Hydraulic hoses are essential components in many industries, but not all hoses are created equal. Understanding the differences between high-pressure and low-pressure hoses is crucial for selecting the right hose for your specific application.

In this blog post, we will dive into the key distinctions between these two types of hoses, including their construction, applications, and performance characteristics.

What Is High Pressure Hydraulic Hose

A high-pressure hydraulic hose is a specialized type of hose designed to withstand and transmit high-pressure hydraulic fluid. These hoses are crucial components in various industries, including construction, agriculture, manufacturing, and automotive.

Key characteristics of high-pressure hydraulic hoses:

- Robust Construction: They are built with strong, durable materials, such as high-quality rubber and steel wire braid reinforcement.

- High Pressure Rating: They can handle significantly higher pressures compared to standard hoses.

- Resistance to Wear and Tear: They are designed to withstand harsh operating conditions, including extreme temperatures, vibration, and exposure to chemicals.

- Flexibility: Despite their robust construction, they are flexible enough to maneuver in various applications.

Common Applications of High-Pressure Hydraulic Hoses:

- Construction Equipment: Excavators, bulldozers, and cranes

- Agricultural Machinery: Tractors, combines, and other farm equipment

- Industrial Machinery: Presses, injection molding machines, and machine tools

- Automotive Industry: Power steering systems, brake systems, and suspension systems

By understanding the specific requirements of your application, you can select the appropriate high-pressure hydraulic hose to ensure optimal performance and safety.

What Is Low Pressure Hydraulic Hose

A low-pressure hydraulic hose is designed to handle lower pressure hydraulic fluid. These hoses are commonly used in applications where the pressure requirements are not as demanding as in high-pressure systems.

Key characteristics of low-pressure hydraulic hoses:

- Lighter Construction: They often have a simpler construction, with less reinforcement compared to high-pressure hoses.

- Lower Pressure Rating: They are designed to handle lower pressure levels.

- Increased Flexibility: They are more flexible and easier to route.

Common Applications of Low-Pressure Hydraulic Hoses:

- Low-Pressure Hydraulic Systems: Used in various industrial and agricultural applications where lower pressure is sufficient.

- Return Lines: Used to return hydraulic fluid to the reservoir after it has been used.

- Suction Lines: Used to draw hydraulic fluid from the reservoir to the pump.

While low-pressure hoses are not as robust as high-pressure hoses, they are well-suited for their specific applications and offer a cost-effective solution for lower-pressure hydraulic systems.

High Pressure Hose and Low Pressure Hose Different Standards

While there’s no universally accepted standard for classifying hydraulic hoses as high-pressure or low-pressure, several factors are considered:

Pressure Rating:

- Low-Pressure Hoses: Typically have a maximum working pressure below 2,000 PSI (138 bar).

- High-Pressure Hoses: Designed to handle pressures exceeding 2,000 PSI (138 bar), often reaching 3,000 PSI (207 bar) or more.

Construction and Reinforcement:

- Low-Pressure Hoses: Often reinforced with textile braids, which provide flexibility but limited strength.

- High-Pressure Hoses: Typically reinforced with wire braid or spiral wire, offering superior strength and resistance to high pressure.

Applications:

- Low-Pressure Hoses: Used in applications with lower pressure requirements, such as agricultural equipment, light industrial machinery, and automotive systems.

- High-Pressure Hoses: Employed in demanding applications requiring high pressure, such as construction equipment, mining machinery, and heavy-duty industrial equipment.

Industry Standards:

