Selecting the correct hydraulic hose diameter, encompassing both inner diameter (ID) and outer diameter (OD), is crucial for ensuring efficient and safe hydraulic system operation. The hose’s diameter directly influences fluid flow, pressure, and system performance. An incorrect diameter can lead to inefficiencies, leaks, or even catastrophic failures.

This guide will walk you through the essential considerations for choosing the right hydraulic hose diameter. We’ll explore the significance of ID for fluid flow and OD for fitting compatibility and external protection. Understanding these dimensions helps you optimize your hydraulic system, preventing costly errors and ensuring reliable performance.

What Is Hydraulic Hose Diameter

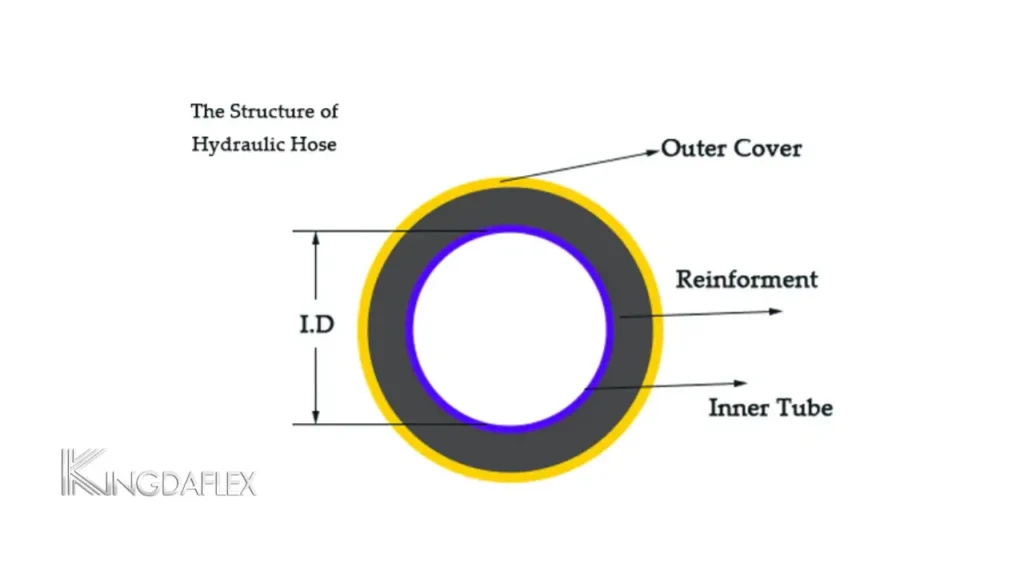

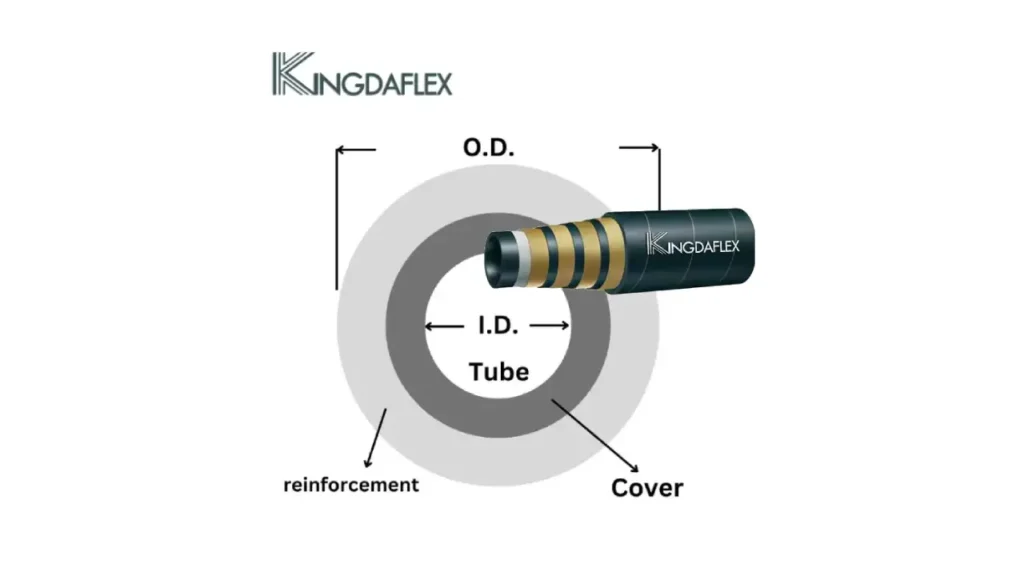

Hydraulic hose diameter refers to the inside diameter of the hose. It is measured in inches or millimeters and determines the maximum flow rate of the hydraulic fluid through the hose. The diameter affects the pressure drop, which is the difference between the inlet and outlet pressures of the hose.

Hydraulic Hose I.D and O.D

Understanding the inner diameter (ID) and outer diameter (OD) of hydraulic hoses is essential for ensuring proper system functionality. These dimensions directly impact fluid flow, pressure ratings, and fitting compatibility. Choosing the correct ID and OD prevents inefficiencies, leaks, and potential system failures.

Inner Diameter (ID)

The inner diameter (ID) of a hydraulic hose refers to the inside measurement of the hose’s bore. This dimension is crucial for determining the volume of fluid that can flow through the hose at a given velocity. A smaller ID restricts fluid flow, leading to increased pressure and potential overheating, while a larger ID can result in lower fluid velocity, affecting system performance. The ID is typically measured in inches or millimeters and is a primary factor in selecting the appropriate hose for a specific application.

Properly matching the ID to the system’s flow rate requirements is vital for optimal performance. An incorrect ID can cause excessive pressure drops, increased system temperatures, and reduced efficiency. When selecting a hose, consider the system’s flow rate, fluid viscosity, and pressure requirements. Manufacturers provide ID specifications to help you choose the right hose for your application, ensuring smooth and efficient fluid transfer.

