Hydraulic hoses often feature numbers printed along their surface, but many users may not fully understand what these numbers mean. These codes are not random; they represent important details about the hose’s specifications. Knowing how to interpret them helps ensure safe, efficient, and correct use of hydraulic equipment.

The numbers typically indicate details like size, pressure rating, and international standards that the hose complies with. By reading these markings, operators and technicians can quickly identify whether a hose is suitable for their specific application. This knowledge reduces risk, prevents system failures, and ensures compatibility with hydraulic machinery.

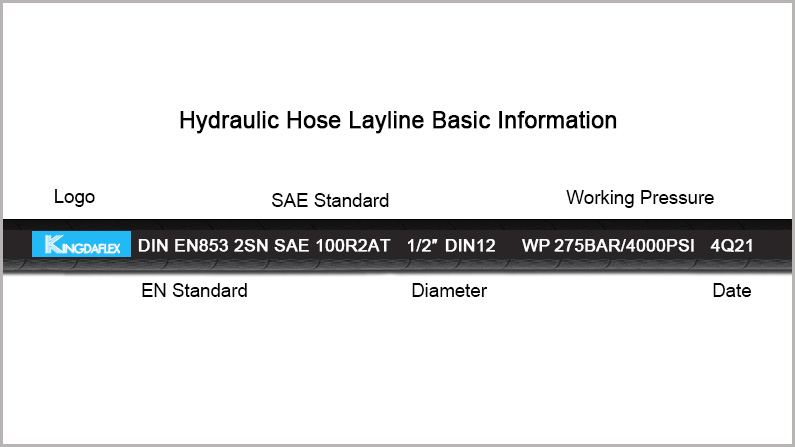

Hydraulic Hose Layline Numbers

Hydraulic hose layline numbers are printed markings that provide key information about the hose. These numbers help identify hose specifications, ensuring correct selection, installation, and safe operation. Understanding layline markings prevents mistakes, reduces downtime, and keeps hydraulic systems running smoothly in different applications.

- Hydraulic Hose Size: Layline numbers display the hose’s inner diameter. We ensure proper sizing helps maintain fluid flow, prevent pressure loss, and match fittings correctly, reducing risks of leaks and system inefficiency.

- Pressure Rating: Numbers indicate maximum working pressure. We make sure selecting hoses with the correct rating keeps systems safe, avoiding bursts or failures under high-pressure operations.

- Temperature Range: Layline markings often show the recommended temperature limits. We provide hoses suitable for specific conditions, ensuring performance stability and longer lifespan in hot or cold environments.

- Standards Compliance: Numbers also indicate international standards like SAE or EN. We guarantee compliance ensures quality, safety, and compatibility with global hydraulic systems, making maintenance and replacement easier.

- Manufacturer Code: Layline numbers may include manufacturer details or batch codes. We use these identifiers to track production quality, simplify reordering, and provide traceability for consistent hose performance.

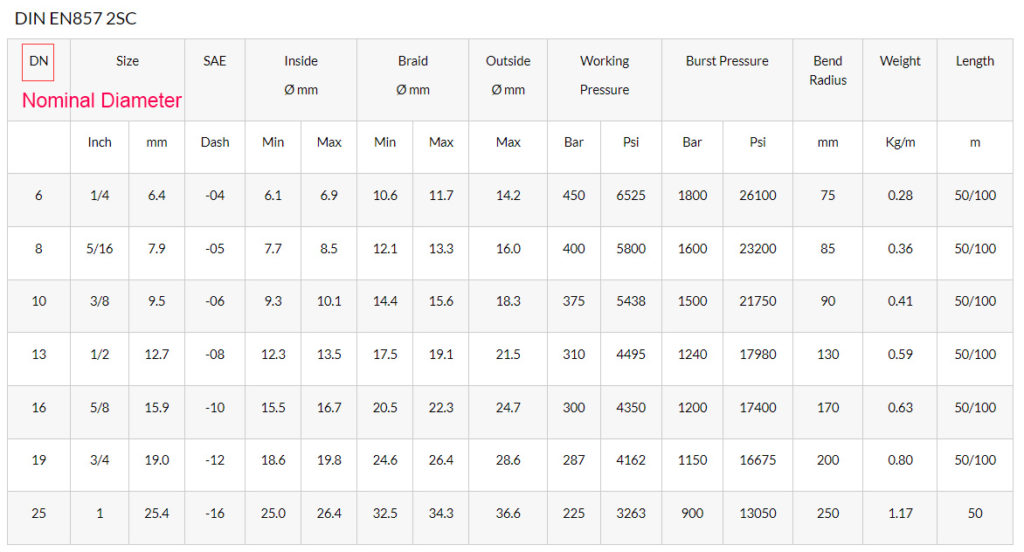

What Is DN in Hydraulic Hose?

