Hydraulic hose leaks are a common issue in industrial and mobile equipment, affecting system efficiency and safety. Leaks can lead to fluid loss, pressure drops, and potential damage to connected components. Understanding the causes of hydraulic hose leaks is essential to prevent failures and maintain smooth system operation.

Identifying and addressing leaks promptly reduces downtime and maintenance costs. Proper installation, regular inspections, and choosing the right hose type are key to preventing issues. By learning effective troubleshooting and repair techniques, operators can ensure reliable performance, extend hose life, and maintain a safe working environment.

Why Hydraulic Hose Leaks

Hydraulic hose leaks can disrupt system performance, reduce efficiency, and create safety hazards. Understanding the common causes of leaks helps prevent failures and ensures reliable operation. By identifying and addressing these issues, operators can maintain hydraulic systems effectively and avoid costly repairs or downtime.

- Wear and Abrasion: Constant rubbing against surfaces or exposure to rough environments wears down the hose outer cover. Over time, this creates weak points that can develop leaks, compromising fluid containment and reducing overall hydraulic system performance.

- Excessive Pressure: Operating hoses beyond their rated pressure causes stress on hose walls. Repeated exposure to high pressure may lead to bursts or small leaks, risking system damage and unsafe working conditions. Proper pressure management is critical for hose longevity.

- Improper Installation: Twisting, bending beyond minimum radius, or poorly routed hoses can weaken hose structure. Incorrect installation increases the likelihood of leaks, kinks, or premature hose failure, impacting system efficiency and requiring costly maintenance interventions.

- Aging and Material Fatigue: Over time, hoses naturally degrade due to pressure cycles, heat, and environmental exposure. Material fatigue reduces elasticity, making hoses more susceptible to cracks, leaks, and ruptures, necessitating timely inspection and replacement.

- Fitting or Connection Issues: Loose or incompatible fittings, damaged seals, or improper attachment can cause fluid to escape. Ensuring proper fittings and secure connections is vital to maintain leak-free operation and prevent hydraulic system failures.

Rubber Material Matters Most

The hydraulic hose is made of synthetic rubber material, and the quality of the rubber material can determine the quality of the hydraulic hose.

The top-rated rubber material can determine the hydraulic hose quality and class from the root, and we only use the very high-quality rubber material to make a hydraulic hose. The rubber material is durable, with high strength, also flexible.

Choosing the good rubber material is also a big task, here top-rated rubber selection needs to consider many factors, including hardness, tensile strength, conductivity, environment resistance, such as oil resistance, acid resistance, weather resistance and etc.

And we are professional to choose the right rubber type according to the hydraulic hose performance we aim to achieve. For example, NBR material has excellent oil resistance, so NBR is ideal for making hydraulic hoses to convey oil-based hydraulic fluids.

Rubber Milling

During the hydraulic hose manufacturing process, the compounding rubber process is the first step, we need to mix the rubber material and make it suitable to make a hydraulic hose. Our hydraulic hose manufacturer will use the rubber refining miller to mix the raw material and other compounding materials to get the mixture material for making the hydraulic hose in the following manufacturing process.

The rubber milling process is also important, which can enhance the crude rubber material to the next level. There should not exist any tiny air bubbles in the rubber properties. Synthetic rubber sheets with high density can make finished hydraulic hoses much more durable, close-knit to avoid hydraulic hose leak during its service life.

Refined rubber is perfect to make the inner tube of the hydraulic hose, and then the rubber should be vulcanized to get a stable physical structure for good hydraulic hose performance.

The rubber milling machine, also called rubber miller is also an important to factor, which can ensure the quality of the milling process.

These factors, the skilled hydraulic hose technicist is also playing an important role in the hydraulic hose quality, and our hydraulic hose factory owns over 200 experienced workers to control the quality of each step of the hydraulic hose manufacturing process.

Hydraulic Hose Leaking Reasons

Hydraulic hoses leak due to wear and abrasion, excessive pressure, improper installation, aging and material fatigue, or issues with fittings and connections. Identifying these causes helps prevent failures, maintain system efficiency, and ensure safe hydraulic operation.

