We are a reliable hydraulic hose manufacturer, providing high-performance hoses and assemblies for diverse industrial and mobile applications. With over 20 years of experience, Kingdaflex offers a wide range of hydraulic hoses, including SAE and DIN EN series, designed for safety, efficiency, and long-term reliability in demanding systems.

Wide Hose Range: We offer a wide selection of hydraulic hoses, including SAE and DIN EN series, to meet different pressure, temperature, and application requirements.

Custom Fittings and Assemblies: We provide various fittings and hose assemblies tailored to your machinery needs, ensuring secure connections and leak-free operation in hydraulic systems.

Reliable Quality: We maintain strict quality control to deliver hoses that withstand high pressure, temperature fluctuations, and wear, providing long-lasting performance and system reliability.

Competitive Prices: We offer cost-effective solutions without compromising performance, allowing businesses to source reliable hydraulic hoses at competitive rates.

Customization Options: We help customize hoses by length, diameter, reinforcement layers, and outer covers to match specific operational conditions and ensure optimal system efficiency.

Kingdaflex is a leading hydraulic hose factory, specializing in the manufacture of SAE and DIN EN series hoses for industrial and mobile applications. With over 20 years of experience, we provide durable hoses, custom fittings, and assemblies. Our solutions ensure reliable fluid transfer, system efficiency, and long-term performance, all at competitive prices for global customers.

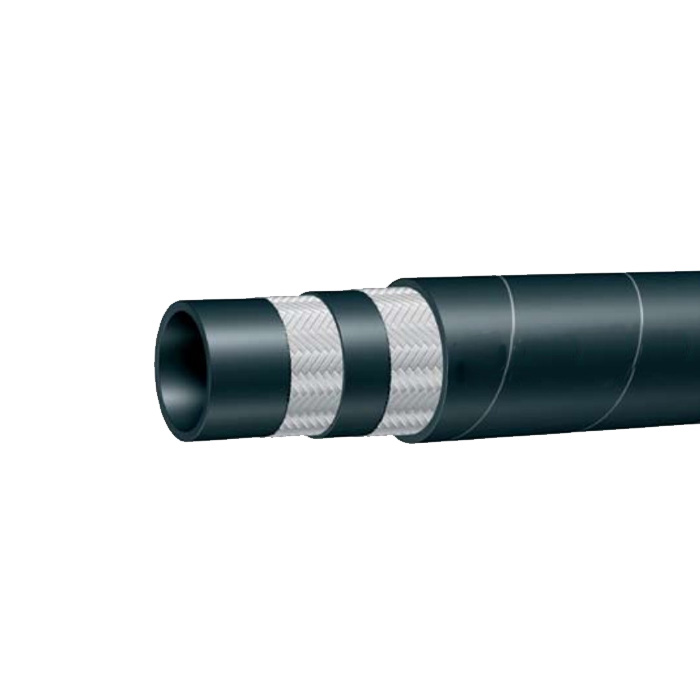

Inner Tube: This innermost layer is responsible for carrying the hydraulic fluid. It’s designed to be compatible with the fluid—whether it’s oil, water, or a chemical—to prevent degradation and ensure a leak-proof seal. Materials like synthetic rubber or thermoplastics are commonly used.

Reinforcement Layer: The “muscle” of the hose, this layer provides the strength needed to resist the extreme internal pressure. It’s made of high-strength materials like braided or spiraled steel wire or synthetic fibers. The type and number of layers determine the hose’s pressure rating.

Outer Cover: This protective skin shields the inner layers from external damage like abrasion, weathering, oil, and ozone. It’s typically made of a durable, resistant synthetic rubber.

Braided Wire Reinforcement: The first and second hoses show a wire braid reinforcement. This consists of interwoven layers of high-tensile wire, typically steel, which provides good flexibility and resistance to pressure. The braiding pattern distributes stress evenly across the hose.

Spiraled Wire Reinforcement: The third and fourth hoses illustrate spiraled wire reinforcement. Multiple layers of wire are wrapped in a spiral pattern around the inner tube. This type of reinforcement offers excellent pressure resistance and is often used in high-pressure hydraulic applications.