Here is the explanation about the hydraulic hose DN meaning: The screenshot is the hydraulic hose specification chart, and you can see DN in the first column.

DN is the hydraulic hose abbreviation of Nominal Diameter. DN, Nominal Diameter is also the outside diameter of the hydraulic hose, measured by millimeters.

DN is the measurement in millimeters of the interior of the hose. This measurement of length comes from the English nomenclature. 1 inch equals 25.40 millimeters, also the inside of the hose as a reference.

You can use the vernier caliper to measure the hydraulic hose to get the hydraulic hose DN size.

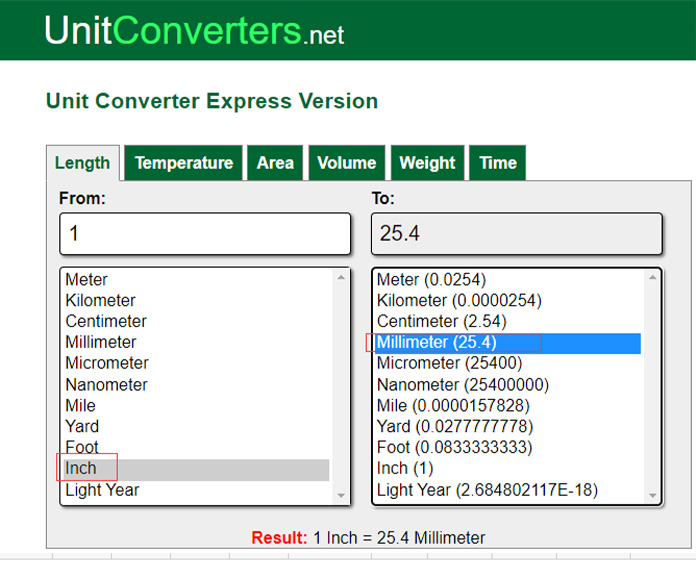

Inch to MM

Inch and mm are units of length, used to measure the hydraulic hose length, and here we can use the unit converter to calculate that: How to convert inches to millimeters. 1 inch is equal to 25.4 millimeters.

So you can read the inch size and mm size of the hydraulic hose listed on the hydraulic hose size chart, and different units are used to satisfy measurement of different countries.