Outer Diameter (OD)

The outer diameter (OD) of a hydraulic hose is the measurement of the hose’s outside dimension, including any reinforcement layers. This dimension is crucial for ensuring compatibility with fittings, clamps, and other system components. The OD also affects the hose’s flexibility and its ability to fit within tight spaces. It is essential to consider the OD when designing or maintaining hydraulic systems to prevent installation issues and ensure proper connections.

The OD is influenced by the hose’s reinforcement layers, which provide strength and durability. High-pressure hoses typically have multiple layers of reinforcement, resulting in a larger OD. When selecting fittings, it is crucial to match the fitting’s dimensions with the hose’s OD to ensure a secure and leak-free connection. Manufacturers provide OD specifications to help you choose compatible components and ensure proper installation.

Importance of Choosing the Right Hydraulic Hose Diameter

Choosing the correct hydraulic hose diameter, which includes both the inner diameter (ID) and outer diameter (OD), is paramount for the efficient and safe operation of hydraulic systems. An incorrect diameter can lead to a multitude of issues, from reduced system efficiency and increased energy consumption to potential leaks and catastrophic failures.

The right diameter ensures that fluid flow is optimized, pressure drops are minimized, and system components are compatible, contributing to overall system reliability and longevity.

Here’s why selecting the right hydraulic hose diameter is crucial:

Optimized Fluid Flow:

The ID of the hose directly affects the volume and velocity of fluid flow. An appropriately sized ID ensures that the system operates within its designed flow rate, preventing excessive pressure drops and ensuring smooth, efficient operation.

Pressure Management:

An incorrect ID can lead to increased or decreased pressure within the system. Too small an ID can cause excessive pressure buildup, potentially damaging components, while too large an ID can result in insufficient pressure for proper system function.

Component Compatibility:

The OD of the hose is critical for ensuring compatibility with fittings, clamps, and other system components. Mismatched diameters can lead to leaks, connection failures, and system downtime.

