Proper hydraulic hose routing is essential for maintaining system efficiency, safety, and longevity. Poor routing can cause hose wear, kinks, and leaks, leading to downtime, maintenance costs, and potential hazards. Understanding best practices ensures hoses operate smoothly under pressure while reducing the risk of premature failure.

In this guide, we explore key strategies for hydraulic hose routing, including bending radius, support, and clearance considerations. Following these best practices prevents damage, improves fluid flow, and extends hose life. Whether for industrial machinery, automotive systems, or construction equipment, proper routing is critical for reliable hydraulic performance.

What is Hydraulic Hose Routing

Hydraulic hose routing refers to the careful planning and installation of hydraulic hoses within a system to ensure optimal performance, safety, and longevity. Proper routing minimizes stress on hoses, prevents kinks, and maintains smooth fluid flow, reducing the risk of leaks or failures in industrial, automotive, and construction applications.

Effective hydraulic hose routing involves considering bend radius, hose length, support points, and clearance from moving parts or heat sources. By strategically positioning hoses, technicians can avoid excessive wear, friction, and mechanical damage, ensuring reliable operation of hydraulic systems while improving maintenance efficiency and overall system safety.

Hydraulic Hose Routing Best Practices

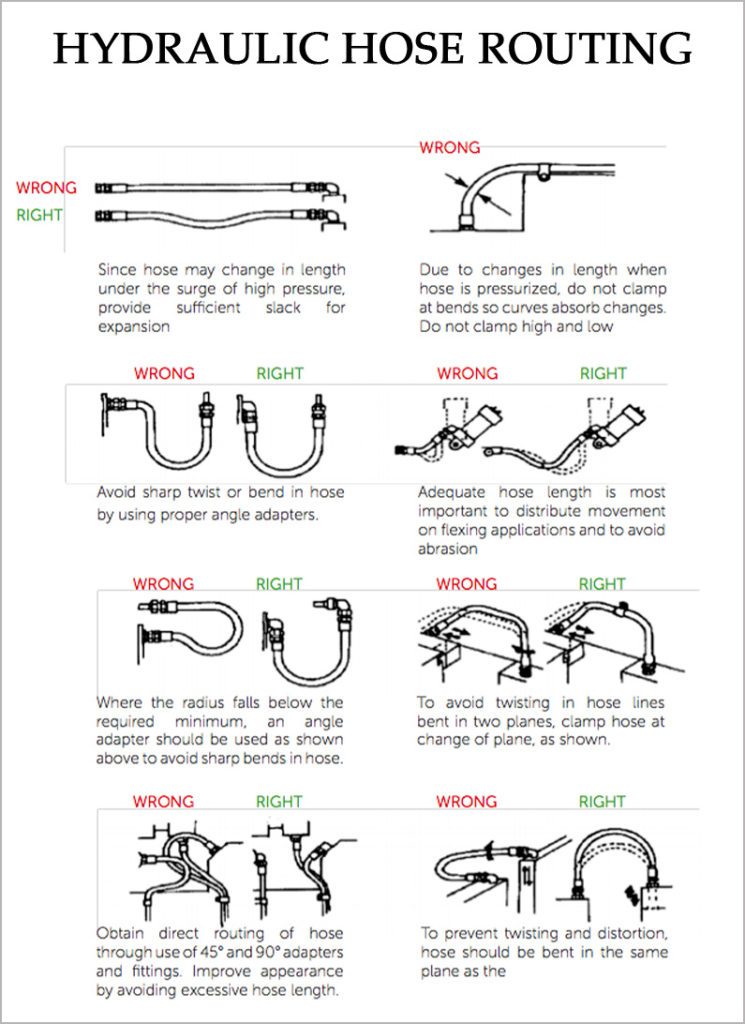

The image above illustrates some key best practices for properly routing hydraulic hoses to ensure safety, efficiency, and longevity. Following these guidelines helps prevent common failures, such as hose bursting or kinking, and reduces wear on components.

