It is to say that the hydraulic hose assembly is an important part of the hydraulic system, the successful hydraulic hose assembly can ensure your hydraulic project can work smoothly and fluently.

Here we are the top hydraulic hose manufacturer to supply all types of hydraulic hoses, and you can order hydraulic hose online from our website, to start your hydraulic project. When it comes time to replace a hydraulic hose assembly, how do you know which hoses and fittings are the right ones?

Read on to learn the most essential tips to consider when building a hose assembly. Successfully hydraulic hose assembly starts here.

What Is the I.D. or Dash Size for Application?

how to size hydraulic hose

how to size hydraulic hose

Hydraulic hose I.D. is the inner diameter (inside diameter) of the hydraulic hose. The hydraulic hose ID is also known as the dash size, measured in the 16th of an inch. The hose inside diameter can be measured manually, you can use the vernier caliper to measure the hose, to get the accurate size of inner diameter (ID), an outer diameter (OD).

And the hydraulic hose ID and dash size will be printed on the hydraulic hose layline, this is the basically important specification for selecting a hydraulic hose. Becasue the hose ID can determine the flow velocity or flow rate of the hydraulic fluids in the hydraulic system.

Too high flow rate can cause the leaking fluid drops and then result in the hydraulic hose breaking, bursting, too low flow will cause sluggish performance. So it is very important to choose the hydraulic hose with the suitable ID. Please feel free to contact us to get detailed info about the hydraulic hose ID and dash size.

Ambient Temperature and Media Temperature

hydraulic hose temperature rating

The temperature is also an important factor that can determine the hydraulic hose selection. Here are 2 aspects of the temperature, ambient temperature, and media temperature.

Ambient temperature is the temperature outside of the hydraulic hose, of the surrounding environment where you assemble the hydraulic hose. Media temperature is the temperature of the media (hydraulic fluids) being conveyed through the hydraulic hose, touching the inner tube of the hose.

The temperature rating of the hydraulic hose should be much higher than the ambient temperature and media temperature. At the same time, you also need to consider the media type, because the media will affect the temperature, to increase or decrease.

Here we have different hydraulic hoses to meet different temperature ratings to convey different hydraulic fluids, and we can offer high-to-low temperature hoses to widen your hydraulic hose selection.

If you want to know more about the hydraulic hose ambient temperature and media temperature, please feel free to contact us right now.

Hydraulic Hose Application Is Different

The hydraulic hose application for each hydraulic project or hydraulic system is entirely different, so you need to consider many factors before hydraulic hose application.

Here are some factors you need to consider seriously.

- What type of equipment is involved in hydraulic hose assembly?

- What are the environmental factors?

- Are there hydraulic hose routing requirements?

- What types of hydraulic hose fittings are needed?

Some standards are required to certify the hydraulic hose quality.

- SAE (Society of Automotive Engineers) Standard [Hydraulic Hose SAE Standards]

- EN (European Norm) Standard [Hydraulic Hose EN Standards ]

- DIN (Deutsches Institute für Normung)

- ISO(International Organization for Standardization)

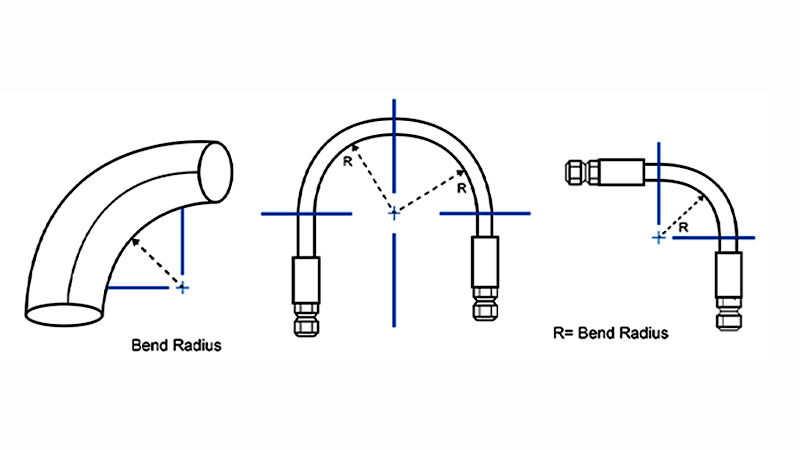

Does Your Application Require A Tight Bend Radius?

hydraulic hose bend radius[/caption]

hydraulic hose bend radius[/caption]The minimum bend radius of a hose refers to the minimum radius that the hydraulic hose may be bent through while operating at the maximum allowable working pressure.

