Selecting the correct hydraulic hose size is crucial for the efficient and safe operation of any hydraulic system. Incorrect sizing can lead to pressure drops, overheating, and even system failures. This blog will guide you through the essential steps of measuring and selecting the appropriate hydraulic hose sizes, ensuring optimal performance and longevity for your equipment.

We’ll delve into the factors influencing hose size selection, including flow rate, pressure requirements, and application specifics. By understanding these elements, you can make informed decisions and avoid costly mistakes. This guide aims to provide practical insights and clear instructions, empowering you to choose the right hydraulic hose sizes for your needs.

What Hydraulic Hose Sizes Include

Understanding hydraulic hose sizes is crucial for ensuring the proper functioning and efficiency of hydraulic systems. These sizes are standardized to ensure compatibility and consistent performance across various applications. We will explore the different aspects of hydraulic hose sizes and what they include.

Nominal Hose Size (Dash Size)

Nominal hose size, often referred to as “dash size,” is a numerical code that approximates the inside diameter (ID) of the hydraulic hose. This size is typically expressed in sixteenths of an inch. For example, a -8 hose has an approximate ID of 8/16 inch, or 1/2 inch. Dash sizes are used throughout the hydraulic industry to standardize hose dimensions and facilitate easy selection and replacement.

Inside Diameter (ID)

The inside diameter (ID) of a hydraulic hose is the actual measurement of the hose’s bore, which determines the volume of fluid that can flow through it. ID is critical for calculating flow rates and pressure drops within the hydraulic system. Selecting the correct ID ensures optimal fluid velocity and minimizes energy loss. Manufacturers provide detailed specifications for ID in their hose catalogs, allowing for precise system design.

Outside Diameter (OD)

The outside diameter (OD) of a hydraulic hose includes the thickness of the hose’s reinforcement layers and outer cover. OD is essential for determining the space required for hose routing and installation. It also influences the hose’s flexibility and bend radius. When designing hydraulic systems, consider the OD to ensure adequate clearance and prevent hose damage from tight bends or obstructions.

Wall Thickness

Wall thickness refers to the thickness of the hydraulic hose’s inner tube, reinforcement layers, and outer cover. It directly impacts the hose’s pressure rating and durability. Thicker walls provide greater pressure resistance and protect the reinforcement layers from abrasion and environmental factors. Selecting the appropriate wall thickness is crucial for ensuring the hose can withstand the operating pressures of the hydraulic system.

Length

Hydraulic hose length is a critical factor in system design and installation. The length of the hose affects pressure drop and fluid velocity within the system. Longer hoses may result in increased pressure drop and reduced flow rates. Accurate measurement and selection of hose length are essential for maintaining system efficiency and performance. Manufacturers offer hoses in various standard lengths and can also provide custom lengths to meet specific application requirements.

Why Are Hydraulic Hose Sizes Important?

So the hydraulic hose is the fundamental considered to work for your machinery, engined by hydraulic system, and the hydraulic hose sizes are matters most importantly. Selecting the hydraulic hose with the right size is basically an important step to ensure the hydraulic system can work well.

You can get the way how to measure hydraulic hose and the hydraulic hose sizes are described by the measurement of hydraulic hose parts, including hydraulic hose ID, OD, and length.

