Ever wondered how tight you can bend a hydraulic hose without causing damage? The bend radius is a crucial factor in hydraulic system design and maintenance. Understanding how to calculate the minimum bend radius ensures optimal performance and longevity of your hoses, preventing kinks and potential failures.

This blog post will guide you through the simple process of calculating the minimum bend radius for your hydraulic hoses. We’ll break down the key factors involved and provide you with practical steps to ensure your hydraulic systems operate safely and efficiently. Let’s dive in!

What Is Hydraulic Hose Bend Radius

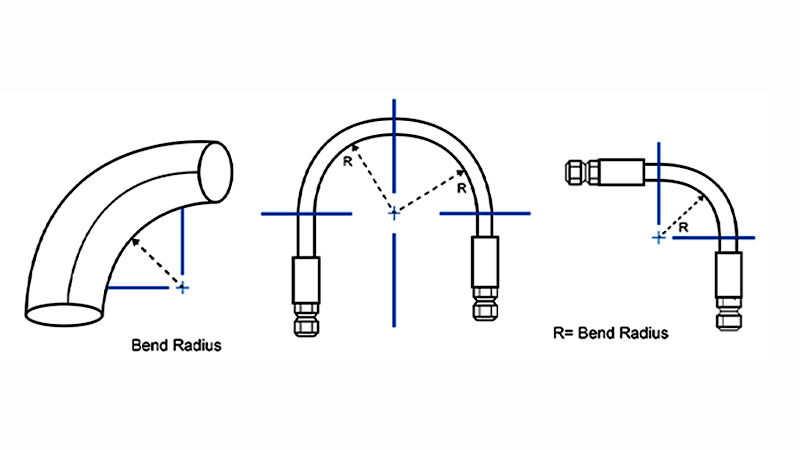

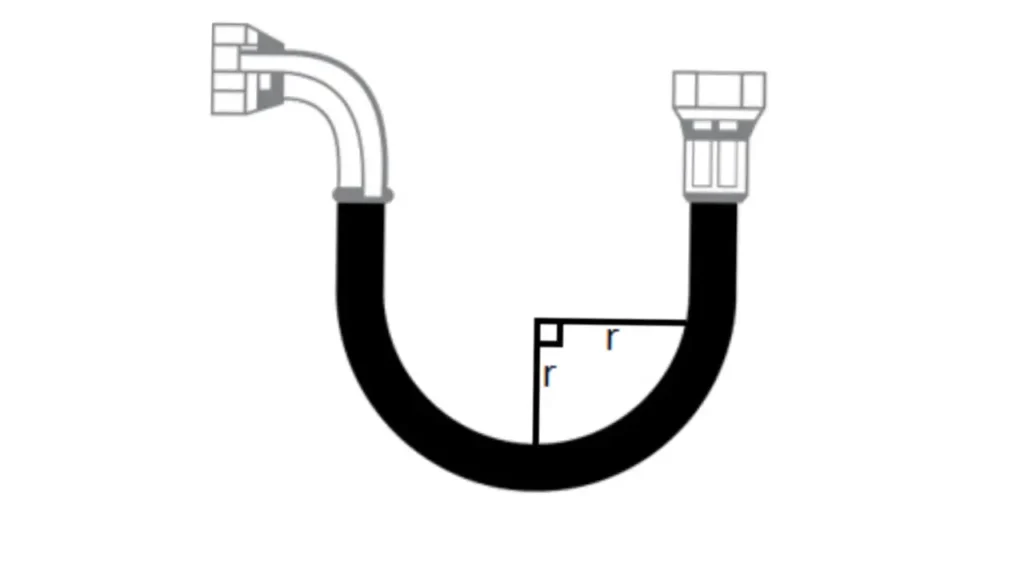

Bend radius, we use this to measure the inside curvature of the hydraulic hose, and the bend radius is the minimum radius one can bend a pipe, tube, sheet, cable, or hose without kinking it, damaging it, or shortening its life.

The bend radius of the hydraulic hose is measured as the distance to the inside edge of the hydraulic hose when you make a 90° bend.

The bend radius of the hydraulic hose can present the smallest diameter that a looped hydraulic hose can achieve. And R is short for bend radius, and bend radius is different because of the different structures of the hydraulic hose, including inner tube, reinforcement, and cover. The hydraulic hose structure can determine the hydraulic hose bend radius.

Minimum Bend Radius for a Hydraulic Hose

The minimum bend radius for a hydraulic hose is the smallest diameter that a looped hose can achieve without damaging its internal structure or significantly shortening its lifespan.