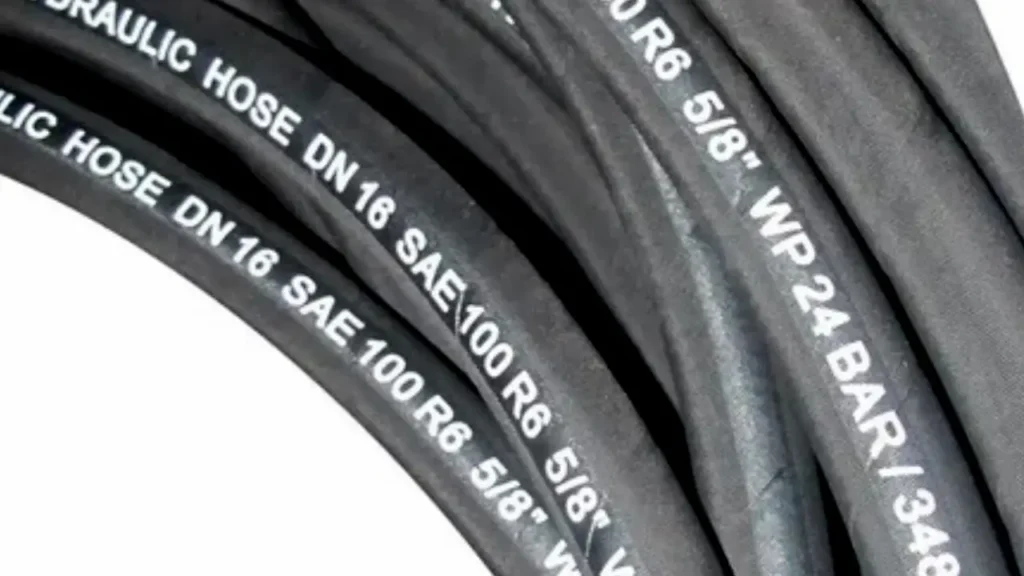

- SAE (Society of Automotive Engineers): SAE 100R series standards define various types of hydraulic hoses, including high-pressure and low-pressure classifications.

- ISO (International Organization for Standardization): ISO standards provide guidelines for hydraulic hose design, performance, and testing.

It’s important to note that the specific classification and pressure ratings can vary depending on the manufacturer and the intended application.

Please consult our hydraulic hose manufacturer to get the detailed hydraulic hose specifications and industry standards to ensure the correct selection and use of hydraulic hoses for your specific needs.

High Pressure Hose and Low Pressure Hose Different Applications

High-Pressure Hydraulic Hoses

High-pressure hydraulic hoses are designed to withstand and transmit high-pressure hydraulic fluid. They are crucial components in various industries, including construction, agriculture, manufacturing, and automotive.

Key applications of high-pressure hydraulic hoses:

- Construction Equipment: Excavators, bulldozers, and cranes

- Agricultural Machinery: Tractors, combines, and other farm equipment

- Industrial Machinery: Presses, injection molding machines, and machine tools

- Automotive Industry: Power steering systems, brake systems, and suspension systems

Low-Pressure Hydraulic Hoses

Low-pressure hydraulic hoses, on the other hand, are designed for applications that require lower pressure levels.

Common applications of low-pressure hydraulic hoses:

- Low-Pressure Hydraulic Systems: Used in various industrial and agricultural applications where lower pressure is sufficient.

- Return Lines: Used to return hydraulic fluid to the reservoir after it has been used.

- Suction Lines: Used to draw hydraulic fluid from the reservoir to the pump.

Key Differences between high pressure hydraulic hoses and low pressure hydraulic hoses:

| Feature | High-Pressure Hose | Low-Pressure Hose |

|---|---|---|

| Pressure Rating | High pressure rating | Lower pressure rating |

| Construction | Robust construction with multiple layers of reinforcement | Simpler construction with fewer layers of reinforcement |

| Flexibility | Less flexible due to thicker reinforcement | More flexible due to simpler construction |

| Applications | Heavy-duty applications requiring high pressure | Lower-pressure applications like return lines and suction lines |

By understanding the differences between high-pressure and low-pressure hydraulic hoses, you can select the right hose for your specific application, ensuring optimal performance and safety.

High Pressure Hose and Low Pressure Hose Different Diameters

Diameter and High / Low-Pressure Hoses

The diameter of a hydraulic hose is a crucial factor in determining its pressure rating and suitability for specific applications.

Generally, high-pressure hoses tend to have smaller diameters compared to low-pressure hoses. This is because a smaller diameter can withstand higher pressures without compromising the hose’s integrity.

However, it’s important to note that the diameter of a hose is not the sole determinant of its pressure rating. Other factors, such as the material of the hose, the thickness of the walls, and the type of reinforcement used, also play significant roles.

Factors Affecting Diameter Selection:

- Flow Rate: A larger diameter hose can handle higher flow rates, which is essential for applications that require significant fluid flow.

- Pressure Rating: Higher pressure ratings often require smaller diameter hoses to maintain structural integrity.

- Space Constraints: In some applications, space limitations may dictate the use of smaller diameter hoses.

Consulting with our Hydraulic Hose Specialist

To ensure the correct selection of hydraulic hoses, it’s recommended to consult with a hydraulic hose specialist. They can help you determine the appropriate diameter and pressure rating based on your specific application requirements.

By considering factors such as flow rate, pressure, and space constraints, you can choose the right hydraulic hose to optimize your system’s performance and efficiency.

