To ensure the quality of each hydraulic hose, all hydraulic hoses must be tested strictly to satisfy the hydraulic hose testing standards.

The hydraulic hose quality is defined and evaluated by SAE standards, EN standards, and ISO standards. These hydraulic hose testing standards are most widely used all over the world.

These hydraulic hose testing standards are basically important to scale the hydraulic hose quality satisfaction after the hydraulic hose manufacturing process.

How Often Should Hydraulic Hose Be Tested?

Our hydraulic hoses are applied for heavy-duty machinery, it is the first important thing to use the hydraulic hose with safety.

So the hydraulic hose annual test is the must-have action to help you find out the potential problems in time. The hydraulic hose damage failure can cause serious problems in running the heavy-duty machine.

We do recommend that you can test hydraulic hoses once a year at least, even once a quarter. And you need to check the hydraulic hoses regularly if you store them in the hydraulic hose warehouse for a very long time.

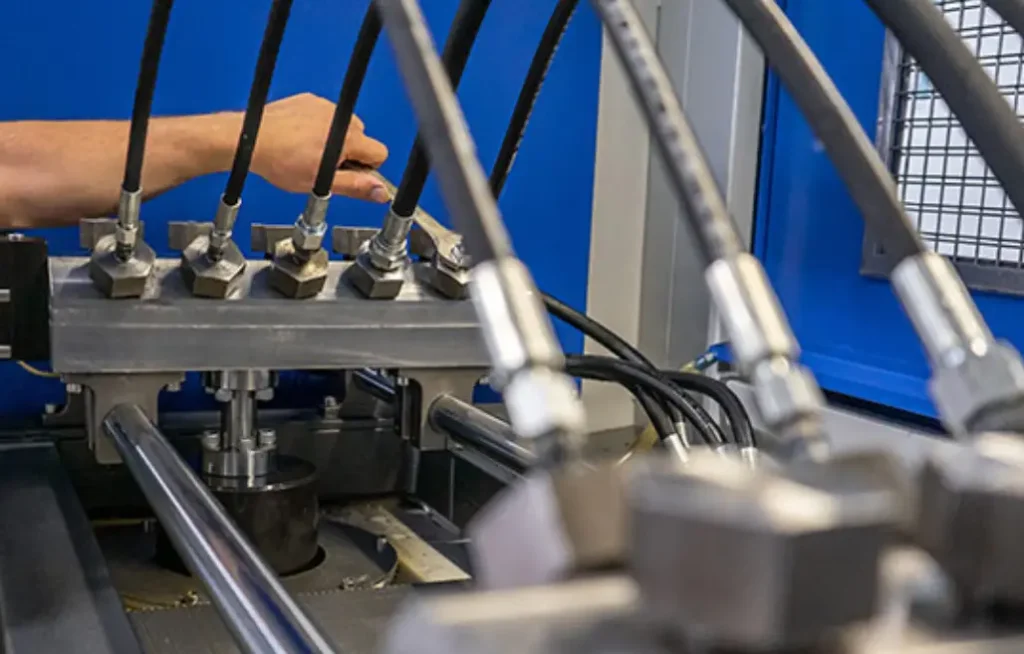

Here are many places of the hydraulic hose you need to test, including hydraulic hose fittings, hydraulic hose heads and hydraulic hose ends, especially the places near the hydraulic line of the hydraulic system.

If you find something abnormal, such as hydraulic hose leaking, or hydraulic fluid exudation, please fix the hydraulic hose or replace it at once.

It is necessary for you to prepare the easy-use hydraulic hose tester at home, or in your hydraulic hose warehouse to test hydraulic hose in your daily life. And you can go to the hydraulic hose shop to test the hydraulic hose using the expert hydraulic hose testing equipment.

In a word, annual testing for hydraulic hoses is important, please keep it in your mind all the time.

Hydraulic Hose Impulse Testing

The hydraulic hose impulse testing is basically important to test hydraulic hose abrasion. The impulse testing for the hydraulic hose is one of the most key testing projects to predict the hydraulic hose service life.

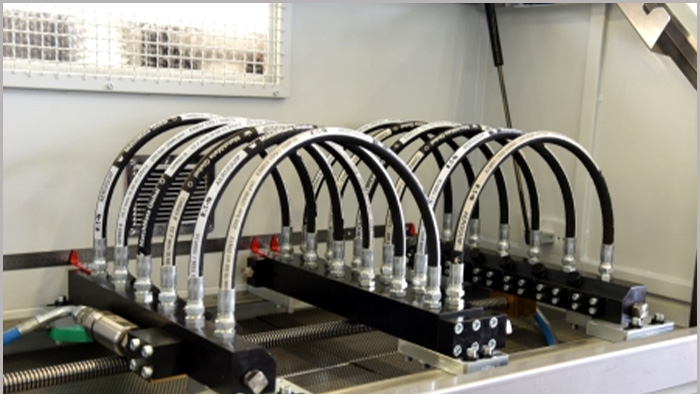

The impulse testing for hydraulic hoses can involve the pressurizing or cycling of hydraulic hose pressure, regularly times up to 200% of working pressure. Each finished hydraulic hose will be stuck to the hydraulic hose impulse tester machine with a certain bend radius, 90° or 180°, and keep this position for almost 3 days without stopping.

The hydraulic hose impulse testing is strict and serious to predict the shelf life of the hydraulic hose before you buy them to your place. The hydraulic hose impulse testing must meet or exceed the minimum number of impulse cycles, to ensure that the hydraulic hose can be used for the industry field.

