Hydraulic hoses are critical components in many industrial and mobile applications, transmitting pressurized fluid to power equipment.

However, these hoses are subject to wear and tear, leading to leaks, ruptures, and potential system failures. While some issues may require professional replacement, minor repairs can be attempted in certain situations.

This blog post will guide you through some basic steps on how to repair a hydraulic hose. We’ll cover common issues, safety precautions, and simple repair techniques.

Why Hydraulic Hose Repair is Important?

When hydraulic hoses fail, machinery grinds to a halt, leading to costly downtime and significant productivity losses. Leaking hoses don’t just create a mess; they can lead to hazardous working conditions, environmental contamination, and even catastrophic equipment failure. Prompt and professional hydraulic hose repair is essential not only to restore your equipment’s functionality swiftly but also to:

- Minimize Downtime: Get your operations back up and running quickly, avoiding extended periods of inactivity.

- Prevent Further Damage: Address leaks before they escalate, protecting other vital hydraulic components from contamination or insufficient fluid levels.

- Enhance Safety: Eliminate slippery conditions and the risk of high-pressure fluid injections, creating a safer environment for your team.

- Reduce Costs: Repairing a hose is often significantly more cost-effective than a full replacement, saving on parts and labor.

- Extend Equipment Lifespan: Regular maintenance and timely repairs contribute to the overall longevity and reliability of your valuable machinery.

Signs of a Damaged Hydraulic Hose

Hydraulic hose repair can be a cost-effective alternative to replacement. True

In many cases, hydraulic hoses can be repaired instead of replaced entirely. Repairing a damaged hose can save time and money compared to the cost of purchasing and installing a new one. Qualified technicians can often repair leaks, cuts, and other minor damage, extending the life of the hose and reducing downtime for equipment.

Hydraulic hose repairs are always a safe and cost-effective solution. False

While hydraulic hose repair can be a viable option in some cases, it’s not always the safest or most economical choice. Improper repairs can weaken the hose, leading to potential leaks and catastrophic failures. Factors like the severity of the damage, the type of hose, and the availability of qualified technicians all influence the feasibility and safety of a repair. In many instances, replacing the hose entirely is the more prudent and cost-effective solution in the long run.

To determine whether a hydraulic hose needs repair, you must be aware of the common signs of damage. Conducting regular visual inspections can help you identify potential issues before they escalate. Here are some signs to watch out for:

- Visual inspection: Look for any visible signs of damage, such as cuts, abrasions, bulges, or blistering on the hose’s outer cover.

- Leaks and drips: Check for any fluid leaks or drips along the length of the hose. Leaking hydraulic fluid can indicate a compromised hose. You can click here to get more detailed info about leaking hydraulic hose.

- Decreased performance: If you notice a decrease in hydraulic system performance, such as slower movement or weaker force, it could be a result of a damaged hose.

Repair or Replace Hydraulic Hoses

When your hydraulic hose shows signs of wear, such as leaks, cracks, or bulges, you’re faced with a critical decision that impacts both your operational efficiency and safety. Ignoring these issues can lead to catastrophic equipment failure, costly downtime, and potential hazards, turning a minor issue into a major crisis. Don’t let a failing hose jeopardize your entire operation. Instead, evaluate the damage carefully:

- Minor issues: For small abrasions or superficial wear that hasn’t compromised the hydraulic hose’s integrity, a professional repair might be a viable, cost-effective solution, extending the life of your existing hose.

- Significant damage: However, for severe leaks, deep cuts, kinks, or burst sections, replacement is the safest and most reliable option. A new hydraulic hose guarantees optimal performance and prevents future failures, ensuring your machinery runs smoothly and securely. Prioritize replacement when safety and long-term reliability are paramount.

