Hydraulic hoses are essential components of hydraulic systems used in various applications, including heavy machinery, construction, agriculture, and industrial equipment. The type of hydraulic hose used in a particular application depends on several factors, including the operating pressure, temperature, and flow rate.

Two of the most common hydraulic hoses are 2 wire and 4 wire hydraulic hoses. In this article, we’ll explore the differences between 2 wire hydraulic hose and 4 wire hydraulic hoses and help you understand which one is best suited for your application.

What Is A Hydraulic Hose?

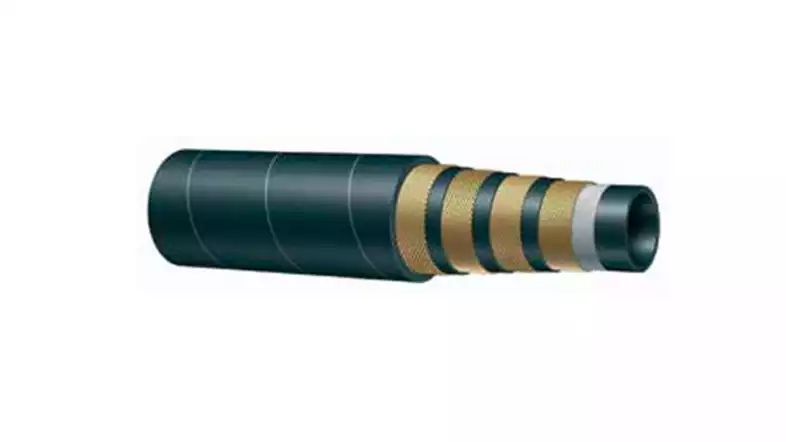

A hydraulic hose is a flexible tube that carries hydraulic fluid between the components of a hydraulic system. The hydraulic fluid is typically oil-based and under high pressure, making it critical to choose the right type of hydraulic hose for the application. Hydraulic hoses are made of several layers of materials, including an inner tube, reinforcement layers, and an outer cover.

A hydraulic hose is a flexible tubing made of synthetic rubber, thermoplastic or Teflon material that is designed to transmit hydraulic fluid from one component to another in a hydraulic system. Hydraulic hoses are widely used in various industries including agriculture, construction, manufacturing, and transportation to transmit high-pressure fluids or gases to operate machines or equipment.

Hydraulic hoses come in different sizes, pressure ratings, and temperature ranges to suit specific applications. They are typically composed of three layers: the inner tube that carries the hydraulic fluid, the outer cover that protects the hose from abrasion, and the reinforcement layer that provides strength to the hose under high pressure. The reinforcement layer is typically made of braided wire or spiral-wound wire.

Proper selection, installation, and maintenance of hydraulic hoses are crucial for ensuring the safe and efficient operation of a hydraulic system. Improper use of hydraulic hoses can lead to leaks, hose failure, and potentially dangerous accidents.

Understanding 2 Wire Hydraulic Hoses

These hoses are typically used in applications with moderate pressure and temperature ratings. The two layers of steel wire reinforcement provide excellent strength and flexibility to the hose while allowing it to bend easily. 2 wire hydraulic hoses are available in various sizes and configurations, making them suitable for a wide range of applications.

Understanding 4 Wire Hydraulic Hoses

A 4 wire hydraulic hose is a type of hydraulic hose that features four layers of steel wire reinforcement. These hoses are designed for high-pressure applications and are typically used in heavy-duty machinery, construction, and industrial equipment. The four layers of steel wire reinforcement provide exceptional strength and flexibility to the hose while maintaining its structural integrity even under extreme pressure and temperature conditions.

Differences between 2 Wire and 4 Wire Hydraulic Hoses

The primary difference between 2 wire and 4 wire hydraulic hoses is the number of layers of steel wire reinforcement. While 2 wire hoses feature two layers of steel wire reinforcement, 4 wire hoses feature four layers of steel wire reinforcement. As a result, 4 wire hoses can handle higher pressure and temperature ratings than 2 wire hoses.

Advantages of 2 Wire Hydraulic Hoses

- Lightweight and flexible

- Easy to bend and route

- Suitable for low to moderate pressure and temperature applications

- Lower cost than 4 wire hoses

- Available in various sizes and configurations

Advantages of 4 Wire Hydraulic Hoses

- Extremely strong and durable

- Capable of handling high-pressure and temperature applications

- Resistant to wear, abrasion, and corrosion

- Suitable for heavy

When to Use 2-Wire Hydraulic Hose

2 wire hydraulic hoses are ideal for low to moderate pressure and temperature applications. They are lightweight, flexible, and easy to route, making them suitable for applications that require a lot of movement. They are also more cost-effective than 4-wire hoses, making them an excellent choice for applications that don’t require high pressure or temperature ratings.