This critical parameter is determined by the hose’s construction (materials, layers, reinforcement type), size, and pressure rating. Exceeding the minimum bend radius can lead to internal pressure stress, kink formation, reduced flow, and ultimately, hose failure.

Key Considerations:

- Hose Construction: Different hose types (braided, spiral, thermoplastic) have varying bend radii due to their reinforcement layers. Spiral hoses generally have larger minimum bend radii than braided hoses.

- Hydraulic hose Size: Larger diameter hoses typically have larger minimum bend radii.

- Pressure Rating: Higher pressure hoses often require larger bend radii to prevent internal pressure stress.

- Hydraulic Hose Application: The specific application and operating environment will influence the acceptable bend radius.

Importance of Adhering to Minimum Bend Radius:

- Prevent Hose Failure: Exceeding the minimum bend radius can cause internal pressure stress, leading to leaks, ruptures, and potential injury or equipment damage.

- Maintain Flow: Sharp bends can restrict fluid flow, reducing system efficiency and potentially damaging components.

- Extend Hose Life: Adhering to the minimum bend radius helps prevent premature wear and tear, extending the service life of the hydraulic hose.

Finding Minimum Bend Radius Information:

- Manufacturer’s Data Sheets: The most reliable source is the manufacturer‘s data sheet for the specific hose type.

- Industry Standards: Relevant industry standards and guidelines provide valuable information on minimum bend radii.

By carefully considering the minimum bend radius and designing hydraulic systems accordingly, you can ensure optimal performance, safety, and longevity of the hydraulic system.

What is the Standard Bending for Hydraulic Pipes?

The standard bending for hydraulic pipes ensures safe and efficient fluid flow while preventing damage to the pipe and hydraulic system. Proper bending maintains structural integrity, minimizes pressure loss, and extends the service life of hydraulic components, making it essential for industrial and mobile hydraulic applications.

- Minimum Bending Radius: The minimum bending radius is the smallest radius a pipe can be bent without kinking or damaging it. We calculate it based on pipe material, diameter, and wall thickness to maintain strength and prevent leaks.

- Bending Angle Limits: Standard bending angles define the maximum allowable curvature during installation. We adhere to these limits to avoid stress concentrations, ensure uniform fluid flow, and maintain the reliability and safety of the hydraulic system.

- Material Considerations: Different materials, such as steel, stainless steel, or aluminum, have unique bending properties. We select the appropriate material and bending method to prevent cracking, deformation, or reduced performance under operational pressure.

- Pressure and Flow Impact: Bending affects the internal flow and pressure within hydraulic pipes. We design bends to minimize turbulence and pressure loss, ensuring efficient operation, system longevity, and reliable performance under various load conditions.

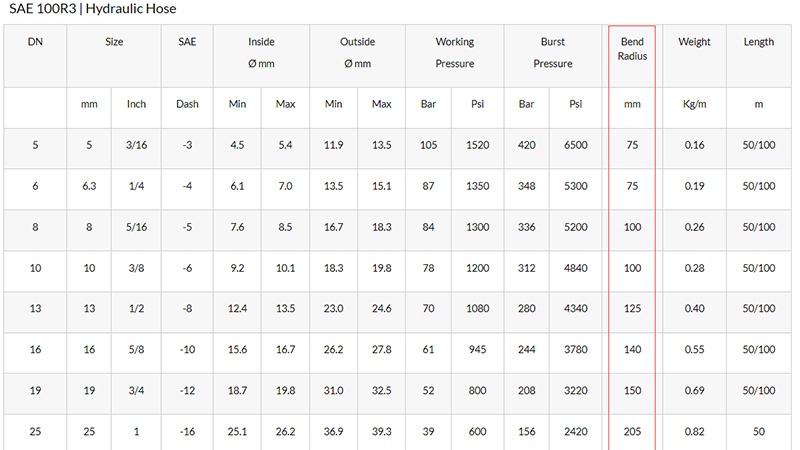

Hydraulic Hose Bend Radius Chart

hydraulic hose bend radius chart

You can see the hydraulic hose bend radius chart to get to know the bending capacity of the hydraulic hose pipe.

You can select the hydraulic hose for your hydraulic system, please be serious about the hydraulic hose bend radius. This may cause hydraulic hose kinking when a hydraulic hose goes beyond its rated bend radius.

While specific bend radius values vary greatly depending on the hydraulic hose’s construction, materials, pressure rating, and manufacturer, here’s a general example of how a bend radius chart might be structured. Always consult the manufacturer’s datasheet for the exact specifications of your hose.