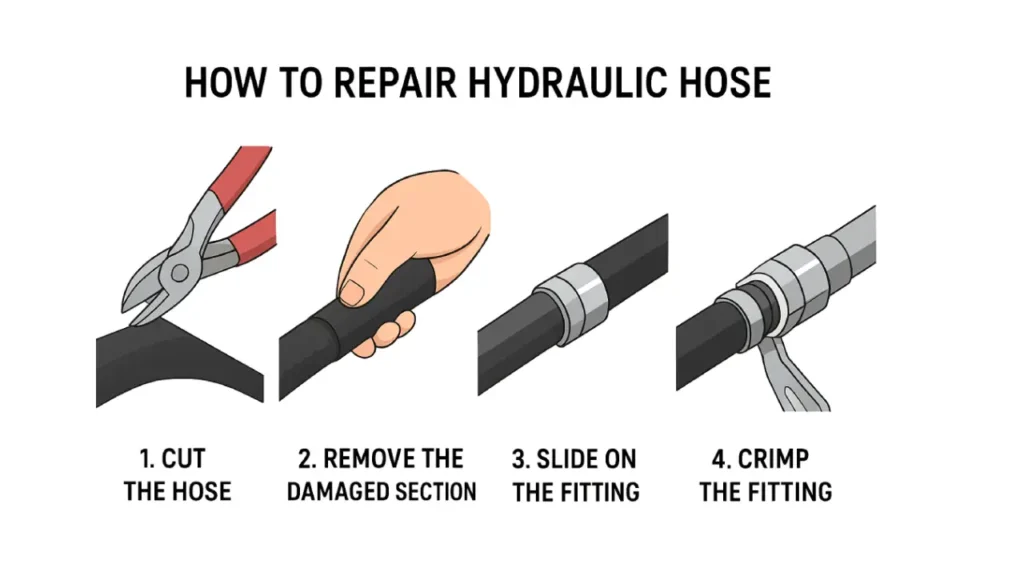

How to Repair a Hydraulic Hose?

Repairing hydraulic hoses is crucial for maintaining machinery efficiency and safety. This guide outlines the essential steps for effective hose repair, from initial assessment to final testing, ensuring a reliable and lasting fix for your hydraulic systems.

Step 1: Assess the Hydraulic Hose Damage

This initial step involves a thorough inspection of the hydraulic hose to identify the exact location and nature of the damage. Look for cuts, abrasions, bulges, leaks, or any signs of wear that compromise the hose’s integrity. Accurately assessing the damage is critical for determining whether a repair is feasible or if replacement is necessary.

Once the damage is located, evaluate its severity and type to decide on the appropriate repair method. Minor surface abrasions might be repairable, while deep cuts or burst sections typically necessitate replacing the damaged hose segment or the entire hose assembly. This assessment guides the subsequent repair actions.

Step 2: Prepare the Hydraulic Hose and Work Area

Before commencing repairs, ensure the hydraulic system is depressurized and locked out to prevent accidental activation and injury. Thoroughly clean the exterior of the hose around the damaged area to remove any dirt, grease, or debris. A clean work environment prevents contamination of the hydraulic system during the repair process.

Gather all necessary tools and materials, including hose cutters, crimping tools, replacement fittings, and the appropriate type and size of replacement hose. Proper preparation ensures a smooth and efficient repair process, minimizing downtime and potential complications during the fix.

Step 3: Cut and Strip the Damaged Section

Carefully cut out the damaged section of the hydraulic hose using a specialized hose cutter, ensuring a clean and perpendicular cut. The cut should be precise to allow for proper fitting attachment and to maintain the hose’s intended length and routing within the machinery.

After cutting, strip back the outer cover of the hose to expose the reinforcement layers, following the manufacturer’s specifications for the particular hose and fitting type. Proper stripping prepares the hose end for secure and reliable attachment of new fittings.

Step 4: Install New Fittings

Select the correct type and size of new fittings that match the hose and the hydraulic system’s requirements. Carefully insert the fittings onto the prepared hose ends, ensuring they are fully seated and aligned according to the manufacturer’s instructions.

Once the fittings are in place, use a crimping tool to securely crimp them onto the hose. The crimping process creates a strong, leak-proof connection that can withstand the high pressures of hydraulic systems, ensuring the integrity of the repair.

Step 5: Test the Repaired Hose

After the repair is complete, it is crucial to test the hydraulic hose under operating conditions to ensure there are no leaks or weaknesses. Gradually re-pressurize the system and carefully inspect the repaired section for any signs of weeping, spraying, or bulging.