1. Provide Sufficient Slack

It’s crucial to provide a little slack in a hydraulic hose, as shown in the “RIGHT” image. When a hose is under high pressure, it can change length, a phenomenon known as axial elongation or contraction. If a hose is routed too tightly, without any slack, this change in length can cause stress on the fittings and lead to premature failure.

The “WRONG” image shows a hose that is stretched taut. Without enough slack, the hose cannot absorb the changes in length that occur during pressurization. This constant stress can fatigue the hose’s reinforcement layers and metal fittings over time, ultimately causing a leak or a catastrophic burst.

2. Avoid Clamping at Bends

Proper routing requires that hoses are not clamped at the point of a bend, as seen in the “WRONG” image. As pressure surges through the system, the hose needs to flex to absorb changes in length. Clamping it at a bend restricts this movement, concentrating stress at that single point and weakening the hose’s structure.

The “RIGHT” image demonstrates the correct approach: clamp the hose on a straight section, away from the bend. This allows the curve to flex freely, distributing the pressure and movement evenly along the hose’s length. This practice prevents the development of stress points and significantly extends the life of the hose.

3. Use Proper Angle Adapters

Routing a hose with a sharp, U-shaped bend is incorrect, as shown in the “WRONG” image. This forces the hose to bend beyond its minimum bend radius, leading to internal damage, kinking, and restricted fluid flow. The intense stress on the inner and outer layers can cause the hose to fail prematurely.

The “RIGHT” image illustrates the correct method: use a 90-degree angle adapter. These adapters allow for a change in hose direction without forcing the hose itself into an excessively tight bend. This maintains the hose’s integrity and ensures smooth fluid transfer, which is vital for system performance.

4. Distribute Hose Length for Flexing

The “WRONG” image depicts a hose that is too short, leading to all the movement being concentrated in a small section. This concentrated flexing causes fatigue and abrasion in one specific area, leading to accelerated wear and a high risk of failure.

The “RIGHT” image shows a hose with adequate length. Distributing the hose’s length correctly allows for the flexing to be spread out over a larger area, reducing concentrated stress. This also ensures that the hose doesn’t rub against other components, preventing abrasion that could compromise the hose’s cover and internal structure.

5. Clamp Hose at Change of Plane

Twisting a hose as it changes planes is a common but dangerous mistake, as shown in the “WRONG” image. A twisted hose can become distorted under pressure, leading to uneven stress on its reinforcing layers. This can severely weaken the hose, making it susceptible to bursting.

The “RIGHT” image shows the proper way to route a hose through a plane change: use a clamp at the point of transition. This prevents the hose from twisting, ensuring it remains in its natural, untwisted state. Maintaining the hose’s original alignment is critical for its performance and durability.

6. Avoid Direct Routing with Adapters

Directly routing a hose with tight, continuous bends is problematic, as seen in the “WRONG” image. This can lead to excessive hose length and complicated, inefficient pathways that are hard to inspect and maintain. This practice increases the risk of the hose rubbing against other parts.

The “RIGHT” image illustrates a better solution: use 45-degree and 90-degree adapters to create a cleaner and more direct routing path. This improves the system’s appearance, simplifies maintenance, and reduces the overall hose length, which in turn minimizes the chance of abrasion and kinking.

7. Bend Hose in the Same Plane

Bending a hose in different planes is a key cause of twisting and distortion, as shown in the “WRONG” image. This introduces torsional stress into the hose, which can cause the internal reinforcing layers to separate or shift, leading to a loss of strength and potential rupture.

The “RIGHT” image demonstrates the correct method: ensure all bends are kept in a single, consistent plane. This simple practice prevents the hose from twisting on its axis when pressurized. By avoiding torsional forces, you ensure the hose operates within its design parameters, extending its service life significantly.

8. Use Angle Adapters for Minimum Bend Radius

Routing a hose with a bend that is too tight, falling below its minimum bend radius, is a recipe for failure, as shown in the “WRONG” image. This crushes the internal layers of the hose, restricts fluid flow, and can cause the outer cover to crack.