System Efficiency:

Using the correct hose diameter minimizes energy loss and maximizes system efficiency. This results in reduced operating costs and improved overall performance.

Safety:

Selecting the right hose diameter is crucial for safety. Incorrect diameters can lead to hose failures, leaks, and potential hazards, especially in high-pressure hydraulic systems.

How to Measure Hydraulic Hose Diameter?

Accurately measuring hydraulic hose diameter is essential for ensuring compatibility with fittings and maintaining system integrity. Incorrect measurements can lead to leaks, inefficiencies, and even system failures. We’ll guide you through the process, ensuring you achieve accurate results with the right tools and techniques.

Tools Needed:

- Caliper (digital or vernier)

- Measuring tape or ruler

- Thread pitch gauge (optional, for threaded fittings)

Step 1: Measuring the Inner Diameter (ID)

To measure the inner diameter (ID) of a hydraulic hose, use a caliper. Insert the caliper’s inside jaws into the hose’s opening and expand them until they touch the inner walls. Ensure the caliper is positioned perpendicular to the hose’s axis for an accurate reading. Record the measurement in millimeters or inches, depending on your preference. This measurement is crucial for determining the hose’s flow capacity and ensuring compatibility with fittings.

Accurate ID measurement is vital for fluid flow. Use a caliper, and ensure it’s perpendicular. Record the measurement in millimeters or inches.

Step 2: Measuring the Outer Diameter (OD)

For the outer diameter (OD), use the caliper’s outside jaws. Place the jaws on the outer surface of the hose and close them until they make contact. Again, ensure the caliper is perpendicular to the hose’s axis for an accurate reading. Record the measurement in the same units as the ID. This measurement is essential for selecting compatible fittings and clamps, as well as considering the hose’s fit within confined spaces.

Accurate OD measurement ensures fitting compatibility. Use a caliper, and ensure it’s perpendicular. Record the measurement in the same units as the ID.

Step 3: Measuring Threaded Fittings (Optional)

If the hose has threaded fittings, you’ll need to measure the thread size and pitch. Use a thread pitch gauge to determine the number of threads per inch or the pitch in millimeters. For tapered threads, like NPT, measure the diameter at the first full thread from the end. For straight threads, measure at any point along the thread length. Record these measurements accurately, as they are crucial for selecting compatible threaded fittings.

Threaded fitting measurements require a thread pitch gauge. Measure the thread size and pitch accurately. Record these measurements.

How to Measure Hydraulic Hose Size

Properly measuring hydraulic hose size is essential for ensuring a secure fit and optimal system performance. Using the wrong size can lead to leaks, pressure drops, and catastrophic equipment failure. There are three key measurements to consider for an accurate fit.

Step 1: Measure the Inner Diameter (ID)

The inner diameter is the most critical measurement and determines the flow rate of the fluid. Use a caliper to measure the open end of the hose from one inner wall to the other. This measurement is typically represented by a “dash size” in sixteenths of an inch.

Step 2: Measure the Outer Diameter (OD)

While not as critical as the ID for flow, the outer diameter is important for selecting the correct hose clamps and protective sleeves. Measure the outside of the hose from one outer wall to the other using a caliper.