Concentric Wrapped Reinforcement: The fifth hose displays a concentric wrapped reinforcement. Layers of reinforcement material, potentially wire or fabric, are wrapped directly over each other. This construction provides high strength and stability to the hose under extreme pressure conditions.

We manufacture a full range of hydraulic hoses to meet every industrial need. Our extensive product line includes SAE and DIN EN series hoses, spiral hoses, and more. With over 20 years of expertise, we guarantee durability, reliability, and peak performance for your equipment.

When you need a versatile and reliable solution, our wire braided hydraulic hoses are a perfect choice. We reinforce these hoses with one or more layers of braided high-tensile steel wire, giving them the flexibility and durability you need. They’re ideal for medium to high-pressure jobs in construction, mining, and industrial machinery, ensuring your equipment performs reliably every time.

For your most demanding, heavy-duty applications, we recommend our wire spiral hydraulic hoses. We engineer these with multiple layers of spiraled steel wire to give them superior strength and resistance to extreme pressure surges. While they’re less flexible, their incredible robustness makes them essential for large-scale equipment like earthmovers and oil drilling machinery, providing the power and safety you depend on.

If your application requires a lightweight and highly flexible solution, our thermoplastic hydraulic hoses are the answer. We manufacture these from high-quality synthetic materials, which makes them resistant to chemicals, UV radiation, and kinking. These hoses are perfect for low to medium-pressure systems and mobile equipment, giving you a smaller bend radius and the reliability you need in tight spaces.

We understand that not every application needs high pressure. Our textile braided hydraulic hoses are designed for low-pressure environments, such as return lines, air lines, and lubrication systems. We use high-strength textile fibers for reinforcement, giving you a lightweight and highly flexible hose that is easy to route and install in tight spaces.

When you need to move fluids to or from your hydraulic system’s reservoir, our suction and return hydraulic hoses are the perfect solution. We build these hoses with a strong reinforcement to prevent collapse under vacuum, while still providing the flexibility you need. They are designed for low-pressure applications, ensuring a smooth flow of fluid and preventing damage to your system.

When you’re dealing with extreme temperatures or aggressive chemicals, you need a hose that can handle it all. Our PTFE hydraulic hoses, also known as Teflon hoses, are made with a non-reactive inner tube and reinforced with stainless steel wire braid. This construction gives you a hose with excellent chemical compatibility, high temperature resistance, and a longer service life, making it perfect for specialized industrial applications.

We offer a complete range of hydraulic hoses engineered to meet diverse pressure ratings. From low-pressure return lines to ultra-high-pressure spiral hoses for heavy machinery, our products are manufactured to strict SAE and DIN EN standards. You can count on our hoses for durability, reliability, and safe operation in any application.

SAE 100R3: A low to medium-pressure hose reinforced with two braids of synthetic textile fibers, making it lightweight and flexible. It’s suitable for hydraulic return lines and applications where a steel braid isn’t needed.

SAE 100R4: This hose is designed for low-pressure suction and return lines. It features a textile reinforcement with a spiral steel wire to prevent collapse under vacuum conditions.

SAE 100R6: This is a very lightweight, low-pressure hose with a single textile braid reinforcement, ideal for general-purpose hydraulic systems.

SAE 100R1: A common high-pressure hose reinforced with a single braid of high-tensile steel wire. It’s a versatile workhorse for many hydraulic applications.

SAE 100R2: Similar to the 100R1, but for higher pressure applications. This hose is reinforced with two braids of high-tensile steel wire, offering greater strength and durability.

SAE 100R5: This is a medium-pressure hose that combines a single wire braid with a textile braided cover. It’s often used in automotive applications like air brakes and power steering systems.

SAE 100R16: A more compact version of the 100R2. This hose has a smaller diameter but performs at similar pressure ratings, making it a great choice when you need a more flexible hose for tight spaces.

SAE 100R17: A high-pressure, compact hose reinforced with one or two steel wire braids. It’s designed to be lightweight and highly flexible while maintaining a 3000 psi constant working pressure across all sizes.

SAE 100R7: A medium-pressure thermoplastic hose reinforced with synthetic fibers. It’s lightweight, non-conductive, and resistant to a variety of chemicals and weather conditions.