High-Pressure vs Low-Pressure Hose: Manufacturing Techniques

While the fundamental principles of hydraulic hose manufacturing are similar for both high-pressure and low-pressure hoses, there are key differences in the materials and techniques used to create these products.

High-Pressure Hose Manufacturing

Key Techniques:

- Reinforcement: High-pressure hoses often employ multiple layers of reinforcement, typically using wire braid or spiral wire. This reinforcement provides exceptional strength and durability to withstand high-pressure applications.

- Material Selection: The inner tube and outer cover of high-pressure hoses are made from high-quality, durable materials that can resist the effects of high pressure, temperature, and chemical exposure.

- Strict Quality Control: Rigorous quality control measures are implemented throughout the manufacturing process to ensure the hose meets stringent performance standards.

Low-Pressure Hose Manufacturing

Key Techniques:

- Simpler Construction: Low-pressure hoses often have a simpler construction, with fewer layers of reinforcement.

- Textile Reinforcement: Textile braids are commonly used as reinforcement material for low-pressure hoses, providing flexibility and durability.

- Less Rigorous Testing: While quality control is still important, the testing standards for low-pressure hoses may be less stringent compared to high-pressure hoses.

In summary, the primary differences in the manufacturing techniques for high-pressure and low-pressure hoses lie in the materials used, the reinforcement layers, and the level of quality control.

By understanding these distinctions, you can select the appropriate hose for your specific application, ensuring optimal performance and safety.

How to Choose High-Pressure Hose and Low-Pressure Hose

Selecting the right hydraulic hose is crucial for system performance and safety. High-pressure and low-pressure hoses serve distinct purposes, and understanding their differences ensures optimal operation.

Here’s a guide to help you choose the appropriate hose for your application.

High-Pressure Hose Selection

High-pressure hoses are designed to withstand significant hydraulic pressures, typically exceeding 3,000 PSI. When selecting a high-pressure hose, consider the maximum operating pressure of your system, the type of fluid being conveyed, and the temperature range. Look for hoses with reinforced layers, such as steel wire braiding or spiral wrapping, to ensure durability and prevent burst failures. Also, check the hose’s burst pressure rating, which should be significantly higher than the system’s operating pressure, providing a safety margin.

Low-Pressure Hose Selection

Low-pressure hoses are used in applications where hydraulic pressures are below 3,000 PSI. These hoses are typically more flexible and lightweight than high-pressure hoses. When selecting a low-pressure hose, consider the system’s operating pressure, the type of fluid, and the temperature range. Look for hoses with appropriate reinforcement, such as textile braiding or single wire braiding, depending on the pressure requirements. Ensure the hose has adequate flexibility for the application and is compatible with the fittings being used.

Difference Between a High Pressure Hose and a Regular Hose

The fundamental difference between a high-pressure hose and a regular hose lies in their construction and ability to withstand internal fluid pressure. Regular hoses, like typical garden hoses, are designed for low-pressure applications, handling household water pressures ranging from about 30-150 PSI.

High-pressure hoses, conversely, are engineered with robust, multi-layered reinforcements, often including steel wire braids or spirals, allowing them to safely convey fluids at pressures ranging from thousands to tens of thousands of PSI for demanding industrial or cleaning tasks.

- Pressure Rating: Regular hoses are built for low-pressure domestic use, typically tolerating pressures up to 150 PSI. High-pressure hoses are significantly reinforced to withstand extreme pressures, commonly ranging from 1,000 PSI to over 40,000 PSI in specialized industrial applications.

- Construction and Materials: Regular hoses are usually made from lighter materials like PVC or basic rubber with minimal reinforcement, prioritizing flexibility and cost. High-pressure hoses feature multiple layers of durable synthetic rubber or thermoplastic, heavily reinforced with braided or spiral-wound steel wire for immense strength and burst resistance.

- Flexibility vs. Rigidity: While some high-pressure hoses offer flexibility, their heavy reinforcement makes them generally stiffer and less pliable than regular hoses. Regular hoses are designed for maximum flexibility and ease of coiling, as they don’t require the same structural integrity under low pressure.

Conclusion

Understanding the differences between high-pressure and low-pressure hydraulic hoses is crucial for selecting the right hose for your specific application. By considering factors such as pressure rating, temperature range, fluid compatibility, and flexibility, you can ensure optimal performance and safety.

Need custom hydraulic hoses tailored to your specific requirements?

Kingdaflex offers a wide range of high-quality hydraulic hoses, including both high-pressure and low-pressure options. Our experienced team can work with you to design and manufacture hoses that meet your exact needs.

Contact us today to explore our custom hydraulic hose solutions.