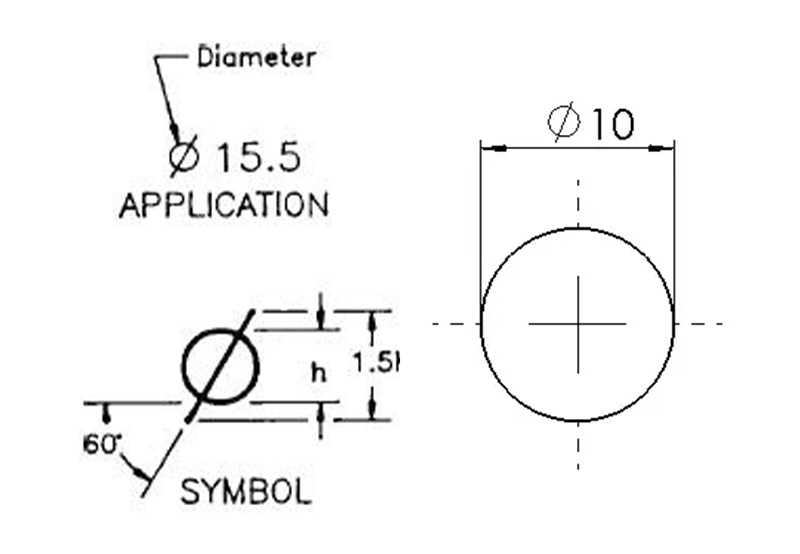

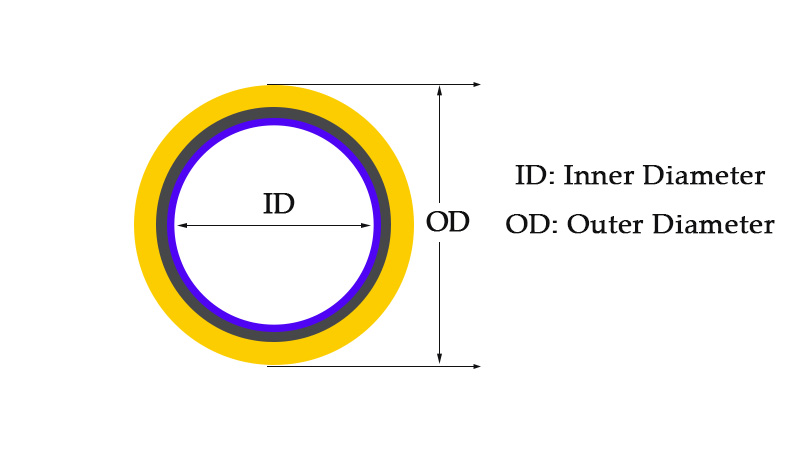

What Does Ø Mean?

Ø is the diameter symbol. And we can use this diameter symbol to Ø to measure the hydraulic hose size.

As the hydraulic hose standard, we use ID, OD to measure the hydraulic hose diameters.

- ID: Inner Diameter (or I.D, I.D.) is the span of the empty space in a circular hose cross-section that affects the flow velocity of the fluid within the hose. A hose with an oversized I.D. will result in sluggish system performance problems, while an undersized I.D. can cause excessive pressure drops, leaks, and system damage. So it’s important to get the accurate ID specification, and they are accurate to one decimal point.

- OD: Outer Diameter (or I.D, I.D.) measures the entire span of the hose cross-section, including the tube, reinforcement, and cover. The difference between the O.D. and I.D. is the thickness of the hose wall. Outer diameter is important for sizing industrial hoses to appropriate fittings and system components.

Hydraulic Hose Marking Systems

Hydraulic hose marking systems are critical for safety, maintenance, and correct replacement of hose assemblies. They provide vital, easily identifiable information directly on the hose’s exterior, ensuring users select the right component for a specific application. Understanding these marks is essential for operational reliability.

- Manufacturer and Type: These markings clearly identify the producer and the specific hose series or family. This information is crucial for checking compatibility and sourcing exact replacements, ensuring the hose’s material and construction meet system requirements for pressure and fluid.

- Pressure Rating and Size: Hoses are marked with their Maximum Operating Pressure (MOP) and nominal inner diameter (ID). Using a hose above its MOP is extremely dangerous and leads to failure. The size is vital for ensuring correct flow rate and minimizing pressure drops.

- Date of Manufacture: The manufacturing date is usually indicated by a four-digit code (e.g., YY/Q or WW/YY) to track the hose’s age. This is important for proactive maintenance programs, as hoses degrade over time, and regular replacement before the specified service life is recommended.

- Industry Standards (SAE, EN, ISO): Marks indicating adherence to standards like SAE, EN, or ISO guarantee the hose meets universally recognized performance and quality criteria. This assures users of the hose’s ability to handle required pressures, temperatures, and fluid compatibility safely across various industrial applications.

