Understanding the cost of hydraulic hoses is crucial for budgeting and ensuring the longevity of your equipment. This guide will break down the various factors that influence the price of hydraulic hoses, helping you make informed purchasing decisions.

From materials and construction to size and pressure ratings, numerous elements contribute to the final cost. By exploring these aspects, you’ll gain insights into getting the best value for your investment in hydraulic components.

How Much Do Hydraulic Hoses Cost

The cost of hydraulic hoses can vary depending on several factors, but here’s a general guideline:

- Basic hydraulic hose: $10 – $20 per 10ft for low pressure applications (e.g., 3/8″ diameter, synthetic rubber, single braid)

- Heavy-duty hydraulic hose: $100 – $150 per 100ft for high-pressure applications (e.g., 1″ diameter, thermoplastic elastomer, 5000 PSI)

Here are some key factors affecting hydraulic hose prices:

- Size and Length: Larger diameter and longer hoses cost more.

- Pressure Rating: Higher pressure rating translates to a higher price.

- Material: Synthetic rubber is cheapest, followed by thermoplastic elastomer (TPE), and stainless steel being the most expensive.

- Number of Braids: More braids for higher pressure handling mean a higher cost.

- Fittings: Pre-assembled hoses with specific fittings cost more than bulk hose.

Remember, these are just estimates. To get an accurate quote, consult a hydraulics specialist considering your specific needs.

How Much Does It Cost to Have Hydraulic Hoses Made

The cost of hydraulic hoses can vary significantly depending on several factors, including:

1. Hydraulic Hose Type and Material

- Standard Hydraulic Hoses: These are the most common type and are typically made from rubber or thermoplastic materials. They are suitable for lower-pressure applications and are relatively affordable.

- High-Pressure Hydraulic Hoses: Designed for high-pressure applications, these hoses are often made from more durable materials like wire braid or spiral wire reinforcement. They are more expensive than standard hoses.

- Specialized Hoses: Hoses designed for specific applications, such as those used in extreme temperatures or corrosive environments, can be more costly.

2. Hydraulic Hose Length and Diameter

- Longer Hoses: Longer hoses require more material and labor, increasing the cost.

- Larger Diameters: Larger diameter hoses require more material and often have more complex fittings, which can also increase the cost.

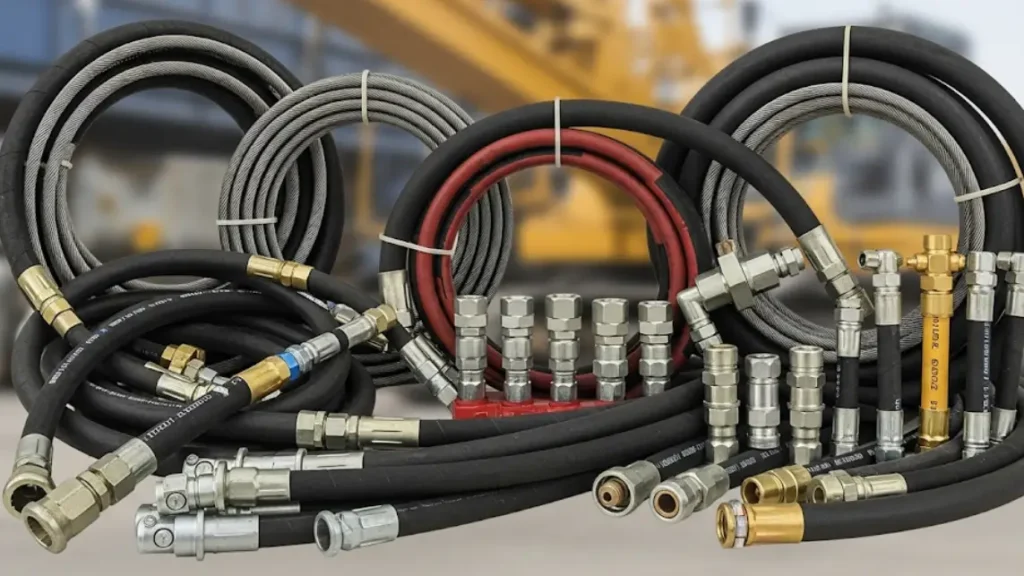

3. Fittings and Couplings

- Type of Fittings: Different types of fittings, such as JIC, ORFS, and NPT, have varying costs.