The “RIGHT” image shows that when a sharp bend is necessary, an angle adapter should be used. This allows the hose to maintain its proper bend radius, preventing kinking and internal damage. Angle adapters are essential for maintaining fluid dynamics and protecting the hose’s structure in confined spaces.

Proper Hydraulic Hose Routing Guidelines

These are hydraulic hose routing methods shown above in the diagrammatic drawing, and please pay attention to the points telling right or wrong, this can tell you if your hydraulic hose routing method is proper or improper.

Here are some hydraulic hose routing guidelines, which can tell you how to plan the hydraulic hose routing, in which way you can route the hydraulic hose on the hydraulic line. And you can view the schematic diagram showing the hydraulic hose routing method, and this is the hose routing map to guide the layout of the hydraulic hose pipes properly.

It is much easier for you, as the hydraulic hose expert, or hydraulic hose worker, to follow these hydraulic hose installation methods to organize your hydraulic hose routing.

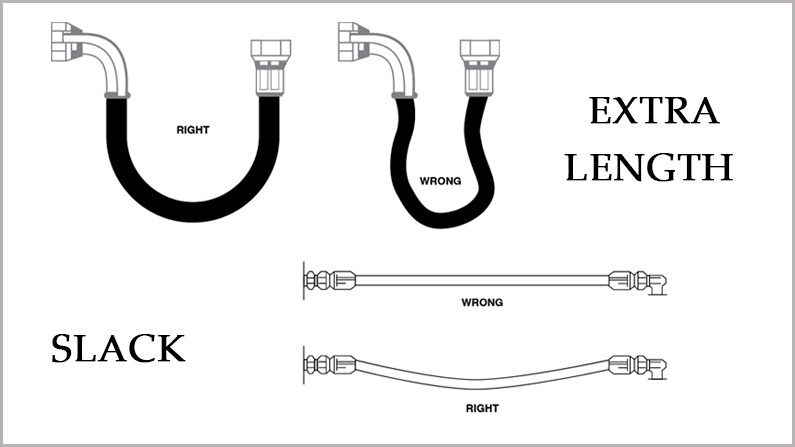

Slack Hydraulic Hose Is Allowed

You can prepare an extra length of hydraulic hose for hydraulic hose measurement, to allow some changes when the hydraulic hose is pressurized. Don’t make the hydraulic hose pull or drag too tightly, this will cause the hydraulic hose a potential hazard.

The high pressure in the hydraulic hose will lead to hydraulic hose tension. And the high pressure will also stress the hydraulic hose fitting connection, or pull out the loose fittings, to cause hydraulic hose sealing failure.

So it is important to leave some extra length to avoid the risk of hydraulic hose snagging or breakage.

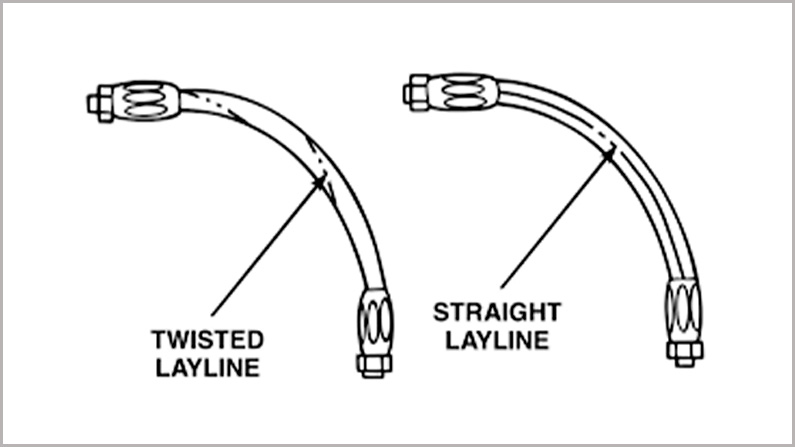

Don’t Twist Hydraulic Hose

Don’t make the hydraulic hose twisted while hydraulic hose routing and the twisted hydraulic hose will cause premature hose failure. This is the difference between twisted layline and straight layline.