Here is the table showing you the hydraulic hose bend raduis.

| Hose Inner Diameter (ID) | Example Minimum Bend Radius Ratio | Example Minimum Bend Radius |

| 1/4″ (0.25 inches) | 4:1 | 1 inch |

| 3/8″ (0.375 inches) | 4:1 | 1.5 inches |

| 1/2″ (0.5 inches) | 4:1 | 2 inches |

| 3/4″ (0.75 inches) | 5:1 | 3.75 inches |

| 1″ (1.0 inches) | 6:1 | 6 inches |

Important Considerations:

- Pressure: Higher operating pressures often require a larger minimum bend radius. The chart provided by the manufacturer will usually specify the minimum bend radius at the hose’s maximum working pressure.

- Hose Construction: Different reinforcement types (e.g., wire braid, wire spiral, textile braid) will have different bend radius capabilities.

- Dynamic vs. Static Applications: Hoses that are subjected to flexing during operation may require a larger bend radius than those in static applications. The manufacturer may provide a “dynamic bend radius” that accounts for this movement.

- Temperature: Extreme temperatures can affect the flexibility of the hose and thus the minimum bend radius.

Always refer to the specific datasheet for your hydraulic hose from the manufacturer for accurate bend radius information. This table is for illustrative purposes only.

What Determines Hydraulic Hose Bend Radius

Hydraulic hose bend radius is critical for ensuring proper hose performance, preventing kinks, and maintaining system efficiency. Understanding the factors that affect bend radius helps select the right hose and installation method, reducing stress, prolonging hose life, and ensuring safe hydraulic operation.

- Hose Construction and Layers – The material, reinforcement layers, and thickness of a hydraulic hose directly affect its bend radius. We consider these factors to prevent excessive stress, kinking, and premature failure while ensuring smooth fluid flow under pressure.

- Hydraulic Hose Diameter – Larger diameter hydraulic hoses require a greater bend radius to maintain proper flow and prevent deformation. We carefully select hoses that balance flexibility with pressure requirements for efficient system performance.

- Operating Pressure – Higher-pressure hydraulic hoses need a larger bend radius to withstand internal stress. We account for operating pressure to prevent hose damage, leaks, or failures in demanding industrial and automotive applications.

- Temperature Conditions – Temperature variations impact hydraulic hose flexibility and bend radius. We evaluate operating temperatures to ensure hoses maintain performance without kinking, cracking, or losing mechanical integrity.

- Installation Environment – Space constraints, routing paths, and nearby components influence bend radius selection. We plan hose layout to prevent sharp bends, reduce wear, and maintain long-term reliability in confined or complex hydraulic systems.

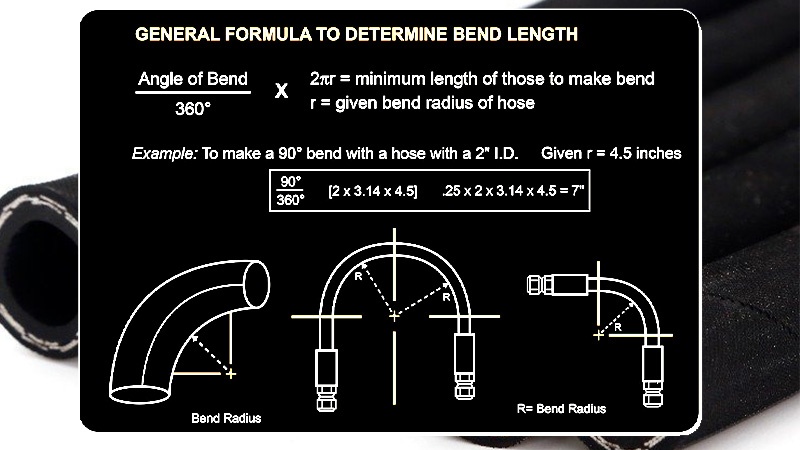

How to Calculate Bend Radius?

Ever wondered how to figure out the gentlest curve your hydraulic hose can handle without causing trouble? Calculating the bend radius is simpler than you might think and it’s key to keeping your hydraulic systems running smoothly and safely. Let’s walk through the steps to determine this important measurement.

Step 1: Identify the Hydraulic Hose Diameter

First things first, you’ll need to know the inner diameter (ID) of your hydraulic hose. This measurement is usually printed directly on the hose itself. Look for a number followed by an inch symbol (“) or a millimeter symbol (mm). This diameter is the foundation for calculating the minimum bend radius.

