Have you experienced a hydraulic hose burst? A hydraulic hose burst is the most popular hydraulic hose damages, which can result in hydraulic hose failure.

Let’s dive into the hydraulic hose burst.

What Causes Hydraulic Hose Burst?

Why is the hydraulic hose bursting? Here must be some reasons causing the hydraulic hose burst, it is basically important to find out what cause the

The hydraulic hose is used to convey various types of hydraulic fluids, so we need to consider what substances exist in the hydraulic fluids that could result in the hydraulic burst.

It is responsible for the hydraulic hose experts or techniques to find out the problems when the hydraulic hose bursts. The hydraulic hose burst injury will lead to serious hydraulic hose failure, so the hydraulic hose bursting is the one of main hydraulic hose damages reasons.

Let’s see what can cause a hydraulic hose to burst. From this checklist, you can identify the hydraulic hose bursting reasons. Here are some popular reasons why hydraulic hose burst.

Why Do Hydraulic Hoses Burst

Hydraulic hoses can burst for several reasons. Here are the key factors that can lead to hydraulic hose failure and bursting:

Excessive Pressure:

Hydraulic systems operate under high pressure, typically ranging from 1,000 to 5,000 psi or more.

If the pressure in the system exceeds the rated pressure capacity of the hose, it can cause the hose to burst.

This can happen due to system malfunctions, blockages, or incorrect pressure settings.

Abrasion and Wear:

Hydraulic hoses can become worn and weakened over time due to constant flexing, rubbing against surfaces, and exposure to the environment.

Improper installation, routing, or lack of protection can accelerate the abrasion and wear on the hose.

This can lead to the hose’s outer cover and inner lining becoming damaged, compromising its structural integrity.

Chemical Degradation:

Hydraulic fluids, solvents, and other chemicals can react with the hose material, causing it to swell, soften, or become brittle.

This chemical degradation can weaken the hose and make it more susceptible to bursting.

Extreme Temperatures:

Exposure to high or low temperatures can affect the hose material, causing it to become more rigid or flexible, respectively.

Extreme temperatures can lead to accelerated aging and deterioration of the hose, increasing the risk of bursting.

Improper Installation or Maintenance:

Incorrect hose routing, tight bends, or improper clamping can create stress points and weaken the hose.

Failure to replace hoses at the recommended intervals or during routine maintenance can also contribute to hose bursts.

Age and Fatigue:

Hydraulic hoses have a finite lifespan, and over time, the constant flexing and pressure cycling can lead to fatigue and eventual failure.

Older hoses are more prone to bursting, especially if they have not been properly maintained or replaced.

Hydraulic Hose Burst Injury

Hydraulic hose injuries are some of the most serious injuries that can occur in an industrial setting. They are caused by a pressurized fluid being injected into the body through a puncture wound. The fluid, which is often hot and contaminated, can cause severe tissue damage, infection, and even amputation.

Causes of Hydraulic Hose Burst Injury

Hydraulic hose injuries can be caused by a number of factors, including:

- A burst hose: This is the most common cause of hydraulic hose injuries. Hoses can burst due to a variety of factors, including high pressure, wear and tear, or improper installation.

- A loose fitting: If a fitting on a hydraulic hose is loose, it can spray fluid at high pressure. This can easily puncture the skin and cause a serious injury.

- A broken hose: If a hose is broken, it can release fluid at high pressure. This can also cause a puncture wound and serious injury.

Symptoms of Hydraulic Hose Burst Injury

The symptoms of a hydraulic hose injury can vary depending on the severity of the injury. Some common symptoms include:

- Pain

- Swelling

- Bruising

- Bleeding

- Numbness

- Tingling

- Loss of movement

In severe cases, hydraulic hose injuries can lead to infection, gangrene, and even death.

Treatment of Hydraulic Hose Burst Injury

If you suspect that you or someone you know has suffered a hydraulic hose injury, it is important to seek medical attention immediately. The doctor will assess the severity of the injury and develop a treatment plan. Treatment may include:

- Cleaning the wound

- Debridement (removal of dead tissue)

- Antibiotics

- Surgery

- Physical therapy

Preventing Hydraulic Hose Burst Injury

There are a number of things that can be done to prevent hydraulic hose injuries, including:

- Inspecting hoses regularly for signs of wear and tear

- Replacing hoses that are damaged or worn

- Using the correct hoses for the application

- Ensuring that hoses are properly installed and maintained

- Wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses

By following these precautions, you can help to prevent serious hydraulic hose injuries.