- Number of Fittings: The more fittings required, the higher the cost.

- Material of Fittings: Stainless steel fittings are more expensive than carbon steel or brass fittings.

4. Hose End Configuration

- Straight or Crimped: Crimped hose ends are generally more expensive than straight ends, as they require specialized equipment and labor.

- Custom Configurations: Custom configurations, such as bent hoses or hoses with specific angles, can add to the cost.

5. Labor Costs

- Cutting and Crimping: The labor involved in cutting the hose to the correct length and crimping the fittings can significantly impact the overall cost.

- Assembly: The complexity of the assembly process, including the number of fittings and the required precision, can also affect labor costs.

6. Customization and Special Requirements

- Custom Lengths: Hoses that require custom lengths will incur additional cutting and crimping fees.

- Special Materials: Hoses made from specialized materials, such as those resistant to extreme temperatures or chemicals, will be more expensive.

- Specialized Fittings: Unique or hard-to-find fittings can increase the cost of the hose assembly.

While it’s challenging to provide a precise cost without specific details about the hose requirements, it’s clear that a variety of factors can influence the final price. By understanding these factors and working with a reputable hydraulic hose supplier, you can ensure that you get the best value for your money.

How Much Does It Cost to Replace a Hydraulic Hose?

The hydraulic hose replacement cost can vary significantly, typically ranging from $20 to $150 for the hydraulic hose itself, but the total cost depends on several key factors beyond just the hydraulic hose price. This includes labor, the complexity of the job, and the specific type of hydraulic hose and fittings required.

It’s crucial to consider all these elements when budgeting for a replacement to avoid unexpected expenses and minimize downtime.

Here are the main factors influencing the total cost:

Hydraulic Hose Material and Type:

- Basic synthetic rubber hydraulic hoses are generally the most affordable.

- Hydraulic hoses designed for higher pressures, extreme temperatures, or specific chemical resistance (e.g., multi-braid, thermoplastic, PTFE) will be more expensive per foot.

- Specialized hydraulic hoses for unique applications also command a higher price.

Hydraulic Hose Size and Length:

- Larger diameter hydraulic hoses require more material and are thus more expensive.

- Longer hydraulic hoses, naturally, cost more due to increased material usage.

Fittings and Couplings:

- The type of fittings (e.g., JIC, ORFS, NPT) and their material (e.g., carbon steel, stainless steel) will impact the price.

- Pre-assembled hydraulic hoses with crimped fittings are often more convenient but can be pricier than purchasing bulk hydraulic hose and fittings separately.

Labor Costs:

- This is a significant factor. Labor rates vary by region and technician experience.

- Complex hydraulic systems or hard-to-reach hydraulic hoses will incur higher labor costs due to increased time and effort required for removal and installation.

- Emergency or after-hours service will also significantly increase labor expenses.

Downtime and Additional Components:

- The cost of lost productivity while equipment is down can be substantial, often outweighing the direct replacement cost.

- Sometimes, a hydraulic hose failure might indicate other underlying issues, leading to the need for additional parts or repairs within the hydraulic system.

Hydraulic Hose Repair Cost

The cost to repair or replace a hydraulic hose can vary significantly, ranging from as low as $20 to over $1,000, depending on various factors. While a simple hose replacement might be relatively inexpensive, the total cost can quickly escalate when you factor in labor, specialized equipment, and the complexity of the repair. For businesses, the cost of downtime caused by a failed hose can often far exceed the actual repair cost, making quick and efficient service a high priority.