SAE 100R8: A high-pressure version of the 100R7, with multiple layers of synthetic fiber reinforcement. It’s also non-conductive and ideal for applications where electrical conductivity is a concern.

SAE 100R14: This is a specialty hose with a PTFE (Teflon) inner tube and a stainless steel wire braid reinforcement. It’s excellent for high-temperature and chemically corrosive applications.

SAE 100R18: A high-pressure thermoplastic hose designed for non-conductive applications, with a constant 3000 psi working pressure. It offers great flexibility and a tight bend radius.

At Kingdaflex, we offer hydraulic hoses with different cover types to meet the specific demands of your operating environment. The cover is critical for protecting the hose’s reinforcement and inner tube from external threats like abrasion and weather. We provide both smooth and wrapped cover options, each with unique advantages for your application.

We manufacture these hydraulic hoses with a textured, fabric-imprinted outer layer. This finish results from our traditional curing process using nylon fabric strips. The wrapped cover provides excellent grip and is highly resistant to abrasion and weather, making it a reliable choice for heavy-duty applications in harsh industrial and outdoor environments where physical contact and wear are common.

We produce our smooth cover hoses using a more modern curing process that leaves a clean, sleek surface. This type of cover is not only aesthetically pleasing but also offers superior resistance to cracking from ozone exposure. Smooth covers are easier to clean and work well in tight, congested routing paths, as they are less likely to snag, ensuring a cleaner installation and easier leak detection.

The hydraulic hose manufacturing process involves multiple precision steps to ensure safety, durability, and performance. From selecting high-quality materials to extrusion, reinforcement, braiding, and assembly, each stage is carefully controlled. This process produces hoses capable of handling high pressure, extreme temperatures, and demanding industrial or mobile hydraulic applications reliably.

Inner Tube Extrusion: We begin by extruding a synthetic rubber compound through a specialized machine to create the inner tube. This process ensures a smooth and uniform inner diameter, which is crucial for the efficient flow of hydraulic fluid.

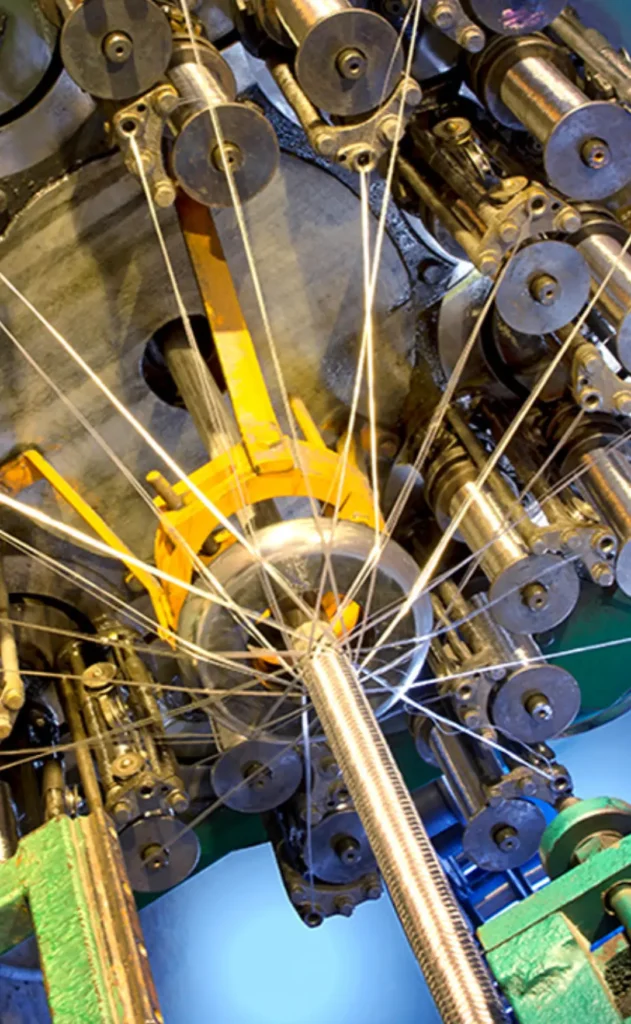

Reinforcement Layer Application: Next, we apply the reinforcement layer. Depending on the hose type, we use a braiding or spiraling machine to wrap high-tensile steel wire or textile fibers around the inner tube. This step is what gives the hose its strength.