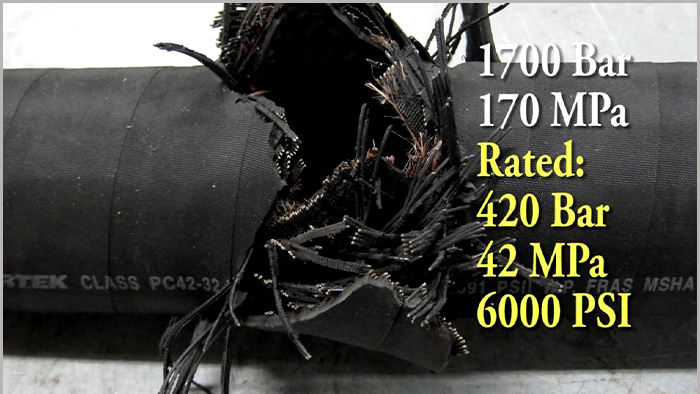

You can read the working pressure and burst pressure printed on the hydraulic hose layline, and get to know that the bursting pressure is much higher than the working pressure.

Our hydraulic hose impulse cycles are up to 200,000 times, to mimic that the hydraulic hose is used in the worst working condition. So that you can use the hydraulic hose with safely and protection, without any potential problems such as hydraulic hose abrasion, hydraulic hose leaking, etc.

Hydraulic Hose Pressure Testing

Hydraulic hose pressure testing is a critical procedure used to evaluate the structural integrity and performance of hydraulic hoses under simulated operating conditions. This process involves subjecting hoses to controlled pressure levels, often exceeding their rated working pressure, to identify potential weaknesses, leaks, or failures. The primary objective is to ensure that hoses can safely and reliably handle the pressures they will encounter in the field of hydraulic systems.

The importance of pressure testing cannot be overstated, as it directly impacts the safety and efficiency of hydraulic operations. By rigorously testing hoses, hydraulic hose manufacturers and users can verify that they meet industry standards and manufacturer specifications. This proactive approach helps prevent catastrophic failures, which can lead to equipment damage, fluid leaks, and potential safety hazards. It’s a key component of preventative maintenance in hydraulic systems.

Here are the primary objectives and benefits of hydraulic hose pressure testing:

- Safety Assurance: Verifies the hose’s ability to withstand operational pressures, minimizing the risk of ruptures and leaks.

- Quality Control: Confirms that hoses meet industry standards and manufacturer specifications.

- Preventive Maintenance: Identifies potential weaknesses or defects before they lead to failures.

- Performance Evaluation: Assesses the hose’s performance under simulated operating conditions.

- Longevity Extension: Helps determine the hose’s expected lifespan and informs maintenance schedules.

Hydraulic Hose Salt Spray Test

The salt spray test also called the salt fog test, is the method to test the hydraulic hose corrosion resistance. The hydraulic hose salt spray test can simulate a harsh environment to do a corrosive attack on the hydraulic hose cover and coating during the testing procedure.

This magic salt spray test can accelerate the corrosion speed to create a salt fog environment to test the hydraulic hose’s durability. Our hydraulic hose will pass this salt spray testing due to the top-rated synthetic rubber material’s stable performance.

Also, we can make complex hydraulic hose coating, to enhance the ability to avoid corrosion harm. Here we have wrapped hydraulic hose, designed with a protective outer cover to ensure that your hydraulic hose can be used longer.

Hydraulic Hose Burst Test

The hydraulic hose burst test is the hydrostatic pressure test of the hydraulic hose assembly, which can determine the hydraulic hose’s actual burst strength.

The hydraulic hose failure will happen, if the hydraulic hose begins to leak, bulge, or burst when used in the minimum rated burst pressure. And the maximum burst pressure is a super important operating performance that a hydraulic hose technique must know, respect, and follow to ensure the hydraulic hose can be used safely.

You have to read the hydraulic hose layline to get the hydraulic hose burst pressure before you buy hydraulic hoses in the local hydraulic hose shop, and of course, you can consult your desired hydraulic hose to meet your burst pressure range.

Regularly, the burst pressure is up to 4 times the working pressure, the burst pressure is much higher to ensure the hydraulic hose safety during its normal working process.

You guys can get to know more about hydraulic hose working pressure and bursting working to help you find the most suitable hydraulic hose for your project.

Hydraulic Hose Cold Flex Test

The hydraulic hose will be used in various conditions, including warm temperature to ambient temperature.

The hydraulic hose cold flex test is also the cold flexibility test, this test can notify that if you can use the hydraulic hose in the cold ambient temperature.

A certified hydraulic hose is flexible so that it can’t crack, leak, or break while in harsh cold working conditions. And our hydraulic hose can be used in cold places, with a low temperature that is rated at –70° F (–57° C).

The synthetic rubber hose is flexible with the proper bend radius, soft and flexible, so the hydraulic hose can’t be frozen and then become cracked. You can still use the hydraulic hose even if you are living in extremely cold places where exist snow and ice.

Conclusion

In summary, hydraulic hose testing is indispensable for ensuring the safety and efficiency of hydraulic systems. For those new to the field in 2025, understanding the intricacies of pressure, impulse, and other testing methods is paramount. Adherence to industry standards and meticulous testing procedures prevents catastrophic failures, minimizing downtime and safeguarding personnel.

Investing in high-quality testing equipment and staying abreast of evolving standards are crucial for maintaining system integrity. Regular testing, coupled with informed hose selection, prolongs equipment lifespan and reduces operational costs. This proactive approach underscores the importance of rigorous testing in modern hydraulic applications.

For dependable, hydraulic hoses that meet stringent testing standards, choose Kingdaflex. We offer a comprehensive range of wholesale hydraulic hoses designed to withstand demanding applications. Contact us today to explore our product offerings and ensure your hydraulic systems operate with optimal safety and performance.