The hydraulic hose plays an important role in the construction field, and today I am happy to share with you the hydraulic hose manufacturing process here, how to manufacture hydraulic hose step by step in our hydraulic hose manufacturer.

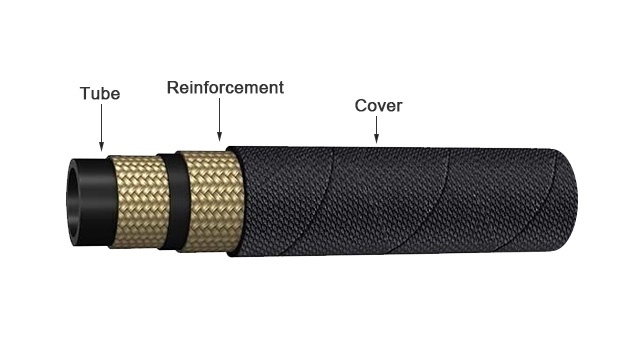

How is a hydraulic hose manufactured? You got to know the hydraulic hose structure and a hydraulic hose pipe has three parts, including an inner tube, reinforcement, and outer cover.

We can manufacture the hydraulic hose following its structure, to create a hydraulic hose inner tube, and then reinforcement, and finally outer cover.

So now drive into the part of the hydraulic hose fabrication, to get full about making hydraulic hose, step by step.

Here are go!

Step 1: Prepare Raw Materials (Synthetic Rubber and Stainless Steel Wire)

At the very beginning of the hydraulic hose manufacturing process, we need to prepare all of the raw materials ahead of time, and here is the synthetic rubber material and stainless steel wire.

You guys can click here to know what hydraulic hose is made of. We will prepare enough raw material rubber in our hydraulic hose manufacturer workshop.

Here is a video showing the rubber compounding process to prepare for manufacturing hydraulic hoses.

Synthetic rubber material

You can see the rubber pieces lying here, get ready to manufacture the inner tube of the hydraulic hose. We use the Banbury rubber mixing machine to mix the rubber material, to make the rubber become the raw material for making the hydraulic inner tube.

Stainless steel wire

At the same time, we also need to prepare the stainless steel wire to get ready for manufacturing the reinforcement of the hydraulic hose.

Here is the stainless steel wire as the raw material to manufacture the reinforcement layer for hydraulic hoses. We source the very long stainless steel wire, up to 50k meters in a roll, to prepare the next step.

And then we need to twist some stainless steel wire together to combine a thick stainless steel wire. The reinforcement of the hydraulic hose is designed to add much more strength to the whole hydraulic hose pipe, to work well under high pressure.

The more stainless steel wire can make the hydraulic hose much stronger. Regularly, our manufacturer can combine 7-8 stainless steel wires into one, of course, we can twist the stainless steel wire according to your requirements. Then we will roll the combined stainless steel to the stainless steel cylinder tube.

Step 2: Extrude the Synthetic Rubber to Create an Inner Tube

Now is the time to manufacture the inner tube of the hydraulic hose. We use the rubber extruder machine to extrude the rubber material to create the inner tube.

Here is a steel rod in the rubber extruder machine, to squeeze out the empty rubber tube. And the diameter of the steel rod equals the inner diameter (I.D) of the finished hydraulic hose.

We will get the inner tube of the hydraulic hose after extruding process, and the inner tube has a smooth surface, looking shining.

Rubber extrusion is a manufacturing process used to create rubber hydraulic hoses in continuous lengths. It involves forcing a rubber compound through a die of a specific shape under high pressure.

Hydraulic hoses are a common product made through rubber extrusion. They are essential components in various industries, from construction and agriculture to manufacturing and mining.

PP Stick Is Used for Hydraulic Hose Inner Tube Extrusion

A PP stick, also known as a soft core or mandrel, is a crucial component in the manufacturing of hydraulic hoses. It’s a long, slender rod made of polypropylene plastic that serves as a temporary core during the extrusion process.

Here’s how a PP stick is used in hydraulic hose extrusion:

- Shape Retention: The PP stick provides a stable, cylindrical form around which the rubber or thermoplastic hose material is extruded. This ensures the hose maintains its desired diameter and shape throughout the manufacturing process.

- Smooth Inner Surface: The smooth surface of the PP stick transfers to the inner surface of the hose, resulting in a smooth bore. This minimizes friction and improves fluid flow within the hose.

- Easy Extraction: After the hose is cured, the flexible PP stick can be easily removed, often through mechanical or hydraulic means. This minimizes the risk of damaging the hose during the extraction process.