The bending radius can provide enhanced flexibility and eases routing. However, bending the hose below the minimum bending radius will cause mechanical strength loss and result in hose failure during the hydraulic hose installation.

Please be serious about the minimum bend radius of the hydraulic hose before determining it is to be used for your hydraulic project.

Is Hydraulic Hose Abrasion A Factor?

When selecting a hose, you need to consider external conditions for an application. Is there a risk of abrasion?

The most hose has neoprene outside, but if you have hoses that will inevitably rub against materials, against machinery, against the jib or boom, any application where it can rub back and forth, a high abrasion carcass is a good way to go.Hoses tend to fail by rubbing on the outside until they wear through the outer wall into the braiding and start wearing that away, and eventually, enough so that the hose can no longer contain pressure.

At that point, the hose will burst. External abrasion is probably the number one cause of hose failure. Parker recommends using Tough Cover (TC) for harsh environments and SuperTough (ST) for extremely abrasive environments.

Is Media Compatibility A Concern?

Hoses should be selected with media compatibility in mind. The media being conveyed through the hose should not only be compatible with the inner tube, but also the, cover, fittings, and O-rings as well. Incompatible media will cause several problems to hose assemblies and hydraulic systems. In order to prevent hose failures, check hose compatibility by using our chemical resistance chart.

Do Not Ignore Maximum Pressure Ratings

When considering hose pressure, be sure to consider the system working pressure as well as any surge or spike pressures. These pressures should be below the rated maximum working pressure of the hose. Although Parker hydraulic hoses have been tested to meet a 4:1 pressure safety factor, they are not intended to be used at higher than published working pressures.

It is important to note when considering hose assembly pressure, the maximum working pressure of the system is the lowest rated piece of the assembly.

For example, if the fittings are rated to a lesser pressure than the hose, the maximum working pressure of the entire assembly is the working pressure of the fittings.

Hose pressures can be found on the engineering specifications for each hose as well as our hose overview chart and the hydraulic hose layline. To find the pressure rating for fittings, please see the pressure rating of the hose end connectors chart.

Fitting Selection Can Be Complicated

The fitting-to-hose mechanical interface must be compatible with the hose selected. The proper mating thread end must be chosen so that connection of the mating components will result in leak-free sealing.

There are two general categories of fittings to connect most types of hose: the permanent type (used primarily by equipment manufacturers, large-scale rebuilders, and maintenance shops) and the field-attachable type.

- crimped fittings are cold-formed onto the hose. They are available for most rubber and thermoplastic hoses and offer a wide range of dependable connections at a low cost. Assemblies made in the field with portable machines are relatively simple; these machines are economical and easy to operate. These fittings are less complicated to install than other types.

- The screw-together fitting attaches to the hose by turning the outer coupling shell over the outside diameter of the hose. The fitting insert is then screwed into the fitting shell.

Another component of fitting selection is thread type. For hydraulic hose assemblies, there are several different types of thread types:

- German DIN hose fittings

- British Standard Pipe (BSP)

- French Gas fittings

- Japanese fittings

- North American Thread Types such as Dryseal American Standard Taper Pipe Thread (NPTF), SAE 37⁰ JIC, SAE 45⁰ Flare, SAE O-rings (Boss Type), O-ring Face Seal (ORFS) Flange Fittings (Code 61 and Code 62), and 4-Bolt Split Flange

At the end of the day, all fittings are only as good as the assembler who installs them. There are proper assembly procedures for each of the fitting styles, and strict adherence to those steps makes the difference between a solid connection and a problem waiting to happen. To assure the correct identification, the threads must be measured and compared to the tables listed here.

Parker has some great resources for hydraulic hoses, fittings, and equipment including online literature that outlines the proper hose assembly techniques.