Step 2: Determine the Minimum Bend Radius Ratio

Next, you’ll need to find the minimum bend radius ratio for your specific hose type. This ratio is typically provided by the hose manufacturer in their product specifications or datasheets. It’s usually expressed as a multiple of the hose’s inner diameter (e.g., 4:1). Different hose constructions and materials will have different bend radius ratios, so always refer to the manufacturer’s information.

Step 3: Perform the Calculation

Once you have the hose’s inner diameter and the minimum bend radius ratio, the calculation is straightforward. Multiply the inner diameter of the hose by the minimum bend radius ratio. For example, if your hose has an inner diameter of 1 inch and the minimum bend radius ratio is 4:1, the minimum bend radius would be 1 inch* 4 = 4 inches. This calculated value represents the smallest radius to which the hose should be bent to avoid damage and ensure optimal performance.

How to Find Hydraulic Hose Bend Radius

1. Consult our hydraulic hose manufacturer‘s Data Sheet:

- Most Reliable Source: This is the absolute best way to determine the minimum bend radius for a specific hydraulic hose.

- Information Provided: Data sheets typically include detailed specifications, including minimum bend radii for different hose sizes and pressure ratings.

2. Refer to Industry Standards:

Guidelines and Best Practices: Industry standards and guidelines provide general recommendations for minimum bend radii.

- Examples: SAE (Society of Automotive Engineers), ISO (International Organization for Standardization) standards.

3. Consider the Hose Construction:

Reinforcement Type: Different hose constructions (braided, spiral, thermoplastic) have varying bend radii capabilities.

- Spiral hoses generally have larger minimum bend radii than braided hoses.

4. Account for Hose Size and Pressure Rating:

- Larger Diameters: Larger diameter hoses typically require larger bend radii.

- Higher Pressures: Hoses designed for higher pressures often have more stringent bend radius requirements.

5. Assess the Application:

Operating Environment: The specific application and operating environment will influence the acceptable bend radius.

- Consider factors like temperature extremes, vibration, and abrasion.

6. Use a Bend Radius Gauge (Optional):

- Physical Measurement: For precise measurements, you can use a bend radius gauge to physically measure the bend in the hose.

By following these steps, you can effectively determine the appropriate bend radius for your hydraulic hoses, ensuring optimal performance, safety, and longevity of your hydraulic system.

Hydraulic Hose Bend Radius in Inches

The minimum bend radius of a hydraulic hose is a critical specification measured in inches, representing the tightest curve the hose can form without causing damage. Exceeding this limit will significantly reduce the hose’s lifespan and pressure capacity, leading to premature failure and costly system downtime.

- Understanding the Measurement: The bend radius is measured from the hose’s centerline to the inside of the curve. This measurement ensures the reinforcement layers are not unduly stressed or kinked. Ignoring this specification is the number one cause of hose degradation and immediate loss of the working pressure rating.

- Impact on Hose Life: When a hose is bent tighter than its rated radius, the outer layers stretch and the inner layers compress excessively. This causes the internal wire or textile reinforcement to break down, leading to early fatigue, leaks, and catastrophic burst failure under normal operating pressure.