Outer Cover Extrusion: After the reinforcement is in place, we extrude a final layer of durable rubber to create the outer cover. This protective layer shields the hose’s reinforcement from external elements like abrasion, weather, and ozone, extending its service life.

Vulcanization and Curing: The final hose assembly is then vulcanized, or cured, under heat and pressure. This process bonds all the layers—the inner tube, reinforcement, and outer cover—into a single, strong, and durable unit that can withstand high pressure.

Quality Testing: Finally, we rigorously test each batch of hoses for quality and safety. We perform pressure tests to ensure they meet specified working and burst pressures, guaranteeing the reliability you need for your applications.

Kingdaflex hydraulic hoses are engineered to perform reliably across a vast range of industries and applications. Our durable and high-quality hoses are the critical components that power machinery in some of the world’s most demanding sectors. They ensure the safe and efficient transfer of hydraulic fluid, enabling everything from construction to agriculture.

The construction industry relies heavily on hydraulic power for heavy-duty tasks. Our hoses are the vital links in excavators, bulldozers, cranes, and loaders, transmitting the immense pressure needed to lift, dig, and move materials. They are built to withstand the constant abrasion, vibrations, and harsh environmental conditions found on job sites, ensuring your equipment operates without interruption.

In the agricultural sector, hydraulic systems are essential for the operation of tractors, combines, sprayers, and other farm machinery. Our hydraulic hoses are designed to withstand exposure to a variety of weather conditions, chemicals, and fertilizers. They provide the reliable power transfer needed for lifting heavy loads, steering, and operating attachments, contributing to increased efficiency and productivity on the farm.

In the agricultural sector, hydraulic systems are essential for the operation of tractors, combines, sprayers, and other farm machinery. Our hydraulic hoses are designed to withstand exposure to a variety of weather conditions, chemicals, and fertilizers. They provide the reliable power transfer needed for lifting heavy loads, steering, and operating attachments, contributing to increased efficiency and productivity on the farm.

In manufacturing facilities, hydraulic hoses are used in a wide array of industrial machinery, including presses, injection molding machines, and robotic arms. We provide hoses that meet the specific requirements of these applications, from resistance to various fluids to flexibility for complex movements. Our hoses ensure that industrial processes run smoothly and safely, minimizing downtime and maximizing output.

Hydraulic systems are crucial for transportation and material handling equipment, such as forklifts, dump trucks, and various lifting platforms. Our hoses are built to withstand the constant use and varied pressures found in these applications. They provide the dependable power for lifting, tilting, and steering, ensuring the safe and efficient movement of goods and materials in warehouses and logistics operations.

Exceptional Quality Control: We adhere to the strictest international standards, including ISO 9001. Every stage of our manufacturing process, from material selection to final inspection, is meticulously monitored to ensure our hoses meet or exceed all industry requirements for safety and performance.

Comprehensive Product Range: We offer an extensive selection of hydraulic hoses, from low-pressure textile braided to ultra-high-pressure spiral hoses. This broad product line ensures we can provide the perfect hose solution for any application, no matter the pressure, temperature, or environmental challenges.

Decades of Experience: With over 20 years in the industry, our expertise is unmatched. We have a deep understanding of hydraulic systems and the specific demands of various applications, allowing us to provide you with expert guidance and superior products.

Customization and Flexibility: We understand that some projects have unique requirements. We offer custom manufacturing services, working closely with you to design and produce hydraulic hoses that are tailored to your exact specifications, ensuring a perfect fit and optimal performance.

Competitive Pricing: As a direct manufacturer, we eliminate the middleman, allowing us to offer our high-quality hoses at a more competitive price. We provide you with excellent value without compromising on the durability or reliability you expect from a premium product.

Global Reach and Reliable Service: We have a well-established global distribution network, ensuring that our hoses can be delivered to you efficiently, wherever you are. Our dedicated customer service team is always ready to assist you with technical support and order inquiries, making your experience seamless.