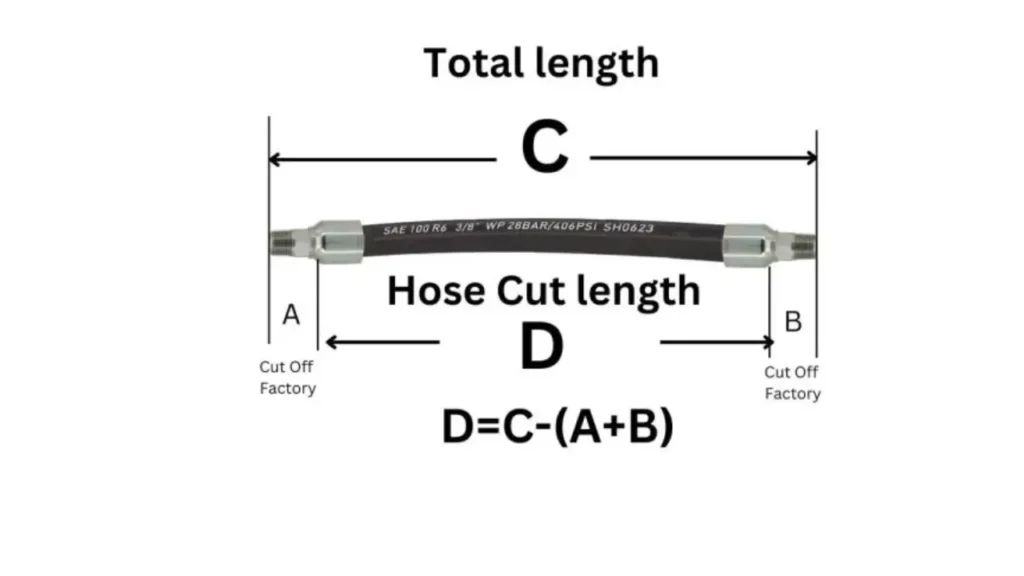

Step 3: Determine the Length

Measure the overall length of the hose assembly from end to end. If the hose has bent fittings, measure from the tip of the fitting on one end to the tip of the fitting on the other. This ensures the replacement hose will fit properly without being too tight or too loose.

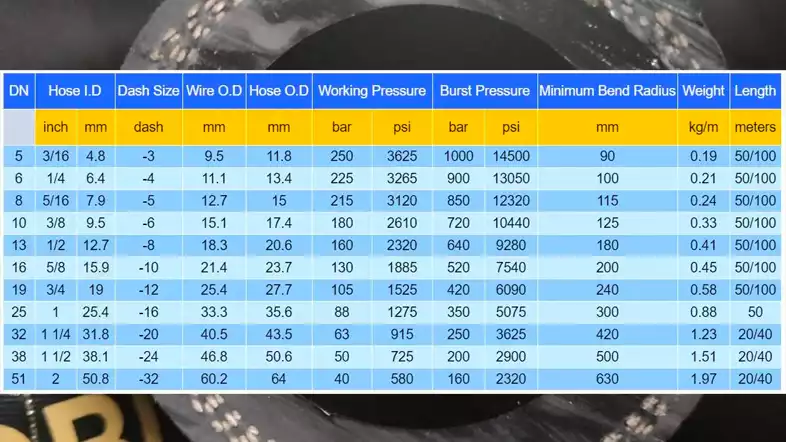

Hydraulic Hose Diameter Chart

A hydraulic hose diameter chart provides a reference guide to the most common hydraulic hose diameter sizes and their corresponding measurements in both inches and millimeters. Here is a hydraulic hose diameter chart:

Hydraulic Hose Diameter Chart:

| Size (inches) | Size (mm) |

|---|---|

| 1/4 | 6 |

| 3/8 | 10 |

| 1/2 | 13 |

| 5/8 | 16 |

| 3/4 | 20 |

| 1 | 25 |

It is essential to note that there may be variations in hydraulic hose diameter sizes depending on the manufacturer and the specific hydraulic system’s requirements. Therefore, it is crucial to consult the manufacturer’s specifications or an expert in hydraulic systems to determine the appropriate diameter size for your specific application.

3/8 Hydraulic Hose Outside Diameter

The outside diameter of a 3/8 hydraulic hose depends on the type and construction of the hose. However, the outside diameter of a typical 3/8 hydraulic hose ranges from 0.75 inches (19.05 mm) to 0.96 inches (24.38 mm).

It is essential to know the outside diameter of the hydraulic hose as it affects the routing and installation of the hose. The outside diameter determines the minimum bend radius and the amount of space required to accommodate the hose.

When selecting a hydraulic hose size, it is crucial to consider both the inside diameter and outside diameter of the hose. It is also essential to select a hydraulic hose that meets or exceeds the manufacturer’s specifications and industry standards.