Monitor the hose for a period to confirm its integrity and performance under pressure and flow. This final testing step verifies the effectiveness of the repair, preventing potential failures during operation and ensuring the safety of the machinery and personnel.

Identify the Right Hydraulic Hose

Here are many different types of hydraulic hoses on the market, and heavy equipment will use different hydraulic hoses at the same time, because of the different functions required. And each hydraulic hose requires different pressure tolerance, so it is basically important to choose the right hydraulic hose for your equipment.

Don’t install the wrong hydraulic hose with the wrong specifications for the hydraulic project, and keep in mind that it is very dangerous to use an incorrect hydraulic hose, even temporarily. Please be serious about selecting the hydraulic hose. And don’t hesitate to consult your hydraulic hose engineer if you have any questions about the hydraulic hose selection.

Remove the Damaged Hydraulic Hose

If you finish the hydraulic hose selection step, and then you need to remove the damaged hydraulic hose from the hydraulic equipment, to cut off the damaged area of the hydraulic hose pipe. If you find the hydraulic hose is leaking, you have to remove the whole hydraulic hose with the leaking hole.

And then you need to clean the hydraulic hose removed, to make it tidy and clean, without any dirt, dust, oil contamination, or greasy dirt. Because dirt like this could contaminate the hydraulic fluid, making it unpure.

So please be sure that the hydraulic hose and hydraulic hose fittings are clean before proceeding to repair the hydraulic hose.

Seal Hydraulic Hose

Don’t forget to wrap the hydraulic hose using the spiral hose guard, or fire sleeve to protect the hydraulic hose after the maintenance process. Choosing the right hydraulic hose protector can keep the hydraulic hose stay safe during its service life, and it is also important to expand the hydraulic hose life span, up to 3-5 years.

If you have some questions about the selection of a spiral guard for the hose, or fire sleeve protector, please feel free to contact us at any time if you need help.

Consult Hydraulic Hose Protector

Replace A New Hydraulic Hose

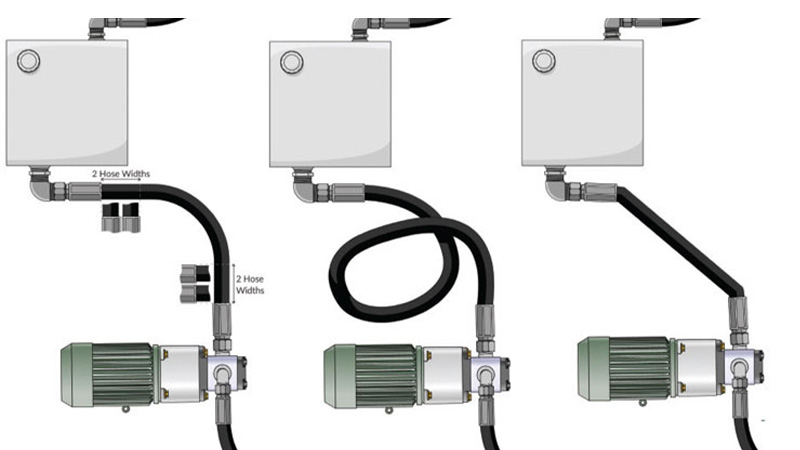

After identifying the warning signs of the hydraulic hose breakage, then you need to replace a new hydraulic hose after removing the bad one. And a hydraulic hose adapter is required to install the repaired hydraulic hose. The memo is that you need to prepare some substitute hydraulic hoses in your toolbox for hydraulic hose replacement if needed.

Please choose the right length of the hydraulic hose, longer is much better than shorter. You can cut off the damaged area once if you find some problems in a certain area.

During the installation, please use the proper wrench to screw the new hydraulic hose to the hydraulic equipment, and you can install the hydraulic hose fittings to the hydraulic hose pipe head before installing them to the machine.

Screw the hydraulic hose fittings in the opposite direction using the wrenches to tighten the hydraulic hose fittings, to avoid the hydraulic hose would get loose in the future.