Hydraulic hoses are flexible, reinforced conduits used in hydraulic systems to transmit hydraulic fluid under high pressure. They serve as the vital “arteries” of a hydraulic system, connecting components like pumps, valves, cylinders, and motors.

Hydraulic hoses are generally made of three main components: an inner tube, a reinforcement layer, and an outer cover. The specific materials used for each layer vary depending on the hose’s intended use, such as the type of fluid it will carry, the pressure it will withstand, and the operating environment.

This is the innermost layer that is in direct contact with the hydraulic fluid. Its material must be compatible with the fluid to prevent chemical degradation and permeation. Common materials for the inner tube include:

Synthetic rubber: A widely used and versatile material, often made from compounds like nitrile rubber or neoprene, which offer good resistance to petroleum-based hydraulic oils.

Thermoplastics: Materials like nylon or polyurethane are used for lightweight, flexible hoses, and are known for good chemical and abrasion resistance.

PTFE (Teflon): A synthetic polymer that provides excellent chemical resistance and can withstand very high temperatures, making it suitable for aggressive fluids and extreme environments.

The reinforcement layer is the structural backbone of the hose, providing the strength needed to withstand high internal pressure. It is located between the inner tube and the outer cover. The reinforcement can be made of:

Steel wire: This is the most common reinforcement material. The wires can be braided or spiral-wound in multiple layers. Braided wire is typically used for medium-pressure applications, while spiral-wound wire is used for ultra-high-pressure applications.

Textile yarn or synthetic fibers: These are used for low-pressure applications, such as return lines, where flexibility is more important than extreme pressure resistance.

The outer cover protects the reinforcement layer and the inner tube from external damage. Its material is chosen to resist the environmental conditions of the application, such as abrasion, weather, oil, ozone, and UV rays. Common materials for the outer cover include:

Synthetic rubber: A durable and flexible material that is resistant to abrasion and weathering.

Thermoplastic polyurethane (TPU): A tough plastic that offers excellent resistance to abrasion and impact.

Stainless steel braiding: In some cases, the stainless steel reinforcement itself acts as the outer cover, providing maximum durability and corrosion resistance.

There are many different types of hydraulic hoses, which are typically classified based on their construction, pressure rating, and application.

The most common classification systems are governed by standards like those from the SAE (Society of Automotive Engineers) and ISO (International Organization for Standardization).

Here’s a breakdown of the main types:

These are the most common type of hydraulic hose. They have a reinforcement layer of one or more braided steel wires or synthetic fibers. The crisscross pattern of the wires provides a good balance of strength and flexibility. They are generally used for medium to high-pressure applications in a variety of equipment, from construction to agriculture.

Single-braid: Used for lower-pressure applications.

Double-braid: Used for medium to high-pressure applications.

Triple-braid: A specialty hose used for very high pressures, offering a lighter alternative to spiral hoses.

Designed for heavy-duty, ultra-high-pressure applications, these hoses have multiple layers of spiral-wound, high-tensile steel wire reinforcement. The parallel layering of the wires makes them extremely strong and durable, and they are excellent at handling high-impulse applications with frequent pressure spikes. You’ll find them in large, heavy machinery like mining equipment and earthmovers.

These hoses are made from synthetic materials like nylon or polyurethane, with reinforcement from synthetic fibers or braided wire. They are known for being lightweight and flexible and offer good chemical resistance and a wide temperature range. They are often used in applications where weight is a concern or where they may be exposed to chemicals or UV radiation.

Beyond the main categories, some hoses are designed for specific tasks:

Low-Pressure/Return Hoses: These hoses are not reinforced with wire and are designed to return fluid to the hydraulic system’s reservoir. They are very flexible and typically used in low-pressure lines.

Suction Hoses: These hoses have a helical wire coil embedded in the hose to prevent it from collapsing under vacuum pressure as it draws fluid into the system.

PTFE (Teflon) Hoses: These hoses have a smooth PTFE inner tube, often with a stainless steel braid reinforcement. They are highly resistant to chemicals and extreme temperatures, making them ideal for aggressive fluid applications.

Choosing a suitable hydraulic hose is a critical process that directly impacts the safety, efficiency, and longevity of a hydraulic system. A common industry-standard method for making this selection is the S.T.A.M.P.E.D. acronym, which stands for:

Size

Temperature

Application

Material

Pressure

Ends

Delivery

By following this checklist, you can ensure you select a hose that meets all the necessary requirements for your specific use.