Hydraulic Hose Fitting Is Off

The most common problem is that the hydraulic hose fitting is blown off, so please be serious and strict for the original hydraulic hose assembly, you have to lock the hydraulic hose fittings firmly using the right wrench.

The hydraulic hose types are determined by the hydraulic hose, please purchase the original hydraulic hose fittings from the place that also makes hydraulic hose, that is to say, you’d better ensure that the hydraulic hose and fittings are from the same brand or the same manufacturer.

This way can ensure the quality of the hydraulic hose fittings can be certified and qualified, and also the hydraulic hose fittings can suit well to fit the hydraulic hose size.

Don’t forget to double-check after the hydraulic hose installation, to ensure that the hydraulic hose can work well to avoid some potential problems that happen in the near future. And please check the hydraulic hose fittings situations regularly, monthly, yearly.

You need to remove the aged hydraulic hose fittings to replace the new ones right away if you find some hydraulic hose fittings are not working well. You’d better stock some same hydraulic hose fittings for the replacement in your warehouse because the hydraulic hose fittings are the wearing parts for the hydraulic hose application.

Hydraulic Hose Reinforcement Is Broken

Second, the quality of the hydraulic hose is the basically important element, please order the hydraulic hoses from a trustworthy hydraulic hose manufacturer. The reinforced layer of the hydraulic hose is to adds much strength to the whole hydraulic hose pipe, making it much more durable and long-lasting.

If you find visible hurt from the hydraulic hose cover, please detect the hydraulic hose seriously, because the hydraulic hose can’t work anymore if the hurt permeates to the hydraulic hose reinforcement.

The reinforcement is broken, you have to replace the hydraulic hose. The damaged hydraulic hose will cause a hydraulic hose burst, please remove the damaged hose to change the new one.

Improper Hydraulic Hose Routing

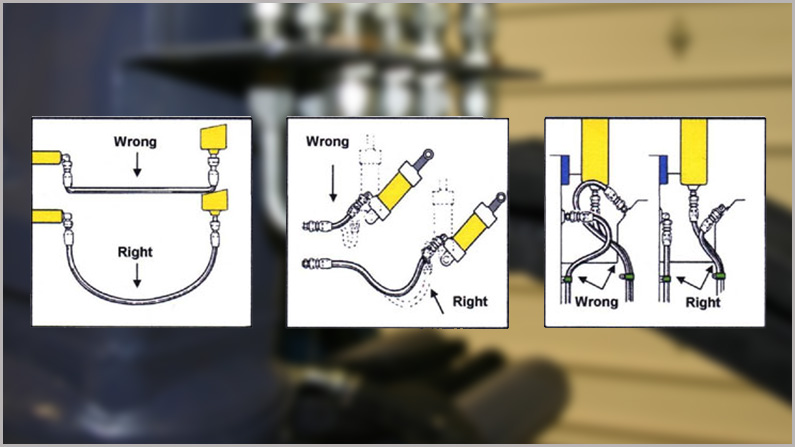

Route your hydaulic hose in the wrong way will cause some potential safety problems, please plan a good hydraulic hose routing before the hydraulic hose assembling. Please avoid the torn cover or deteriorated hose, and assemble the hydraulic hose following its natural curves. Don’t make it twisted for the hydraulic project. Please keep away from the sharp objects or edges while routing the hydraulic hose, the sharp edges will do damage to the hydraulic hose cover, causing the hydraulic hose abrasion. You need to follow the hydraulic hose installation guidelines to ensure that each hydraulic hose can be installed safely. Please bend the hydraulic hose without any twisting or turning, the actual radius is much larger than the minimum bend radius. You need to be clear about the hydraulic hose bend radius ahead of hydraulic hose selection.

Hydraulic Hose Burst Protection Wrap

In order to avoid the hydraulic hose burst, here you can provide hydraulic hose burst protection, wrapping it with the spiral hose guard, and fire sleeve. The hydraulic burst sleeve is protective to avoid the hydraulic hose burst injury, to ensure that your hose hydraulic pipe can be used for a much longer time.

It is helpful to provide hydraulic hose burst and leak protection to keep away from making the hydraulic hose leaking hydraulic fluid drops, so we do recommend that you’d better use the hydraulic hose anti-burst protection to keep it safe during its service life.

Final Thoughts

If you want to know more about the hydraulic hose burst, please feel free to contact us at any time. And welcome to get FREE hydraulic hose samples right now.