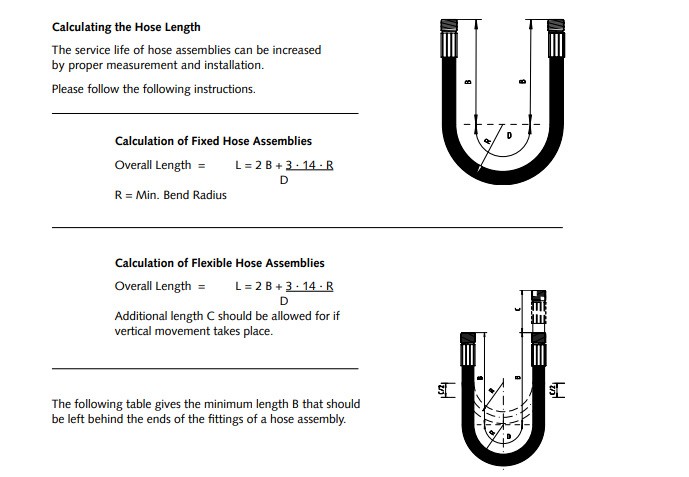

How to Measure Hydraulic Hose Length

Measuring hydraulic hose length is important to ensure correct installation, avoid system stress, and maintain safe performance. Following the proper steps helps prevent leaks, kinks, and premature wear, keeping your hydraulic equipment reliable in demanding applications.

Step 1: Identify Hose Routing

Start by identifying the hose routing path within the hydraulic system. Measure along the exact route where the hose will be installed, including bends and curves. This ensures the hose fits properly, preventing excessive tension, twisting, or slack that could affect system performance.

Step 2: Measure Fitting to Fitting

Measure the length from one hose fitting connection to the other. Always take measurements from the sealing surface of each fitting, not the overall hose ends. This provides accuracy in installation and ensures that the hose connects seamlessly without unnecessary strain.

Step 3: Consider Bend Radius

Account for the hose’s minimum bend radius during measurement. A hose that bends tighter than its rating may kink or fail prematurely. Always measure with bends that respect the hose’s radius to extend service life and maintain smooth hydraulic flow.

Step 4: Allow for Flexibility

Add extra length to the hose to allow for movement and vibration during operation. Hydraulic systems are dynamic, and hoses need slight slack to absorb motion. Measuring with this flexibility helps prevent stretching, fatigue, and damage to fittings or components.

Step 5: Record and Verify

After measuring, record the hose length accurately and verify with system requirements. Double-check against the manufacturer’s recommendations to avoid errors. Proper documentation ensures easy ordering, correct replacement, and consistent system performance with every installation or maintenance operation performed.