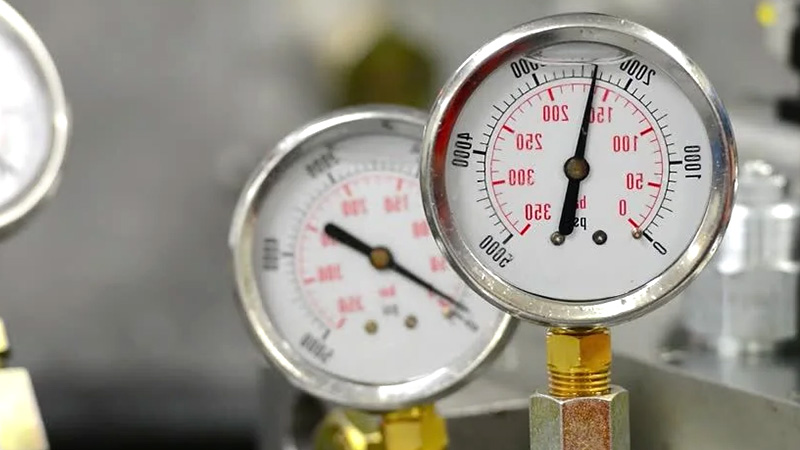

Check Hydraulic Hose Pressure

The checking step is also important, you need to check the hydraulic pressure using the pressure gauge or pressure meter to test if the hydraulic hose can work well.

Please turn on the hydraulic system to let it work to simulate the daily working status, and then circulate the hydraulic fluid at low pressure. This method can recognize the leaking position of the hydraulic hose, to find the potential leaking points or other damaged areas.

How to Fix a Hydraulic Hose Leak

Repairing a leaking hydraulic hose is vital for preventing fluid loss, maintaining system efficiency, and ensuring operational safety. This guide details the process from identifying the leak to thoroughly testing the repair, securing a reliable fix for your hydraulic system.

Step 1: Identify the Leak Source

Begin by thoroughly inspecting the hydraulic hose system to pinpoint the exact location of the leak. Look for visible signs of fluid weeping, spraying, or accumulation around the hose, fittings, or connections. A precise identification of the leak’s origin is crucial for effective repair.

Once the leak is located, assess its severity and cause. A minor seep might indicate a loose fitting, while a forceful spray suggests a rupture or a severely damaged section. Understanding the nature of the leak guides the subsequent repair strategy.

Step 2: Depressurize and Prepare the System

Before any repair attempts, it is imperative to fully depressurize the hydraulic system and implement lockout procedures. This prevents accidental fluid injection injuries and ensures a safe working environment for the repair personnel. Safety is paramount during this stage.

After depressurizing, clean the area around the leak thoroughly to remove any accumulated hydraulic fluid, dirt, or debris. A clean work surface is essential to prevent contamination of the hydraulic system during the repair and to ensure a good seal.

Step 3: Address the Leak (Repair or Replace)

Depending on the leak’s source, decide whether to repair or replace the component. For loose fittings, tighten them to the manufacturer’s specifications. If the hose itself is damaged (e.g., a cut or abrasion), the damaged section might need to be cut out and replaced.

If a section of the hose is beyond repair, or if fittings are damaged, carefully remove the faulty part. Install a new section of hose or new fittings, ensuring they are of the correct type and size for the application, and crimp them securely if required.

Step 4: Test the Repaired Hose

Once the repair is completed, it is critical to thoroughly test the hydraulic system to ensure the leak has been successfully addressed. Gradually re-pressurize the system and meticulously inspect the repaired area for any signs of continued leakage.

Monitor the system under operational pressure for a sustained period to confirm the integrity of the repair. This final verification step is essential to ensure the hydraulic system operates safely and efficiently without any further fluid loss.

Quick Fix Hydraulic Hose Repair Kit

A “Quick Fix” hydraulic hose repair kit typically refers to a portable and compact kit designed for on-site repairs of minor hydraulic hose damage. These kits usually contain the essential tools and components to quickly address issues like:

- Minor leaks: Often caused by loose fittings or slight abrasions.