The size of the hose refers to both its inside diameter (ID) and length.

Inside Diameter: The hose’s ID must be correctly sized for the system’s flow rate. An ID that is too small can cause excessive fluid velocity, leading to pressure drops, turbulence, and heat generation, which can damage the hose and other components. An ID that is too large can make the hose bulky and heavy, leading to potential routing and space issues.

Length: The hose must be long enough to accommodate movement, bending, and vibration without putting undue stress on the fittings. It should not be so long that it causes kinks or rubs against other components.

You must consider two types of temperatures:

Fluid Temperature: The temperature of the fluid being conveyed through the hose. The hose’s inner tube and reinforcement must be rated to withstand the minimum and maximum temperatures of the fluid.

Ambient Temperature: The temperature of the environment surrounding the hose. The outer cover must be rated to withstand the external temperatures, which can affect the hose’s flexibility and durability.

This refers to the conditions in which the hose will be used. Consider factors such as:

Mechanical Stress: Will the hose be subjected to constant flexing, vibration, or bending? The hose’s minimum bend radius is a crucial specification to consider here.

Environmental Factors: Will the hose be exposed to abrasion, UV light, ozone, saltwater, or other corrosive elements? Choosing a hose with a highly durable and resistant outer cover is essential for longevity.

Installation: Is the hose used in a static or dynamic application? This will influence the required flexibility and reinforcement type (e.g., braided vs. spiral).

The hose material must be compatible with the fluid it is carrying. Incompatibility can lead to the hose’s inner tube deteriorating, contaminating the fluid, and causing system failure. Always consult a chemical resistance chart to ensure the hose’s inner tube, outer cover, and fittings are compatible with the specific hydraulic fluid (e.g., petroleum-based oil, synthetic fluid, water-based solution).

This is one of the most critical factors. The hose’s maximum working pressure must be equal to or greater than the system’s maximum operating pressure, including any momentary pressure spikes or surges. The hose’s burst pressure, which is the pressure at which the hose is likely to fail, should be significantly higher than the working pressure to provide a safety margin (typically a 4:1 safety factor).

The end fittings must be compatible with both the hose and the connection points on the equipment.

Type: There are numerous types of fittings, including male, female, straight, angled (e.g., 45° or 90°), and various thread types (e.g., NPT, JIC, ORFS).

Connection: Fittings are either permanently crimped or field-attachable. It is vital to use the correct fitting for the specific hose type from the same manufacturer to ensure a proper and secure seal.

This final factor relates back to the hose’s inside diameter and overall system performance. The hose must be able to deliver the required volume and velocity of fluid without generating excessive pressure drop or heat. If a hose is too small, the high flow rate can erode the inner tube, leading to premature failure.

Based on information from their own website and other industry sources, Kingdaflex promotes its hydraulic hoses by highlighting several key advantages:

1. Reliable Quality and Durability

Kingdaflex emphasizes its strict quality control and use of high-quality raw materials. They state that their hoses are manufactured according to international standards such as SAE, DIN, and ISO. They also conduct impulse tests to ensure the hoses can withstand repeated pressure cycles, which is critical for real-world applications.

2. Wide Range of Products and Customization

The company offers a broad selection of hydraulic hoses, including braided, spiral, and thermoplastic types, suitable for various industries such as construction, mining, agriculture, and marine. They also offer customization services for specific needs, including different sizes, lengths, and even branded printing on the hose layline.

As a Chinese manufacturer, Kingdaflex states that they offer their products at competitive prices by eliminating middlemen. This allows them to provide a balance of quality and cost-effectiveness.

4. Industry Expertise and Experience

Kingdaflex highlights its years of manufacturing and sales experience in the hydraulic hose market. They mention having an experienced staff and receiving technical support from Qingdao University of Science & Technology to stay updated on the latest developments in hydraulic hose technology.

5. Certifications and Standards

The company holds certifications such as SGS, CE, and ISO, which provide assurance that their products meet certain quality and safety standards. This can be an important factor for clients seeking to comply with specific regulations.