By using PP sticks as mandrels, hydraulic hose manufacturers can produce high-quality hydraulic hoses with consistent dimensions, smooth inner surfaces, and optimal performance.

Step 3: Manufacture Hydraulic Hose Reinforcement Layer

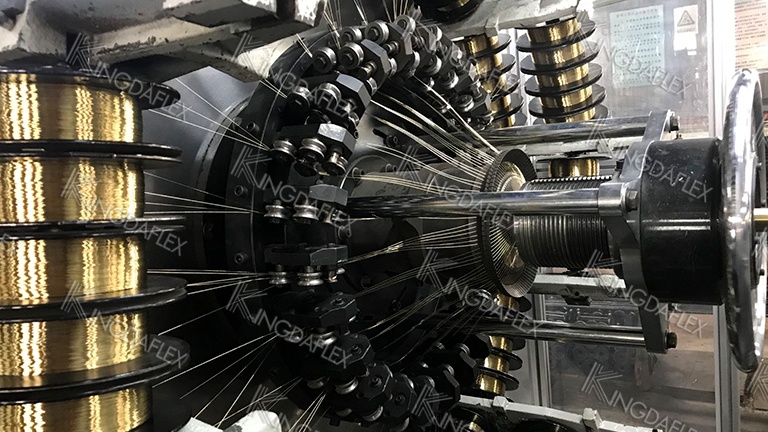

Now we prepare the stainless steel wire to create the reinforcement layer of the hydraulic hose. Here are 2 different methods to manufacture the stainless steel reinforcement, so here are 2 types of hydraulic hose we can manufacture in this step, braided hydraulic hose and spiral hydraulic hose.

Braided hydraulic hose

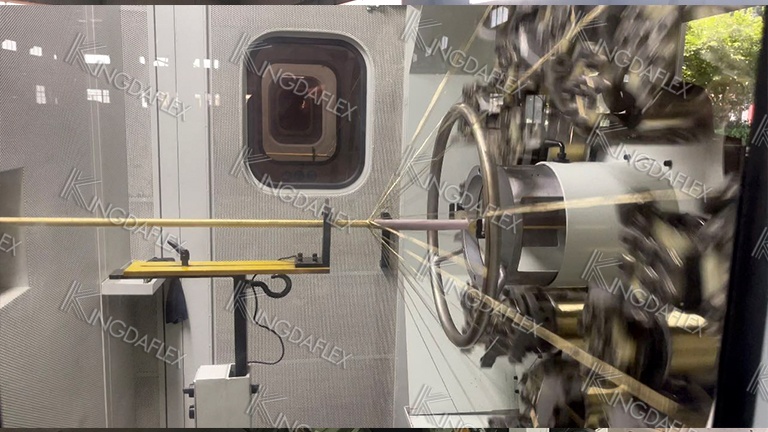

We use the hydraulic hose braiding machine to create the braided reinforcement, to get the braided hydraulic hose.

Braided hydraulic hose is a common type of reinforced flexible tubing used in hydraulic systems to transport fluid under high pressure. Unlike spiral wound hoses, which use a parallel helical arrangement of wires, braided hoses feature one or more layers of high-tensile steel wire or synthetic fibers woven in a crisscross pattern around the inner tube. This braided reinforcement provides exceptional tensile strength and flexibility, allowing the hose to withstand high pressures and a tighter bend radius without kinking or bursting. This makes it a popular choice for a wide range of applications.

Key advantages include:

- Flexibility: The braided design allows for a tighter bend radius, making them ideal for installations in confined spaces or on equipment that requires frequent movement.

- Durability: The woven reinforcement provides excellent resistance to abrasion, pressure impulses, and physical damage, extending the hose’s service life.

- High-Pressure Resistance: While not as rigid as spiral hoses, braided hoses are capable of handling medium to high-pressure applications, typically up to several thousand PSI.

- Versatility: They are used in various industries, including construction, agriculture, manufacturing, and automotive, for systems like hydraulic lifts, power steering, and other fluid transfer applications.

Here is the video showing you how the braided hydraulic hose is manufactured by the hydraulic hose braiding machine.

And then we will get the semi-finished hydraulic hose with braided reinforcement.

The braided hydraulic hose reinforcement looks like the gold hair braids.

Spiral Hydraulic Hose

The machine used to manufacture the spiral hydraulic hose is different, and this is the 4-wire spiraling machine for braiding hydraulic hose.

Spiral hydraulic hoses are engineered for extremely high-pressure and high-impulse applications, setting them apart from their braided counterparts. Instead of a crisscrossing weave, their reinforcement layer consists of multiple wraps of high-tensile steel wire wound helically on top of each other.