- Small cuts or punctures: Limited in size and not affecting the hose’s structural integrity.

Typical components of a Quick Fix kit may include:

- Reusable fittings: These allow for quick and easy replacement of damaged hose ends.

- Cutting tools: To cut the damaged section of the hose.

- Crimping tools: To securely attach the new fittings to the hose.

- Clamps and bands: For sealing minor leaks or reinforcing repairs.

- Hose clamps: To secure fittings to the hose.

- Instruction manual: Provides guidance on proper usage and safety precautions.

Important Considerations:

- Limitations: Quick Fix kits are designed for minor repairs. They may not be suitable for major damage, such as large cuts, punctures, or significant internal damage.

- Safety: Always follow safety precautions when using any hydraulic repair kit. Wear appropriate protective gear, such as safety glasses and gloves.

- Training: If you are not experienced in hydraulic hose repair, it is crucial to receive proper training before using any repair kit.

Note: The specific contents and capabilities of Quick Fix kits can vary depending on the manufacturer and the intended use.

Mobile Hydraulic Hose Repair

Mobile hydraulic hose repair services bring the convenience of hose repair directly to your location, minimizing downtime and maximizing productivity.

Here’s how it works:

- On-Site Service: Mobile repair technicians come equipped with the necessary tools, equipment, and a wide range of hoses and fittings to perform repairs right at your job site, in your workshop, or even on your vehicle.

- Reduced Downtime: By bringing the repair service to you, it significantly reduces the time your equipment is out of service, minimizing costly delays and production interruptions.

- Increased Efficiency: No need to transport heavy or cumbersome equipment to a repair shop, saving time and resources.

- Expert Service: Mobile technicians are typically highly skilled and experienced in diagnosing and repairing various types of hydraulic hoses.

- Emergency Repairs: Many mobile services offer 24/7 emergency repair services, ensuring that critical equipment can be quickly restored to operation, even outside of regular business hours.

Benefits of Mobile Hydraulic Hose Repair:

- Minimized Downtime: Reduced equipment downtime translates to increased productivity and cost savings.

- Increased Efficiency: On-site repairs streamline the process and save time.

- Convenience: No need to transport equipment or wait for repairs to be completed.

- Expert Service: Access to highly skilled and experienced technicians.

- Cost-Effectiveness: Can often be more cost-effective than transporting equipment to a repair shop.

If you rely on hydraulic systems in your operations, consider the benefits of a mobile hydraulic hose repair service. It can be a valuable asset in keeping your equipment running smoothly and minimizing downtime.

Can You Fix a Hydraulic Hose With Tape

No, you cannot fix a hydraulic hose with tape.

Hydraulic hoses operate under very high pressure, and a tape repair wouldn’t be able to withstand that pressure. Attempting to fix a hydraulic hose with tape could result in a catastrophic failure and potential injury when the hose is pressurized.

Tape might temporarily stop a leak, but it is not a safe or long-term solution. It’s important to replace a damaged hydraulic hose as soon as possible to prevent further damage to the hydraulic system and ensure personal safety.

If a hydraulic hose is leaking or damaged, it should be properly repaired or replaced by a professional or someone who is trained to do so. Working with hydraulic systems can be dangerous due to the high pressures involved, so it’s important to always follow safety guidelines.

Conclusion

Proper hydraulic hose maintenance and repair are essential for maximizing equipment performance and longevity. By following careful procedures, you can quickly address leaks, replace worn components, and ensure safe operations. Preventive maintenance paired with timely repairs keeps hydraulic systems running smoothly and efficiently

At Kingdaflex, we provide high-quality hydraulic hoses designed for durability and reliability. Whether you need replacement hoses, custom sizes, or bulk orders, our products meet diverse industrial demands. Trust Kingdaflex to supply hoses that support long-term performance and minimize unexpected failures in your hydraulic systems.

For businesses and technicians, sourcing hydraulic hoses from Kingdaflex ensures competitive pricing and consistent quality. Our wholesale options help reduce costs while maintaining safety and operational standards. Partnering with us simplifies procurement, keeps your systems operational, and supports the success of every hydraulic project you undertake.