Compatibility: Identify the types of fluids the hose is designed for.

3. Fittings:

- Type: Examine the fittings attached to the hose (e.g., flared, crimp-on, or reusable).

- Size: Measure the fitting size using a caliper.

- Thread Type: Identify the thread type (e.g., SAE, metric, JIC).

4. Markings:

- Layline: Look for a continuous line running along the length of the hose. This often indicates the direction of fluid flow.

- Other Markings: Some hoses may have additional markings, such as a date code or specific identification numbers.

5. Reference Materials:

- Hydraulic Hose Catalogs: Consult manufacturer catalogs or online resources to compare hose specifications and identify matches.

- Industry Standards: Refer to industry standards (e.g., SAE, ISO) for specific guidelines on hose identification and selection.

By carefully examining these factors, you can accurately identify hydraulic hoses and ensure that they are suitable for your specific application. If you have any doubts, it’s always recommended to consult a hydraulic hose specialist for assistance.

Conclusion

Proper identification of hydraulic hoses is crucial for safety, efficiency, and compliance. By understanding the key factors involved in hose identification and utilizing the information provided on hydraulic hose labels, you can ensure that your hydraulic system operates smoothly and reliably.

Need custom hydraulic hose labels that meet your specific requirements? Look no further than Kingdaflex. Our team of experts can design and manufacture labels that provide all the necessary information while adhering to industry standards.

Contact us today to discuss your labeling needs and explore our customization options. Let Kingdaflex help you ensure the safety and efficiency of your hydraulic systems with our premium hydraulic hoses and labels.

Visit our website or reach out to our sales team to learn more about Kingdaflex and our labeling services.