Using the wrong size or type of hydraulic hose can result in system failure, damage, or injury. Therefore, it is crucial to consult an expert in hydraulic systems or the manufacturer’s specifications for guidance and recommendations on selecting the appropriate hydraulic hose size and type for your specific application.

Hydraulic Hose Size Calculator

A hydraulic hose size calculator is a tool used to determine the appropriate hydraulic hose size based on the flow rate, velocity, pressure, and temperature of the hydraulic system. Here is a simple hydraulic hose size calculation:

- Determine the flow rate (Q) in gallons per minute (GPM) or liters per minute (LPM).

- Calculate the velocity (V) in feet per second (FPS) or meters per second (MPS) using the hydraulic hose diameter formula:

V = (Q x 0.3208) / A

Where: Q = Flow rate in GPM or LPM A = Cross-sectional area of the hose in square inches (in²) or square centimeters (cm²)

- Determine the pressure drop (ΔP) in pounds per square inch (PSI) or bars using the formula:

ΔP = K x (V² / 2g)

Where: K = Pressure drop coefficient (0.017 for smooth bore hoses, 0.027 for convoluted hoses) V = Velocity in FPS or MPS g = Acceleration due to gravity (32.2 ft/s² or 9.81 m/s²)

- Calculate the maximum allowable pressure (MAP) in PSI or bars using the formula:

MAP = (ΔP x SF) + EP

Where: SF = Safety factor (typically 4:1 or 2.5:1) EP = End pressure (pressure at the end of the hose)

- Select the hydraulic hose size based on the maximum allowable pressure (MAP) and the manufacturer’s specifications or recommendations.

It is crucial to note that this hydraulic hose size calculator is a basic tool and may not account for all variables or factors that affect hydraulic system performance. Therefore, it is essential to consult an expert in hydraulic systems or the manufacturer’s specifications for guidance and recommendations on selecting the appropriate hydraulic hose size for your specific application.

By inputting parameters such as flow rate and fluid velocity, the calculator provides a recommended ID that minimizes pressure drops and ensures efficient fluid transfer. This tool helps prevent issues like overheating and reduced system performance, ensuring the hydraulic system operates within its designed parameters and maximizes efficiency.

Hydraulic Hose Size Calculator

Factors to Consider When Choosing Hydraulic Hose Diameter

When choosing the hydraulic hose diameter, there are several factors to consider to ensure optimal hydraulic system performance and safety. These factors to choose a hydraulic hose include:

- Flow Rate: The flow rate of the hydraulic system is the volume of fluid that passes through the hose per unit time. It is essential to choose a hydraulic hose with an appropriate inside diameter that can accommodate the required flow rate.

- Velocity: The velocity of the fluid passing through the hydraulic hose should be within the manufacturer’s recommended limits. An excessively high velocity can cause erosion, while a low velocity can result in the formation of sediment or contamination.

- Pressure: The hydraulic hose must be able to handle the maximum working pressure of the hydraulic system. A hose with a smaller inside diameter may not handle the required pressure, resulting in hose failure and potential damage to the system.

- Temperature: The temperature of the hydraulic fluid can affect the performance and lifespan of the hydraulic hose. It is important to choose a hose with a suitable temperature range that can withstand the maximum operating temperature of the system.

- Application: The specific application and environment of the hydraulic system can influence the choice of hydraulic hose diameter. For example, a hydraulic hose used in a harsh environment may require a larger diameter to ensure adequate flow and pressure.

- Hydraulic Hose Length: The length of the hydraulic hose can impact the flow rate, pressure, and velocity of the system. It is important to choose a hose with an appropriate inside diameter and length to minimize pressure drop and ensure optimal system performance.

Choosing the appropriate hydraulic hose diameter requires consideration of various factors such as flow rate, velocity, pressure, temperature, application, and hose length. It is crucial to consult an expert in hydraulic systems or the manufacturer’s specifications for guidance and recommendations on selecting the appropriate hydraulic hose diameter for your specific application.