Key factors that influence the total cost include:

- Hose Specifications: The price is heavily dependent on the hose’s size (diameter and length), pressure rating (PSI), and material. High-pressure, larger diameter, or specialized hoses (e.g., for extreme temperatures) are more expensive.

- Fittings and Couplings: The end fittings are a significant part of the cost, especially for specialized or high-quality materials like stainless steel. Custom-made fittings also add to the price.

- Labor and Service: Labor costs vary based on the technician’s skill, the complexity of the job, and the accessibility of the hose on the machine. Emergency or on-site mobile services will have a higher labor rate.

- Downtime: The most significant cost for many businesses is the lost productivity and revenue while the equipment is out of service. This hidden cost often drives the decision to choose a quicker, though more expensive, repair option.

Factors Affecting Hydraulic Hose Prices

Size and Length: Hydraulic hose size refers to its inner diameter, typically ranging from 1/8 inch to 2 inches. Larger diameter hoses can handle higher flow rates but naturally cost more due to the increased material used. Likewise, hose length plays a role. Sold by the foot or pre-cut lengths, longer hoses will obviously cost more than shorter ones.

Pressure Rating: Hydraulic hoses are designed to withstand specific pressure loads. This pressure rating, measured in pounds per square inch (PSI), varies depending on the application. Hoses with higher PSI ratings, meant for heavy-duty machinery, will be more expensive than those with lower PSI ratings for less demanding uses.

Material: The type of material used in the hose construction significantly impacts the cost. Here’s a breakdown of common materials:

- Synthetic Rubber: The most widely used material, offering a good balance of affordability, flexibility, and resistance to oil and water.

- Thermoplastic Elastomer (TPE): Known for its excellent flexibility and resistance to a wider range of fluids, including bio-oils, making it a good choice for environmentally friendly applications. However, TPE hoses tend to be more expensive than synthetic rubber.

- Stainless Steel: Used for extreme pressure and temperature applications, stainless steel hoses are the most durable and most expensive option.

Number of Wire Braids: Hydraulic hoses often incorporate one or two layers of braided steel wire reinforcement to enhance strength and pressure handling. More braids translate to higher pressure capacity and consequently, a higher price.

Fittings: The end connectors that attach the hose to machinery come in various configurations and materials. Crimped or reusable fittings, along with the material (e.g., brass or steel), can affect the overall cost.

Pre-Assembled vs. Bulk Hose: Pre-assembled hydraulic hoses, with fittings already attached and cut to specific lengths, are a convenient option but typically cost more than buying bulk hose and installing your own fittings.

Hydraulic Hose Price Examples

To give you a practical idea of hydraulic hose pricing, here are some examples based on commonly available options:

- Basic 3/8″ x 10 ft. SAE 100R2 hydraulic hose (synthetic rubber, single wire braid, low pressure): ~$10 – $20 [online retailers]

- Pre-assembled 1/2″ x 25 ft. high-pressure hydraulic hose with steel braided construction and swivel fittings: ~$50 – $75 [hydraulic supply stores]

- Heavy-duty 1″ x 100 ft. bulk hydraulic hose made with thermoplastic elastomer and rated for 5000 PSI: ~$100 – $150 [industrial hose suppliers]

Remember, these are just ballpark figures. The actual price of a hydraulic hose will depend on the specific factors mentioned above. It’s always best to consult with a hydraulics specialist or supplier to get an accurate quote based on your exact requirements.

Additional Cost Considerations:

- Installation: If you’re not comfortable installing hydraulic hoses yourself, you’ll need to factor in labor costs from a qualified technician.

- Testing and Certification: In some critical applications, hydraulic systems might require pressure testing and certification to ensure safety compliance. These additional steps can add to the overall project cost.

Saving Money on Hydraulic Hoses:

- Buy in bulk (if applicable): If you need multiple hoses of the same size and specifications, buying in bulk can often lead to per-unit cost savings.

- Compare prices: Get quotes from several hydraulic suppliers before making a purchase. Online retailers and local hydraulics shops may offer competitive pricing.