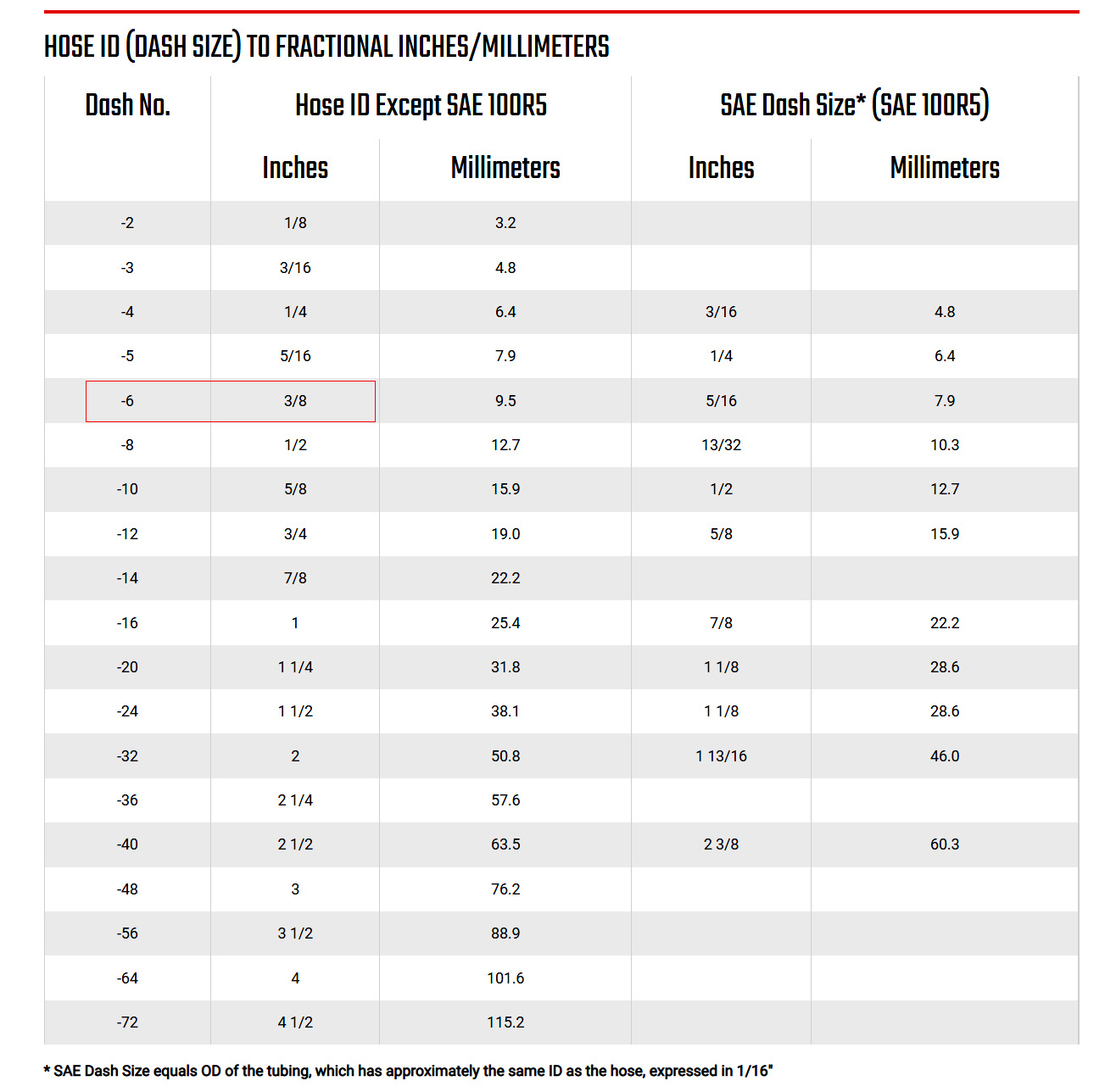

What Is Dash Size?

Dash size is a common term used to identify the inner diameter of hydraulic hoses and fittings. It is expressed in sixteenths of an inch, helping ensure proper compatibility, accurate sizing, and efficient performance in hydraulic systems across different industries and applications.

- Definition: Dash size refers to the hose’s internal diameter measured in sixteenths of an inch. We use this system to simplify sizing, ensuring fittings and hoses connect correctly for safe and efficient hydraulic operations.

- Sizing Example: A -08 dash size indicates an inner diameter of 8/16 inch (½ inch). We provide hoses labeled with clear dash sizes, making it easy to select the right option for hydraulic equipment.

- Compatibility: Dash size ensures hoses and fittings match perfectly. We emphasize proper sizing prevents leaks, reduces installation errors, and maintains system efficiency by ensuring every component fits as intended.

- Industry Standard: Dash size is an internationally recognized sizing method. We follow this system to guarantee our hoses and fittings meet global standards, simplifying selection and ensuring interchangeability across different equipment brands.

- Practical Use: Knowing dash size helps technicians quickly identify or replace hoses. We design products with clear markings, making maintenance and ordering simpler while reducing downtime and operational disruptions.