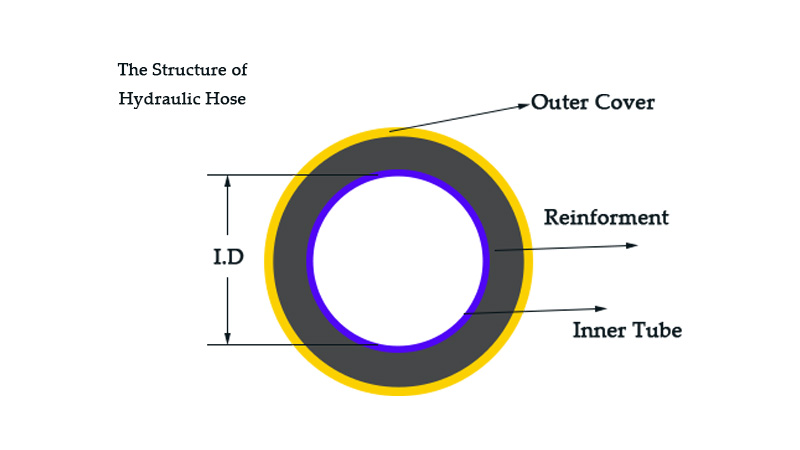

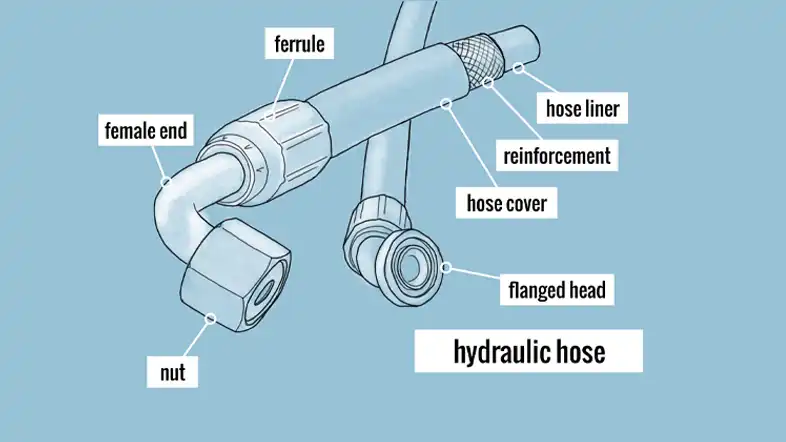

ID is the hydraulic hose inner diameter, OD is the outer diameter, so ID, OD can determine the hydraulic hose size. You can see the hydraulic hose structure, to get a clue about hydraulic hose sizing.

The ID and OD sizes are very important, they can’t be too small or too big. The proper inner diameter can ensure the hydraulic fluids inside the hydraulic hose can be conveyed fluently, without any jams, pumps. The proper outer diameter can ensure the hydraulic hose can be assembled well, to match the hydraulic hose fittings. And the hydraulic hose fitting sizes can be determined by the hydraulic hose’s outer diameter.

The right hydraulic hose ID and OD can avoid some hydraulic hose failure problems, such as hydraulic hose leaking, breaking, crushing and etc. So the hydraulic hose pipe sizes are greatly important, at the very beginning of your hydraulic system building.

Here you can download the Hydraulic Hose Size Chart PDF, to be clear about the standard hydraulic hose sizes.

How to Measure Hydraulic Hose Size?

Accurately measuring hydraulic hose size is crucial for selecting the correct replacement or designing a new hydraulic system. Incorrect measurements can lead to leaks, pressure drops, and system failures. We’ll guide you through the essential steps to measure hydraulic hose size correctly.

Step 1: Identify the Hose Type and Size Markings

Begin by identifying the type of hydraulic hose and checking for any size markings printed on the hydraulic hose’s outer cover. These markings often include the hose’s dash size, inside diameter (ID), and pressure rating. However, these markings may fade or become illegible over time, so it’s essential to verify the dimensions using physical measurements. If the markings are clear, note them down as they provide a good starting point for your measurements.

Step 2: Measure the Inside Diameter (ID)

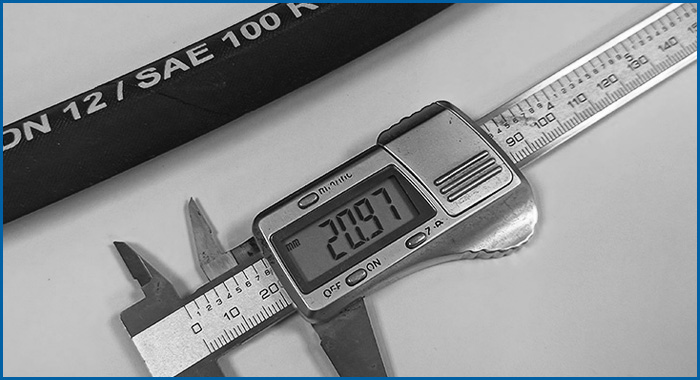

To measure the inside diameter (ID), use calipers or an inside micrometer to measure the bore of the hose. If the hose is still connected to the system, disconnect it and measure the ID at the hose’s end. Take multiple measurements at different points to ensure accuracy, as the ID can vary slightly due to manufacturing tolerances or wear. The ID is critical for calculating flow rates and pressure drops within the hydraulic system.

Step 3: Measure the Outside Diameter (OD)

Use calipers or an outside micrometer to measure the outside diameter (OD) of the hose. Take multiple measurements along the hose’s length to account for any variations. The OD is essential for determining the space required for hose routing and installation. It also influences the hose’s flexibility and bend radius. Ensure you measure the OD including the outer cover, as this is the dimension that determines the hose’s overall size.