You need to allow the hydraulic hose routing direction naturally, without disturbing it to towards the opposite. The straight hydraulic hose can convey the hydraulic fluids with flexibility, without any barriers.

It is very dangerous if the hydraulic fluid is plugged within the hydraulic hose, which may cause the hydraulic hose bursting problems.

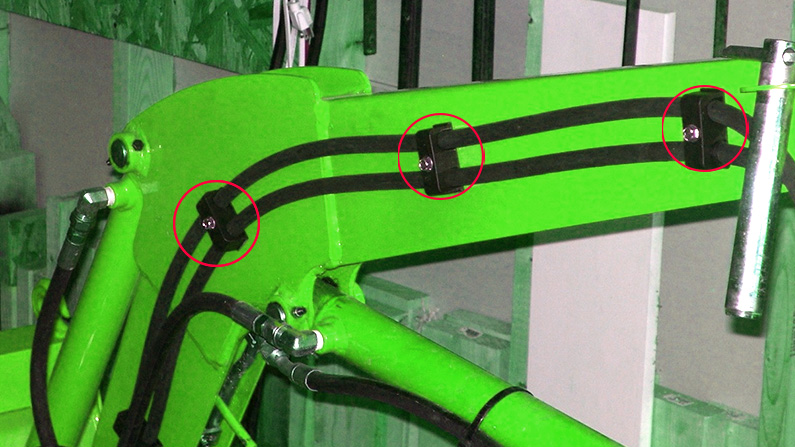

Use Hydraulic Hose Clamps

The heavy-duty hydraulic hose machinery, such as crane, lift, mining machine and etc, will require multiple hydraulic hoses. So the hydraulic hose fastness will be very important, and the hydraulic hose routing clamps can help a lot.

The hydraulic hose routing clamps can lock the hydraulic hoses well, making them attached and sealed onto a fitting such as a barb or nipple, to be firmer to avoid falling from the hydraulic system.

Use Matched Hydraulic Hose Fittings

Don’t mix the hydraulic hose and fittings during the hydraulic hose installation process, and please ensure that you can use the proper hydraulic hose fittings to match your hydraulic hose diameter.

It’s better to choose the hydraulic hose fittings from the same manufacturer, and the hydraulic hose fittings are also vital to ensure to seal hydraulic hoses with safety and qualified.

The hydraulic hose model is required with standard, and please feel free to consult the experienced hydraulic hose expert or just contact us if you are confused about the hydraulic hose fittings selection.

Use Hydraulic Hose Sleeve

In order to expand the service life of the hydraulic hose, please wrap the hydraulic hose with the hydraulic hose sleeve, such as the spiral hose guard, fire sleeve. Here are various types of hydraulic hose protectors, don’t forget to choose the ones to protect your hydraulic hose away from potential damages.

Conclusion

Effective hydraulic hose routing protects hoses from mechanical wear, kinks, and leaks, ensuring consistent performance and safety. By adhering to best practices, businesses reduce downtime, prevent costly repairs, and maintain optimal system efficiency across various applications. Proper planning and installation are key to long-lasting hydraulic operations.

Regular inspection and maintenance complement proper routing, helping identify early signs of hose wear or misalignment. Ensuring correct bend radii, supports, and clearances minimizes stress on hoses, protecting hydraulic systems from leaks or failures. Following these practices results in improved reliability and reduced operational risks.

At Kingdaflex, we provide wholesale hydraulic hoses designed for durability and performance. Our hoses support efficient routing, withstand high pressure, and resist wear, ensuring long-lasting operation. Partner with Kingdaflex today to get hydraulic hoses tailored to your industrial, automotive, or construction applications at competitive wholesale prices.