Improper Hydraulic Hose Crimping

The hydraulic hose crimping also matters to the hydraulic hose. It’s necessary to crimp the hydraulic hose before hydraulic hose assembly, to connect the hydraulic hose fittings to hydraulic hose heads, locking them together firmly, and then install the hydraulic hoses to the hydraulic system, for the heavy-duty machinery, which is powered by the hydraulic fluids.

It is important to choose the right hydraulic hose crimper dies, with a suitable crimp diameter, to avoid the hydraulic hose fitting getting loose, resulting in hydraulic hose leaks. Leak-free hydraulic hose fittings can prevent vibration hydraulic hose failure during service life.

And you need to check if the shell compressed correctly to bite on the hydraulic hose firmly, and the hydraulic hose fitting can’t be too tight or too loose. Too tight a hydraulic hose fitting will break the hydraulic hose cover, to make it damaged to cause hydraulic fluid to permeate; too loose a hydraulic hose fitting will cause a hydraulic hose leak at the fitting.

Wrong Working Pressure

You need to take the STAMPED principle into your consideration, for your hydraulic hose selection.

P is the abbreviation of Pressure so you need to check out the working pressure at the very beginning, and you can find the parameters about working pressure and burst pressure of a hydraulic hose.

Hose Catalogue from Kingdaflex This is our hydraulic hose catalog PDF, and you can find the working pressure range for hydraulic hose applications of each hydraulic hose you want to order for your hydraulic system.

The hydraulic hose with the wrong working pressure could leak due to very high pressure in the working conditions, and please be clear about your actual working pressure and then select the right hydraulic hose. If any questions about hydraulic hose selection, please don’t hesitate to contact us to get some suggestions.

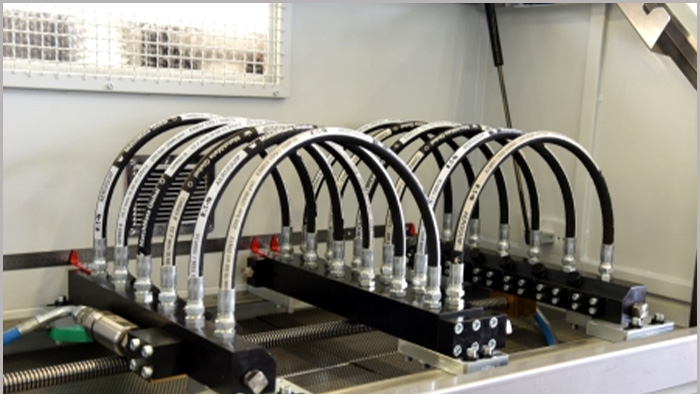

Failed Hydraulic Hose Impulse Testing

The hydraulic hose impulse testing is an important hydraulic hose test, used to predict the lifespan of the hydraulic hose, and other wear hydraulic hose accessories in the hydraulic system.

The hydraulic hose impulse testing has been 3 days, experiencing the repeated impulse curves again and again, up to 40,000 times. The pressure impulse test consists of flow pressurized hydraulic fluids through the hydraulic hose inside.

The impulse testing equipment can stretch and curve the hydraulic hose samples to test the quality. If the hydraulic hose doesn’t pass the impulse testing, that means this hydraulic hose is unqualified.

The imperfect hydraulic hose has the potential harm to leak while conveying hydraulic fluids, so we have to do the hydraulic hose impulse test before loading the finished hydraulic hoses to the shipping container.

How to Fix a Hydraulic Hose Leak?

Hydraulic hose leaks can disrupt system performance, cause fluid loss, and create safety hazards. Repairing leaks promptly ensures smooth operation, prevents equipment damage, and reduces downtime. By following proper safety precautions and step-by-step repair procedures, you can restore hydraulic hoses effectively while maintaining system reliability and long-term performance.

Step 1: Ensure safety

Before starting any repair, turn off the hydraulic system and release all pressure. This precaution prevents accidents, protects personnel from high-pressure fluid sprays, and ensures a safe working environment while performing maintenance on the hydraulic hoses.