Step 4: Measure the Hose Length

Measure the overall length of the hydraulic hose from end to end, including any fittings or couplings. Use a measuring tape or ruler to obtain an accurate length measurement. Ensure the hose is laid out straight to avoid any inaccuracies caused by bends or curves. The length measurement is crucial for determining the hose’s pressure drop and ensuring it fits within the hydraulic system’s design.

Step 5: Verify and Compare Measurements

After taking all measurements, verify and compare them with the manufacturer’s specifications or industry standards. Ensure the measured dimensions align with the required sizes for your hydraulic system. If there are any discrepancies, consult a hydraulic hose specialist or refer to a size chart to ensure you select the correct hose size. Accurate measurements are essential for maintaining the system’s efficiency and preventing potential failures.

What Size Hydraulic Hose Do I Need?

Hydraulic Hose Size Calculator

Calculating the correct hydraulic hose size is crucial for ensuring optimal performance and safety in hydraulic systems. Several factors need to be considered, including the flow rate, velocity, pressure drop, and the type of fluid being transmitted. While a professional hydraulic engineer or technician is best suited to perform accurate calculations, you can use a general guideline to estimate the hose size.

Here’s a simplified method to get a rough idea of the hydraulic hose size:

- Determine the Flow Rate: Identify the required flow rate in gallons per minute (GPM) or liters per minute (LPM). This can be determined based on the system’s needs, such as the hydraulic cylinder or equipment being powered.

- Calculate the Velocity: Calculate the velocity of the fluid within the hose. The recommended velocity for most hydraulic systems is typically between 10 to 15 feet per second (3 to 4.5 meters per second). To calculate the velocity, divide the flow rate by the cross-sectional area of the hose.

- Estimate the Hose Size: Refer to the hydraulic hose manufacturer‘s specifications or hydraulic hose catalogs to find the recommended maximum flow velocity for various hose sizes. Based on the calculated velocity from step 2, choose a hose size that can accommodate the flow rate while maintaining a suitable velocity.

- Consider Pressure Ratings: Ensure that the selected hose size has a pressure rating that exceeds the maximum operating pressure of the system. This information can be found in the manufacturer’s specifications or on the hose itself.

- Consult with our Professionals: For accurate calculations and to ensure the selection of the appropriate hose size, it is always recommended to consult with our hydraulic engineers, technicians, or reputable suppliers who can provide expert guidance based on specific system requirements.

Remember, this is a simplified method, and there are additional factors to consider, such as hose length, fittings, and specific application requirements. For precise and reliable results, it is best to consult with professionals who have expertise in hydraulic system design and can perform detailed calculations using hydraulic software or formulas.

Hydraulic Hose Dash Size

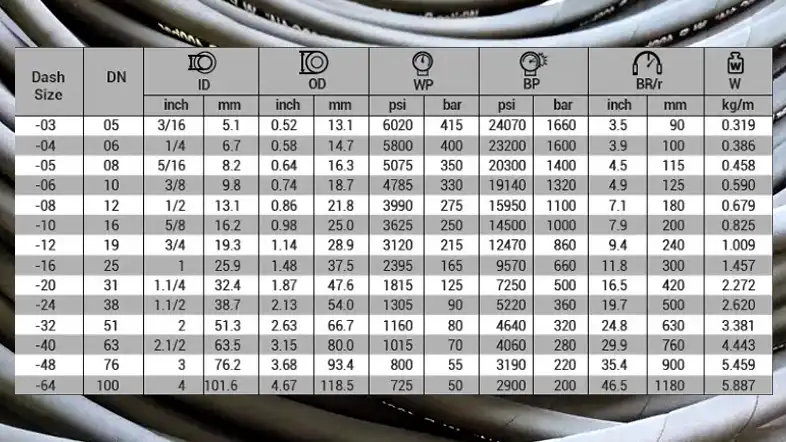

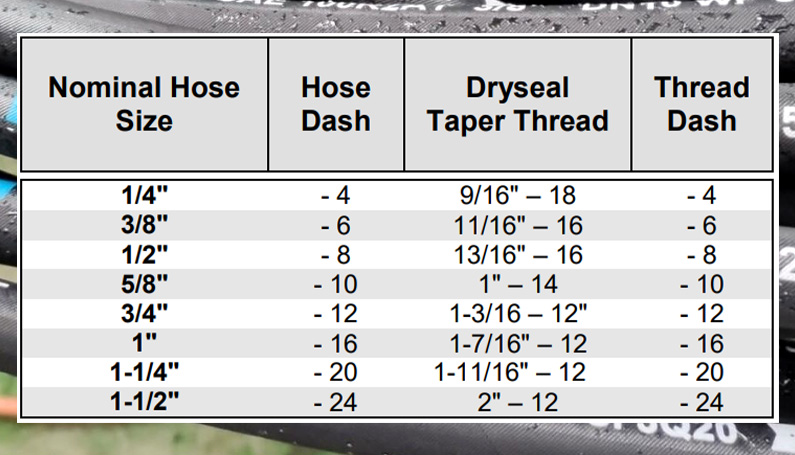

In hydraulic hoses, the dash size refers to the industry standard sizing system used to identify the size of the hose. The dash size represents the nominal inside diameter (ID) of the hose in sixteenths of an inch.