- Consider used hoses (with caution): In some non-critical applications, used hydraulic hoses might be an option. However, ensure they are thoroughly inspected and certified to be safe for your intended use.

Hydraulic Hose Price per Foot

Hydraulic hose prices are typically quoted per foot, especially for bulk hydraulic hose (hose without pre-attached fittings).

Here’s a breakdown of hydraulic hose prices per foot based on common options:

- Basic 3/8″ diameter SAE 100R2 hose (synthetic rubber, single wire braid, low pressure): ~$1 – $2 per foot [online retailers]

- High-pressure 1/2″ diameter hydraulic hose with steel braided construction and swivel fittings: ~$2 – $3 per foot [hydraulic supply stores]

- Heavy-duty 1″ diameter bulk hose made with thermoplastic elastomer and rated for 5000 PSI: ~$1 – $1.5 per foot [industrial hose suppliers]

Remember, these are just ballpark figures. The exact price can vary depending on factors like:

- Brand and Retailer: Different brands and suppliers might have varying pricing structures.

- Bulk vs. Pre-cut: Bulk hose is generally cheaper per foot than pre-cut hoses.

- Volume Discounts: Buying larger quantities might qualify you for a discount.

Here are some tips for finding the best price on hydraulic hose per foot:

- Compare prices online and at local hydraulics shops.

- Consider buying in bulk if you need multiple hoses of the same size and specifications.

- Look for sales or promotions offered by retailers.

OEM Best Price High Pressure Hydraulic Hose

While I can’t directly recommend specific brands or products due to search result limitations, I can guide you in finding the best priced high-pressure OEM hydraulic hose manufacturers for you to get hydraulic hose:

Factors to Consider:

- Specifications: Determine the exact hose size (diameter), length, pressure rating (PSI), and material (e.g., synthetic rubber, thermoplastic elastomer, stainless steel). Consulting your machinery’s manual or contacting the manufacturer is recommended to ensure you get the right OEM hose.

- Number of Braids: High-pressure hoses typically have one or two braids. More braids indicate higher pressure capacity but also a higher price.

- Fittings: Decide if you need pre-assembled hoses with specific fittings or bulk hose to install your own fittings. Pre-assembled is convenient but pricier.

Finding the Best Price:

- Contact OEM Hydraulic Parts Suppliers: Look for authorized distributors or parts suppliers for your specific equipment brand. They’ll likely carry OEM hoses and provide accurate pricing.

- Request Quotes from Online Hydraulics Retailers: Search online for reputable hydraulics suppliers. Many offer a wide range of OEM and aftermarket hoses. Get quotes specifying the exact hose requirements you identified earlier.

- Compare Prices: Compare quotes from OEM suppliers and online retailers, considering factors like shipping costs and minimum order quantities.

Additional Tips:

- Consider Aftermarket Options: While OEM parts are guaranteed to be compatible, some high-quality aftermarket hoses might be a cost-effective alternative. Ensure the aftermarket hose meets or exceeds the OEM specifications for pressure, temperature, and material.

- Buy in Bulk (if applicable): If you need multiple hoses of the same size and specifications, buying in bulk from an online supplier might offer a per-unit discount.

Remember: Safety is paramount. Ensure the chosen hydraulic hose meets the pressure requirements for your application. When unsure, consult a qualified hydraulics technician.

Steel Wire Braid Hydraulic Hose Cost

The cost of a steel wire braid hydraulic hose can vary significantly depending on several key factors. Unlike standard rubber hoses, steel wire braid hoses are designed for higher pressure and durability, which naturally increases their price. The cost is typically calculated per foot, and you can expect prices to range from a few dollars to upwards of $30 or more per foot. The final cost of an assembly will also include the price of the end fittings and the labor for crimping, which can vary based on the complexity and material of the fittings.

Key factors that influence the cost include:

- Number of Braids: Hoses with a single wire braid (e.g., SAE 100R1) are less expensive than those with multiple braids (e.g., SAE 100R2), as more braids are needed for higher pressure applications and require more material and a more complex manufacturing process.