Always wear protective gear, including gloves and safety goggles. Confirm that nearby equipment is de-energized and that hydraulic lines are fully depressurized. Taking these precautions reduces the risk of injury and ensures the repair process proceeds smoothly and safely.

Step 2: Locate the leak point

Inspect the hose thoroughly to identify where fluid is escaping. Look for oil drips, wet spots, or spray patterns along the hose, which indicate the exact location of the leak needing repair.

Check the hose along its entire length, including connections and bends. Pay attention to any bulges, cracks, or abrasions that may cause leaks. Accurately locating the leak ensures the repair addresses the correct section without unnecessary replacements.

Step 3: Relieve pressure

Release any residual pressure in the system using the pressure relief valve or manufacturer-recommended method. Ensuring the system is depressurized prevents fluid from spraying during hose removal.

Double-check that all hydraulic lines are depressurized before touching the hose. This step is critical to avoid sudden fluid ejection, which can cause injury and damage to surrounding equipment.

Step 4: Remove damaged section

Disconnect the affected hose section from fittings using a wrench or pliers. Inspect the removed hose for additional damage, wear, or weaknesses that might require attention.

Carefully loosen fittings without twisting the hose excessively. Removing the damaged section safely ensures no further damage occurs and prepares the system for accurate replacement with minimal risk of leaks.

Step 5: Cut out the damaged area

Use a hose cutter or sharp knife to remove punctured or torn sections. Make a clean, straight cut to ensure proper fitting attachment and reliable sealing.

Avoid jagged edges or angled cuts, which can compromise the new hose installation. A precise cut ensures a secure fit for the replacement hose and maintains system integrity under pressure.

Step 6: Select a replacement hose

Measure the removed section and choose a hose with the same type, size, and pressure rating. Ensure compatibility with the hydraulic fluid used in the system.

Using the correct hose prevents premature wear or failure. Selecting an appropriate replacement ensures consistent hydraulic flow, safe operation, and long-lasting performance in demanding applications.

Step 7: Attach fittings

Slide the correct fittings onto both ends of the new hose. Secure them using hose clamps or crimping tools according to manufacturer guidelines.

Ensure fittings are seated fully and properly aligned. Correct attachment prevents leaks, maintains pressure integrity, and guarantees that the hydraulic system will function reliably after the repair.

Step 8: Install the new hose

Connect one end of the hose to the system fitting and the other end to its corresponding connection. Confirm tight, secure, and leak-free connections before pressurizing.

Check that the hose is routed correctly, avoiding sharp bends or contact with abrasive surfaces. Proper installation ensures safe operation and minimizes the risk of future leaks or kinks.

Step 9: Test for leaks

Restore power to the system and pressurize it. Observe the repaired hose carefully for any signs of leakage to confirm the repair was successful.

Monitor connections, bends, and previously damaged areas for fluid escape. A thorough inspection ensures the hydraulic system is operating safely, efficiently, and leak-free, preventing future downtime or hazards.

Related:

- How to Replace Sandblast Hose: A Comprehensive Guide

- How to Repair A Hydraulic Hose? [5 Steps to Fix Hydraulic Hose]

Conclusion

Preventing hydraulic hose leaks requires attention to detail, proper handling, and regular maintenance. By monitoring hose condition, following installation guidelines, and addressing minor issues promptly, you can significantly reduce the risk of leaks and improve system reliability. Proactive care protects both equipment and personnel.

Choosing the right hose for specific applications is crucial. Using hoses rated for the correct pressure, temperature, and environment ensures consistent performance and minimizes failures. Regular inspections and timely replacements also help maintain optimal hydraulic system efficiency and safety, reducing costly repairs.

For businesses seeking reliable solutions, get wholesale hydraulic hoses from Kingdaflex. Our hoses are designed for durability, consistent performance, and wide-ranging applications. Partnering with Kingdaflex helps ensure smooth, efficient, and safe hydraulic operations, keeping your systems running reliably while minimizing downtime and maintenance challenges.