When to Use 4 Wire Hydraulic Hose

4 wire hydraulic hoses are designed for heavy-duty applications that require high pressure and temperature ratings. They are ideal for use in heavy machinery, construction, and industrial equipment. They are also resistant to wear, abrasion, and corrosion, making them suitable for harsh environments.

2-Wire Vs 4-Wire Hydraulic Hose

Hydraulic hoses are used to transmit fluid power from one component to another within a hydraulic system. The number of wire reinforcements in a hydraulic hose can impact its strength, durability, and pressure rating. Here are some differences between 2 wire hydraulic hose and 4 wire hydraulic hose:

| Parameter | 2 Wire Hydraulic Hose | 4 Wire Hydraulic Hose |

|---|---|---|

| Pressure Rating | Lower pressure rating (typically up to 5,000 psi) | Higher pressure rating (typically up to 6,000 psi or more) |

| Strength | Less strong than 4 wire hose | Stronger than 2 wire hose |

| Durability | Less durable than 4 wire hose | More durable than 2 wire hose |

| Bend Radius | Typically more flexible than 4 wire hose | Typically less flexible than 2 wire hose |

| Applications | Suitable for low to medium-pressure applications | Suitable for high-pressure and high-impulse applications |

| Cost | Lower cost than 4 wire hose | Higher cost than 2 wire hose |

The selection of a hydraulic hose depends on the application’s specific requirements, including the pressure rating, strength, durability, flexibility, and cost.

The wire reinforcement layer within a hydraulic hose acts as a structural backbone, providing the necessary strength to withstand the high pressures and forces exerted by the hydraulic fluid. Increasing the number of wires adds more structural elements to the hose, enhancing its ability to resist bursting or kinking.

There are two primary methods of wire reinforcement in hydraulic hoses:

- Wire Braid: This involves braiding the wires together, offering a balance of strength and flexibility.

- Wire Spiral: In this method, wires are wound in a spiral pattern, providing greater strength but often with reduced flexibility.

The choice between these methods depends on the specific application and the required balance of strength and flexibility.

For example, applications that require high pressures and minimal bending may opt for wire spiral reinforcement, while those that demand flexibility and moderate pressures might choose wire braid.

Common Applications of 2-Wire Hydraulic Hoses

2 wire hydraulic hoses are commonly used in applications such as:

- Agricultural equipment

- Material handling equipment

- Small machinery

- Mobile equipment

Common Applications of 4-Wire Hydraulic Hoses

4 wire hydraulic hoses are commonly used in applications such as:

- Heavy machinery

- Construction Equipment

- Mining equipment

- Industrial equipment

Choosing the Right Hydraulic Hose for Your Application

Choosing the right hydraulic hose for your application requires careful consideration of several factors, including operating pressure, temperature, flow rate, and environmental conditions. It’s essential to consult with a hydraulic hose expert who can help you select the best hose for your specific application.

Tips for Maintaining Hydraulic Hoses

To ensure the longevity and performance of your hydraulic hoses, consider the following maintenance tips:

- Regularly inspect hoses for signs of wear, damage, or leaks.

- Avoid sharp bends or kinks in the hose.

- Keep hoses clean and free from debris.

- Replace hoses that show signs of wear or damage.

Conclusion

Hydraulic hoses are critical components of hydraulic systems and are available in various types, sizes, and configurations. Understanding the differences between 2-wire and 4-wire hydraulic hoses can help you choose the best hose for your specific application. While 2 wire hoses are suitable for low to moderate-pressure and temperature applications, 4 wire hoses are designed for heavy-duty applications that require high pressure and temperature ratings. Consult with a hydraulic hose expert to ensure you choose the best hose for your application.

FAQs

What is the difference between 2-wire and 4-wire hydraulic hoses?

The primary difference between 2-wire and 4-wire hydraulic hoses is the number of layers of steel wire reinforcement. 4-wire hoses feature four layers of steel wire reinforcement and can handle higher pressure and temperature ratings than 2-wire hoses, which only feature two layers of steel wire reinforcement.

What are the advantages of 2-wire hydraulic hoses?

The advantages of 2-wire hydraulic hoses include being lightweight, flexible, easy to bend and route, suitable for low to moderate pressure and temperature applications, lower cost than 4-wire hoses, and available in various sizes and configurations.

What are the advantages of 4-wire hydraulic hoses?

The advantages of 4-wire hydraulic hoses include being extremely strong and durable, capable of handling high-pressure and temperature applications, resistant to wear, abrasion, and corrosion, and suitable for heavy-duty machinery and industrial equipment.

What are some common applications of 2-wire hydraulic hoses?

Some common applications of 2-wire hydraulic hoses include agricultural equipment, material handling equipment, small machinery, and mobile equipment.

What are some common applications of 4-wire hydraulic hoses?

Some common applications of 4-wire hydraulic hoses include heavy machinery, construction equipment, mining equipment, and industrial equipment.