- Hydraulic Hose Size: The inner diameter (ID) and length of the hose directly correlate with the cost. Larger diameter hoses require more material and are thus more expensive.

- Pressure Rating: Hoses rated for higher working pressures require stronger materials and more layers of braiding, leading to a higher price.

- Fittings and Assembly: The type and material of the end fittings (e.g., carbon steel vs. stainless steel) and whether the hose is purchased as a bulk roll or a pre-assembled unit will also impact the total cost.

Why Are Hydraulic Hoses So Expensive?

Hydraulic hoses often come with a higher price tag due to several key factors that contribute to their specialized nature and critical function. The rigorous demands placed on these hoses, such as handling extremely high pressures, fluctuating temperatures, and aggressive hydraulic fluids, necessitate the use of premium materials and complex manufacturing processes.

This inherent complexity in design and production, coupled with stringent safety standards, significantly drives up their cost, making them a specialized and essential component in hydraulic systems.

- Premium Hydraulic Hose Materials: Hydraulic hoses utilize robust materials like multi-layered synthetic rubber, various types of thermoplastics, and high-tensile steel wire reinforcements. These materials are chosen for their durability, flexibility, and resistance to abrasion, chemicals, and extreme temperatures, all of which are more expensive than standard rubber or plastic.

- Complex Manufacturing Processes: The production of high-pressure hydraulic hoses involves intricate layering and bonding techniques, including precise braiding or spiral-winding of steel wires. This multi-stage manufacturing requires specialized machinery and highly skilled labor, adding to the overall production cost.

- Rigorous Testing and Safety Standards: To ensure safety and reliability in critical applications, hydraulic hoses undergo extensive testing, including burst pressure, impulse, and abrasion resistance tests. Adherence to international standards (e.g., SAE, ISO, EN) ensures their performance under extreme conditions, and these demanding certifications add to the manufacturing expense.

- Customization and Specialized Applications: Hoses designed for specific or niche applications, such as those requiring non-conductivity, extreme flexibility, or resistance to unique chemicals, often involve custom materials and production runs. This specialization further increases their cost compared to general-purpose hoses.

- Fittings and Assembly: The cost of high-pressure hydraulic hoses also includes specialized fittings and couplings, which must withstand the same high pressures as the hose itself. The labor and precision involved in crimping or attaching these fittings to create a safe and leak-proof assembly also contribute to the final price.

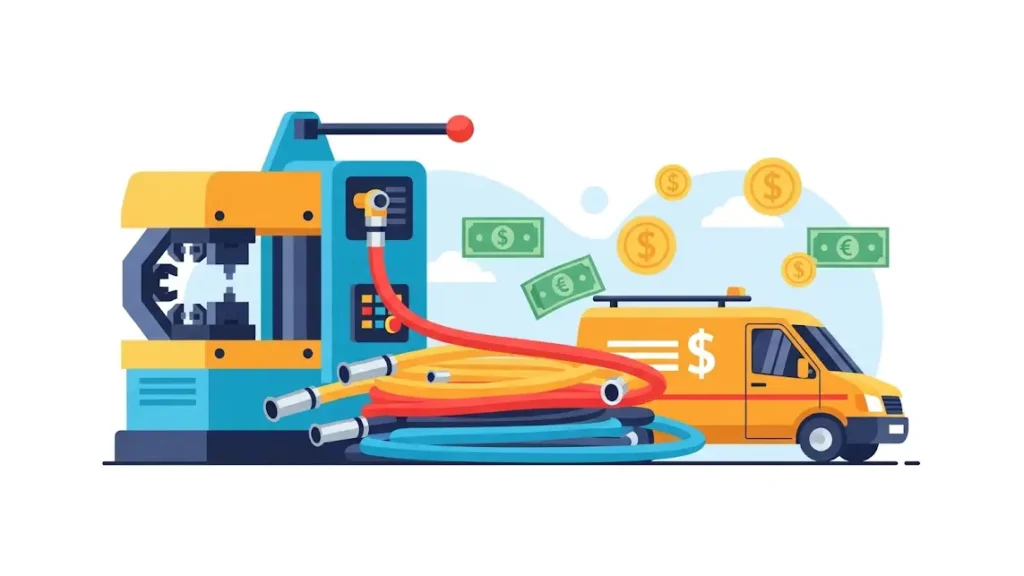

How Much to Start a Hydraulic Hose Business?