Common Hydraulic Hose Diameter Sizes

The most common hydraulic hose diameter sizes are ¼ inch, ⅜ inch, ½ inch, ⅝ inch, and ¾ inch. The selection of the diameter depends on the system’s requirements, such as the flow rate, pressure, and temperature. It is essential to consult the manufacturer’s specifications or an expert in hydraulic systems to determine the appropriate diameter size.

Here is a table showing common hydraulic hose diameter sizes and their corresponding inside and outside diameters:

| Hose Size | Inside Diameter | Outside Diameter |

|---|---|---|

| 1/4 | 0.25 in (6.35 mm) | 0.52 in (13.21 mm) |

| 3/8 | 0.38 in (9.53 mm) | 0.75 in (19.05 mm) |

| 1/2 | 0.50 in (12.70 mm) | 0.87 in (22.10 mm) |

| 5/8 | 0.63 in (15.88 mm) | 1.00 in (25.40 mm) |

| 3/4 | 0.75 in (19.05 mm) | 1.16 in (29.46 mm) |

| 1 | 1.00 in (25.40 mm) | 1.50 in (38.10 mm) |

| 1 1/4 | 1.25 in (31.75 mm) | 1.85 in (46.99 mm) |

| 1 1/2 | 1.50 in (38.10 mm) | 2.17 in (55.12 mm) |

| 2 | 2.00 in (50.80 mm) | 2.65 in (67.31 mm) |

Note that the outside diameter may vary depending on the type and construction of the hose. It is important to consult the manufacturer’s specifications and industry standards when selecting a hydraulic hose diameter to ensure optimal system performance and safety.

What Size is a Standard Hose Diameter?

The “standard” garden hose diameter most commonly refers to the internal diameter (ID) of the hose, which determines the water flow. While several sizes exist, the most prevalent for residential use in the United States is 5/8 inch.

Here are the common standard hose diameters:

- 1/2 inch hydraulic hose (approximately 13 mm): Often used for light residential tasks, smaller gardens, and shorter hoses. It’s suitable for basic watering where high flow isn’t critical.

- 5/8 inch hydraulic hose (approximately 16 mm): This is the most common size for residential garden hoses, offering a good balance between water flow and ease of handling for general watering needs.

- 3/4 inch hydraulic hose (approximately 19 mm): Provides higher water flow and is often preferred for larger gardens, extensive lawn care, or heavy-duty applications like filling pools or using with pressure washers.

Here is the Hydraulic Hose Size CHART PDF

Standard Hydraulic Hose Sizes

Standard hydraulic hose sizes are almost always identified by a “dash size” which represents the hose’s inner diameter (ID) in sixteenths of an inch. This standardized system, used widely in the fluid power industry, makes it easy to quickly identify a hose’s size. For example, a “-8” hose has an ID of 8/16 of an inch, which simplifies to a 1/2-inch ID. This system is crucial for selecting the right hose for a given application to ensure proper flow and prevent system inefficiency or failure.

Key points to remember about hydraulic hose sizing:

- Dash Number: The dash number refers to the hose’s inner diameter (ID) in increments of 1/16 of an inch.

- ID vs. OD: Hoses are sized by their ID (Inner Diameter) for flow, while tubes are measured by their OD (Outer Diameter) for fitting purposes.

- Layline: The most reliable way to determine a hose’s size is to read the layline (the markings printed along the length of the hose), which will specify the dash size and other key information.

- Flow Rate: The correct hose size is critical for maintaining the right flow rate and preventing pressure drop, turbulence, and heat generation.