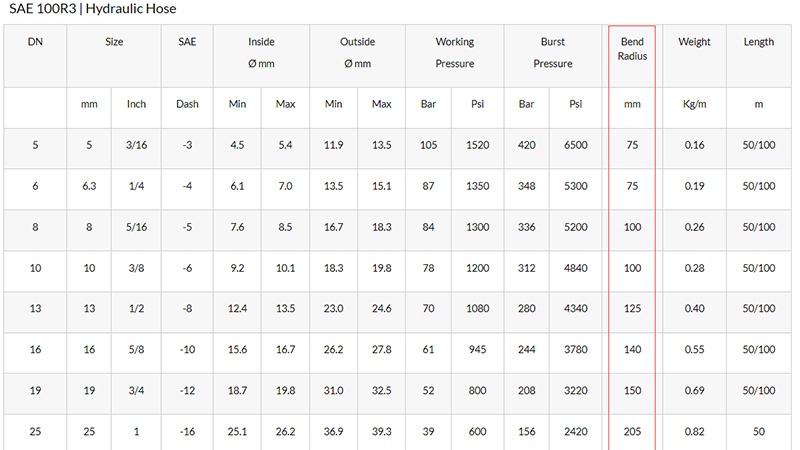

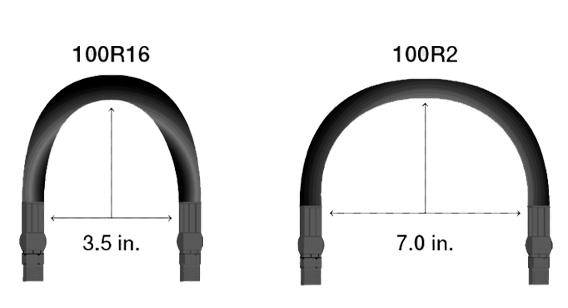

Hydraulic Hose Bend Radius

Hydraulic hose bend radius is the minimum radius a hose can bend without causing damage or reducing performance. Following bend radius guidelines prevents kinks, stress, and early failure, ensuring safe, efficient, and long-lasting hydraulic system operation in demanding industrial, construction, and agricultural environments.

Bend radius is the smallest curve a hose can make without damage. We ensure hoses meet standard bend radius ratings, protecting structural integrity and preventing flow restrictions during operation.

- Importance: Maintaining proper bend radius prevents kinking and bursting. We stress this factor in design and installation, helping extend hose life and maintain consistent hydraulic performance.

- Measurement: Bend radius is measured from the hose’s centerline to the inside curve. We guide customers to measure accurately, ensuring hoses fit installations without exceeding recommended limits.

- Installation: Proper routing respects bend radius to reduce stress. We design hoses for easier installation, helping users achieve safe connections without forcing tight bends that cause premature wear.

- System Efficiency: Correct bend radius maintains smooth fluid flow. We focus on ensuring hydraulic systems operate with minimal restrictions, reducing energy loss and protecting components from unnecessary strain.

Hydraulic Hose Working Pressure vs Burst Pressure

Hydraulic hose working pressure and hydraulic hose burst pressure are also important for you to consider before selecting a hydraulic hose.

Working pressure:

The working pressure means the pressure of the hydraulic hose in the working conditions range, normally called the pressure range. The hydraulic hose working pressure is used to test the normal pressure range during the working process.

Burst pressure:

The burst pressure is the maximum pressure of the hydraulic hose that can be applied to the components without any physical damage. Burst pressure can be defined as the maximum pressure of a hydraulic hose before breaking. When the pressure exceeds the burst pressure, the hydraulic hose will explode.

The pressure test is necessary to ensure the hydraulic hose safety during its service life, and regularly 1/4 working pressure equals to burst pressure.

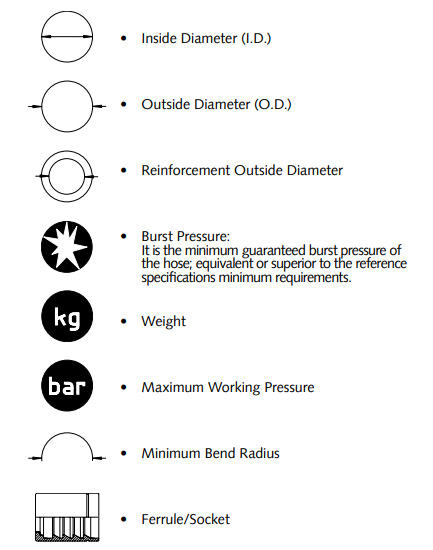

Hydraulic Symbols

Here are some widely used hydraulic hose symbols, and you can get the meaning of these symbols or icons if see them used in the hydraulic hose size chart. And also you can use these to make your hydraulic hose specification pdf.

Conclusion

Understanding what the numbers on hydraulic hoses mean is essential for selecting the right hose for your hydraulic system. These markings serve as quick reference points for specifications like size, pressure capacity, and compliance, which play a vital role in safety and performance.

By learning to read hose numbers correctly, you can prevent mismatched installations, improve efficiency, and extend the service life of your equipment. This practice ensures that your hydraulic systems operate smoothly without unexpected breakdowns or safety risks in demanding working environments.

For businesses needing reliable hose solutions, choosing the right supplier is equally important. At Kingdaflex, we supply wholesale hydraulic hoses designed to meet diverse industry needs. With consistent specifications, durable construction, and wide application compatibility, our hoses provide dependable performance, making us your trusted partner in hydraulic systems worldwide.