This construction provides exceptional strength and resistance to pressure spikes, making them the ideal choice for heavy-duty machinery. While they are less flexible and have a larger minimum bend radius than braided hoses, their durability in the face of constant pressure fluctuations is unmatched.

Key characteristics and applications include:

- High-Pressure Capability: The spiral wire reinforcement allows them to handle much higher working pressures, often exceeding 5000 PSI.

- Impulse Resistance: Designed to withstand rapid and frequent pressure surges, making them perfect for equipment like excavators, mining machinery, and off-highway vehicles.

- Rigid and Durable: The layered spiral design provides superior structural integrity and a high resistance to abrasion, ensuring a longer service life in rugged environments.

- Common Applications: Widely used in industries such as construction, mining, forestry, and heavy-duty industrial equipment where extreme pressure and demanding conditions are the norm.

- Reinforcement Layers: Typically feature four or six layers of spiral wire, designated as 4SH or 6SP in industry standards, indicating their high-performance capabilities.

And you guys can see the difference between braided vs spiral hydraulic hoses. and how spiral hydraulic hose is manufactured in this short video.

This is the manufacturing process to make the spiral hydraulic hose in the workshop.

Then we get the finished spiral hydraulic hose reinforcement.

You guys can see the comparison of braided hydraulic hose and spiral hydraulic hose.

Step 4: Extrude Outer Rubber Cover

And then we need to extrude the rubber to create the outer cover to parcel the reinforcement layer, and this is the third layer of the hydraulic hose, also the last layer.

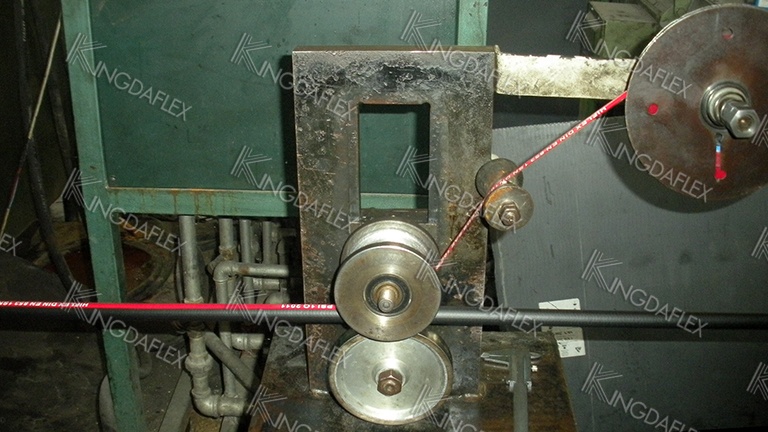

Step 5: Print Hydraulic Hose Private Label

In this step, we can customize your private label or your hose company logo on the surface of the outer cover of the hydraulic hose. All of the hydraulic hose specifications and your brand name will be printed on the surface of the hydraulic hose layline.

At Kingdaflex, we offer private label printing for our hydraulic hoses, allowing you to brand products with your own company name and logo. This service helps build brand recognition and gives your business a professional edge in the market. We ensure the printed labels are durable and resistant to wear and tear.

You can read the basic parameter information from the finished hydraulic hose, and we can print anything you want, such as private label, company logo, hydraulic hose specifications and etc. And at the moment, the hydraulic hose is manufactured with a smooth surface, without any texture.

Step 6: Create Surface Texture

Next, we can create the texture to make the hydraulic hose cover surface look special, and we use the press cloth to create your desired texture on the hydraulic hose surface, by adding much pressure to the hydraulic hose surface. The rubber material is soft, so the press cloth will leave the designed texture on the surface.

Step 7: Vulcanize Hydraulic Hose

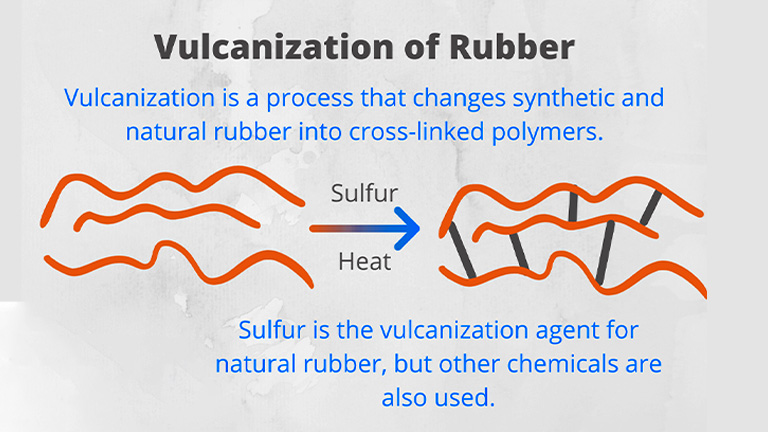

Then we need to vulcanize the hydraulic hose in the vulcanizing boiler equipment, and the press cloth is really important to protect the hydraulic hose during the vulcanizing process. The rich steam heating will mature the rubber material, making rubber molecules become closer, to give the hydraulic hose stable performance.