Starting a hydraulic hose business, whether a physical shop or a mobile service, requires a significant initial investment due to the specialized equipment and comprehensive inventory needed. Costs can vary widely depending on the business model, scale, and location, ranging from tens of thousands to several hundred thousand US dollars.

This initial capital covers everything from essential machinery like crimpers and saws to a diverse stock of hoses and fittings for various applications, alongside operational expenses.

- Hydraulic Hose Manufacturing Equipment Costs: A substantial portion of the startup capital goes into purchasing essential machinery, including professional hydraulic hose crimpers, cut-off saws, and related tools. These specialized machines are critical for accurate and safe hose assembly, often representing a significant upfront expense for the business.

- Initial Inventory: Stocking a wide variety of hydraulic hoses (different sizes, pressure ratings, materials) and a comprehensive range of compatible fittings (JIC, ORFS, NPT, etc.) is crucial. A diverse inventory is necessary to serve a broad customer base and respond quickly to varied repair needs, tying up a considerable amount of capital.

- Vehicle and Mobile Setup (for Mobile Services): For a mobile hydraulic hose repair business, investing in a well-equipped service van is essential. This includes fitting the vehicle with storage solutions, power generators, and potentially a smaller, portable crimping machine, adding significantly to the overall startup costs.

- Shop Space and Utilities (for Physical Shops): If opening a brick-and-mortar location, costs will include rent or purchase of commercial property, utility setup, and interior outfitting for the workshop and reception area. This provides a centralized hub for operations and customer interactions.

- Licenses, Insurance, and Training: Obtaining necessary business licenses and permits, along with comprehensive liability insurance, is mandatory. Additionally, investing in technical training for staff on hydraulic systems, hose assembly, and safety procedures is crucial for quality service and compliance.

How Many Years Do Hydraulic Hoses Last?

The lifespan of hydraulic hoses varies greatly, but on average, they can last between 5 to 10 years under normal operating conditions. However, various factors like high pressure, extreme temperatures, abrasion, chemical exposure, and improper installation can significantly shorten their life, sometimes to as little as a few months or a couple of years. Regular inspection and proper maintenance are key to maximizing their durability.

What Determines Hydraulic Hose Prices?

Hydraulic hose prices are determined by several factors: material composition (rubber, thermoplastic, PTFE), pressure rating (single, multi-braid, spiral), size (inner diameter and length), fittings/couplings required, and brand/quality. Specialized hoses for extreme temperatures or chemicals will also command a higher price.

Where to Buy Cheap Hydraulic Hoses?

For affordable and reliable hydraulic hoses, explore direct manufacturers and large-volume suppliers. Kingdaflex offers qualified hydraulic hoses at competitive prices, shipping globally from Qingdao, Shandong, China. They provide a range of specifications, ensuring you get the right product for your needs without compromising on quality.

Conclusion

In conclusion, understanding the factors that influence hydraulic hose cost is key to making informed purchasing decisions. While prices vary based on material, pressure rating, and size, investing in quality hoses ultimately saves money by reducing downtime and avoiding costly repairs.

Remember, a lower upfront cost doesn’t always translate to long-term savings if the hose fails prematurely. Prioritize durability and performance to ensure your hydraulic systems operate efficiently and safely for extended periods.

For competitive hydraulic hoses that offer both quality and value, look no further than Kingdaflex. We provide a wide range of hoses to meet your specific needs, ensuring you get the best performance for your investment.