The dash size is denoted by a number, followed by a hyphen (-) and sometimes additional numbers or letters that indicate variations or specific features of the hose. For example, dash sizes commonly range from -2 to -32, with each dash size corresponding to a specific ID measurement.

Here are a few examples of dash sizes and their corresponding nominal inside diameters:

- Dash Size -2: 1/8 inch (3.2 mm)

- Dash Size -4: 1/4 inch (6.4 mm)

- Dash Size -6: 3/8 inch (9.5 mm)

- Dash Size -8: 1/2 inch (12.7 mm)

- Dash Size -12: 3/4 inch (19.1 mm)

- Dash Size -16: 1 inch (25.4 mm)

- Dash Size -20: 1 1/4 inch (31.8 mm)

- Dash Size -32: 2 inches (50.8 mm)

It’s important to note that the dash size only represents the nominal inside diameter of the hose and doesn’t provide information about the outside diameter, working pressure, or other specifications of the hose. Therefore, it’s necessary to refer to the manufacturer’s specifications or consult with hydraulic professionals to ensure the correct selection of hydraulic hoses based on specific application requirements.

How to Determine Hydraulic Hose Size

What size hydraulic hose do I need?

Determining the correct hydraulic hose size for your specific hydraulic hose application requires consideration of several factors. Here’s a step-by-step guide to help you determine the appropriate hydraulic hose size:

- Identify the Flow Rate: Determine the required flow rate of the hydraulic system in gallons per minute (GPM) or liters per minute (LPM). This can be based on the equipment being powered or the hydraulic cylinder’s specifications.

- Calculate the Velocity: Calculate the velocity of the hydraulic fluid within the hose. The recommended velocity for most hydraulic systems is typically between 10 to 15 feet per second (3 to 4.5 meters per second). To calculate the velocity, divide the flow rate by the cross-sectional area of the hose.

- Consider Pressure Ratings: Determine the maximum operating pressure of your hydraulic system. It’s crucial to select a hose with a pressure rating that exceeds the maximum operating pressure to ensure safety and reliability.

- Refer to Manufacturer’s Specifications: Consult the manufacturer’s specifications or hydraulic hose catalog to find the recommended maximum flow velocity and pressure ratings for various hose sizes. These specifications will help you choose the right hose size based on the calculated velocity and pressure requirements.

- Account for Hose Length and Fittings: Consider the length of the hose and the fittings that will be used. Longer hoses or certain types of fittings may result in pressure drops or restrictions, requiring a larger hose size to compensate.

- Seek Professional Advice: If you’re unsure or working on a complex hydraulic system, it’s always recommended to consult with hydraulic engineers, technicians, or reputable suppliers who can provide expert guidance and ensure the correct selection of hydraulic hose size for your specific application.

Please remember, selecting the appropriate hydraulic hose size is crucial for optimal performance, efficiency, and safety. By considering factors like flow rate, velocity, and pressure ratings, and seeking professional advice when needed, you can determine the right hydraulic hose size for your hydraulic system.

How to Identify Hydraulic Hose Size

Identifying the size of a hydraulic hose can be done by examining the hose itself and referring to industry standards. Here are a few steps to help you identify the hydraulic hose size:

- Check for Printed Specifications: Look for any printed specifications on the hose itself. Manufacturers often print the size or part number directly on the outer cover of the hose. This information may include the dash size or the nominal inside diameter (ID) of the hose.

- Measure the Outer Diameter (OD): Use a caliper or tape measure to measure the outer diameter of the hose. This measurement can provide a rough estimate of the hose size. However, keep in mind that the OD alone does not determine the hose size accurately, as different hose constructions can have varying ODs for the same nominal size.

- Count the Number of Wire Braids: For hoses with wire braids, you can count the number of wire braids visible on the cut end of the hose. This can provide a clue about the hose size. However, this method is not always reliable as some hoses may have varying numbers of wire braids for the same size.