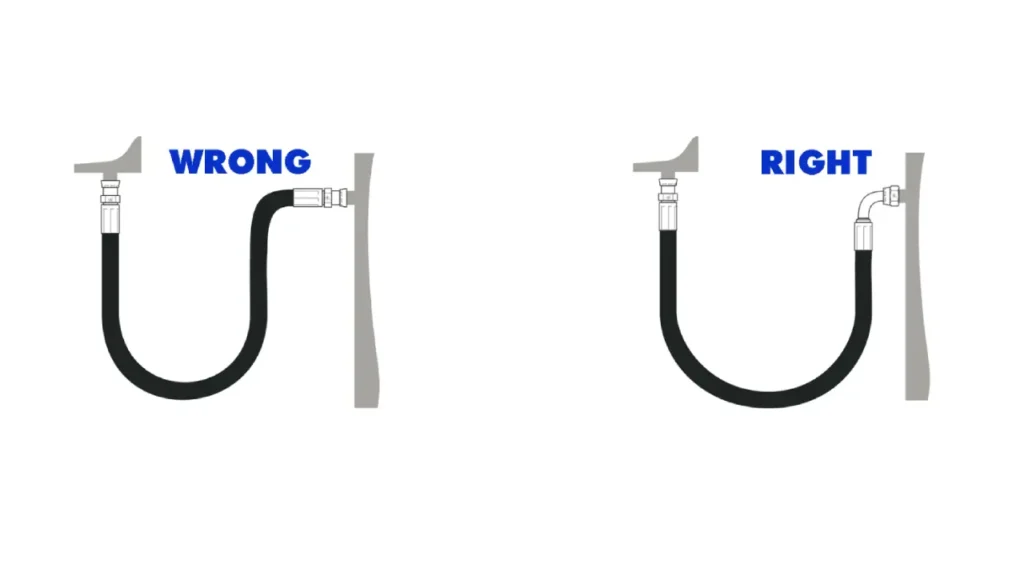

- Installation Best Practice: Always route a hose with a curve larger than the specified minimum bend radius to maximize its service life. Using specialized elbow fittings or routing adapters can often help maintain the necessary radius in tight installations, preventing stress near the connection points.

- Varies by Construction: The minimum bend radius is highly dependent on the hose’s construction, specifically the inner diameter (ID) and the number of reinforcement layers (e.g., 1-wire braid vs. 4-wire spiral). Larger ID and higher pressure ratings generally mean a significantly larger (less tight) minimum bend radius.

Below is a general example table demonstrating typical minimum bend radius values in inches (in) for a common SAE 100R2 (two-wire braid) hose, relative to its nominal inner diameter:

| Nominal Hose ID (in) | Typical Minimum Bend Radius (in) |

| 1/4 | 3.5 |

| 3/8 | 4.5 |

| 1/2 | 5.5 |

| 3/4 | 7.5 |

| 1 | 9.5 |

| 1 1/4 | 12.0 |

| 1 1/2 | 15.0 |

| 2 | 20.0 |

Hydraulic Hose Bend Radius Calculator

Using a hydraulic hose bend radius calculator is essential for correct hose assembly and installation. This tool determines the safe minimum curve to prevent premature hose failure. It relies on specific hose dimensions and ratings to protect the integrity of the reinforcement layers.

- Inputs Required: The calculator needs the Hose Inner Diameter (ID) and the specific Hose Series (e.g., SAE 100R2). These two inputs directly determine the minimum allowable bend, crucial for longevity.

- Output Value: The output is the minimum bend radius in inches or millimeters. This value dictates the tightest permissible curve the hose can be routed through without damaging the internal structure.

- Why Calculate: Calculating ensures the installed hose will not kink or strain the reinforcement. Following this safe limit prevents premature fatigue failure and maintains the hose’s critical working pressure rating.

- Manufacturer Data: Accurate calculations rely on the specific Kingdaflex technical data. Always use the values provided by the manufacturer for the exact hose being installed, not generic industry standards.

Prevent Hydraulic Hose Failure

Hydraulic hose failure can lead to system downtime, safety hazards, and costly repairs. Understanding the common causes of failure and implementing preventative measures helps extend hose life, maintain system performance, and ensure safe, reliable operation in industrial, automotive, construction, and agricultural hydraulic applications.

- Proper Hose Selection – Choosing the correct hydraulic hose for pressure, temperature, and fluid type prevents overstressing the hose. We ensure hoses meet application requirements, reducing the risk of leaks, bursts, and system malfunctions.

- Correct Routing and Bend Radius – Maintaining proper bend radius and avoiding sharp angles prevents kinking and mechanical stress. We plan routing to minimize friction, wear, and stress, ensuring long-term hose integrity and system efficiency.

- Regular Inspection and Maintenance – Frequent checks for wear, abrasion, and leaks help detect issues early. We inspect hoses periodically, replace damaged sections, and maintain connections to prevent unexpected failures and costly downtime.

- Proper Fitting Installation – Correctly installed fittings prevent leaks, pressure loss, and premature hose failure. We ensure fittings are compatible, securely attached, and seated properly to maintain reliable hydraulic system performance.

- Environmental Protection – Shielding hoses from heat, chemicals, and abrasion prevents degradation. We use protective sleeves, wraps, and covers to extend hose life and maintain safe, efficient operation under challenging conditions.

Ask Hydraulic Hose Bend Radius

Conclusion

Determining the correct bend radius for your hydraulic hoses is crucial for optimal system performance, safety, and longevity. By carefully considering factors like hose construction, size, pressure rating, and application, and by consulting our hydraulic hose manufacturer data sheets and industry standards, you can ensure that your hoses are properly installed and operated.

For hydraulic hoses that meet the most stringent industry standards, consider Kingdaflex. We offer a wide range of wholesale hydraulic hoses designed for demanding applications. Contact us today to learn more about our products and discuss your specific requirements.