Standard Hydraulic Hose Size Chart

| Dash Size | Inner Diameter (Inches) | Inner Diameter (mm) |

| -2 | 1/8″ | 3.2 mm |

| -3 | 3/16″ | 4.8 mm |

| -4 | 1/4″ | 6.3 mm |

| -5 | 5/16″ | 8 mm |

| -6 | 3/8″ | 10 mm |

| -8 | 1/2″ | 12.7 mm |

| -10 | 5/8″ | 16 mm |

| -12 | 3/4″ | 19 mm |

| -16 | 1″ | 25.4 mm |

| -20 | 1-1/4″ | 31.8 mm |

| -24 | 1-1/2″ | 38.1 mm |

| -32 | 2″ | 50.8 mm |

Proper Hydraulic Hose Diameter Ensures Efficiency and Safety

Hydraulic systems are commonly used in heavy-duty equipment, manufacturing plants, and many other industries. These systems rely on hydraulic hoses to transmit fluid and power between different components. The proper hydraulic hose diameter is essential for ensuring efficiency and safety in these systems.

Choosing the right hydraulic hose diameter involves several factors, such as flow rate, pressure, temperature, and hose length. Using a hose with an inappropriate diameter can cause various problems, such as:

- Inefficient system performance: If the hose diameter is too small, it can restrict fluid flow and reduce system efficiency. This can lead to increased energy consumption, slower operation, and decreased overall performance.

- Increased pressure drop: Pressure drop occurs when the fluid flow encounters resistance, such as when it passes through a hose. A hose with an inadequate diameter can result in excessive pressure drop, reducing the system’s ability to deliver fluid to its intended destination.

- Premature hose failure: Using a hose with an incorrect diameter can lead to excessive stress on the hose, resulting in premature hydraulic hose failure, leaks, and potential safety hazards.

- Safety risks: In some cases, using an inappropriate hose diameter can result in safety risks, such as hose bursts, fluid injection injuries, or other accidents.

Selecting the right hydraulic hose diameter is crucial for ensuring efficient and safe system operation. When choosing a hydraulic hose diameter, it is important to consider the manufacturer’s recommendations, industry standards, and specific application requirements. Working with a hydraulic system expert can also help ensure the optimal performance and safety of the system.

Hose Size Selection Nomograph

A Hose Size Selection Nomograph is an invaluable graphical tool for quickly determining the ideal hydraulic hose ID. It simplifies complex calculations by visually representing the relationship between three key variables: desired flow rate (e.g., gallons per minute or liters per minute), recommended flow velocity (e.g., feet per second or meters per second), and the corresponding hose Inner Diameter (ID), often given in “dash sizes” (increments of 1/16th of an inch).

By knowing any two of these values, you can use a straightedge to connect them on the nomograph’s scales, and the intersection point on the third scale will reveal the unknown variable. This makes it an efficient method for ensuring proper hose sizing to prevent issues like excessive pressure drop, heat generation, or sluggish system performance.

Here’s how it generally works:

- Identify Your Knowns: Determine which two of the three variables (flow rate, flow velocity, or hose ID) you already know for your specific application.

- Locate on Scales: Find these two known values on their respective scales on the nomograph.

- Draw a Straight Line: Use a straightedge to connect the two known values.

- Read the Result: The point where your straightedge intersects the third scale will give you the value of the unknown variable, indicating the optimal hose ID for your needs.

Conclusion

Choosing the correct hydraulic hose diameter is crucial for the efficiency and longevity of your hydraulic system. Both the Inner Diameter (ID) and Outer Diameter (OD) play distinct yet equally important roles. The ID directly impacts flow rate and pressure drop, while the OD influences routing, clearance, and the overall physical fit.

Mismatching these specifications can lead to problems like overheating, energy loss, and premature hose failure. Taking the time to accurately select the right dimensions based on your system’s specific requirements will significantly improve performance and reliability.

Ultimately, a well-chosen hydraulic hose ensures optimal fluid velocity, minimizes turbulence, and allows your system to operate at peak efficiency. This precision prevents common pitfalls and contributes significantly to the operational success of your hydraulic equipment.

Ready to optimize your hydraulic systems? Contact Kingdaflex today to explore our extensive range of wholesale hydraulic hoses. Our experts can help you find the perfect ID and OD specifications for your unique applications, ensuring seamless operation and maximum efficiency.