Of course, vulcanized rubber is much more stable than natural rubber. The vulcanizing process is also necessary for producing hydraulic hose with high quality.

The vulcanization for hydraulic hose production is the process that changes the synthetic and natural rubber into cross-linked polymers. Sulfur is the vulcanization agent for natural rubber (other chemicals are also used if needed). Vulcanizing hydraulic hoses using sulfur with heat and high temperature can make the hydraulic hose’s physical structure much more durable and stable.

Here, we can make a smooth and wrapped hydraulic hose during this vulcanizing process, using different materials for rubber vulcanization.

Smooth hydraulic hose: Wrap the plastic-coated material before the vulcanizing process, and get the smooth surface of the hydraulic hose.

Wrapped hydraulic hose: Use the water press to wrap the hydraulic hose, to get the special cloth marks overlapping the water cloth after the vulcanizing process, and then remove the water press. the cloth mark will be imprinted on the surface of the hydraulic hose permanently.

If you want to know the differences between the smooth vs wrapped hydraulic hose, please feel free to contact us to get free samples.

And remove the press cloth after the steaming process in the vulcanizing boiler.

We finally get the hydraulic hose printed with specifications after removing the press cloth.

Step 8: Hydraulic Hose Pressure Test

A hydraulic hose pressure test is a critical procedure that verifies the integrity and safety of a hose assembly by subjecting it to a controlled pressure level. This process is essential for ensuring that hoses can withstand the high-pressure demands of their applications without leaking, bulging, or bursting. It helps identify manufacturing defects, improper crimping, and material fatigue before the hose is put into service, thereby preventing costly failures and potential injuries.

The two main types of tests are proof testing, which uses a pressure higher than the working pressure to confirm integrity, and burst testing, which pushes the hose to its failure point to determine its ultimate pressure rating.

- Proof Pressure Testing: A non-destructive test that applies a pressure typically 1.5 to 2 times the hose’s maximum working pressure for a short period to confirm its structural integrity and safety.

- Burst Pressure Testing: A destructive test that increases pressure until the hose ruptures, providing the ultimate pressure limit and helping manufacturers ensure their products meet safety standards.

- Hydrostatic Testing: A common method that uses a non-compressible fluid, such as water or oil, to pressurize the hose, as it’s a safer alternative to using compressed air or gas which could become a projectile if the hose fails.

Step 9: Pack Hydraulic Hose

Proper packing of hydraulic hoses is essential for preventing damage during transport and storage, ensuring they arrive in optimal condition. The method used depends on the size, length, and quantity of the hoses. Coiling is the most common technique for smaller to medium-sized hoses, which are then secured with durable straps or ties to prevent uncoiling and kinking. For larger or more rigid hoses, wooden reels or straight packaging in sturdy boxes may be required to maintain their shape and integrity.

Additionally, protecting the delicate hose fittings is critical; they should be capped or wrapped with protective padding like bubble wrap to prevent impact damage.

- Avoid Over-Bending: Hydraulic hoses should never be bent beyond their minimum bend radius during packing, as this can cause permanent damage to the reinforcement layers.

- Coiling and Securing: Hoses are coiled neatly and secured with woven belts, plastic film, or strong ties to prevent them from becoming tangled or kinked.

- Protective End Caps: Fittings are often covered with plastic caps to shield them from dirt, moisture, and physical damage during transit.

- Pallets and Wooden Boxes: For large quantities or heavy-duty hoses, they are often placed on wooden pallets or in crates, which provides stability and protection for safe transport.

- Proper Labeling: Each package is clearly labeled with product details, including hose type, size, length, and handling instructions, to ensure accurate and efficient delivery.

We use the woven bag to pack the hydraulic hose. The packing material is different though, plastic film and the woven bag are the most popular to pack the hydraulic hose, and the packing material is strong enough to store the hydraulic hose inside well. And the packed hydraulic hose rolls are also much easier to stack well in the hydraulic hose warehouse before loading time.