- Refer to the Manufacturer’s Specifications: If you have access to the manufacturer’s specifications or documentation, refer to it for accurate identification. The specifications should provide details about the hose size, dash size, or nominal inside diameter.

- Compare to Industry Standards: Hydraulic hoses generally follow industry standards, such as the SAE (Society of Automotive Engineers) or ISO (International Organization for Standardization) standards. Refer to these standards to match the measurements or information you have obtained and identify the corresponding hose size.

- Consult with Professionals: If you’re uncertain about the hose size or need accurate identification, it’s recommended to consult with hydraulic engineers, technicians, or reputable suppliers. They have expertise and access to resources that can help determine the correct hose size based on specific requirements.

Identifying the hydraulic hose size accurately is important for proper replacement or compatibility. While visual inspection and measurements can provide some guidance, referring to manufacturer specifications and seeking professional advice will ensure accurate identification.

Hydraulic Hose Size Chart

A hydraulic hose size chart is a valuable tool for selecting the appropriate hose for a specific hydraulic system. It typically involves a graphical representation (often a nomograph) that helps determine the ideal hose size based on key factors:

1. Flow Rate:

- The volume of fluid that needs to pass through the hose per unit of time (e.g., gallons per minute or liters per minute).

2. Fluid Velocity:

- The speed at which the fluid travels through the hose.

- Higher velocities can lead to increased pressure drop, erosion, and excessive heat generation.

- Lower velocities can result in insufficient flow for the application.

3. Hose Inner Diameter (I.D.):

- The critical dimension that directly influences flow capacity and pressure drop.

How the Chart Works:

- Nomographs: These charts utilize aligned scales for each of the three variables (flow rate, velocity, and hose I.D.).

- By connecting the known values for flow rate and desired velocity with a straight line, the corresponding hose I.D. can be read directly from the chart.

Key Considerations:

- Pressure Rating: The chart itself doesn’t directly provide pressure information.

- It’s crucial to select a hose with a pressure rating that significantly exceeds the maximum operating pressure of the hydraulic system to ensure safety and prevent failures.

- Temperature Range: The chosen hose must be able to withstand the expected temperature extremes of the operating environment.

- Fluid Compatibility: The hose material must be compatible with the hydraulic fluid used in the system (e.g., resistance to chemical attack, swelling, or degradation).

- Application: The specific application (e.g., high-pressure applications, high-temperature environments, abrasive environments) will influence the choice of hose material and construction.

Finding a Hydraulic Hose Size Chart:

- Manufacturer Websites: Most hydraulic hose manufacturers provide size charts and selection guides on their websites.

- Hydraulic Component Distributors: These distributors often have access to comprehensive charts and can provide expert guidance on hose selection.

- Engineering Handbooks: Many engineering handbooks contain sections on fluid power and include relevant sizing charts.

By carefully considering these factors and utilizing a hydraulic hose size chart, you can select the most suitable hose for your application, ensuring optimal system performance, efficiency, and longevity.

| Factor | Consideration | Importance | Example |

|---|---|---|---|

| Inner Diameter | 3/8-inch is standard | Ensures compatibility and optimal water flow | Using a 1/4-inch hose can restrict water flow and reduce cleaning power |

| Pressure Rating | Exceeds pressure washer’s maximum output | Prevents hose bursts and leaks | A 3000 PSI hose for a 2600 PSI pressure washer |

| Length | Balance reach with pressure loss | Longer hoses can reduce pressure | 50ft for greater reach, 25ft for less pressure loss |

| Material | Durability and kink resistance | Impacts longevity and performance | Steel-braided or reinforced rubber for heavy-duty use |

| Coupling | Secure connection to pressure washer | Prevents leaks and maintains pressure | Quick-connect or threaded for easy attachment |

Conclusion

Selecting the appropriate hydraulic hose size is paramount for ensuring efficient and safe operation of your hydraulic system. By carefully considering factors such as working pressure, flow rate, fluid type, and environmental conditions, you can make informed decisions and avoid potential problems.

Remember, a hydraulic hose that is too small can restrict flow, leading to increased pressure and reduced system performance. Conversely, a hose that is too large may not be able to withstand the required pressure, resulting in leaks or bursts.

Ready to invest in a custom hydraulic hose that perfectly suits your system’s needs?

Contact Kingdaflex today! Our team of experts can provide personalized guidance and design a hose that meets your exact specifications. With our commitment to quality and customer satisfaction, you can trust Kingdaflex to deliver a hydraulic hose that exceeds your expectations.

Don’t settle for anything less than the best. Reach out to us for a free consultation and discover how our custom hydraulic hoses can enhance your system’s performance and reliability.