What’s more, we can print your logo or something you want on the surface of the hydraulic hose packing material, including your hydraulic hose brand name, hydraulic hose model number and etc. The printed text is helpful for you to know what hydraulic hose is inside the packing film.

Hydraulic Hose Manufacturing Equipment

The production of hydraulic hoses involves a complex process that requires specialized equipment. Here are the primary types of equipment used in hydraulic hose manufacturing:

Core Wire Extrusion Machine

- Purpose: Extrudes the inner core wire, which provides structural support to the hose.

- Process: Melts and extrudes the wire material, typically steel or synthetic fiber, onto a mandrel.

Rubber Extrusion Machine / Hydraulic Hose Extruder

- Purpose: Extrudes the rubber layers that form the hose’s inner and outer layers.

- Process: Melts and extrudes rubber compounds onto the core wire, creating a tube-like shape.

Hydraulic Hose Braiding Machine

- Purpose: Applies a braided layer of wire or textile fibers over the rubber layers for additional strength and reinforcement.

- Process: Winds wire or textile fibers around the rubber tube, creating a braided layer.

Covering Machine

- Purpose: Applies an outer layer of rubber or other material to protect the hose from abrasion, weather, and other environmental factors.

- Process: Extrudes a layer of material over the braided layer, forming the final outer layer of the hose.

Hydraulic Hose Crimping Machine

- Purpose: Attaches fittings to the ends of the hose, ensuring a secure and leak-proof connection.

- Process: Applies pressure to the fitting and hose, crimping them together.

Hydraulic Hose Cutting Machine

- Purpose: Cuts the hose to the desired length.

- Process: Uses a specialized cutting tool to accurately cut the hose.

Hydraulic Hose Testing Equipment

- Purpose: Ensures the quality and performance of the hoses.

- Process: Conducts tests such as pressure testing, burst testing, and flex testing.

Additional Equipment:

- Mixing Machines: Mix rubber compounds and other materials.

- Calendering Machines: Flatten rubber sheets for specific applications.

- Curing Presses: Vulcanize rubber components to improve their properties.

- Inspection Equipment: Visual inspection, dimensional checks, and other quality control measures.

The specific equipment and processes used can vary depending on the type of hose being manufactured and the manufacturer‘s production methods. However, these are the core components of a typical hydraulic hose manufacturing facility.

Here is a video showing you how to pack the hydraulic hose using the manual hydraulic hose packing machine.

Keep Hydraulic Hose in Warehouse

Proper hydraulic hose storage is crucial for maintaining the quality and extending the lifespan of hydraulic hoses in a warehouse. Environmental factors like temperature, light, and humidity can significantly degrade the hose material over time, leading to premature failure. Following best practices ensures hoses remain in optimal condition until they are put into service, preventing costly damage and ensuring safety.

- Controlled Environment: Store hoses in a cool, dark, and dry area with temperatures between -15°C and 40°C. Protect them from direct sunlight, UV light, and high humidity, which can cause the rubber to crack or become brittle.

- Proper Positioning: Hoses should be stored in a relaxed state, free from kinks, twists, or sharp bends. Use racks or reels to hang them, or coil them loosely on shelves to prevent physical stress and deformation. Never stack heavy items on top of hoses.

- Protection from Contaminants: Keep hoses away from chemicals, solvents, and other corrosive materials. Ensure the ends of the hoses are sealed with protective caps to prevent dust, dirt, or moisture from entering and contaminating the internal fluid lines.

- First-In, First-Out (FIFO): Implement an inventory system where older hoses are used before newer ones. This ensures hoses are used within their recommended shelf life, typically around 5-7 years, and prevents them from aging in storage.

Ship Hydraulic Hose

We will use the forklift with wooden pallets to send the packed hydraulic hose to the container, and the wooden pallets can protect the hydraulic hose away from damage.

Conclusion

In conclusion, the manufacturing of hydraulic hoses is a precise and multi-step process that combines material science, engineering, and quality control. From the initial extrusion of the inner tube to the final vulcanization and testing, each stage is critical for producing a product that can withstand the extreme pressures and demanding conditions of modern machinery.

The quality of a hydraulic hose directly impacts the performance and safety of the equipment it’s used on. A well-manufactured hose prevents costly downtime and, most importantly, protects against catastrophic failures. Understanding the intricate steps involved helps you appreciate what distinguishes a high-quality hydraulic hose from a subpar one.

For businesses seeking reliable and high-performance hydraulic hoses, choosing a trusted manufacturer is key. At Kingdaflex, we specialize in producing durable and safe hydraulic hoses that adhere to the highest standards. To equip your operations with the best, get wholesale hydraulic hoses directly from us.

Related: